T&D SecureEx SX-LS-P7 Series Technical Document

SX EX ELECTROMAGNETIC

LOCK (REVISION 2)

INSTALLATION OPERATION

& MAINTENANCE GUIDE

(IOMG)

PART NO: SX-LS-P7XXXXA

CERTIFICATE ISSUE: No .2

ABOUT SECUREX

SECUREX TECHNOLOGY, IS A SPECIALIST SECURITY

AND SAFETY SOLUTIONS PROVIDER

Supplying solutions for use in both Safe & Hazardous Areas (Zones 1 & 2,

21 & 22), we work with the very best security industry partners to provide

the ultimate solutions for hazardous areas.

SecurEx offer a comprehensive range of high-quality products supplied

either as individual components or as matched building blocks of a

complete bespoke solution

Products typically are CE, ATEX, IECEx and/or UL certified for use in various

gas and dust environments (see individual certifications). Wherever there is a

hazardous area, we offer a solution. Our technology finds a home in diverse

market sectors including:

2

• Petrochemical

• Chemical Manufacture

• Pharmaceutical

• Utilities

• Food

• Military

• Government,

• Beverage

• Distilleries,

• National Infrastructure

• Agriculture

• Aerospace

PRODUCT OVERVIEW…

INDEX

3

Page 3 – INDEX

Page 4 – PRODUCT OVERVIEW

Page 5 – MECHANICAL INSTALLATION

Page 6 – MOUNTING OPTIONS

Page 7 – ELECTRICAL INSTALLATION

Page 8 – OPERATION

Page 9 – MAINTENANCE

Page 10 – ELECTROMAGNETIC LOCK GA

Page 11 – ARMATURE (KEEPER) GA

Page 12 – ATEX PRODUCT CERTIFICATE

Page 15 – DECLARATION OF CONFORMITY

Page 16 – PRODUCT TEST CERTIFICATE

Page 17 – TECHNICAL SPECIFICATIONS

Page 18 - NOTES

i

INTRODUCTION

The SX EX ELECTROMAGNETIC LOCK (also known as the SX Ex Maglock) is a

member of the unique SecurEx SX product family which has been specifically

designed for use in harsh hazardous (Ex) environments.

This unique certified device works with both our door controller and access products

or with third party ACU systems to provide a highly effective security solution for

access control in Ex classified hazardous areas Zones 1, 2, 21 & 22.

Developed and manufactured for SecurEx under license by our partner company, Wath Group Ltd this

unique Sx Ex Electromagnetic Door Lock has been specifically designed to be a true ‘Ex Certified’

Security Locking product. Elegantly designed with both ‘form and function’ in mind, the lock is

manufactured from a single solid mono-block of 316 Stainless Steel and is supplied as standard

factory fitted with a 5-metre multi-core user cable.

Engineered to withstand loads of up to 550 kgf / 1200 lbs, the unit may be fitted to a wide variety of

door configurations including left or right-handed and in or outward opening doors by using the

appropriate approved matching mounting systems (sold separately). Cabling can exit to either the

right or the left-hand side of the lock as required to suit the installation as the unit can be fitted in any

orientation. The fully sealed IP67 unit is suitable for use in on-shore and off-shore environments and

the lock is available in a choice of 12 or 24V DC versions.

In most standard configurations the unit is usually supplied fitted with door status monitoring and is

provided with a special door armature (Keeper unit), which includes a door status magnet. For higher

security applications, the product has been designed with special versions available providing graded

door status contacts with anti tamper and product fault monitoring.

The wide variety of configurations available for this locking system make it particularly useful when

used as part of an integrated access control solution where it can provide both enhanced safety and

security for personnel.

PRODUCT OVERVIEW…

PRODUCT OVERVIEW

4

SPECIAL NOTE 1:

Subject to normal use, mechanical installation in

approved configurations and appropriate

electrical connections having been made this

locking system should respond reliably.

Reconstruction and alterations to the lock that

might affect the explosion protection are not

allowed. Furthermore EN 60079-14 and EN

61241- 14 have to be applied for the installation

of electrical equipment in explosive areas.

Moreover the special conditions as set out in

the products ATEX / IECEx test certificates

must be observed.

SPECIAL NOTE 2:

ALL main components of this locking system

are clearly and uniquely Serial Numbered using

tamper evident seals which are fitted for your

safety & security.

