B4850 ESS Unit User Manual

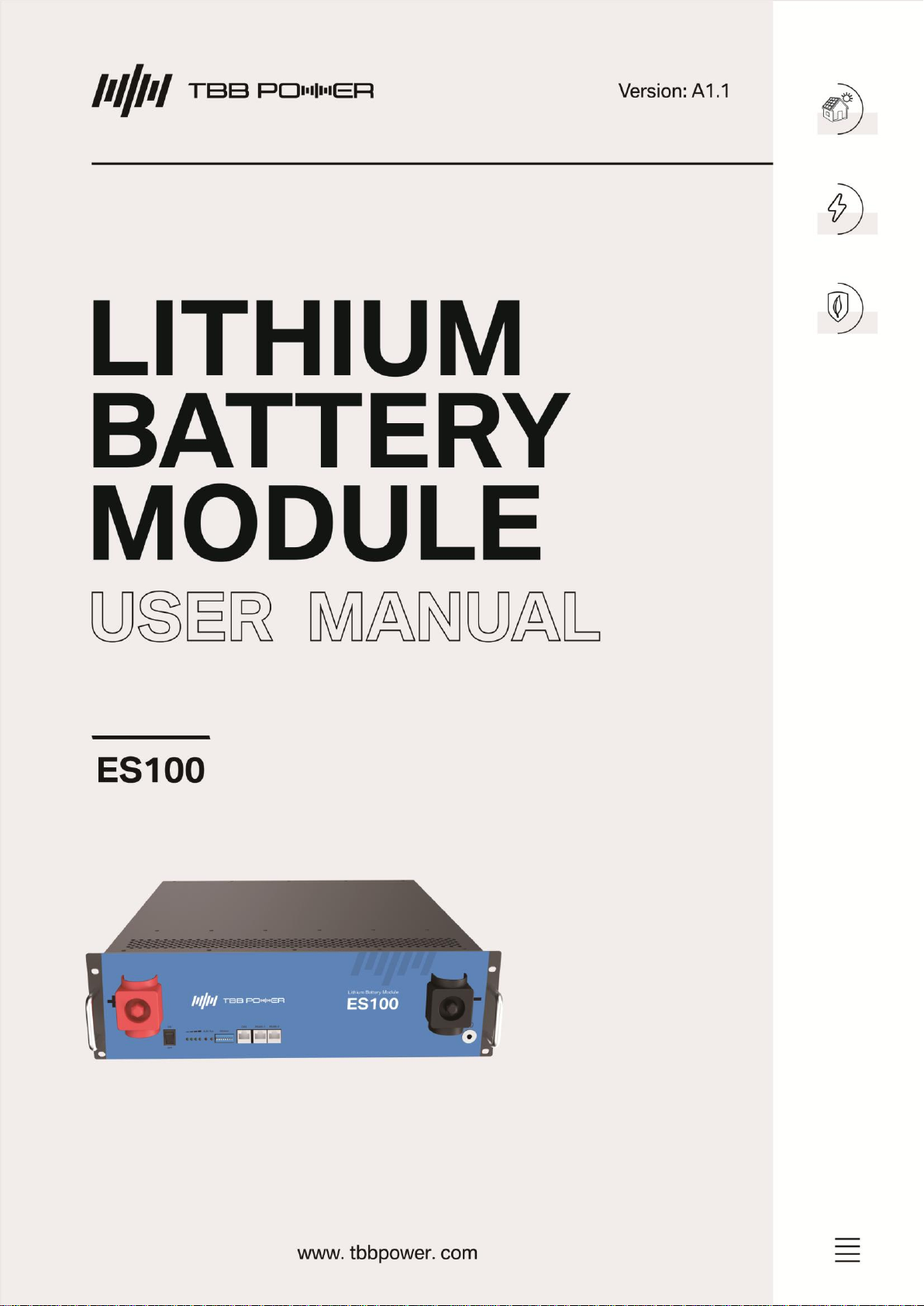

ES100 ESS Unit user manual

Contents

1. Introduction.................................................................................................................................1

1.1 Brief Introduction................................................................................................................1

1.2 Product Properties .............................................................................................................1

1.3 Product identity definition...................................................................................................2

2. Product Specification ..................................................................................................................3

2.1 Size and Weight.................................................................................................................3

2.2 Performance Parameter.....................................................................................................4

2.2.1 Front Panel Interface Definition................................................................................4

2.2.2 Address ...................................................................................................................5

2.2.3 Communication Port Definition.................................................................................7

2.2.4 SOC light display and corresponding battery capacity..............................................7

2.3 Battery Management System (BMS)..................................................................................8

2.3.1 Voltage Protection....................................................................................................8

2.3.2 Current Protection....................................................................................................8

2.3.3 Temperature Protection ...........................................................................................8

2.3.4 Other Protection.......................................................................................................8

3. Installation and Configuration......................................................................................................9

3.1 Ready for installation..........................................................................................................9

3.1.1 Environmental requirements ....................................................................................9

3.1.2 Tools and data.......................................................................................................10

3.1.3 Technical preparation.............................................................................................10

3.1.4 Unpacking inspection.............................................................................................11

3.1.5 Engineering coordination .......................................................................................12

3.2 Equipment installation......................................................................................................12

3.2.1 Installation preparation...........................................................................................13

3.2.2 Mechanical installation...........................................................................................13

3.2.3 Electrical installation...............................................................................................15

4. Use, maintenance and troubleshooting.....................................................................................16

4.1 Battery system usage and operation instructions.............................................................16

4.2 Alarm description and handling ........................................................................................17

4.3 Analysis and treatment of common faults.........................................................................17

4.4 Recycle and disposal.......................................................................................................17