8PD / PCA / PCA PLUS - Rev. 01 - Jun/22

2. To the operator

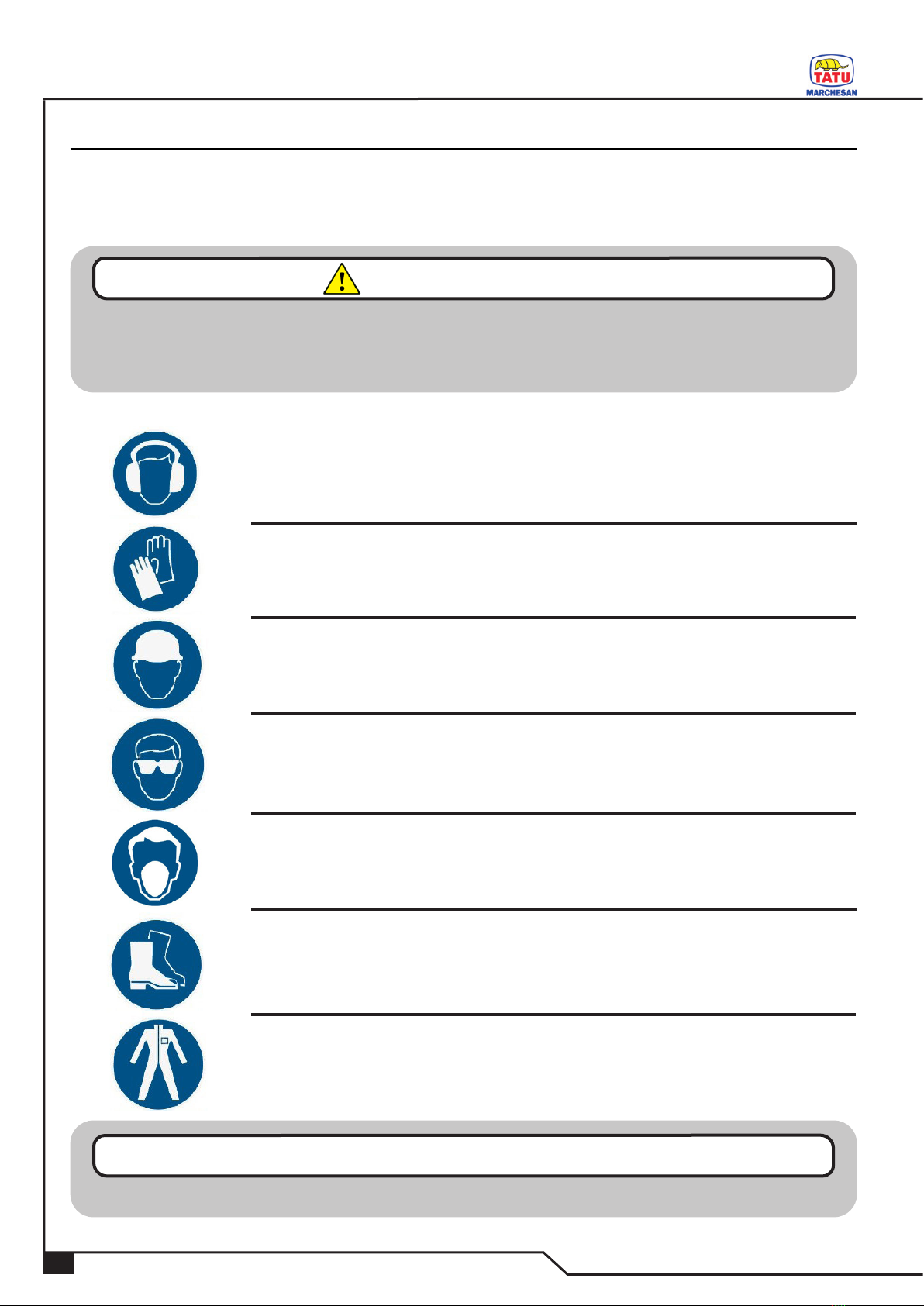

Personal protective equipment (PPE)

The personal protective equipment must be used as stated by the Ministry of LaborThe personal protective equipment must be used as stated by the Ministry of Labor

and Employment on the working standards.and Employment on the working standards.

Personal clothing must be used. Avoid tight or hanging clothes thatPersonal clothing must be used. Avoid tight or hanging clothes that

may become entangled to the moving parts of the equipmentmay become entangled to the moving parts of the equipment.

Use earplugs or muffs to avoid loud noises that may lead toUse earplugs or muffs to avoid loud noises that may lead to

complications or hearing loss.complications or hearing loss.

The foot protection will prevent damages from the impact of objects,

nails or bolts scattered on the floor, crushing hazards, injuries from

falling on slippery or wet areas and so on. Always use foot protecion

during the job.

Use gloves to protect your hands and arms from the abrasiveUse gloves to protect your hands and arms from the abrasive

elements that may cause cuts or scratches. Whenever assembling orelements that may cause cuts or scratches. Whenever assembling or

disassembling the equipment, always use safety gloves.disassembling the equipment, always use safety gloves.

The safety glasses protect the eyes from any type of debris that wouldThe safety glasses protect the eyes from any type of debris that would

cause irritation or injuries.cause irritation or injuries.

Use the respiratory protection to filter the air and avoid that any dirtUse the respiratory protection to filter the air and avoid that any dirt

particles or material debris may be inhaled by the worker, what wouldparticles or material debris may be inhaled by the worker, what would

compromise its respiratory system.compromise its respiratory system.

The safety helmet protect the worker's head from any injury that wouldThe safety helmet protect the worker's head from any injury that would

be caused by falling objects.be caused by falling objects.

- Only certied PPE must be used.

NOTE

- Safety must be present on every working step to avoid accidents, such as the

impact of objects, falling, noises, cuts and similar. Therefore, the working person is

subject to inner and outer damages to the body.

ATTENTION!