2-1 SC_FN1

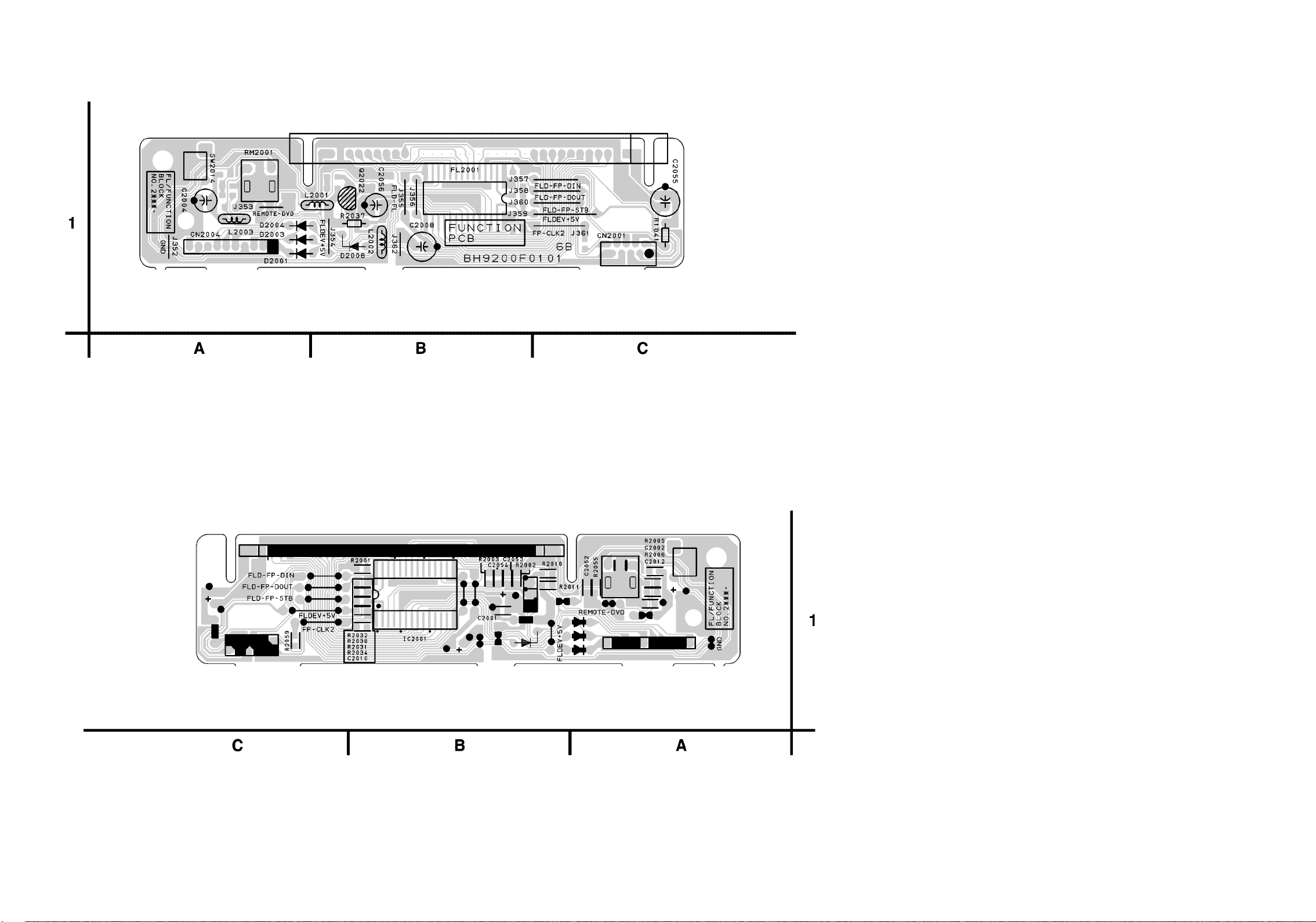

(Top View) (Bottom View)

(Bottom View)

Electrolytic Capacitor

+

Transistor or Digital Transistor

NPN Transistor PNP Transistor

NPN Digital Transistor PNP Digital

Transistor

(Top View)

(Top View)

E C B

E C B

Digital Transistor

CBA Symbols Schematic Diagram Symbols

E C B

(Top View)

(Top View)

