T.A. Plastic Evolution User manual

Table of contents

Popular Tent manuals by other brands

ShelterLogic

ShelterLogic 22556 Assembly instructions

AMERICANA

AMERICANA NAVAJO SHELTER installation instructions

L.L.Bean

L.L.Bean Woodlands Screen House quick start guide

CASARIA

CASARIA 992856 instructions

Sunjoy

Sunjoy A101011500 Assembly instruction

skandika outdoor

skandika outdoor LYON Setup Instruction

Yolico

Yolico PRO 100 Setup instructions

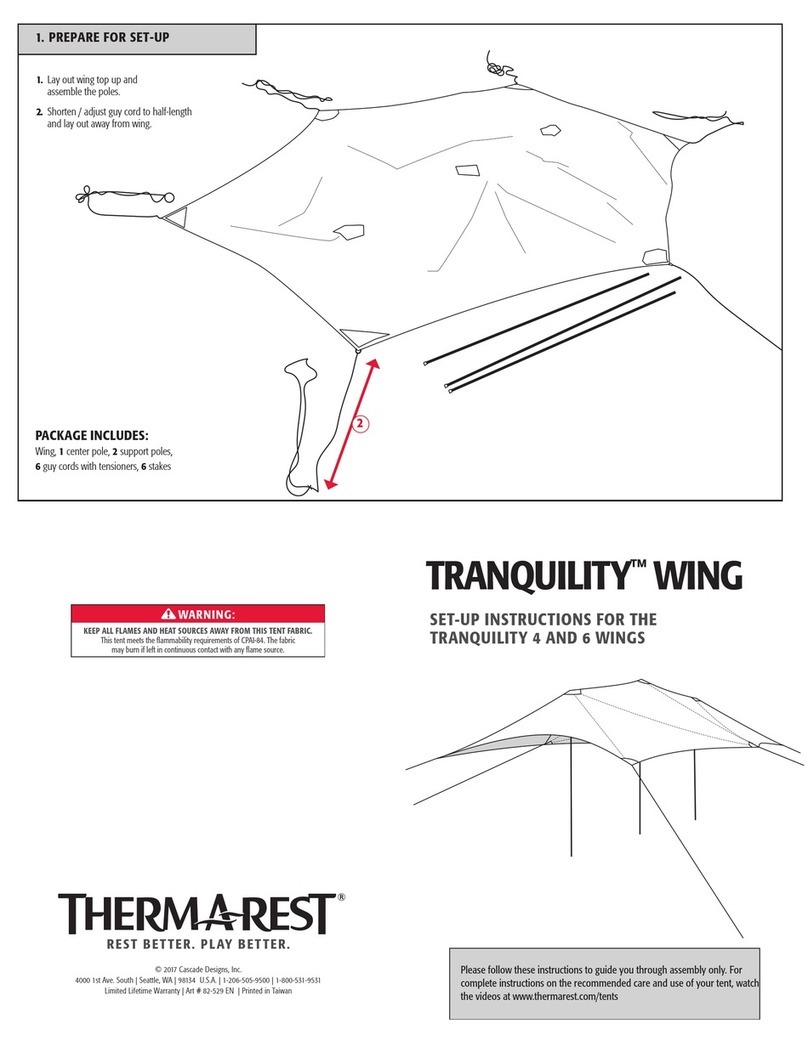

Thermarest

Thermarest TRANQUILITY WING quick start guide

Aqua Products

Aqua Products M3 COMPACT Instruction guide

Yolico

