TB Wood's Sure-Grip Instruction Manual

Installation & Maintenance Manual

Sure-Grip®

Idler Bushing

P-5071-TBW

Form 885D

2TB Wood’s • 888-829-6637 P-5071-TBW • Form 885D

SH-BB 1/4-20NC 5 ft. lb.

SD-BB 1/4-20NC 5 ft. lb.

SK-BB 5/16-18NC 8 ft. lb.

SF-BB 3/8-16NC 15 ft. lb.

E-BB 1/2-13NC 30 ft. lb.

Idler Cap Screw Torque

The Sure-Grip tapered, QD-style interchangeable idler bushing offers flexible and easy installation while

providing many hours of reliable service. To ensure that the bushing performs as specified it must be

properly installed. Before beginning, make sure the correct size and quantity of parts are available for the

installation.

WARNING:

Rotating equipment must be properly guarded.

It is the responsibility of the user to properly guard all rotating equipment to comply with OSHA

or any applicable regulations. Failure to properly guard may contribute to severe injury

should someone come in contact with the rotating parts or should the rotating part fail.

WARNING:

DO NOT use Wood’s products on any primary aircraft drive or any other drive which could

endanger human life should a drive component fail.

WARNING:

It is essential that the idler assembly be installed

as close to mounting structure as possible to minimize overhung loads.

Excessive loads may cause a premature failure of the stud and/or bearings of the idler bushing.

INSTALLATION

IMPORTANT – Do not use lubricants in this installation

1. Thoroughly inspect the bore of the mating hub and the tapered surface of the idler bushing. Any paint,

dirt, grease, oil, etc. MUST be removed.

