TCi MFC A User manual

MFC Sine Wave Filter Kit

Installation Instructions

TCI, LLC

W132 N10611 Grant Drive

Germantown, Wisconsin 53022

Phone: 414-357-4480

Fax: 414-357-4484

Helpline: 800-TCI-8282

Web Site: http://www.transcoil.com

© 2020 TCI, LLC All rights reserved

Effective: 10/22/2020 Version: G

Revision

Description

Date

A

Release

09/27/2016

B

Update to drawings, heat loss

08/07/2018

C

Update to drawings and cooling

12/13/2018

D

Various text updates; added

Maintenance and Service section and

PQconnect option

04/09/2019

E

Updates to PQconnect section

01/09/2020

F

Updates to wiring notes

08/04/2020

G

Updates to PQconnect section

10/22/2020

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in

any form or by any means, mechanical, electronic, photocopying, recording, or otherwise,

without the prior written permission of TCI, LLC. The information in this manual is subject to

change without notice. Every precaution has been taken in the preparation of this manual.

TCI, LLC assumes no responsibility for errors or omissions. Neither is any liability assumed

for damages resulting from the use of the information contained in this publication.

1

Table of Contents

1.0 Introduction .............................................................................................................................3

Safety Instructions Overview............................................................................................................. 3

Warnings and Cautions..................................................................................................................... 3

General Safety Instructions............................................................................................................... 4

2.0 General Information ................................................................................................................5

Intended Audience ............................................................................................................................ 5

Receiving Inspection......................................................................................................................... 5

Storage Instructions .......................................................................................................................... 5

TCI Limited Warranty Policy.............................................................................................................. 5

3.0 Pre-Installation Planning ........................................................................................................7

Verify the Application......................................................................................................................... 7

Product Description........................................................................................................................... 7

Part Number Encoding...................................................................................................................... 8

MFC “A” Filter Kit – Sine Wave Filter Kit with damping resistor........................................................ 9

MFC “A” Filter Kit Part Number and Ratings................................................................................... 10

MFC “R” Filter Kit – Sine Wave Filter Kit without damping resistor ................................................ 11

MFC “R” Filter Kit Part Number and Ratings................................................................................... 11

MFC “P” Filter Kit – Sine Wave Filter Kit with PQconnect .............................................................. 12

MFC “P” Filter Kit Part Number and Ratings................................................................................... 13

Variable Frequency Drive Settings.................................................................................................. 13

Filter Schematic............................................................................................................................... 14

Capacitors ....................................................................................................................................... 16

Capacitor Brackets.......................................................................................................................... 17

Recommendations for MFC Kit Usage............................................................................................ 17

4.0 Installation .............................................................................................................................18

Installation Guidelines..................................................................................................................... 18

Select a Suitable Location............................................................................................................... 18

Mounting the Filter Kit ..................................................................................................................... 19

Power Wiring................................................................................................................................... 19

Line Reactor Wiring......................................................................................................................... 19

Wire Sizing ...................................................................................................................................... 20

5.0 PQconnect Option.................................................................................................................26

Product Description......................................................................................................................... 26

Installation ....................................................................................................................................... 26

Mounting.......................................................................................................................................... 26

Wiring .............................................................................................................................................. 28

Modbus RTU ................................................................................................................................... 30

PQvision PC application Screen Elements..................................................................................... 31

PCB Calibration Process................................................................................................................. 33

Register Map................................................................................................................................... 38

Example Application Using “Simply Modbus Master 8.1.0” ............................................................ 49

USPTL4 RS485 Converter Dip Switch settings .............................................................................. 50

6.0 Troubleshooting....................................................................................................................52

Troubleshooting............................................................................................................................... 52

Communication Problems............................................................................................................... 54

Debug Status Conditions ................................................................................................................ 55

Periodic Maintenance...................................................................................................................... 55

Evaluating MFC Sine Wave Filter Performance ............................................................................. 56

MFC Kit IOM 1.0 Introduction

3

1.0 Introduction

The information presented in this manual covers the MFC Sine Wave Filter Kit

only.

