Fuel and Lubrication

Lower End r IMPORTANT: Failure to mix oil with gasoline will

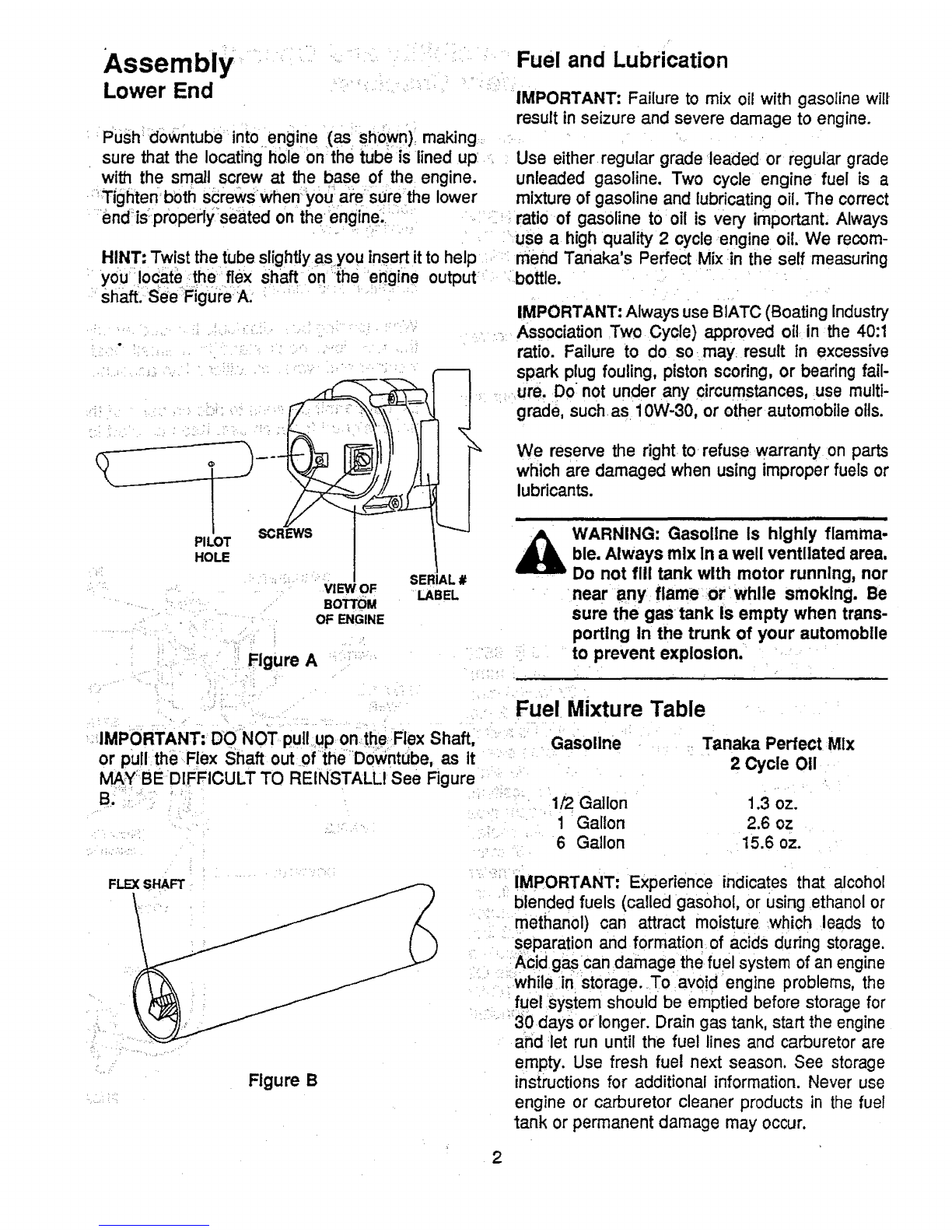

:Push id0wntube into engine (as shown)making •result in seizure and severe..,damage to engine.

sure that the locating hole on the tube is lined up Use either regular grade leaded or regular grade

wit_ the small screw at the base of the engine, unleaded gasoline. Two cycle engine fuel is a

;iTigiiten both screWsWhen you! are Surethe lower mixture of gasoline and lubricating oil. The correct

;endis;properlySedted on theengine_ _ii:, • ___i ratio-of gasoline to oil is very importanL Always

......''_: _ ..... _use ahigh quality 2cycleengine oil. We recom-

HINT: Twist the tube slightly asyou insertitto help _: mend Tanaka's Perfect Mix in the self measuring

: you Iocate;the_flex Shaft on';{he erjgine output: .;;.bottle. .:. " '....

Shaft,:SeeFigur;eA. _; : _;`_'_";:IMPORTANT: Always use BIATc (Boating Industry

........ , :_•_ , _i ,i:,i_,__:_;,,!

• _ .... j:• "_•:.! :;•_ _••'•;•i_ • ...... ii

PILOT

HOLE

VIEW OF

BOTTOM

OF ENGINE

Figure A

SERIAL #

LABEL

_ --._Association .Two Cycle) approved oil in the 40:1

ratio. Failure to do so-may result in excessive

spark plug fouling, piston scoring, or bearing fail-

....`_ .ure, Do not under any c=rcumstances, use multi-

. J 'grade, such.asl0W-30, or other automobile oils.

I _ We reserve the right to refuse warranty on parts

t l which are damaged when using improper fuels or

lubricants.

_WARNING: Gasollne is highly flarnma-

ble. Always mix In a well ventilated area,

Do not fill tank with motor running, nor

near any flame or while smoking. Be

sure the gas tank Is empty when trans-

porting in the trunk of your automobile

to prevent explosion.

Fuel Mixture Table

IMPORTANT: Do-NOT puli,uP ontheFlex Shaft, "

or pu!l theFlex Shaft out 0f_iheDowntube, as it

M/_Y;BE DIFFICULT TO REINSTALLI See Figure

B;

Gasoline Tanaka Perfect Mlx

2 Cycle 011

1/2 Gallon 1.3 oz.

1 Gallon 2.6 oz

6 Gallon 15.6 oz.

FLEXSHAFT

Figure B

:;_ IMPORTANT: Experience indicates that alcohol

blended fuels (called gasohol, or using ethanol or

methanol) can attract moisture .which leads to

separation and formation of acids during storage.

Acid gascan damage the fuel system of an engine

iwhile in storage. To avoid engine problems, the

fuel system should be emptied before storage for

30 days or longer. Drain gas tank, start the engine

and let run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See storage

instructionsfor additional information. Never use

engine or carburetor cleaner products in the fuel

tank or permanent damage may occur.

2