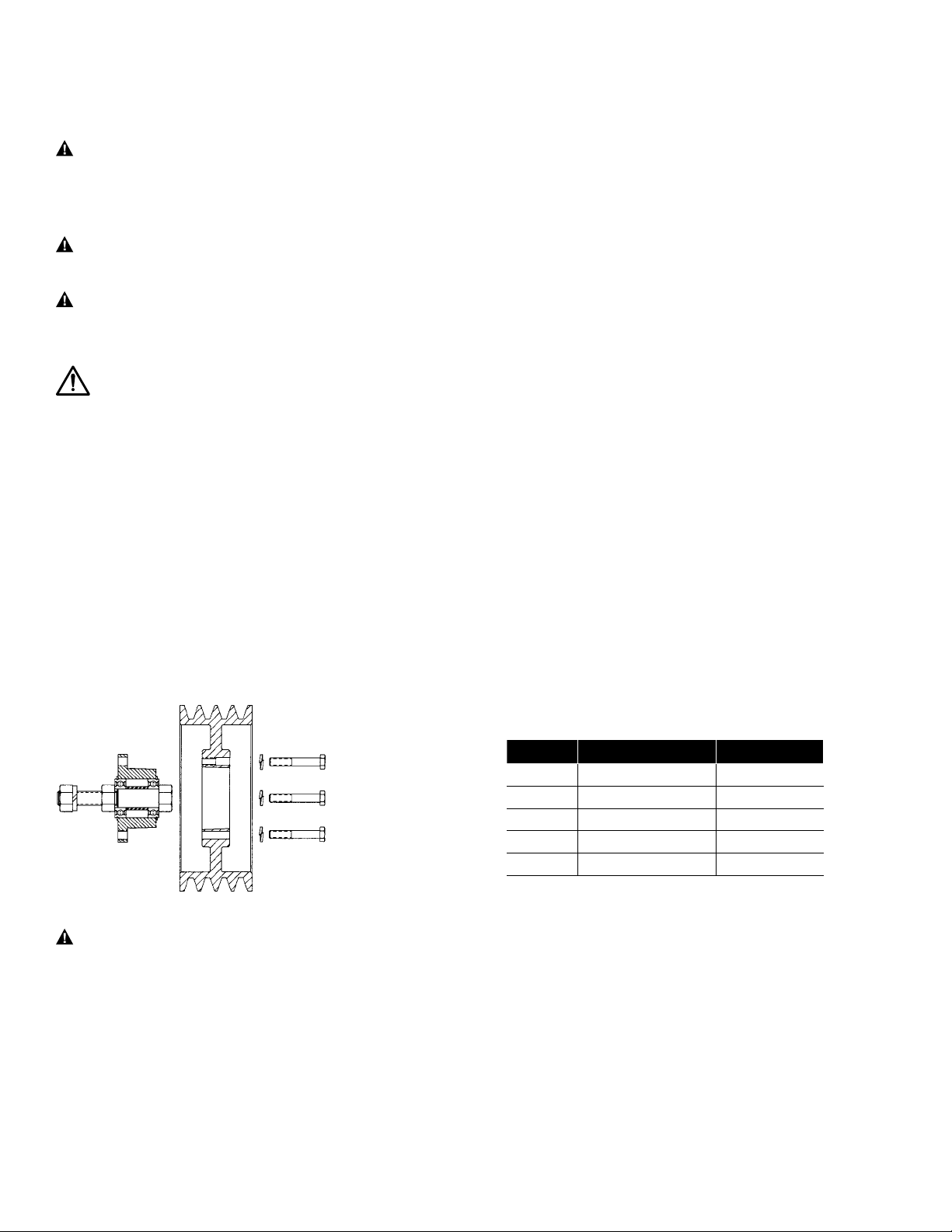

2.Place the idler bushing in the mating hub. Align the drilled holes in the mating hub with the threaded

holes in the idler bushing flange. Insert the cap screws, with lock washers, through the drilled holes in

the mating hub into the tapped holes in the idler bushing flange and finger-tighten, see Figure 1. Using

a torque wrench, tighten all caps screws evenly and progressively in rotation to the torque value listed

in Table 1.

WARNING:

The tightening force on the screws is multiplied many times by the wedging action of the

bushing’s tapered surface. If extreme tightening force is applied, or if a lubricant is used, bursting

pressures will be created in the hub of the mating part.

Do not attempt to over tighten cap screws to a point where the bushing flange touches the face of

the mating part. These torque values must be adhered to or idler assembly will fail prematurely.

Table 1 – Cap Screw Tightening Torque

Figure 1

The Sure-Grip tapered, QD-style interchangeable idler bushing offers flexible and easy installation while

providing many hours of reliable service. To ensure that the bushing performs as specified it must be properly

installed. Before beginning, make sure the correct size and quantity of parts are available for the installation.

WARNING: Rotating equipment must be properly guarded. It is the responsibility of the user to

properly guard all rotating equipment to comply with OSHA or any applicable regulations. Failure to

properly guard may contribute to severe injury should someone come in contact with the rotating

parts or should the rotating part fail.

WARNING: DO NOT use TB Wood’s products on any primary aircraft drive or any other drive

which could endanger human life should a drive component fail.

WARNING: It is essential that the idler assembly be installed as close to mounting structure as

possible to minimize overhung loads. Excessive loads may cause a premature failure of the stud

and/or bearings of the idler bushing.

WARNING: Cancer - www.P65Warnings.ca.gov

INSTALLATION

IMPORTANT – Do not use lubricants in this installation

1. Thoroughly inspect the bore of the mating hub and the tapered surface of the idler bushing. Any paint, dirt,

grease, oil, etc. MUST be removed.

2. Place the idler bushing in the mating hub. Align the drilled holes in the mating hub with the threaded holes

in the idler bushing flange. Insert the cap screws, with lock washers, through the drilled holes in the mating

hub into the tapped holes in the idler bushing flange and finger-tighten, see Figure 1. Using a torque

wrench, tighten all caps screws evenly and progressively in rotation to the torque value listed in Table 1.

WARNING: The tightening force on the screws is multiplied many times by the wedging action

of the bushing’s tapered surface. If extreme tightening force is applied, or if a lubricant is used,

bursting pressures will be created in the hub of the mating part.

Do not attempt to over tighten cap screws to a point where the bushing ange touches the face of

the mating part. These torque values must be adhered to or idler assembly will fail prematurely.

Table 2 – Cap Screw Tightening Torque

Idler Cap Screw Torque

SH-BB 1/4-20NC 5 ft. lb.

SD-BB 1/4-20NC 5 ft. lb.

SK-BB 5/16-18NC 8 ft. lb.

SF-BB 3/8-16NC 15 ft. lb.

E-BB 1/2-13NC 30 ft. lb.

TB Wood’s • 888-829-6637 P-5071-TBW • Form 885D 3

To Remove:

1. Loosen and remove all of the cap screws from the idler assembly.

2. Insert the cap screws into the tapped holes in the mating hub. Evenly and progressively tighten the

cap screws until the idler bushing and mating hub separate.

3. Remove idler assembly from the mounting structure.

Replacement Parts:

Following is a list of the replacement bearings. SH-BB G275

SD-BB G275

SK-BB G276

SF-BB G276

E-BB G277

Bushing Replacement

Size Bearings

(2 per unit)

3.Mount the assembly to the mounting structure. Place lockwasher and then outer nut on idler bushing

stud, Figure 2. Using a torque wrench, tighten the outer nut to the value listed in Table 2.

