System 180 GmbH · Ernst-Augustin-Str. 3 · 12489 Berlin, Germany · phone +49 30.788 58 41 · contact@system180.com · system180.com · V. 06-08-20

Contents

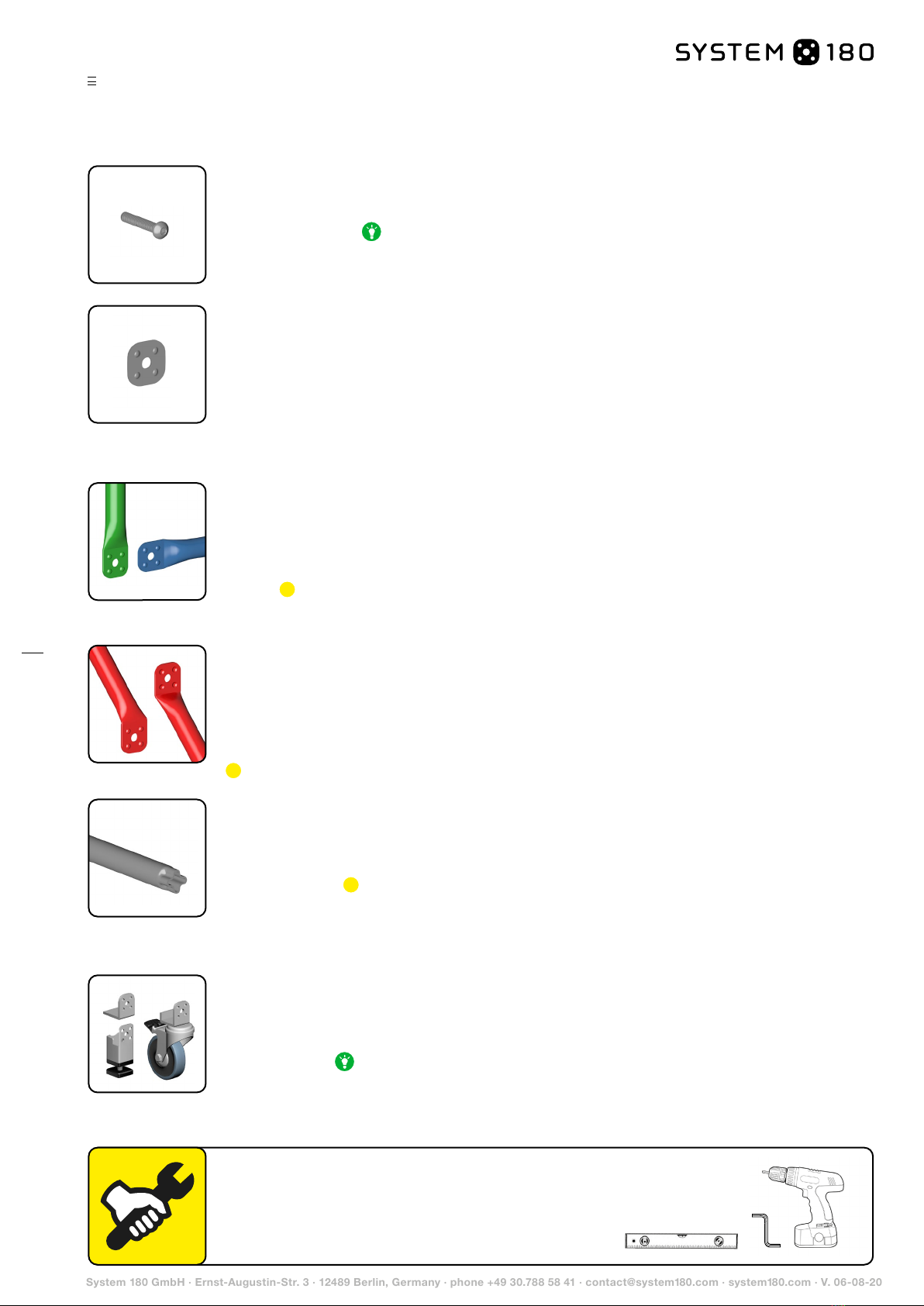

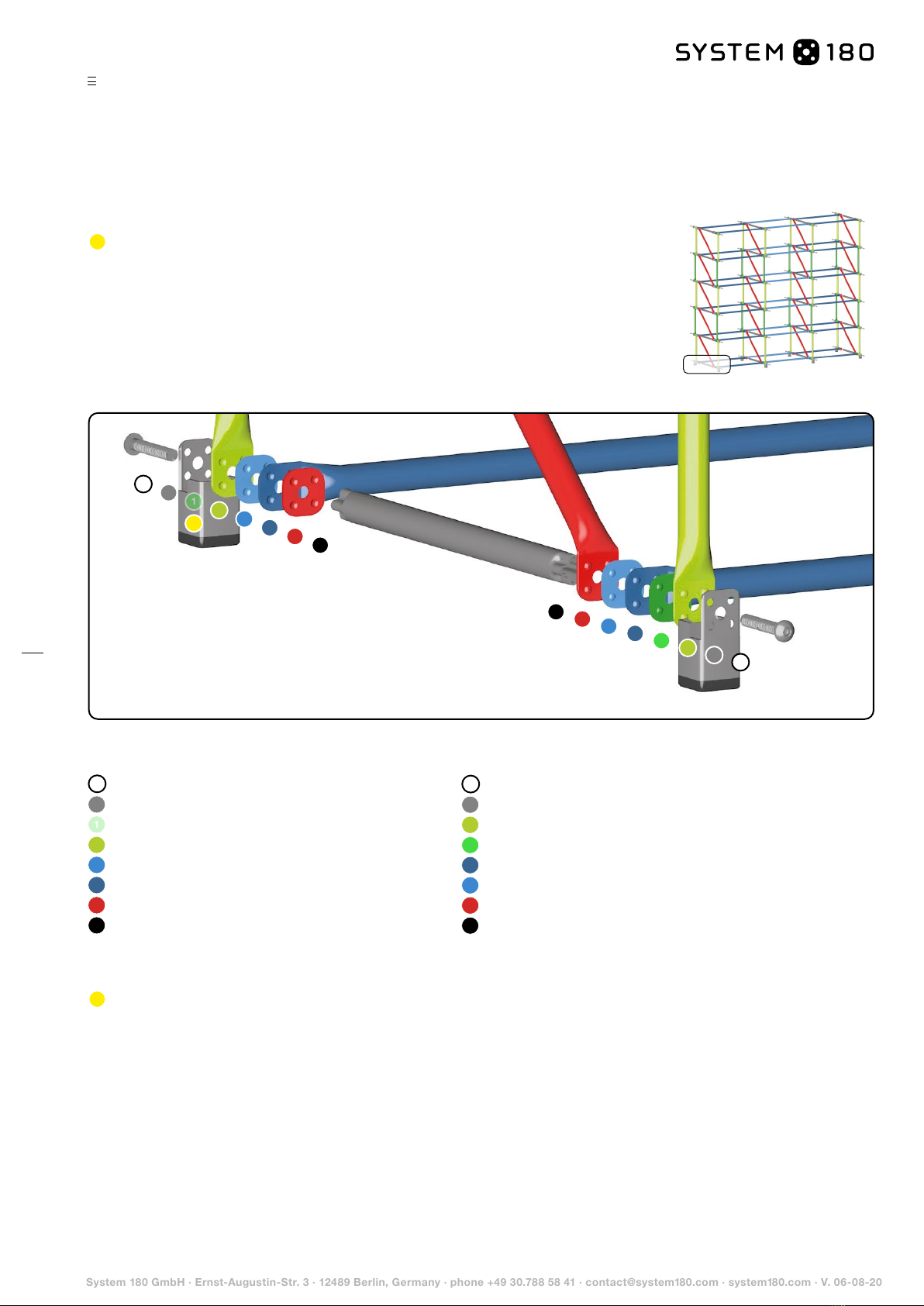

Standard bar (G) Standard bars are stainless steel tubes (20 x 1 mm) with flat-pressed ends and a pattern of