Safety Instructions Overview

This section provides the safety instructions which must be followed when installing, operating, and

servicing the MFC Filter Kit. If neglected, physical injury or death may follow, or damage may occur

to the filter or equipment connected to the filter. The material in this chapter must be read and

understood before attempting any work on, or with, the product.

The MFC Filter Kit is intended to be connected to the output terminals of a variable frequency drive

(VFD). An AC motor is connected to the output terminals of the MFC Kit and receives power from

the VFD through the MFC Filter Kit. The instructions, and particularly the safety instructions, for the

VFD, motor and any other related equipment must be read, understood and followed when working

on any of the equipment.

Warnings and Cautions

This manual provides two types of safety instructions. Warnings are used to call attention to

instructions that describe steps that must be taken to avoid conditions that can lead to a serious

fault condition, physical injury, or death.

Cautions are used to call attention to instructions that describe steps that must be taken to avoid

conditions that can lead to a malfunction and possible equipment damage.

Warnings

Readers are informed of situations that can result in serious physical injury and/or serious damage

to equipment with warning statements highlighted by the following symbols:

Warning

Dangerous Voltage Warning: warns of situations where

high voltage can cause physical injury and/or damage

equipment. The text next to this symbol describes ways

to avoid the danger.

Warning

General Warning: warns of situations that can cause

physical injury and/or damage equipment by means

other than electrical. The text next to this symbol

describes ways to avoid the danger.

Warning

Electrostatic Discharge Warning: warns of situations in

which an electrostatic discharge can damage

equipment. The text next to this symbol describes ways

to avoid the danger.

Cautions

Readers are informed of situations that can lead to a malfunction and possible equipment damage

with caution statements:

Caution

General Caution: identifies situations that can lead to a

malfunction and possible equipment damage. The text

describes ways to avoid the situation.

!

!

MFC Kit IOM 1.0 Introduction

4

General Safety Instructions

These safety instructions are intended for all work on the MFC Filter Kit. Additional safety

instructions are provided at appropriate points on other sections of this manual.

Warning

Be sure to read, understand, and follow all safety

instructions.

Warning

Only qualified electricians should carry out all electrical

installation and maintenance work on the MFC Filter Kit.

Warning

All wiring must be in accordance with the National

Electrical Code (NEC) and/or any other codes that apply

to the installation site.

Warning

Disconnect all power before working on the equipment.

Do not attempt any work on a powered MFC Filter Kit.

Warning

The MFC Filter Kit, drive, motor, and other connected

equipment must be properly grounded.

Warning

After switching off the power, always allow 5 minutes for

the capacitors in the MFC Filter Kit and in the drive to

discharge before working on the MFC Kit, the drive, the

motor, or the connecting wiring. It is a good practice to

check with a voltmeter to make sure that all sources of

power have been disconnected and that all capacitors

have discharged before beginning work.

!

!

!

MFC Kit Instructions 2.0 General Information

5

2.0 General Information

Thank you for selecting the MFC Filter Kit. TCI has produced this filter for use in many VFD

applications that require output voltage filtering. This manual gives an overview of how to install,

operate and maintain the MFC Filter Kit. Please contact TCI Technical Support or visit

https://transcoil.com/Support for additional information

Intended Audience

This manual is intended for use by all personnel responsible for the assembly, wiring installation,

operation and maintenance of the MFC Filter Kit. Such personnel are expected to have knowledge of

electrical wiring practices, electronic components and electrical schematic symbols. Panel design using

a TCI MFCFilter Kit should be performed with appropriateengineering supervisionso the design meets

the requirements based on materials utilized in the construction of the panel, wiring practices followed

by your shop, and the actual ambient conditions of the components for each application.

Receiving Inspection

The MFC Filter Kit has been thoroughly inspected at the factory and carefully packaged for

shipment. When you receive the unit, you should immediately inspect the shipping container and

report any damage to the carrier that delivered the unit. Verify that the part number of the

components you received is the same as the part numbers listed on the engineering drawings for

the kit which can be found at:

https://transcoil.com/products-kmg-mfcdrawings-htm/

Storage Instructions

If the MFC Filter Kit is to be stored before use, be sure that it is stored in a location that conforms

to published storage humidity and temperature specifications in this manual and on the applicable

technical drawings available at: transcoil.com. Store the unit in its original packaging.