The unique serial numbering provides full

traceability for the lock kit and certified parts.

Lock sets MUST ALWAYS be used together as

a complete system.

The Cover Plate ‘Certification label face’ is

marked on the GA is engraved with

Configuration & Certification Details of the

specific lock unit supplied.

MECHANICAL INSTALLATION

PRODUCT ONLY SUITABLE FOR

END USER INSTALLATION ONLY

BY APPROPRIATELY QUALIFIED

PERSONNEL

Installation Considerations

The SX-LS-P7XXXXA series Electromagnetic

locks can be installed and used just like a

conventional electromagnetic lock by being

fitted onto the frame and acting on the armature

plate (keeper unit) which is usually mounted to

the top of the door.

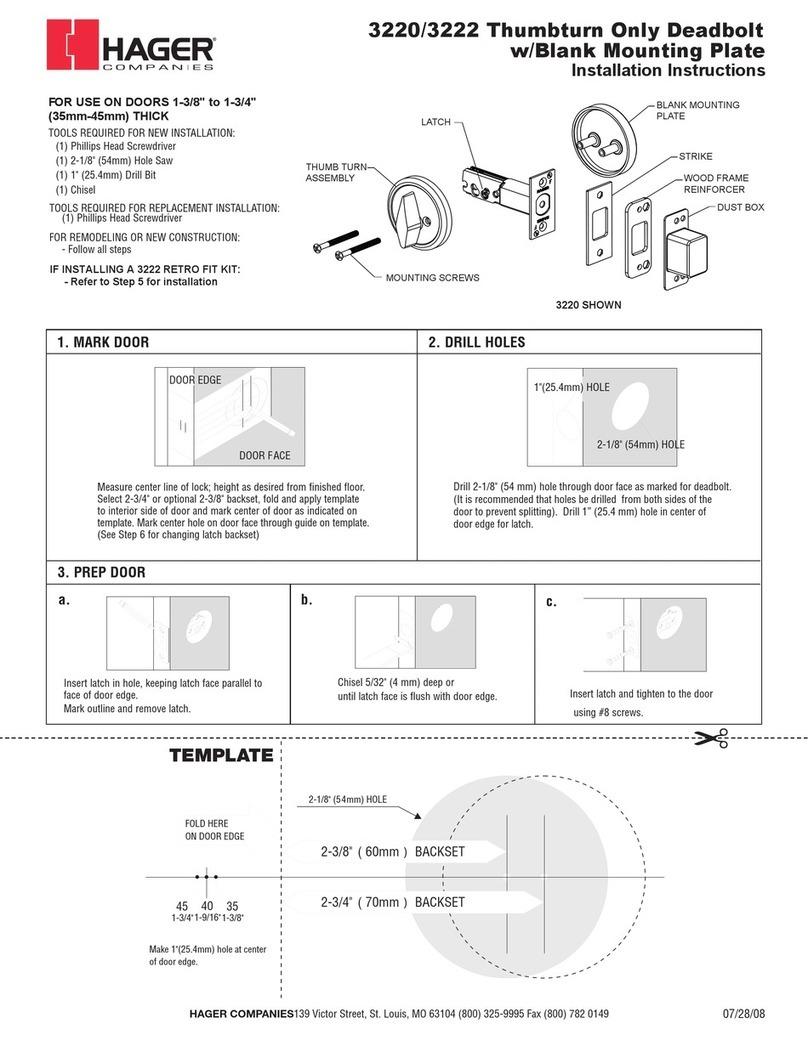

Mechanical Installation

Basic installation requires 4 x M6 Mounting

bolts for the lock.

The Lock is provided as standard fully

assembled with a 5 m user cable factory fitted.

DOOR PREPARATION

Door preparation details are shown on the GA

drawings for the Electromagnetic Lock and

Armature (Keeper) which can be found on the

center pages of this manual.

Care MUST be taken to carefully align the lock

and armature units. This is essential both to

correctly align the door sensor system and to

ensure full engagement of the armature for

optimum performance of the lock.

Depending on the door type you are fitting the

lock to, both the door and frame will need to be

appropriately prepared, drilled and tapped. This

may require appropriate rivet nut inserts to be

fitted or hank bushes to be installed.

Furthermore, depending on the door

configuration, the use of approved matching

mounting systems may be required – See

Mounting Options.