Yolico ADVENTURE EASYLIFT SETUP & TAKEDOWN INSTRUCTIONS

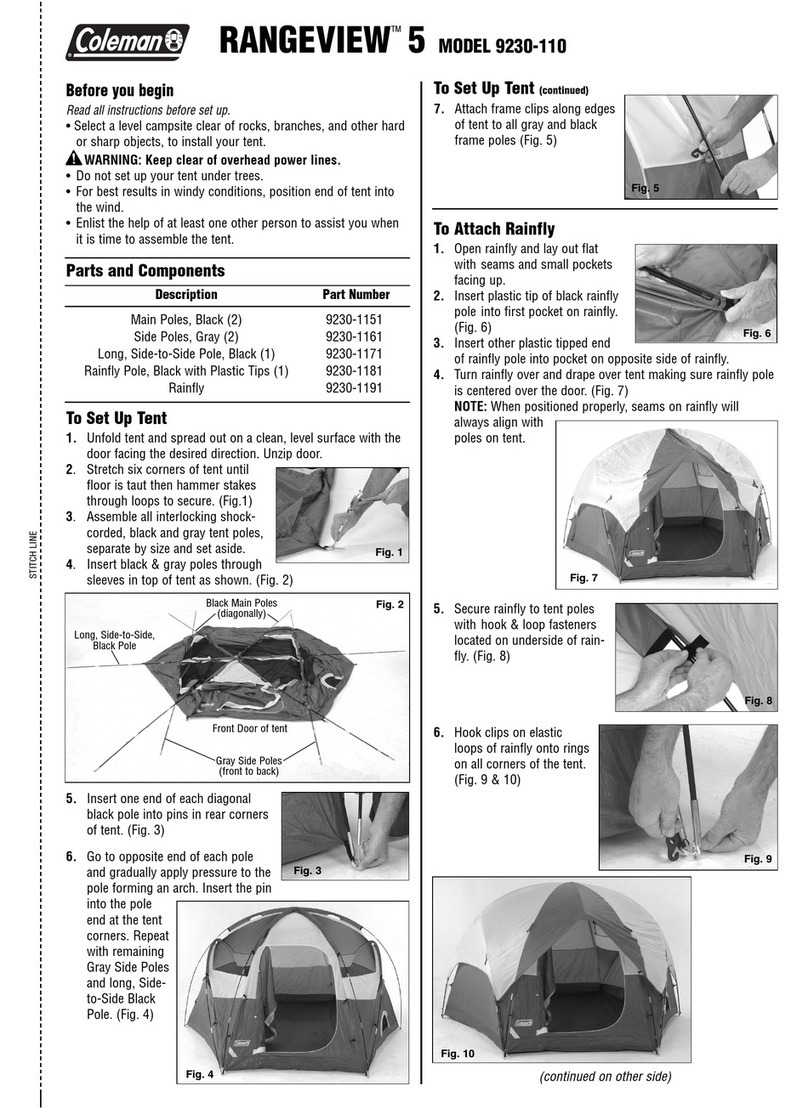

Coleman

Coleman RANGEVIEW 5 9230-110 user manual

Classic Accessories

Classic Accessories 73012 instructions

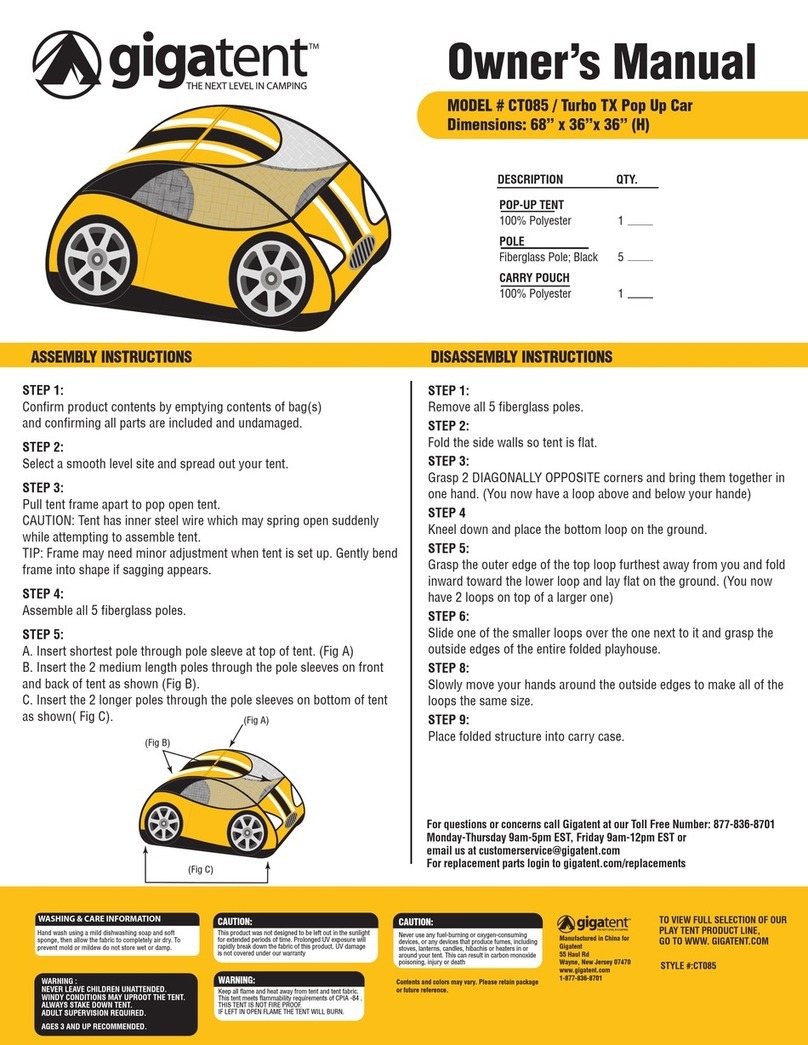

GigaTent

GigaTent CT085 owner's manual

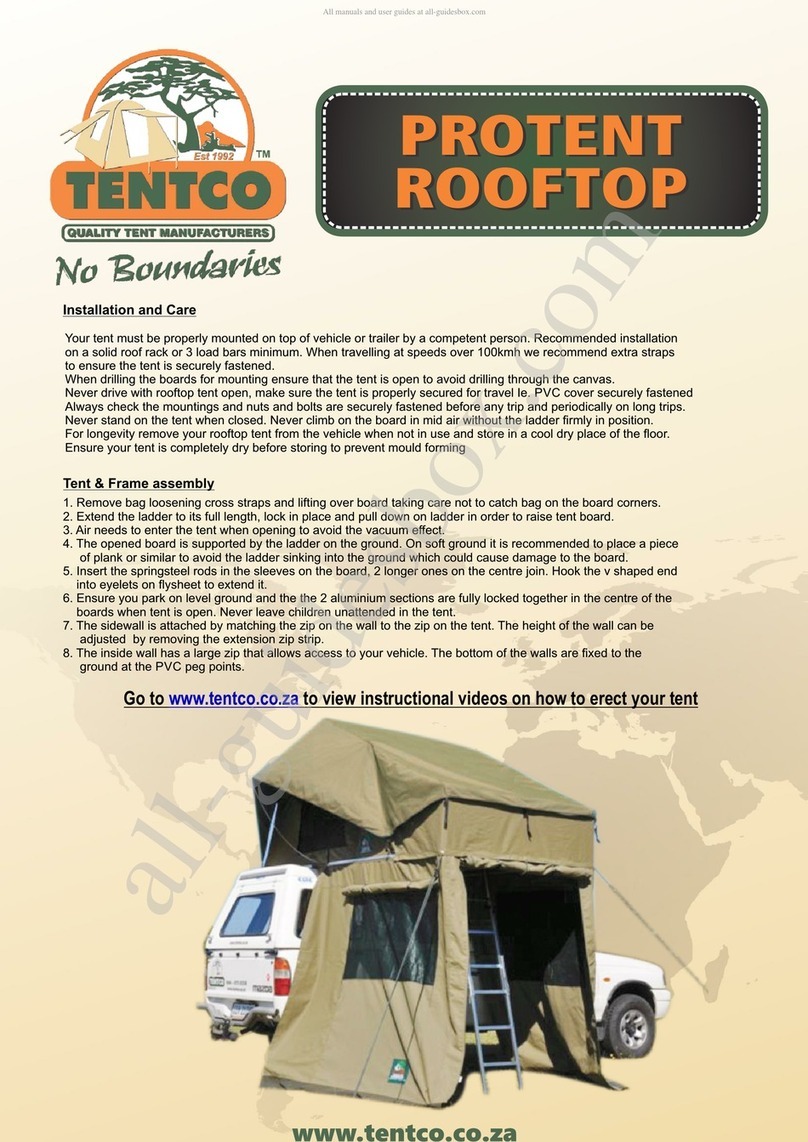

TENTCO