TCI Limited Warranty Policy

TCI, LLC (“TCI”) warrants to the original purchaser only that its products will be free from defects

in materials and workmanship under normal use and service for a period originating on the date of

shipment from TCI and expiring at the end of the period described below:

Product Family

Warranty Period

KLR, KDR

For the life of the drive with which they are installed.

HGA, V1K, KLC,

KLCUL, KMG, MSD

One (1) year of useful service,

not to exceed 18 months from the date of shipment.

PFGuard, HGP, HGL,

HG7, HSD, KRF

Three (3) years from the date of shipment.

KCAP, KTR

Five (5) years from the date of shipment.

All Other Products

One (1) year of useful service, not to exceed 18 months from

the date of shipment.

The foregoing limited warranty is TCI’s sole warranty with respect to its products and TCI makes

no other warranty, representation, or promise as to the quality or performance of TCI’s products.

THIS EXPRESS LIMITED WARRANTY IS GIVEN IN LIEU OF AND EXCLUDES ANY AND ALL

EXPRESS OR IMPLIED WARRANTIES INCLUDING, WITHOUT LIMITATION, ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

This warranty shall not apply if the product was:

a) Altered or repaired by anyone other than TCI;

b) Applied or used for situations other than those originally specified; or

MFC Kit Instructions 2.0 General Information

6

c) Subjected to negligence, accident, or damage by circumstances beyond TCI’s control,

including but not limited to, improper storage, installation, operation, or maintenance.

If, within the warranty period, any product shall be found in TCI’s reasonable judgment to be

defective, TCI’s liability and the Buyer’s exclusive remedy under this warranty is expressly limited,

at TCI’s option, to (i) repair or replacement of that product, or (ii) return of the product and refund

of the purchase price. Such remedy shall be Buyer’s sole and exclusive remedy. TCI SHALL NOT,

IN ANY EVENT, BE LIABLE FOR INCIDENTAL DAMAGES OR FOR CONSEQUENTIAL

DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF INCOME, LOSS OF TIME, LOST

SALES, INJURY TO PERSONAL PROPERTY, LIABILITY BUYER INCURS WITH RESPECT TO

ANY OTHER PERSON, LOSS OF USE OF THE PRODUCT OR FOR ANY OTHER TYPE OR

FORM OF CONSEQUENTIAL DAMAGE OR ECONOMIC LOSS.

The foregoing warranties do not cover reimbursement for removal, transportation, reinstallation, or

any other expenses that may be incurred in connection with the repair or replacement of the TCI

product.

The employees and sales agents of TCI are not authorized to make additional warranties about

TCI’s products. TCI’s employees and sales agent’s oral statements do not constitute warranties;

these shall not be relied upon by the Buyer and are not part of any contract for sale. All warranties

of TCI embodied in this writing and no other warranties are given beyond those set forth herein.

TCI will not accept the return of any product without its prior written approval. Please consult TCI

Customer Service for instructions on the Return Authorization Procedure.

MFC Kit Instructions 3.0 Pre-Installation Planning

7

3.0 Pre-Installation Planning

Verify the Application

MFC Filter Kit Rating

Make sure that the MFC Filter Kit is correct for the application. The voltage rating of the filter kit

must match the voltage and current rating of the connected drive. The horsepower and current

rating of the filter kit must be appropriate for the connected load.

Product Description

The MFC Filter kit is a low-pass sine wave filter designed and developed by TCI to deliver

conditioned power to motor loads driven by PWM drives at a variety of lead lengths. The MFC Kit

is available for 460/480 Volt and 575/600 Volt systems.