5

MOUNTING OPTIONS

MOUNTING OPTIONS

The SX EX ELECTROMAGNETRIC LOCK has been designed for use on a wide range of door types and

configurations including use on both inward and outward opening doors.

Each lock is provided as standard as a two-part set comprising the Electromagnetic Lock and The Armature

Plate (Keeper).

6

OUTWARD OPENING DOORS

A common mounting arrangement for outward opening doors is for the magnetic lock to be fitted neatly

beneath the door frame with the Armature Plate being fitted directly to the door which then closes directly

onto the lock. This requires our optional custom L bracket.

INWARD OPENING DOORS

A typical mounting arrangement for inward opening doors is for the magnetic lock to be fitted directly to the

outside face of door frame with the Armature Plate being stepped off of and up from the door to close

directly onto the lock. This arrangement requires our optional custom Z bracket.

Note: Due to common mounting points the Z bracket can also be used to mount the lock in an alternate

mounting arrangement if required.

MOUNTING KITS

The following kits are available at extra cost:

L Bracket Kit - P/N SX-LS-M70101A

Comprising an L bracket which is designed to

allow the lock to be neatly mounted under the

door frame whist the receiver plate is directly

mounted to the door. Due to common mounting

points this can also be used to mount the

armature (keeper) plate in an alternate

mounting arrangement if required.

Z Bracket Kit - P/N SX-LS-M70201A

Comprising a 2-part adjustable Z bracket, this

kit allows either the armature (keeper) plate or

the lock itself to be set off of the door or frame.

The bracket provides an adjustable offset

clearance of up to 75mm.

S Bracket Kit P/N SX-LS-M7040XA

The S bracket option allows us to create special

custom brackets designed to meet a specific

clients unique requirements.

ELECTRICAL INSTALLATION

PRODUCT IS SUITABLE FOR END USER INSTALLATION ONLY BY

APPROPRIATELY QUALIFIED PERSONNEL

Installation Considerations

The SX-LS-P7XXXXA series Electromagnetic lock can be installed and used just like a conventional

electromagnetic lock by fitted onto the frame and acting on the armature plate (keeper unit) which is

usually mounted to the top of the door.

Electrical Installation

The Electromagnetic Lock is factory fitted as standard with a grey, multi-core ‘wire braided’ cable. The

signal cores MUST be appropriately terminated via a suitable certified Ex e gland into a local Ex e junction

box. 7

12V DC Product Versions – V

Max 13.2V DC 1A

24V DC Product Versions – V

Max 26.4V DC 0.5A

SX EX ELECTROMAGNETIC LOCK - WIRING

CONNECTIVITY & FUSING TABLE BY MODEL

NUMBER for 24V DC PRODUCT

SWITCHING SYSTEM: SPCO

VOLTAGE TEMP

24V DC T6 –40 °C … +45 °

C

SX-LS-P71211A

24V DC T5 –40 °C … +60 °

C

SX-LS-P72211A

CABLE TYPE 7 CORE LINE FUSE

CORE NUMBER 1 +VE 0.5A SLO BLO

CORE NUMBER 2 0 VDC NA

CORE NUMBER 3 NO NA

CORE NUMBER 4 NC NA

CORE NUMBER 5 COMMON 0.5A SLO BLO

CORE NUMBER 6 COMMON 0.5A SLO BLO

EARTH CORE GND NA

SPECIAL NOTE 3:

Only competent personnel should carry out the

electrical connection of this product.

Driver circuits to the lock and the magnetic switch

should be appropriately fused / protected in line as

specified by the ‘X’ conditions to prevent exceeding

the design limits set out in the Technical

Specifications section.

‘SLO-BLO’ is the minimum requirement for fusing

as shown in the tables (see left). We recommend

fused terminals are fitted for this purpose, located

close to the ACS.

To prevent the risk of hazardous voltages

accidentally being transmitted into the hazardous

area we recommend that power to this device is

supplied from a suitable power source, e.g.,

isolating transformer / PELV source.

The user cable is mechanically braided for

protection. However, the electrical installer should

take such additional measures to protect the cable

when installed on-site as may be necessary to

comply with local regulations and good installation

practice. This may require routing the user cable

through an appropriate protective conduit.

For additional protection a safety earth point is

provided. This can be found beneath the gland on

the cable entry side of the Electromagnetic Lock.

