5

CHANGES AND TYPING ERRORS RESERVED CHANGES AND TYPING ERRORS RESERVED

5.5 replacing The indenTer

When the hardness tester cannot be calibrated correctly anymore, the indenter is worn and must be replaced.

• Undo the pivot screw and take out the bottom handle.

• Take out the dial head but leave the cylinder in the frame. You can now see the adjusting nut.

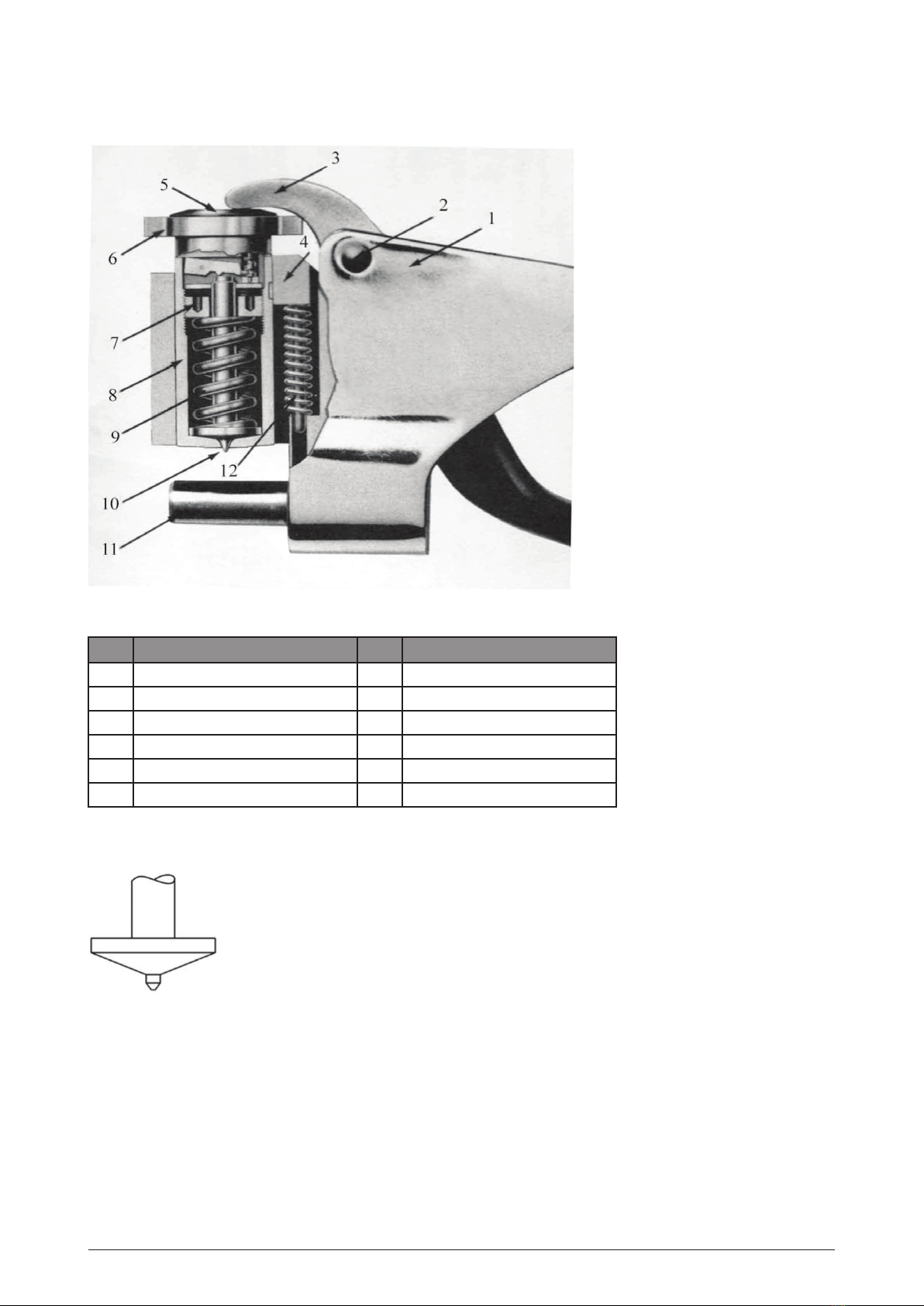

• Loosen the adjusting nut (see also figure 4) and take out the indenter.

• Insert the new indenter and fasten the adjusting nut. Do not fasten the nut too tight as this will damage the

indenter.

• Calibrate the hardness tester as described in paragraphs 5.3 and 5.4.

6. mainTenance

This hardness tester is a precision instrument. Its service life depends on correct use and good maintenance.

• Clean the hardness tester every time you have used it with a soft cloth.

• The various parts of the tester have been treated to protect them against rust. However, always check the tester

for rust when you use it often or when you are using it in a damp environment.

• Never drop the hardness tester. This will influence the correct working of the tester and may even render it

useless.

• Do not remove any parts of the tester other than for calibration purposes. Removing further parts voids the

guarantee.

7. facTors ThaT will inflUence The accUracy of The TesTer

7.1 maTerial

The surface of the material to be measured needs to be free of dust and grains to ensure the accuracy of the

measurement.

7.2 disTance To The edge of The maTerial

The distance between the tip of the indenter and the edge of the material has to be at least 5 mm. When you

measure closer to the edge this may influence the result.

7.3 disTance beTween Two measUring poinTs

The distance between two measuring points has to be at least 6 mm. When you measure too close to an earlier

measuring point this may influence the result.

7.4 oxidaTion

Even though a layer of oxidation is thin, it will influence the result of a measurement. A layer of 10 µm will result

in a deviation of 0.5 to 1 HW (over).

7.5 coaTing

A coating on the material will give you a unreliable result. Therefore you should always remove any coatings with

sanding paper or a solvent.

7.6 (in)correcT Use

• You should check the accuracy of the hardness tester regularly and calibrate it if necessary (see chapter 5).

• Always place the material horizontally between the tip of the indenter and the anvil. Make sure the material

presses well against the anvil.

• Press down the handle firmly in one go. When you add pressure slowly this will result in an inaccurate reading.

• Make sure the material does not shift while measuring.