The MFC Filter kit is a passive filter connected in series with the output terminals of the variable

frequency drive. It is designed to remove the carrier frequency distortion from the output voltage

waveform. The use of this low-pass filter will result in a nearly pure sine wave voltage profile. This

design will reduce the effects of the reflected wave phenomenon, (dV/dt), such as insulation

damage or premature failure in motors, transformers, and VFD output cables. The MFC Filter Kit

will also reduce the effects of stray high frequency harmonic currents, thereby reducing VFD ground

fault problems and noise interference in transducer signals.

The MFC Filter Kit is suitable for all lead lengths extending as far as 15,000 feet.

The MFC Filter Kit consists of the following standard features and components:

•A TCI 3-phase line reactor specifically designed for high PWM ripple current from the

sine wave filter application

•High-endurance, PWM current ripple rated capacitors

•Capacitor bleeder resistors to ensure safe capacitor discharge upon filter shutdown.

•Brackets for mounting capacitors to a panel (only for kits above 50 Amps)

•Damping resistors (optional)

•PQconnect monitoring and communications (optional)

MFC Kit Instructions 3.0 Pre-Installation Planning

8

Table 1: MFC Sine Wave Filter Technical Specifications

Current Ratings

480 V: 5 –1200 Amps

600 V: 8 –750 Amps

Intermittent overload current of 150% for 1 minute / hour

VFD Output Voltage

480 V and 600 V, 3-phase, at fundamental base frequency configured to Volts

per Hz

VFD Output Frequency

Up to 80 Hz

VFD Carrier Frequency

2 kHz to 16 kHz

Filter Performance

Maximum peak voltage of output waveform

480 V models: 815 V

600 V models: 1,018 V

Maximum dV/dt of output waveform

480 V models: 5 V/μs

600 V models: 6 V/μs

Environmental Conditions

Maximum Elevation

6,600 ft (2,000 m), derating required for operation above this level

Operating Temp

-30°C (-22°F) to 50°C (122°F)

Cooling provisions required for operation above this temperature.

Ambient Storage Temp

-40°C (-40°F) to 50°C (122°F)

Maximum Humidity

95% non-condensing

Reference Technical Standards

Voltage Drop

3% at nominal voltage, frequency and rated current

Capacitors

High endurance design (no PCBs)

Agency Approvals

UL & cULus Listed

Part Number Encoding

The figure below indicates the significance of each character in the MFC part number. The example

part number MFC130AR designates an MFC kit that is rated 130A, 480 Volts and does not include

resistors.

Figure 1: MFC Kit Part Number Encoding

NOTE: Individualpart drawings for each component included in the MFC Filter Kits are found at:

https://transcoil.com/products-kmg-mfcdrawings-htm/

MFC Kit Instructions 3.0 Pre-Installation Planning

9

MFC “A” Filter Kit – Sine Wave Filter Kit with damping resistor

The MFC Filter Kit is a sine wave filter component package designed and developed by TCI to allow

qualified customers to build sine wave filters to for the output of VFDs. The filter components are

designed to filter out PWM switching ripple when applied correctly and following the schematic

connections used by TCI. The MFC Filter Kit is available for 480 Volt and 600 Volt systems. When

properly designed, assembled, and installed, the completed product is intended to be suitable for use

with 3-phase PWM AC VFDs. The MFC A Filter Kit component package consists of the following

components:

•A KTRMG or KLRUL series filter reactor.

oThe 480 V/900 HP and larger units include two reactors that need to be wired in

parallel.

•High-endurance, PWM ripple current rated capacitors.

oBleeder resistors to ensure safe capacitor discharge on filter shutdown, located on

capacitors.

•Damping resistors

oHigh power 3-phase damping resistors to reduce VFD control or load dynamic

induced resonances. Damping resistors are recommended for applications which

have dynamically changing loads like hoists, elevators, or servos.

•Capacitor mounting brackets

oCapacitor mounting brackets are provided on kits rated 50 Amps and higher.

oKits under 50 Amps are not provided with capacitor brackets because these units

utilize single phase capacitors that do not have mounting brackets available for

them. These small size single phase capacitors are typically mounted vertically

due to the small size and reduced use of panel space.