SX EX ELECTROMAGNETIC LOCK - WIRING

CONNECTIVITY & FUSING TABLE BY MODEL

NUMBER for 12V DC PRODUCT

SWITCHING SYSTEM: SPCO

VOLTAGE TEMP

12V DC T6 –40 °C … +45 °

C

SX-LS-P71111A

12V DC T5 –40 °C … +60 °

C

SX-LS-P72111A

CABLE TYPE 7 CORE LINE FUSE

CORE NUMBER 1 +VE 1A SLO BLO

CORE NUMBER 2 0 VDC NA

CORE NUMBER 3 NO NA

CORE NUMBER 4 NC NA

CORE NUMBER 5 COMMON 0.5A SLO BLO

CORE NUMBER 6 COMMON 0.5A SLO BLO

EARTH CORE GND NA

LOCKING MECHANISM

When correctly installed mechanically and electrically as described above, the SX EX

ELECTROMAGNETIC LOCK will provide both a reliable locking solution and door status information

for access control purposes.

Locking is achieved when the armature (keeper) is in full contact with the Electromagnetic lock and

either 12V DC or 24V DC is applied (depending on product version).

When electrically locking the door, ideally the lock should ONLY be energized when ‘door closed

status’ has been detected AND after allowing ‘settling time’ to ensure the door to be completely come

to rest in its normal closed position.

SPECIAL NOTE 4:

This is a ‘permanently energized to lock’ product. The case is specially designed to dissipate

heat and acts as a natural heat sink. The external temperature of the unit will therefore rise

under normal use and may become hot.

DOOR STATUS MONITORING

To monitor ‘door status’ the magnetic switch contacts should be appropriately whetted by the

monitoring / ACS system with low current 12/24V DC. The contacts operation may be used by the

monitoring / access control system to positively confirm the state of the secured door.

Contact operation will correspond to the door being opened or closed in line with the truth table for the

specific type variant being supplied. See the Connectivity Wiring & Fusing Table by Model Number on

pages 8 & 9 of this booklet.

The minimum fusing requirements for the door contact should be adhered to in order to comply with

the ‘X’ Conditions of this product.

OPERATION…

OPERATION

8

When used in harsh outdoor conditions, we recommend regular routine maintenance as follows:

• Regularly check the Electromagnetic Lock for correct operation.

• Regularly test the switch contact functionality with the monitoring system for correct contact

operation.

• Regularly clean and remove all dirt and/or particles that could lead to the locks operation or

condition being impaired. In particular ensure the magnetic surfaces are kept clean and clear of

debris which could impair performance.

• Every 3-months check the external sealing of the multicore cable connections and the overall

condition of the unit.

NOTE: In case of problems with the lock, contact SecurEx Technology’s Service Department

and arrange for the return of the unit to us for repair / service / replacement.

The Lock’s case is Torx security screw sealed. User access to the internal mechanism is NOT

required and opening the cover will VOID CERTIFICATION & may compromise the safety &

integrity of the product in its intended use.

MAINTENANCE…

MAINTENANCE / WARRANTY

9

ELECTROMAGNETIC LOCK GA

10

ARMATURE (KEEPER) GA

11

IECEx PRODUCT CERTIFICATE

12

For IECEx Certificate of conformity please download from https://www.iecex-certs.com/home

Certificate number: IECEx EXV 17.0018X

ATEX PRODUCT CERTIFICATE

13

14

EU / EC DECLARATIONS OF CONFORMITY

15

PRODUCT TEST CERTIFICATE

Product Serial Number:

Date of Manufacture:

16

FACTORY DECLARATION

This Locking Mechanism has been fully factory tested, each unit is tested in accordance with ‘clause

15’ of the products ATEX certificate and ‘Conditions of Manufacture’ as set out in the products ATEX

& IECEx certificates.

When correctly installed mechanically and electrically as described, the SX EX ELECTROMAGNETIC

LOCK will provide both a safe & reliable locking solution and door status information for access

control purposes.

DESCRIPTION OF EQUIPMENT OR PROTECTIVE SYSTEM

‘The Magbar’s body is constructed from Stainless-Steel (Grade A2/A4), which houses the

encapsulated electromagnetic coils and corresponding electronics. The silicon-steel core is partially

exposed to facilitate an interlock, with a separate metallic armature plate (keeper). The equipment is

supplied with a flying lead though a factory fitted gland, which requires suitable termination at

installation this can be supplied in various length cords. Optional electronics allow for integration with

different alarm and access control systems.’