Note: If the assembly will be threaded into a tapped hole in the mounting surface, extreme care

should be used to prevent the inner nut from turning against the bearings. Additional tightening force

on inner nut will cause bearings to fail prematurely.

WARNING

The inner nut has been tightened to 5 ft. lbs. DO NOT tamper with or retighten

above this value or the bearings will fail prematurely.

4. Make sure idler assembly is parallel with both the driveR and driveN shaft. Properly align the driveR,

driveN, and idler assembly by the four-point method illustrated in Figure 3, below.

SH-BB 1/2-13NC 60 ft. lb.

SD-BB 1/2-13NC 60 ft. lb.

SD-BB58 5/8-11NC 125 ft. lb.

SK-BB 3/4-10NC 225 ft. lb.

SF-BB 3/4-10NC 225 ft. lb.

SF-BB1 1-8NC 300 ft. lb.

E-BB 1 3/8-8NC 750 ft. lb.

Idler Cap Screw Torque

Table 2 – Outer Nut Tightening Torque

Note: The inner nut torque should not

exceed 5 ft. lbs. when reassembling.

Note: Straight edge must touch

two points on A and two points

on B and C.

Figure 3

Figure 2

3. Mount the assembly to the mounting structure. Place lockwasher and then outer nut on idler bushing stud,

Figure 2. Using a torque wrench, tighten the outer nut to the value listed in Table 2.

Note: If the assembly will be threaded into a tapped hole in the mounting surface, extreme care should be

used to prevent the inner nut from turning against the bearings. Additional tightening force on inner nut will

cause bearings to fail prematurely.

WARNING: The inner nut has been tightened to 5 ft. lbs. DO NOT tamper with or retighten

above this value or the bearings will fail prematurely.

4. Make sure idler assembly is parallel with both the driveR and driveN shaft. Properly align the driveR,

driveN, and idler assembly by the four-point method illustrated in Figure 3, below.

To Remove:

1. Loosen and remove all of the cap screws from the idler assembly.

2. Insert the cap screws into the tapped holes in the mating hub. Evenly and progressively tighten the cap

screws until the idler bushing and mating hub separate.

3. Remove idler assembly from the mounting structure.

Replacement Parts:

Following is a list of the replacement bearings.

Note: The inner nut torque should not exceed 5 ft. lbs. when reassembling.

To Remove:

1. Loosen and remove all of the cap screws from the idler assembly.

2. Insert the cap screws into the tapped holes in the mating hub. Evenly and progressively tighten the

cap screws until the idler bushing and mating hub separate.

3. Remove idler assembly from the mounting structure.

Replacement Parts:

Following is a list of the replacement bearings. SH-BB G275

SD-BB G275

SK-BB G276

SF-BB G276

E-BB G277

Bushing Replacement

Size Bearings

(2 per unit)

3.Mount the assembly to the mounting structure. Place lockwasher and then outer nut on idler bushing

stud, Figure 2. Using a torque wrench, tighten the outer nut to the value listed in Table 2.

Note: If the assembly will be threaded into a tapped hole in the mounting surface, extreme care

should be used to prevent the inner nut from turning against the bearings. Additional tightening force

on inner nut will cause bearings to fail prematurely.

WARNING

The inner nut has been tightened to 5 ft. lbs. DO NOT tamper with or retighten

above this value or the bearings will fail prematurely.

4. Make sure idler assembly is parallel with both the driveR and driveN shaft. Properly align the driveR,

driveN, and idler assembly by the four-point method illustrated in Figure 3, below.

SH-BB 1/2-13NC 60 ft. lb.

SD-BB 1/2-13NC 60 ft. lb.

SD-BB58 5/8-11NC 125 ft. lb.

SK-BB 3/4-10NC 225 ft. lb.

SF-BB 3/4-10NC 225 ft. lb.

SF-BB1 1-8NC 300 ft. lb.

E-BB 1 3/8-8NC 750 ft. lb.

Idler Cap Screw Torque

Table 2 – Outer Nut Tightening Torque

Note: The inner nut torque should not

exceed 5 ft. lbs. when reassembling.

Note:

Straight edge must touch

two points on A and two points

on B and C.

Figure 3

Figure 2

Note: Straight edge must

touch two points on A and two

points on B and C.

Figure 3

Figure 2

Table 2 – Outer Nut Tightening Torque

Idler Cap Screw Torque

SH-BB 1/2-13NC 60 ft. lb.

SD-BB 1/2-13NC 60 ft. lb.