MFC Kit Instructions 3.0 Pre-Installation Planning

10

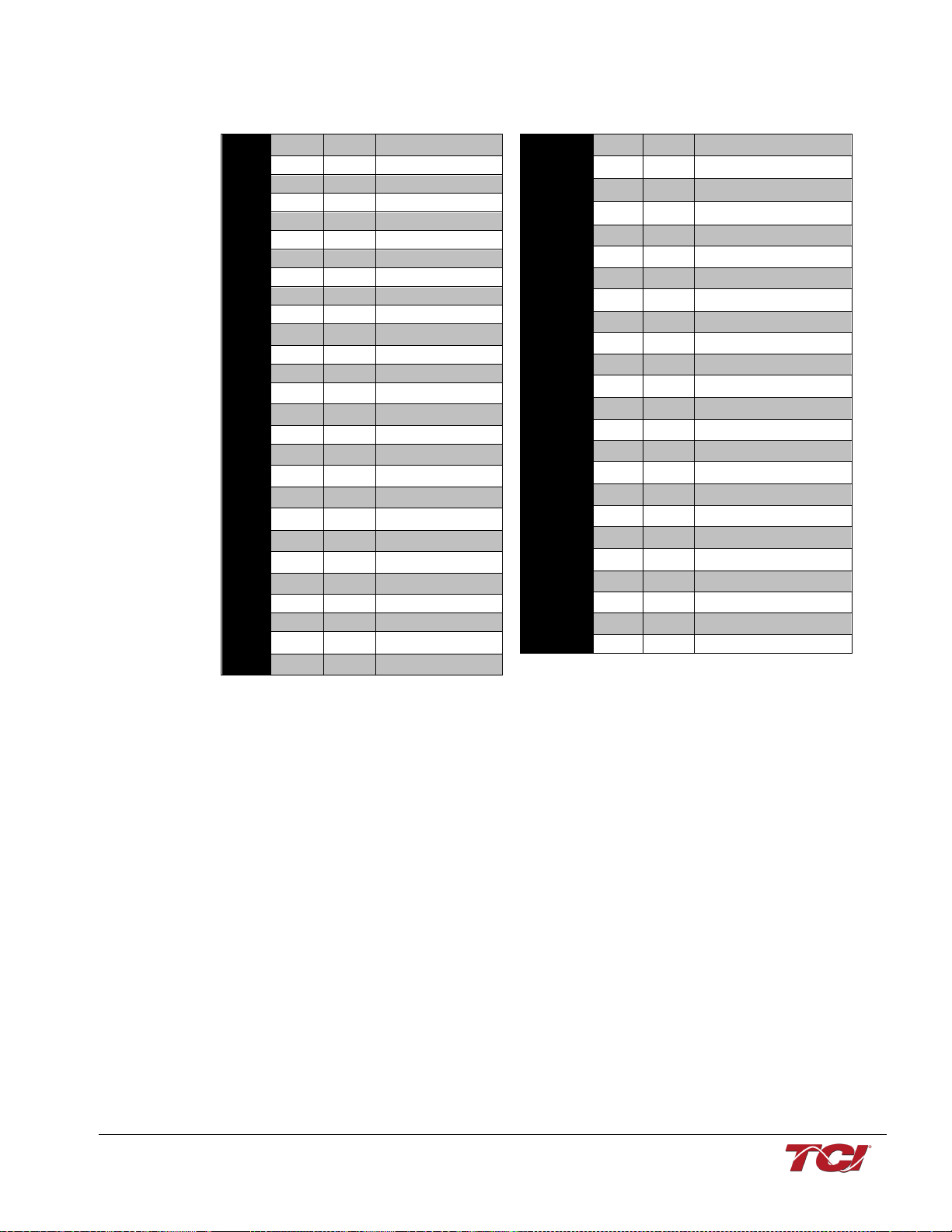

MFC “A” Filter Kit Part Number and Ratings

480 Volt MFC Kit

HP

Amp

480 Volt Model

5

8

MFC008AA

7.5

12

MFC012AA

10

16

MFC016AA

15

23

MFC023AA

20

30

MFC030AA

25

35

MFC035AA

30

45

MFC045AA

40

55

MFC055AA

50

65

MFC065AA

60

80

MFC080AA

75

110

MFC110AA

100

130

MFC130AA

125

160

MFC160AA

150

200

MFC200AA

200

250

MFC250AA

250

305

MFC305AA

300

362

MFC362AA

350

420

MFC420AA

400

480

MFC480AA

450

540

MFC540AA

500

600

MFC600AA

600

750

MFC750AA

700

850

MFC850AA

800

960

MFC960AA

900

1080

MFC1080AA

1000

1200

MFC1200AA

575/600 Volt MFC Kit

HP

Amp

575/600 Volt Model

5

8

MFC008CA

7.5

10

MFC010CA

10

12

MFC012CA

15

20

MFC020CA

20

25

MFC025CA

25

28

MFC028CA

30

35

MFC035CA

40

45

MFC045CA

50

55

MFC055CA

60

65

MFC065CA

75

80

MFC080CA

100

110

MFC110CA

125

130

MFC130CA

150

160

MFC160CA

200

200

MFC200CA

250

250

MFC250CA

300

305

MFC305CA

350

362

MFC362CA

400

420

MFC420CA

450

450

MFC450CA

500

500

MFC500CA

600

600

MFC600CA

750

750

MFC750CA

MFC Kit Instructions 3.0 Pre-Installation Planning

11

MFC “R” Filter Kit – Sine Wave Filter Kit without damping resistor

The MFC Filter Kit is a sine wave filter component package designed and developed by TCI to allow

qualified customers to build sine wave filters to for the output of VFDs. The filter components are

designed to filter out PWM switching ripple when applied correctly and following the schematic

connections used by TCI. The MFC Filter Kit is available for 480 Volt and 600 Volt systems. When

properly designed, assembled, and installed, the completed product is intended to be suitable for use

with 3-phase PWM AC VFDs.

The MFC “R” Filter Kit component package consists of the following components:

•A KTRMG or KLRUL series filter reactor.

oThe 480 V/900 HP and larger units include two reactors that need to be wired in