E C B

E C B

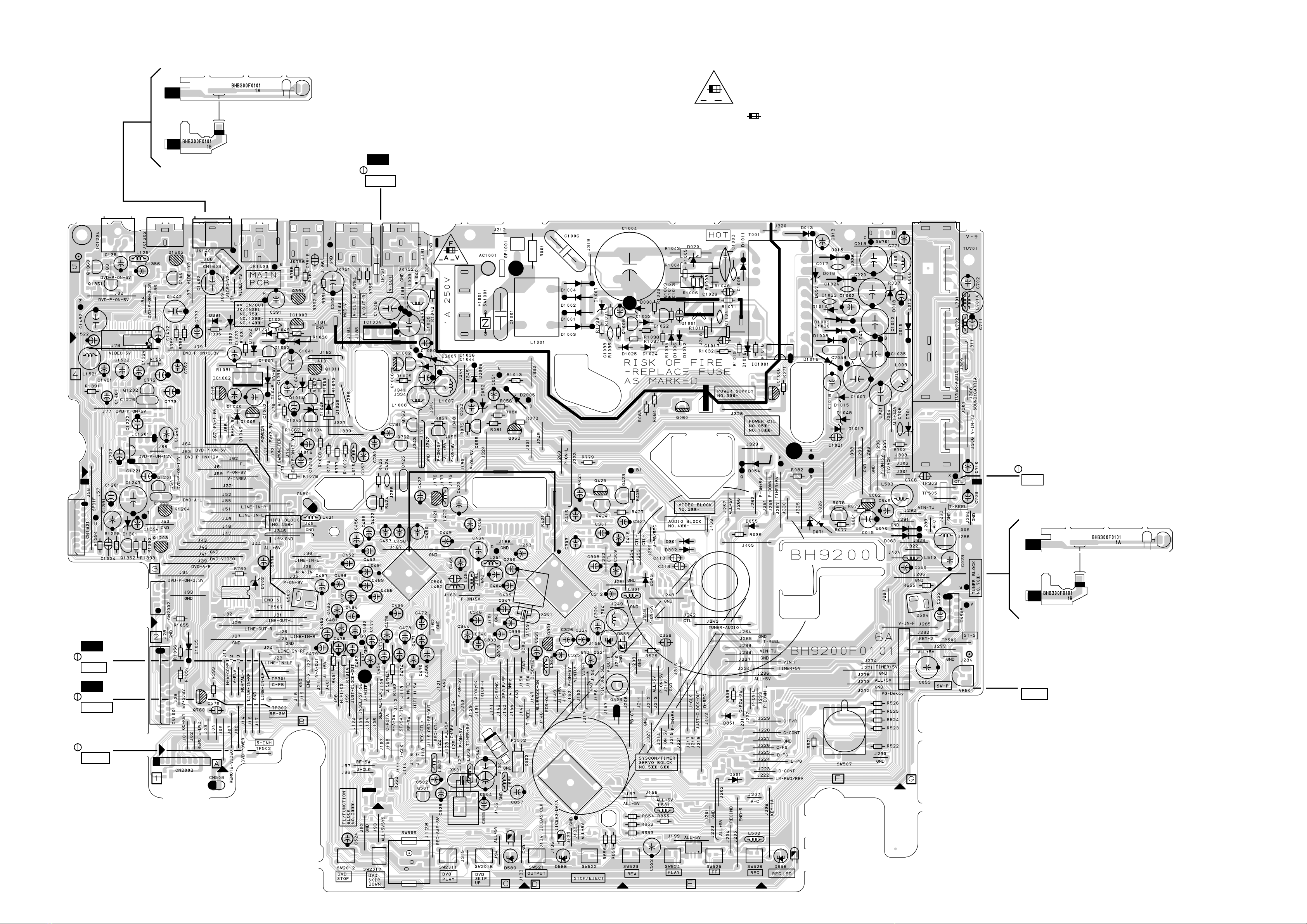

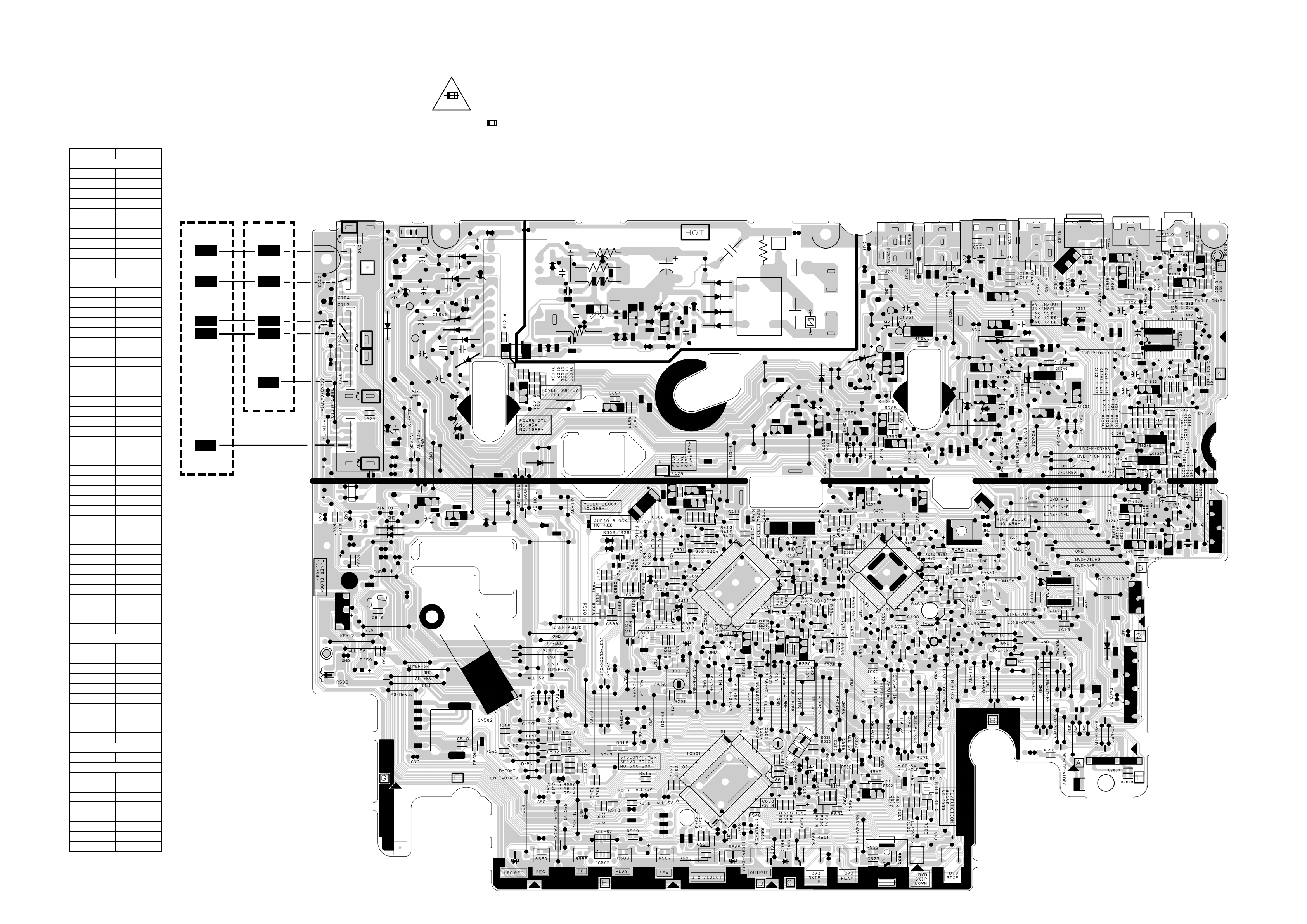

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using replace-

ment components rated for higher voltage, wattage,

etc. Replacement parts that have these special safety

characteristics are identified in this manual and its

supplements; electrical components having such fea-

tures are identified by the mark " #" in the schematic

diagram and the parts list. Before replacing any of

these components, read the parts list in this manual

carefully. The use of substitute replacement parts that

do not have the same safety characteristics as speci-

fied in the parts list may create shock, fire, or other

hazards.