SD-BB 58 5/8-11NC 125 ft. lb.

SK-BB 3/4-10NC 225 ft. lb.

SF-BB 3/4-10NC 225 ft. lb.

SF-BB1 1-8NC 300 ft. lb.

E-BB 1 3/8-8NC 750 ft. lb.

Bushing

Size

Replacement

Bearings

(2 per unit)

SH-BB G275

SD-BB G275

SK-BB G276

SF-BB G276

E-BB G277

P-5071-TBW Form 885D 2/19

www.tbwoods.com

2000 Clovis Barker Road

San Marcos, TX 78666

512-353-4000

The Brands of Altra Motion

Couplings

Ameridrives

www.ameridrives.com

Bibby Turboex

www.bibbyturboex.com

Guardian Couplings

www.guardiancouplings.com

Huco

www.huco.com

Lamiex Couplings

www.lamiexcouplings.com

Stromag

www.stromag.com

TB Wood’s

www.tbwoods.com

Linear Systems

Thomson

www.thomsonlinear.com

Warner Linear

www.warnerlinear.com

Geared Cam Limit Switches

Stromag

www.stromag.com

Engineered Bearing Assemblies

Kilian

www.kilianbearings.com

Electric Clutches & Brakes

Matrix

www.matrix-international.com

Stromag

www.stromag.com

Warner Electric

www.warnerelectric.com

Deltran

www.thomsonlinear.com

Belted Drives

TB Wood’s

www.tbwoods.com

Heavy Duty Clutches & Brakes

Twiex

www.twiex.com

Stromag

www.stromag.com

Svendborg Brakes

www.svendborg-brakes.com

Wichita Clutch

www.wichitaclutch.com

Gearing & Specialty Components

Bauer Gear Motor

www.bauergears.com

Boston Gear

www.bostongear.com

Delevan

www.delevan.com

Delroyd Worm Gear

www.delroyd.com

Nuttall Gear

www.nuttallgear.com

Engine Braking Systems

Jacobs Vehicle Systems

www.jacobsvehiclesystems.com

Precision Motors & Automation

Kollmorgen

www.kollmorgen.com

Miniature Motors

Portescap

www.portescap.com

Overrunning Clutches

Formsprag Clutch

www.formsprag.com

Marland Clutch

www.marland.com

Stieber

www.stieberclutch.com

TB Wood’s Facilities

North America

USA

440 North Fifth Avenue

Chambersburg, PA 17201 - USA

888-829-6637 * 717-264-7161

Belted Drives and Elastomeric

Couplings

Customer Service

1-888-829-6637 (Press #5)

For Application Support

1-888-829-6637 (Press #7)

2000 Clovis Barker Road

San Marcos, TX 78666 - USA

1-888-449-9439

General Purpose Disc Couplings

Customer Service

1-888-449-9439

4970 Joule St

Reno, NV 89502 - USA

775-857-1800

Canada

9779 45 Ave NW

Edmonton, AB T6E 5V8 - Canada

+1 780-439-7979

6305 Danville Road

Mississauga, ON L5T 2H7 - Canada

1-800-829-6631

1073 Rue Bégin

Saint-Laurent, QC H4R 1V8 - Canada

+1 514-332-4812

Mexico

Comisión Federal de Electricidad 850,

Industrial San Luis,

San Luis, S.L.P., 78395 - Mexico

+52 444 137 1500

Europe

Merchant Drive, Hertford

Hertfordshire SG13 7BL - England

+44(0)1992 501900

Elastomeric Couplings

Neither the accuracy nor completeness of the information contained in this publication is guaranteed by the company and may be subject to change in its sole discretion. The operating

and performance characteristics of these products may vary depending on the application, installation, operating conditions and environmental factors. The company’s terms and

conditions of sale can be viewed at http://www.altramotion.com/terms-and-conditions/sales-terms-and-conditions. These terms and conditions apply to any person who may buy,

acquire or use a product referred to herein, including any person who buys from a licensed distributor of these branded products.

©2019 by TB Wood’s LLC. All rights reserved. All trademarks in this publication are the sole and exclusive property of TB Wood’s LLC or one of its afliated companies.

The Brands of Altra Motion

TB Wood’s Facilities

Popular Switch manuals by other brands

AVM

AVM Fritz!Box 7490 Installation and operation

schmersal

schmersal TFH 232-11UEDR operating instructions

SMC Networks

SMC Networks SMC6709GL2 Technical specifications

The GigRig

The GigRig G3 S quick start guide

Wegener

Wegener Unity RF Switch Installation & operating guide

HP

HP A3100-48 v2 Disassembly instructions