4

Important Information

It is important that the installation and servicing instructions throughout this

booklet are followed as any failure to do so may invalidate the warranty of this

appliance.

This appliance must be installed by a qualified Gas Safe Registered engineer. Every

engineer carries a Gas Safe Register ID Card and it is advised you ask to see this

before any work is carried out on installations or converting for use with other gases.

Please pay particular attention to: Gas Safety Regulations

Health & Safety Law

Local & National Building Regulations

Fire Precautions Act

This appliance is supplied with a one year parts and labour warranty.

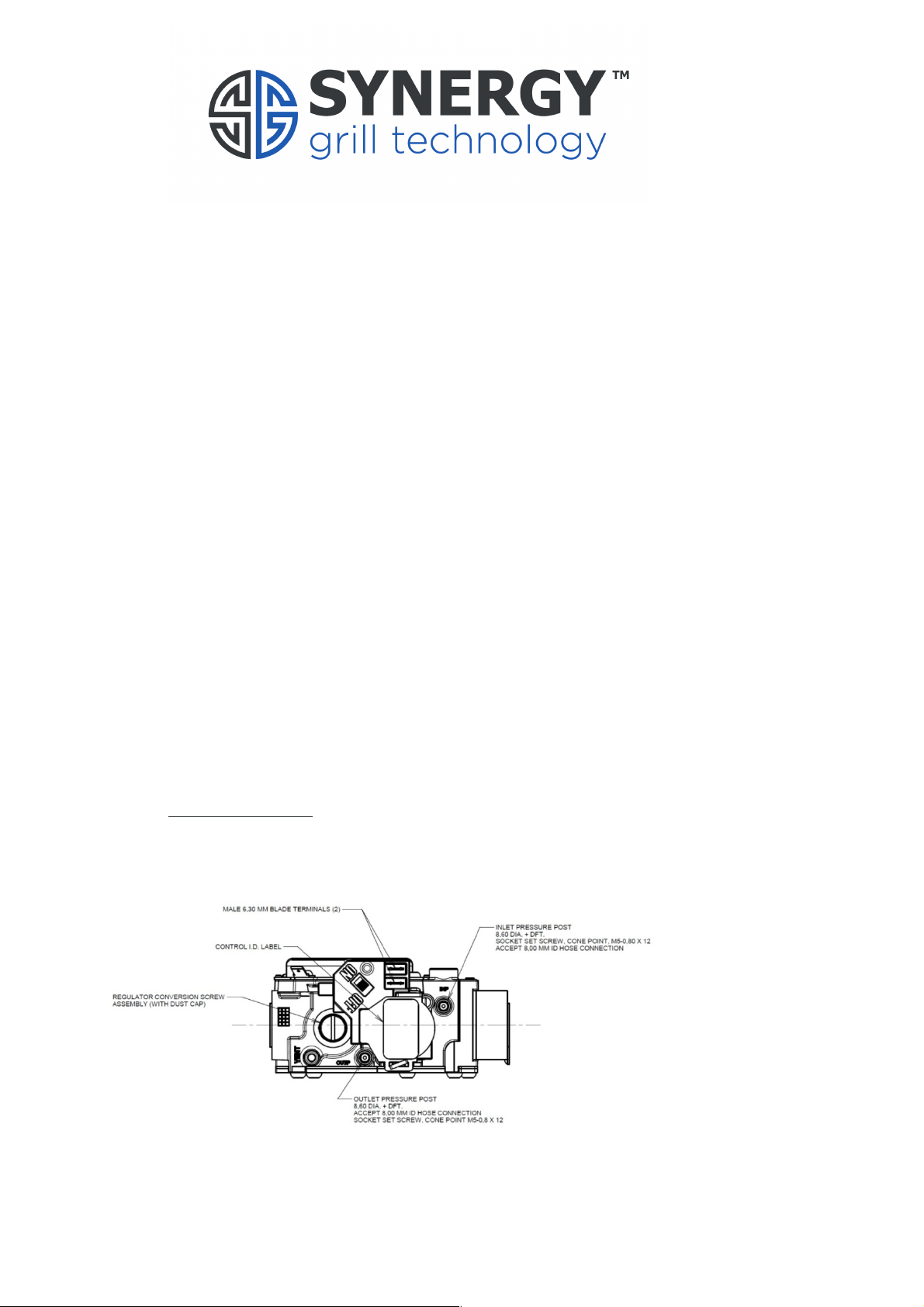

Do not use an external in-line Gas Governor to set the pressure, please do so with

the appliances internal gas valves.

This appliance is CE marked declaring the compliance with EC directives. The Gas

Types and Pressures for the destined country are stated on the appliance Data Plate.

The instructions throughout this document are only valid in the countries stated on

the Data Plate

Unless otherwise stated this unit is set for G20 (Natural Gas), however your Gas Safe

engineer MUST confirm the Outlet Pressure is 15mbar before commissioning the unit.

LPG conversion kits are located within your documentation.

Do not remove the Ceramic Blocks from the unit when moving/installing - putting

the blocks back in may damage the thermal paper and block the vortex holes.

There is a metal divider plate in the ceramic bedding – this must not be removed or

the air flow and heat distribution will not work to full effect.

This appliance must be positioned in a draught free position with good ventilation -

cooling air blowing onto the grill can distort the vortex heat distribution.