PCP-005/015/050/150/500/1000 Rev 1.1

2021/02/03 2/45 Copyright ©2021 by TAEHA CORP. All Rights Reserved

Contents

1 General Information...................................................................................................................................................... 4

1.1 General Information...................................................................................................................................................... 4

1.2 Warranty............................................................................................................................................................................. 4

1.3 Technical Support .......................................................................................................................................................... 4

2 Pro Pump System (PCP) Feature............................................................................................................................. 5

2.1 Pro Pump System........................................................................................................................................................... 5

2.2 Pro Pump System Feature ......................................................................................................................................... 5

2.3 Pro Pump Feature & Specification ........................................................................................................................ 6

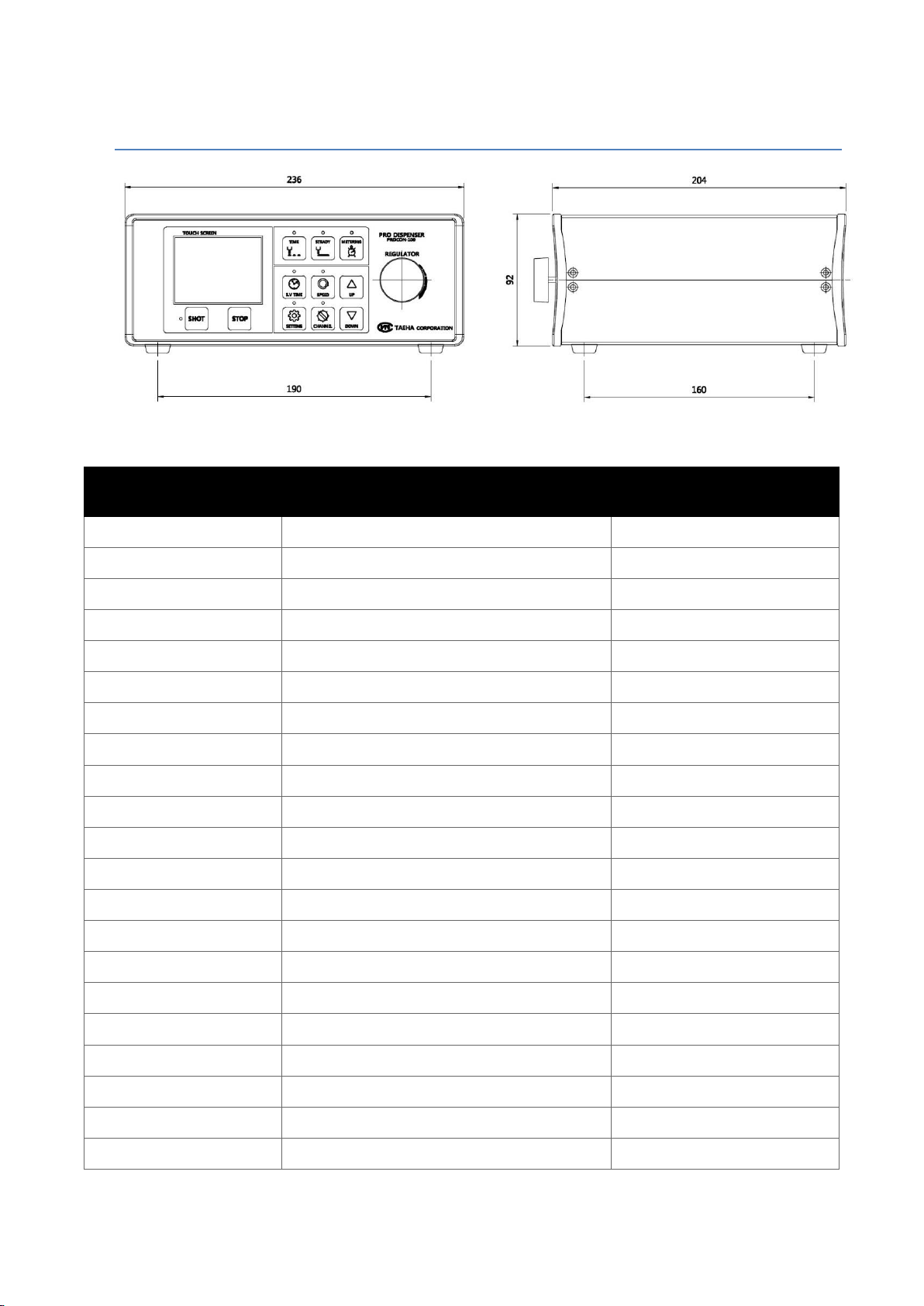

2.4 Pro Pump Controller Feature & Specification .................................................................................................. 8