THE OFFICIAL STAMP OF

SECUREX TECHNOLOGY LTD

QA & Test Stamp

PUBLICATION: SX-LS-P7XXXXA-IOMG ISSUE: 2.0

14-09-2020

THIS DOCUMENT IS COPYRIGHT © SECUREX TECHNOLOGY

(2020).

ALL REASONABLE PRECAUTIONS HAVE BEEN TAKEN TO

ENSURE THE ACCURACY OF THE INFORMATION CONTAINED

IN THIS DOCUMENT AT THE TIME OF PUBLICATION.

IT IS THE END USERS RESPONSIBILITY TO ENSURE THAT THE

PRODUCT IS INSTALLED AND USED IN ACCORDANCE WITH

THE GUIDELINES SET OUT HEREIN.

IN CASE OF DOUBT, NEED FOR FURTHER CLARIFICATION, OR

IF ANY ERRORS OR OMMISIONS ARE FOUND PLEASE INFORM

US / CONTACT US IMMEDIATELY.

SECUREX RESERVES THE RIGHT TO CHANGE AND UPDATE

ANY AND ALL DATA FOUND IN THIS DOCUMENT & CAN

SUPPLY EQUIMPEMT WHICH IS EQUAL TO OR \gREATER IN

SPECIFACION

SX-LS-P7XXXXA PRODUCT

TECHNICAL SPECIFICATIONS

Dimensions & Weight

Electromagnetic Lock

• Dimensions 40.0 x 62.0x 265.0 (HxWxD)

• Weight Approx. 5.00Kg

Magnet Armature

• Dimensions 18.0 x62.0 x265.0 (HxWxD)

• Weight Approx. 2Kg

(Actual Size and Weight may vary iteration dependent).

Enclosure Material

Stainless Steel

• A4 Stainless

(Actual Grade may be equal or greater than A4 stainless. A2

may be used if Pickling and Passivation techniques are

applied supply dependent).

Mounting Detail

Electromagnetic Lock

• M6 Mounting Point (x4)

• M4 External Earth Point (x1)

Magnet Armature

• 4 x M6 Mounting Points (x4)

(External Earth Point fitted with M4 bolt, M4 external serrated

lock washer).

Approved mounting systems

• SX-LS-M70101A - L BRACKET

• SX-LS-M70201A - Z BRACKET

• SX-LS-M704XXA - S BRACKET

(SecurEx Approved mounting systems are required to

maintain product warranty. S bracket is a custom mounting

system on special request).

Ambient Temp Range & T-Class

• (1) –40 °C … +45 °C (T6)

• (2) –40 °C … +60 °C (T5) - STDFS

(Temperature range to be specified at point of order).

Warranty

Factory Warranty

• 18 Months

(Warranty begins at the point of Factory Dispatch).

Switching Systems

•(1) SPCO Contact [S0] - STDFS

•(2) SEOL Grade 2 [S1]**

•(3) TEOL Grade 3 [S2]**

•(4) Alarm + Tamper Loop [S3]**

•(5) SPECIAL Contact [S4]**

•(6)Tamper Loop Only [S5]**

(System specified on order

**Configuration only available on special request )

Switching Electrical Characteristics

• SPCO CONTACT - Max. 0.5A

• SPCO CONTACT - Max. 10W

(Please refer to product certification label)

Operation Life Cycles - MTBF

• >1 million operations (Mechanical)

• 106operations (Electrical)

User Cabling

•(1) 5m - STDFS

• (2) 10m

• (3) 15m

• (4) 15m

• (5) 25m

(The braid protected multi-core user cable supplied has

an individual conductor core size of 0.5mm2or Greater.

Depending on product variant the core count is between

2-6 Cores + Earth).

STDFS – STANDARD FACTORY SPECIFCATION

Part No. SX-LS-P721111A

(Standard factory speciation is a stocked product).

Ex Marking / Certification

• II 2G Ex mb IIC T6/5 Gb

• II 2D Ex mb IIIC T85/100°C Db

• IECEx Ex mb IIC T6/5 Gb

• IECEx Ex mb IIIC T85/100°C Db

Approvals

• ExVeritas 17ATEX0289X

• IECEx EXV 17.0018X Issue No. 2

Ideal Maximum Holding Force

• ~550 kgf. (5500N)

• ~1200 lbs.