nodules embossed them. To help you to see the system size in which a standard bar has been made, it is pro-

vided with a marking consisting of G + the system size (for example: G360, G720, …). The standard bars form

the vertical and horizontal elements of the tube structure. Their length will depend on the height and width of

the module they form part of. The nodules embossed onto all components should always face outwards during

assembly. Note: From a module width of 810, horizontal bars are fitted with a pin to provide support to the

system base panels. Please make sure that you assemble the correct standard bars in the correct positions.

Diagonal bar (D) The system diagonal bar is a stainless steel tube (20 x 1 mm) with flat-pressed, angled

ends, each with embossed nodules facing outwards. The diagonal pieces are designed to provide stiffening

to the tubular structure where no side pieces are included in the module. The length of diagonal bars will vary

according to the height and depth of the module. There is a diagonal piece available for every system height

and depth in the range. The diagonal pieces are always positioned in system nodes directly adjacent to the

connecting bar. The nodules embossed onto all components should always face outwards during assembly.

Note: Diagonal bars are not required where side panels are used.

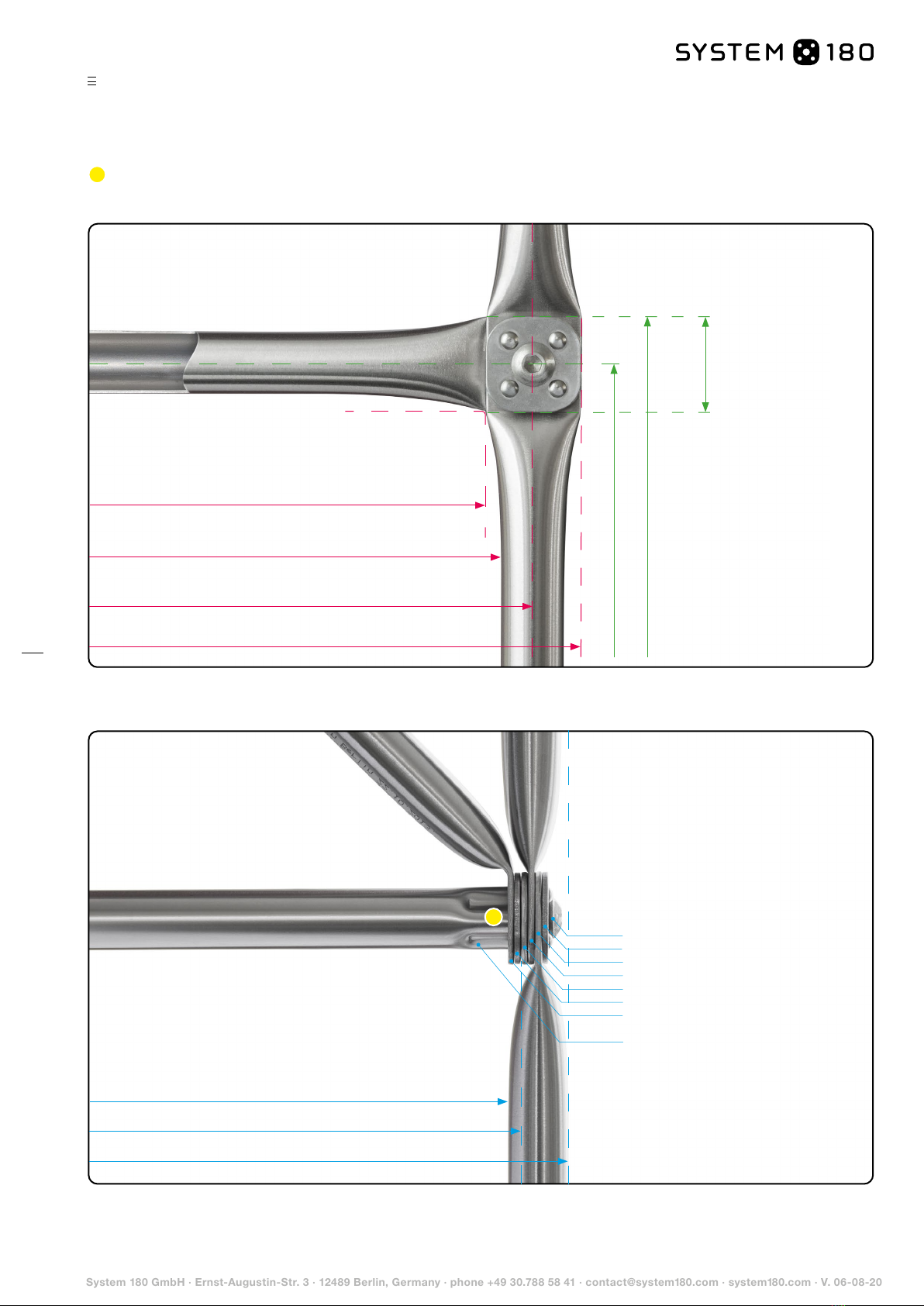

System washers System washers are steel washers (measuring 30 x 30 x 2 mm), each embossed with 4

nodules and a central hole (ø 8.5 mm). They are designed to provide a termination piece and compensating

element for each system node. On outermost nodes on a module they replace the standard pieces that

would otherwise be there. Where side panels are used, they are placed in the position where the diagonal