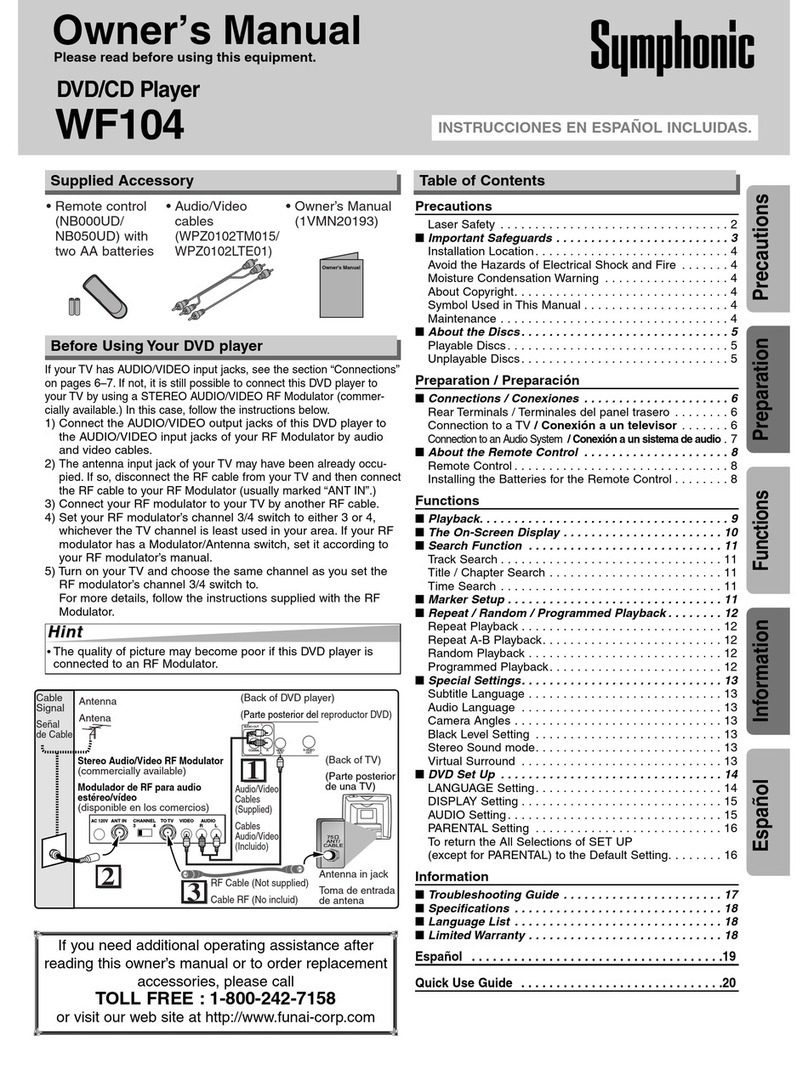

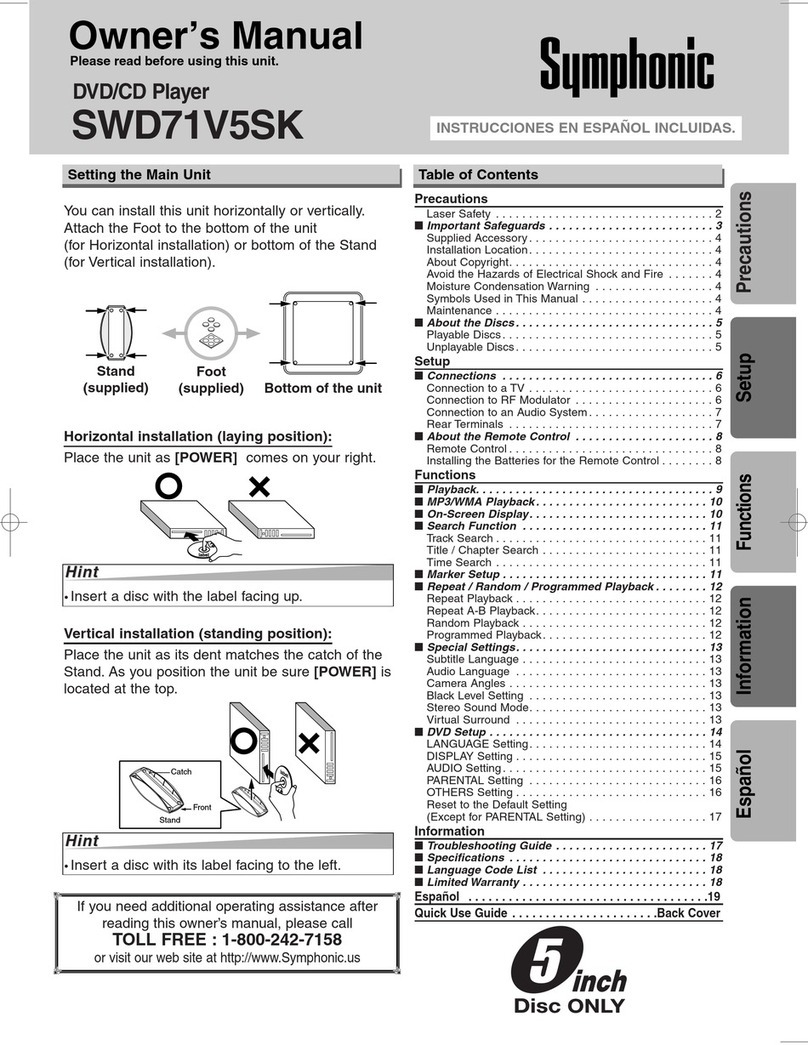

Capacitor Temperature Markings

Capacitors and transistors are represented by the fol-

lowing symbols.

Notes:

1. Do not use the part number shown on these draw-

ings for ordering. The correct part number is

shown in the parts list, and may be slightly different

or amended since these drawings were prepared.

2. All resistance values are indicated in ohms