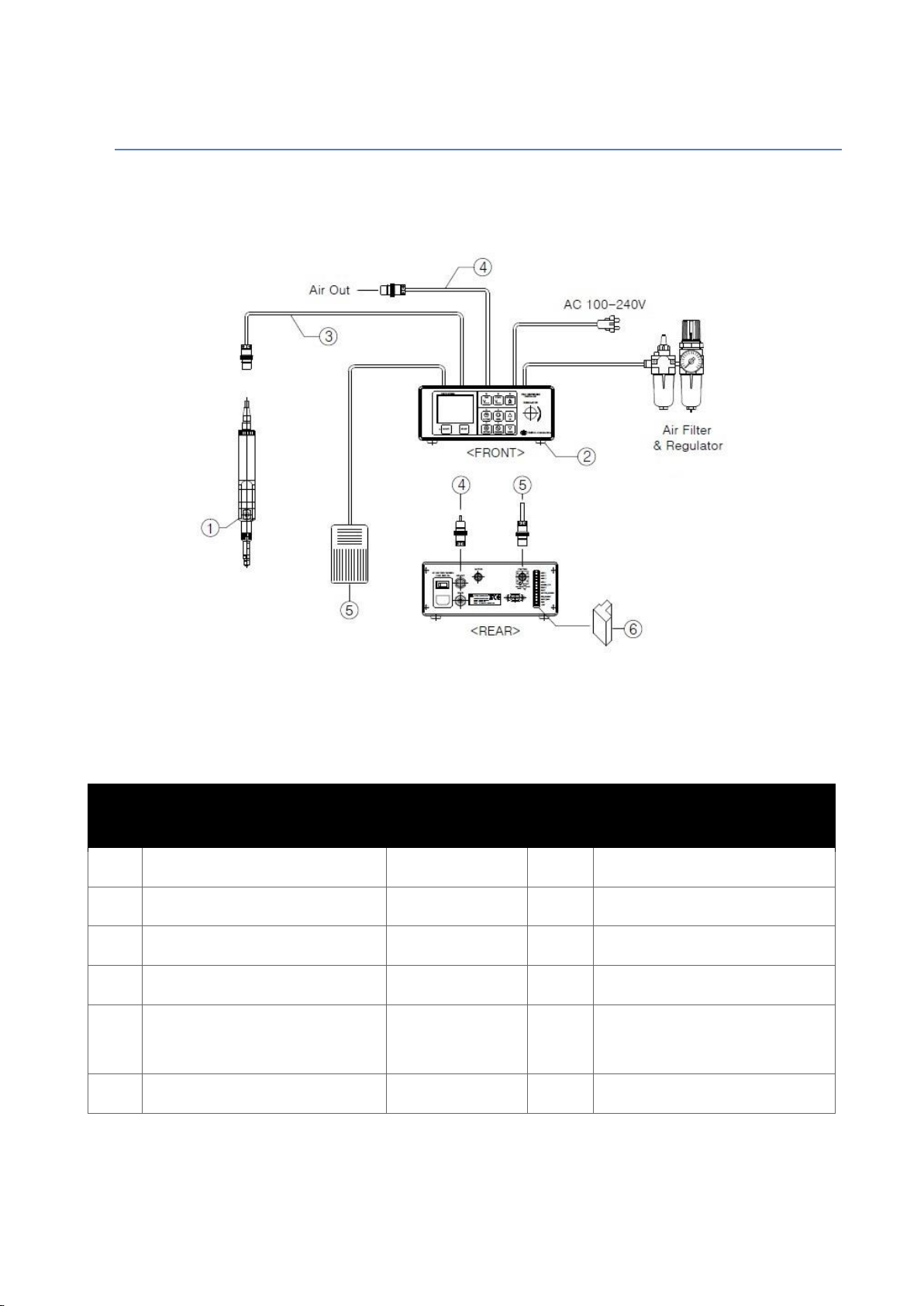

2.5 PCP(Standard) System.................................................................................................................................................. 9

2.6 PCPM (Module Type) System.................................................................................................................................10

3 Name of each part ......................................................................................................................................................11

4 Pro Pump Operation ..................................................................................................................................................12

4.1 Precautions on Use and Assembly ......................................................................................................................12

4.2 Pro Pump Ready to Use ...........................................................................................................................................13

5 Pro Pump Disassemble..............................................................................................................................................14

5.1 PCP-005/015/050 Disassemble..............................................................................................................................14

5.2 PCP-150/500 Disassemble .......................................................................................................................................21

5.3 PCP-1000 Disassemble ..............................................................................................................................................28

6 Pro Pump Partlist .........................................................................................................................................................36

6.1 PCP-005 Partlist ............................................................................................................................................................36

6.2 PCP-015 Partlist ............................................................................................................................................................37

6.3 PCP-050 Partlist ............................................................................................................................................................38

6.4 PCP-150 Partlist ............................................................................................................................................................39

6.5 PCP-500 Partlist ............................................................................................................................................................40