Table of contents

1General description ....................................................................................................... 4

1.1 Information about Installation and operating instructions...............................................4

1.2 Layout of the Installation and operating instructions .....................................................4

1.3 Use of the Installation and operating instructions..........................................................4

1.4 Obligations of the Operator ........................................................................................5

1.5 Training instructions..................................................................................................5

1.6 Requirements for staff...............................................................................................5

1.7 Dangers when operating the Machine ..........................................................................6

1.8 Intended use............................................................................................................6

1.9 Reasonably foreseeable misuse ..................................................................................7

1.10 Warranty claims and liability ......................................................................................7

2Safety instructions ........................................................................................................ 8

2.1 Safety symbols in this Installation and operating instructions .........................................8

2.2 General safety instructions.........................................................................................8

2.3 Safety instructions for operation .................................................................................9

2.4 Safety instructions for setup, maintenance, servicing, repair and troubleshooting ...........10

3Technical data ............................................................................................................. 12

3.1 Complete Machine................................................................................................... 12

3.2 Pneumatic equipment.............................................................................................. 12

3.3 Electrical equipment................................................................................................12

4Setup and function ...................................................................................................... 13

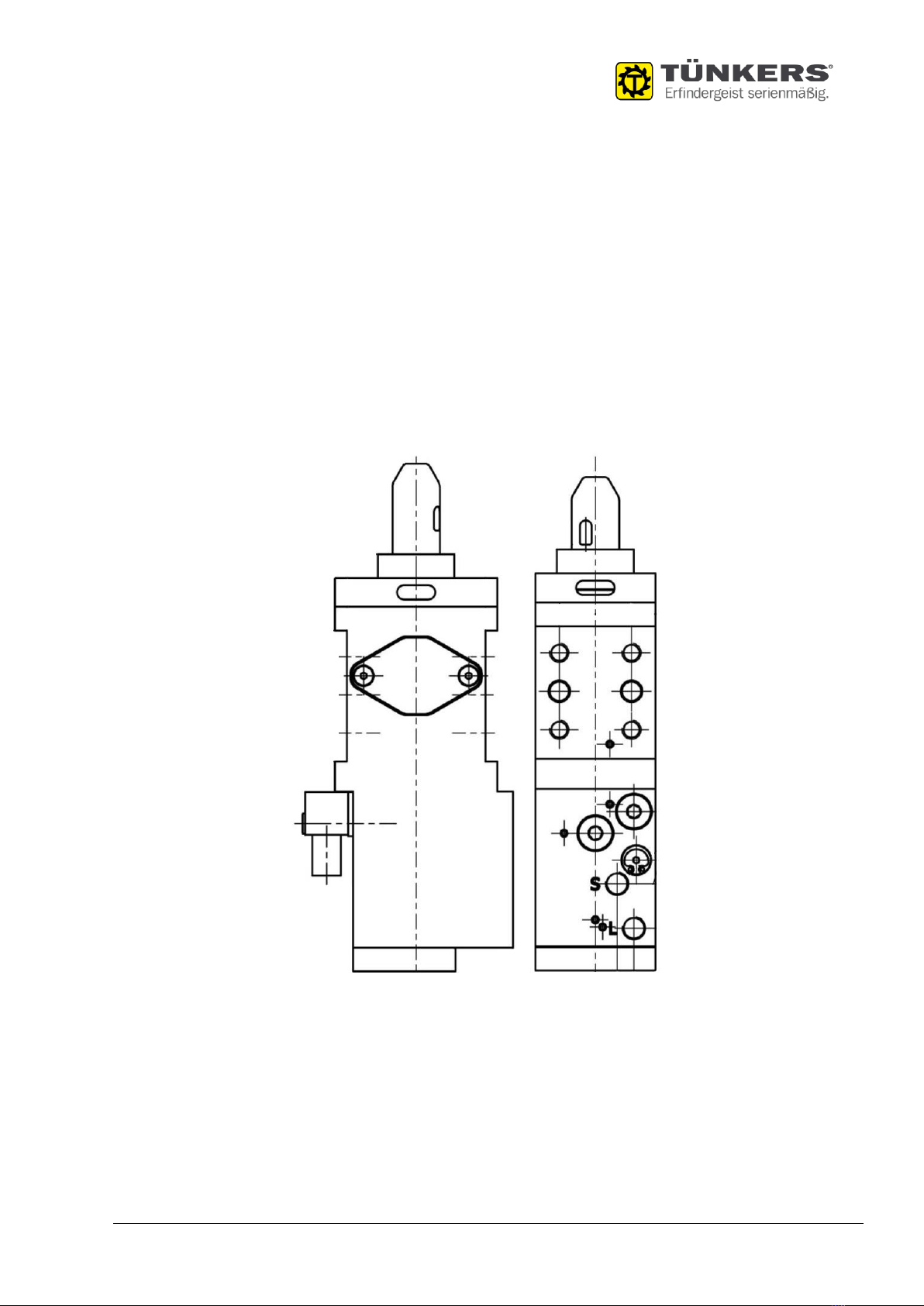

4.1 Overview Pin drawing cylinder with spreading mandrel SDZ 40 F ..................................13

5Transport, Assembly and Commissioning .................................................................... 14

5.1 Assembly...............................................................................................................14

5.2 Initial Start-up........................................................................................................15

6Operation .................................................................................................................... 15

6.1 Safety instructions ..................................................................................................15

6.2 Operating the Pin drawing cylinder with spreading mandrel SDZ 40 F............................15

6.3 Basic checks before and during operation ..................................................................15

7Maintenance ................................................................................................................ 16

7.1 Safety instructions ..................................................................................................16

7.2 Maintenance and repair work.................................................................................... 16

7.3 Maintenance schedule .............................................................................................16

8Troubleshooting .......................................................................................................... 17

8.1 Safety instructions ..................................................................................................17

9Appendix ..................................................................................................................... 18

9.1 Declaration of installation ........................................................................................18