(K=103, M=106).

3. Resistor wattages are 1/4W or 1/6W unless other-

wise specified.

4. All capacitance values are indicated in µF

(P=10-6 µF).

5. All voltages are DC voltages unless otherwise

specified.

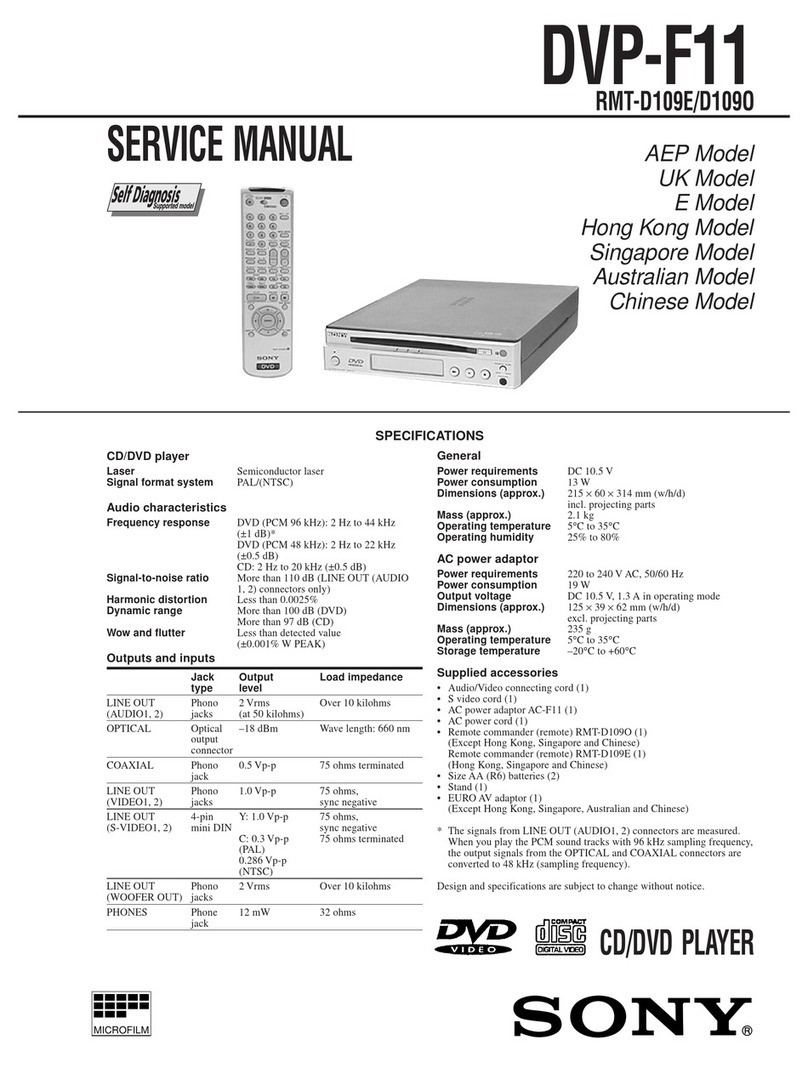

Mark Capacity

change rate

Standard

temperature

Temperature

range

(B) ±10% 20°C -25~+85°C

(F) +30 - 80% 20°C -25~+85°C

(SR) ±15% 20°C -25~+85°C

(Z) +30 - 80% 20°C -10~+70°C