parallel.

•High-endurance, PWM ripple current rated capacitors.

oBleeder resistors to ensure safe capacitor discharge on filter shutdown, located on

capacitors.

•Capacitor mounting brackets

oCapacitor mounting brackets are provided on kits rated 50 Amps and higher.

oKits under 50 Amps are not provided with capacitor brackets because these units

utilize single phase capacitors that do not have mounting brackets available for them.

These small size single phase capacitors are typically mounted vertically due to the

small size and reduced use of panel space.

•Note: There are no damping resistors included, these kits are most suitable for VFD

applications with low load and VFD dynamics

MFC “R” Filter Kit Part Number and Ratings

480 Volt MFC Kit

HP

Amp

480 Volt Model

5

8

MFC008AR

7.5

12

MFC012AR

10

16

MFC016AR

15

23

MFC023AR

20

30

MFC030AR

25

35

MFC035AR

30

45

MFC045AR

40

55

MFC055AR

50

65

MFC065AR

60

80

MFC080AR

75

110

MFC110AR

100

130

MFC130AR

125

160

MFC160AR

150

200

MFC200AR

200

250

MFC250AR

250

305

MFC305AR

300

362

MFC362AR

350

420

MFC420AR

400

480

MFC480AR

450

540

MFC540AR

500

600

MFC600AR

600

750

MFC750AR

700

850

MFC850AR

800

960

MFC960AR

900

1080

MFC1080AR

1000

1200

MFC1200AR

575/600 Volt MFC Kit

HP

Amp

575/600 Volt Model

5

8

MFC008CR

7.5

10

MFC010CR

10

12

MFC012CR

15

20

MFC020CR

20

25

MFC025CR

25

28

MFC028CR

30

35

MFC035CR

40

45

MFC045CR

50

55

MFC055CR

60

65

MFC065CR

75

80

MFC080CR

100

110

MFC110CR

125

130

MFC130CR

150

160

MFC160CR

200

200

MFC200CR

250

250

MFC250CR

300

305

MFC305CR

350

362

MFC362CR

400

420

MFC420CR

450

450

MFC450CR

500

500

MFC500CR

600

600

MFC600CR

750

750

MFC750CR

MFC Kit Instructions 3.0 Pre-Installation Planning

12

MFC “P” Filter Kit – Sine Wave Filter Kit with PQconnect

The MFC Filter Kit is a harmonic filter component package designed and developed by TCI to allow