pieces would otherwise be placed. They are important in ensuring that the distance between all standard

bars is equal. The system washer is always positioned on the outermost position of its node. (Exceptions: feet

and casters). The nodules always face outwards during assembly. If the nodules are all aligned correctly, then all

components will automatically sit in the nodes at right angles to one another.

System bolts System bolts are button-headed cylindrical M8x50 bolts with 5-mm hex sockets. System bolts

are pushed through all the elements in each system node back to the connecting bar. As the bolt is tightened

up, the embossed nodules on each component are pressed together into one another, resulting in a structure

locked firmly into place. Tip: During assembly tighten each node up just enough so that the nodules grip

into one another. This will make assembly much easier and is important for when the time comes to insert the

system base components and any panelling.

Foot bases with level adjustment/foot brackets/casters Feet and casters are mounted on the out-

ward-most position of the node. The adjustment devices on foot bases are designed to allow the furniture

module to be levelled out using a spirit level and to even out any unevenness on the floor. Before assembly,

twist all height adjustment devices completely into the foot base to give yourself the maximum amount of initial

clearance possible. Tip: To ensure that you will be able to reach into the rearmost adjustment devices on the

module, we recommend adjusting the height of the unit before fully assembling all its components (before inser-

ting the bottom base panel in particular). Angled feet and casters provide no adjustment function to fine-tune

relative heights. On hard floors (on parquet flooring, for example), use felt gliders for this purpose instead.