TENTCO PROTENT ROOFTOP quick start guide

skandika outdoor

skandika outdoor COPENHAGEN 8 Setup Instruction

Hesperide

Hesperide EQUADOR 165520 manual

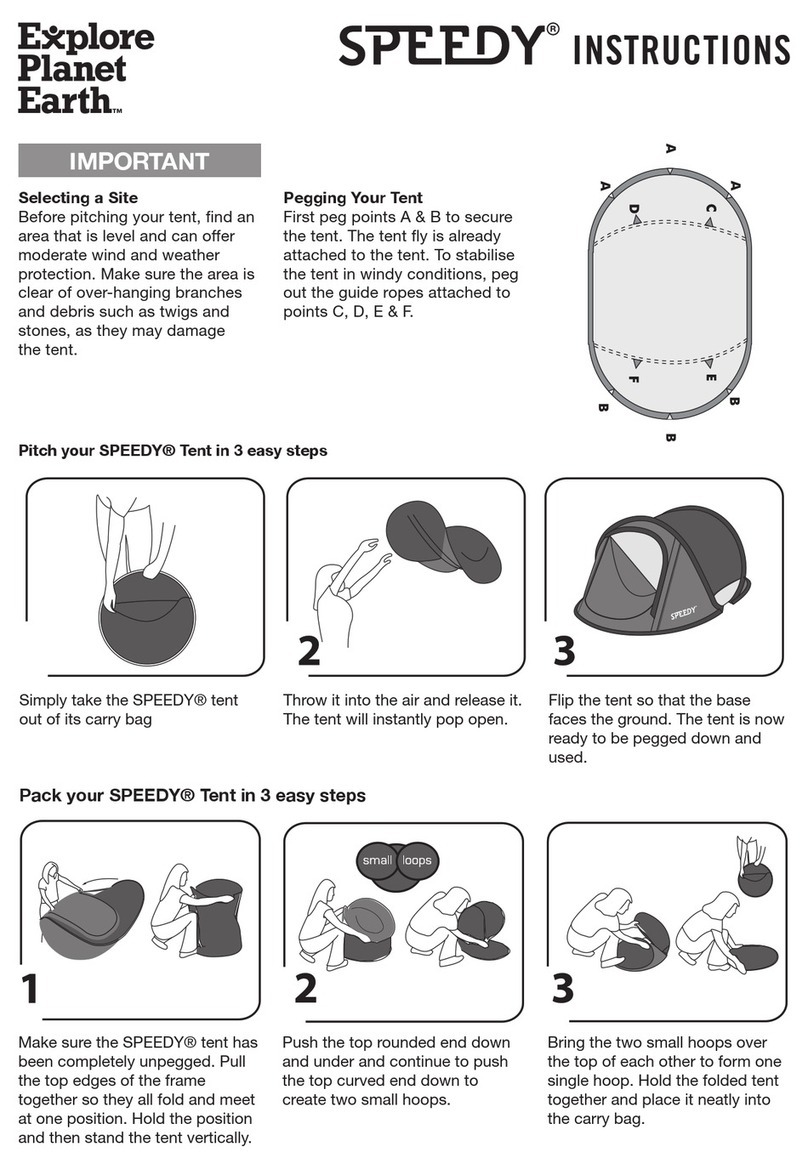

Explore Planet Earth

Explore Planet Earth SPEEDY instructions

Dometic GROUP

Dometic GROUP Kampa Cross AIR TG operating manual