`TALEX Spółka z ograniczoną odpowiedzialnością

ul. Dworcowa 9c, 77-141 Borzytuchom

tel. (59) 821 13 40

www.talex-sj.pl

Page 3of 36

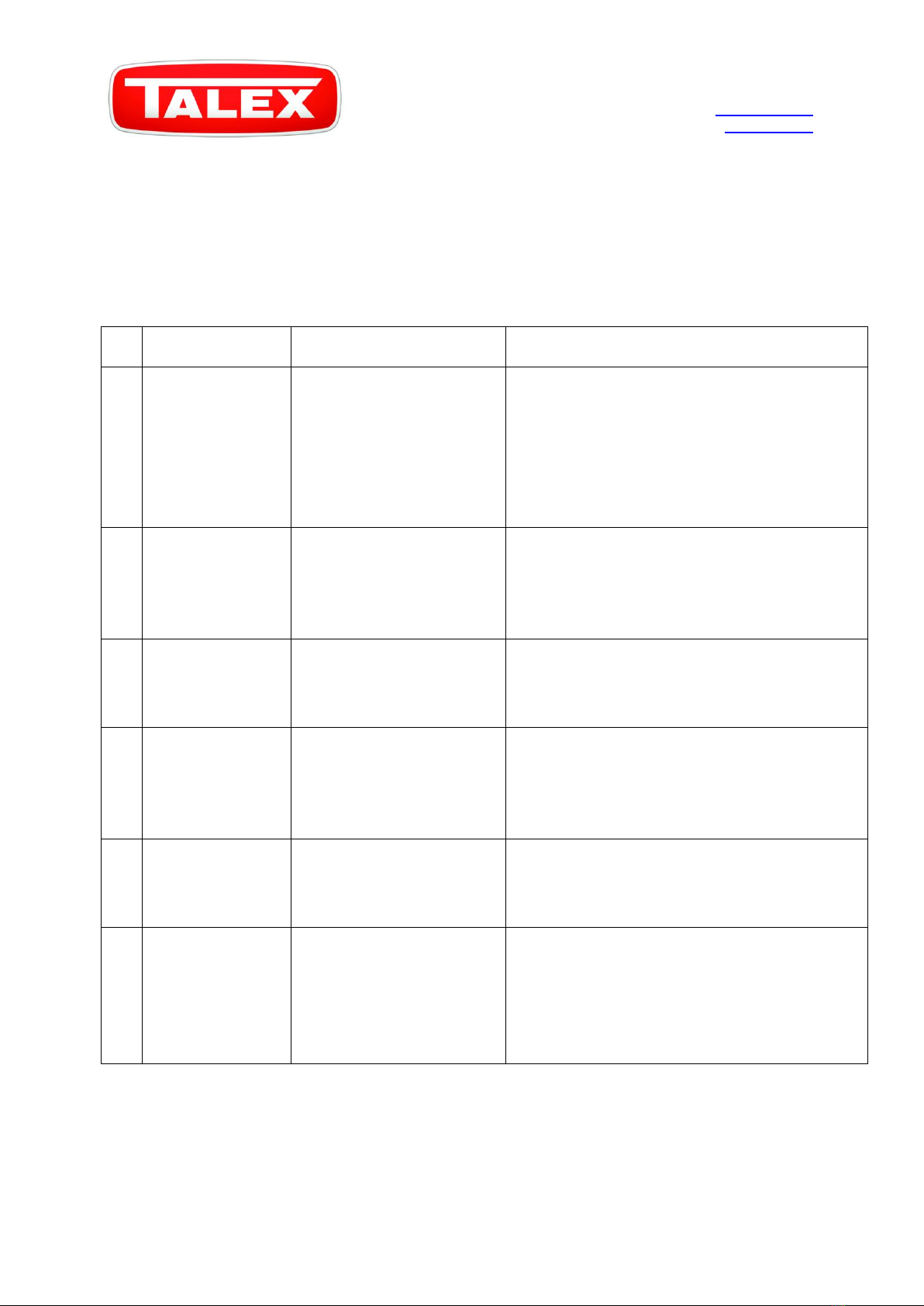

Table of contents

1. Introduction..................................................................................................................................... 4

2. Sweeper identification ........................................................................................................................ 5

3. Safety rules at work............................................................................................................................. 6

3.1. Operator safety ............................................................................................................................ 7

3.2. Connection and disconnection of sweeper.................................................................................. 7

3.3. Hydraulic system .......................................................................................................................... 8

3.4.The sweeper’s transport ............................................................................................................... 9

3.5 Maintenance.................................................................................................................................. 9

3.6 The description of residual risk ................................................................................................... 10

3.6. Information and warning labels ................................................................................................. 11

4. Intended Use ................................................................................................................................. 14

5 Equipment, construction and operation............................................................................................ 14

5.1 Standard equipment.............................................................................................................. 14

5.2 Additional equipment............................................................................................................ 15

5.3 General design of the sweeper ............................................................................................. 16

5.4 Operation .............................................................................................................................. 18

5.5 Construction and operation of the hydraulic system............................................................ 18

6. Machine use .................................................................................................................................. 20

6.1 Proper installation of the sweeper............................................................................................. 21

6.2 Emptying the bucket sweeper............................................................................................... 23

7. Inspections and parts replacement.................................................................................................. 23

7.1 Installation and disassembly of the brush................................................................................... 23

7. Defects and methods of repair..................................................................................................... 26

9. Service and maintenance .................................................................................................................. 26

9.1 After work service ................................................................................................................. 26

9.2. Lubrication points...................................................................................................................... 27

9.3. After seasoon maintance ...................................................................................................... 28

10. Spare parts catalogue................................................................................................................ 29

10.1. General structure . ................................................................................................................ 30

10.2. Body....................................................................................................................................... 31

10.3. Working shaft. ....................................................................................................................... 32