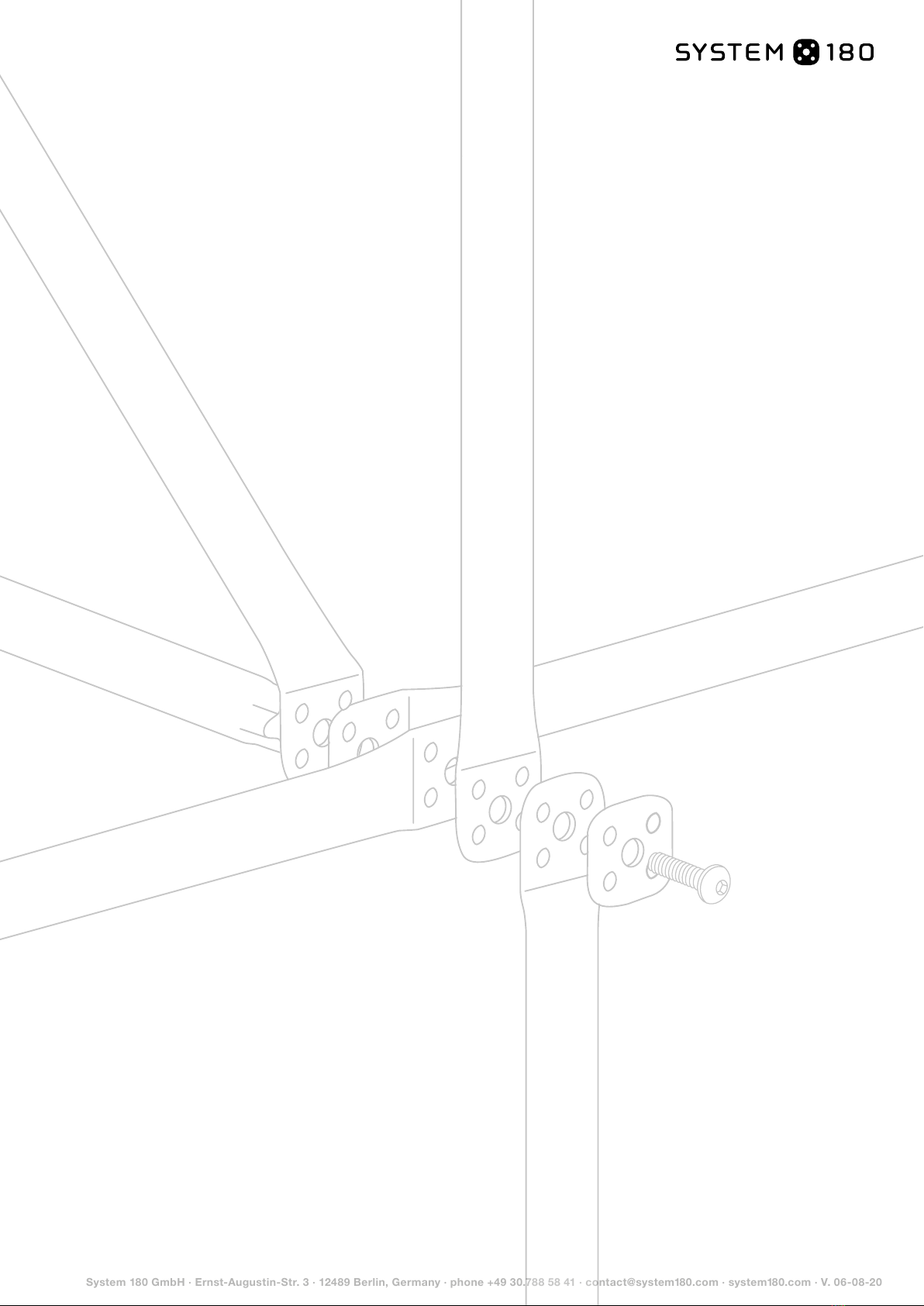

Connecting bar (M) The connecting bar consists of a stainless steel tube (20 x 1 mm) with a threaded insert

(M8) pressed into it at each end. The connecting bars are used as the counterpieces for the system bolts

to firmly secure each system node together. Connecting bars run perpendicular to the front of the furniture

module, back to the depth the system structure. There is a connecting rod of suitable length available for

every system depth. Note: For all module depths of 780 and upwards, connecting bars are fitted with a

pin to provide support to the system bases. Please make sure that you assemble the right connecting bars in

the right positions. To ensure the result looks as it should, make sure while assembling that both ends of the

connecting rod look like a vertical "+" sign when looked at end on.

1.1.2 Parts

!

!

!

To assemble the skeletal structure you will need the following tools:

∙ 5 mm hex (Allen) key or cordless electric screwdriver with

the appropriate screwdriver bit; torque: approx. 7 Nm

∙ Spirit level

1.1 Basic structure