(Magnet holding force is reduced by increasing AC-ripple

in DC supply 0...max. 25%).

IP Protection

• IP 67

(1 Meter for 30 Minutes in fresh water).

Electromagnet Power Requirements

• (1) 12V DC (13.2 Vmax 1A Fused) - STDFS

• (2) 24V DC (26.4 Vmax 0.5A Fused)

(Supply reequipments to be specified on order)

Part No. Product Key

17

NOTES

18

NOTES

19

SecurEx Technology Ltd

Bedford Park, Barnsley Road

Wath-upon Dearne

S63 6DQ

United Kingdom

T: +44 (0)1709 352301 E: info@securex.technology

E-Documents

Electronic copies of this manual together with additional

product information and copies of the IECEx & ATEX

certificates can be found on our download site

www.SecurEx.Technology/downloads

Or simply use the QR code below…

Table of contents

Popular Lock manuals by other brands

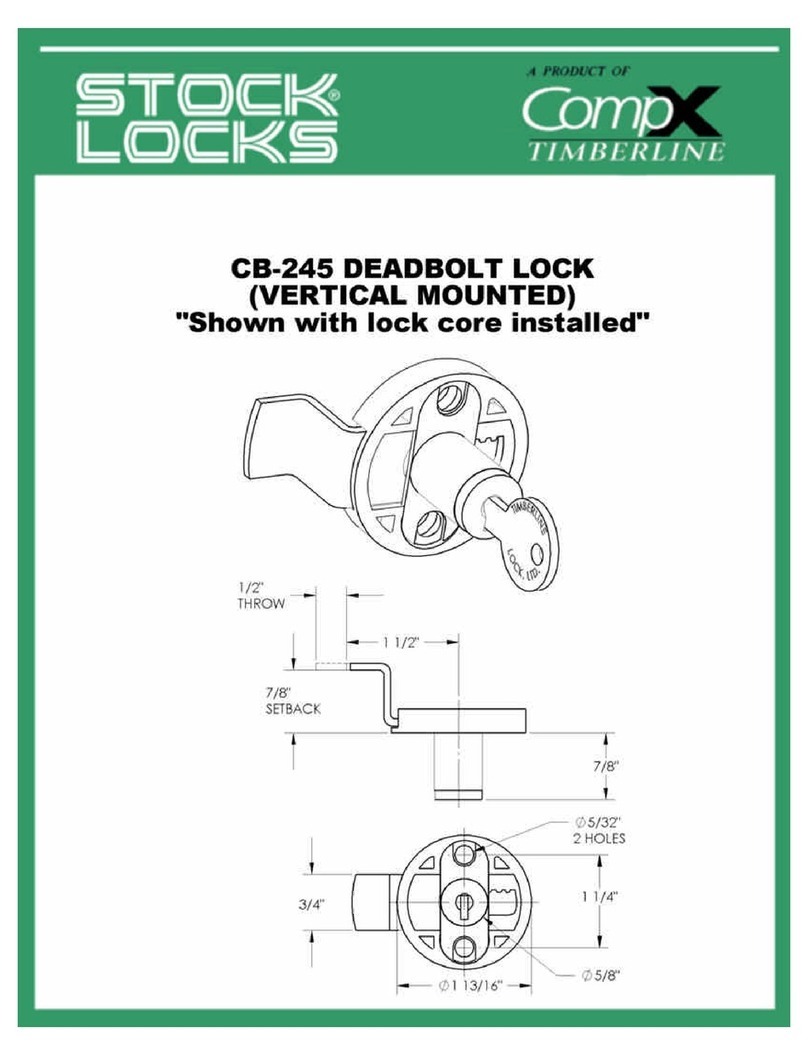

COMPX

COMPX Timberline CB-245 instruction sheet

Promet

Promet PLS-3 user manual

WALDIS

WALDIS PAXOS ADVANCE DUAL LOCK operating instructions

Steren

Steren COM-225 quick start guide

Intelligent Biometric Controls

Intelligent Biometric Controls 1TouchIQ2 Series user guide

Sargent

Sargent ASSA ABLOY SE LP10 installation instructions