qualified customers to build sine wave filters to for the output of VFDs. The filter components are

designed to filter out PWM switching ripple when applied correctly and following the schematic

connections used by TCI. The MFC Filter Kit is available for 480 Volt and 600 Volt systems. When

properly designed, assembled, and installed, the completed product is intended to be suitable for use

with 3-phase PWM AC VFDs.

The MFC “P” Filter Kit component package consists of the following components:

•A KTRMG or KLRUL series filter reactor.

oThe 480 V/900 HP and larger units include two reactors that need to be wired in

parallel.

•High-endurance, PWM ripple current rated capacitors.

oBleeder resistors to ensure safe capacitor discharge on filter shutdown, located on

capacitors.

•Capacitor mounting brackets

oCapacitor mounting brackets are provided on kits rated 50 Amps and higher.

oKits below 50 Amps are not provided with capacitor brackets because these units

utilize single phase capacitors that do not have mounting brackets available for them.

These small size single phase capacitors are typically mounted vertically due to the

small size and reduced use of panel space.

•PQconnect connectivity option

oModbus RTU over RS485 communications, preventative maintenance detection such

as peak overvoltage or high frequency output

•Note: There are no damping resistors included, these kits are most suitable for VFD

applications with low load and VFD dynamics

MFC Kit Instructions 3.0 Pre-Installation Planning

13

MFC “P” Filter Kit Part Number and Ratings

480 Volt MFC Kit

HP

Amp

480 Volt Model

5

8

MFC008AP

7.5

12

MFC012AP

10

16

MFC016AP

15

23

MFC023AP

20

30

MFC030AP

25

35

MFC035AP

30

45

MFC045AP

40

55

MFC055AP

50

65

MFC065AP

60

80

MFC080AP

75

110

MFC110AP

100

130

MFC130AP

125

160

MFC160AP

150

200

MFC200AP

200

250

MFC250AP

250

305

MFC305AP

300

362

MFC362AP

350

420

MFC420AP

400

480

MFC480AP

450

540

MFC540AP

500

600

MFC600AP

600

750

MFC750AP

700

850

MFC850AP

800

960

MFC960AP

900

1080

MFC1080AP

1000

1200

MFC1200AP

575/600 Volt MFC Kit

HP

Amp

575/600 Volt Model

5

8

MFC008CP

7.5

10

MFC010CP

10

12

MFC012CP

15

20

MFC020CP

20

25

MFC025CP

25

28

MFC028CP

30

35

MFC035CP

40

45

MFC045CP

50

55

MFC055CP

60

65

MFC065CP

75

80

MFC080CP

100

110

MFC110CP

125

130

MFC130CP

150

160

MFC160CP

200

200

MFC200CP

250

250

MFC250CP

300

305

MFC305CP

350

362

MFC362CP

400

420

MFC420CP

450

450

MFC450CP

500

500

MFC500CP

600

600

MFC600CP

750

750

MFC750CP

Variable Frequency Drive Settings

Make sure that the variable frequency drive will be set for operation modes and ranges that are

compatible with the MFC Kit:

•Maximum output frequency: 80 Hz

•Constant PWM switching (carrier) frequency between 2 kHz and 16 kHz, ideally 4

kHz to 8 kHz

•Mode of operation: speed control "scalar" or "V/Hz" without DC braking unless the drive

application has been confirmed by TCI Technical Support

•Consult VFD manual for other drive specific recommendations for use with sine wave

filters, specific instructions may include but are not limited to: disabling any variable PWM

switching frequency options such as features to reduce motor noise or control

temperature and setting drive to continuous 3-phase modulation.

Warning

Six-step operation is not compatible with sine wave filter technology.

!

MFC Kit Instructions 3.0 Pre-Installation Planning

14

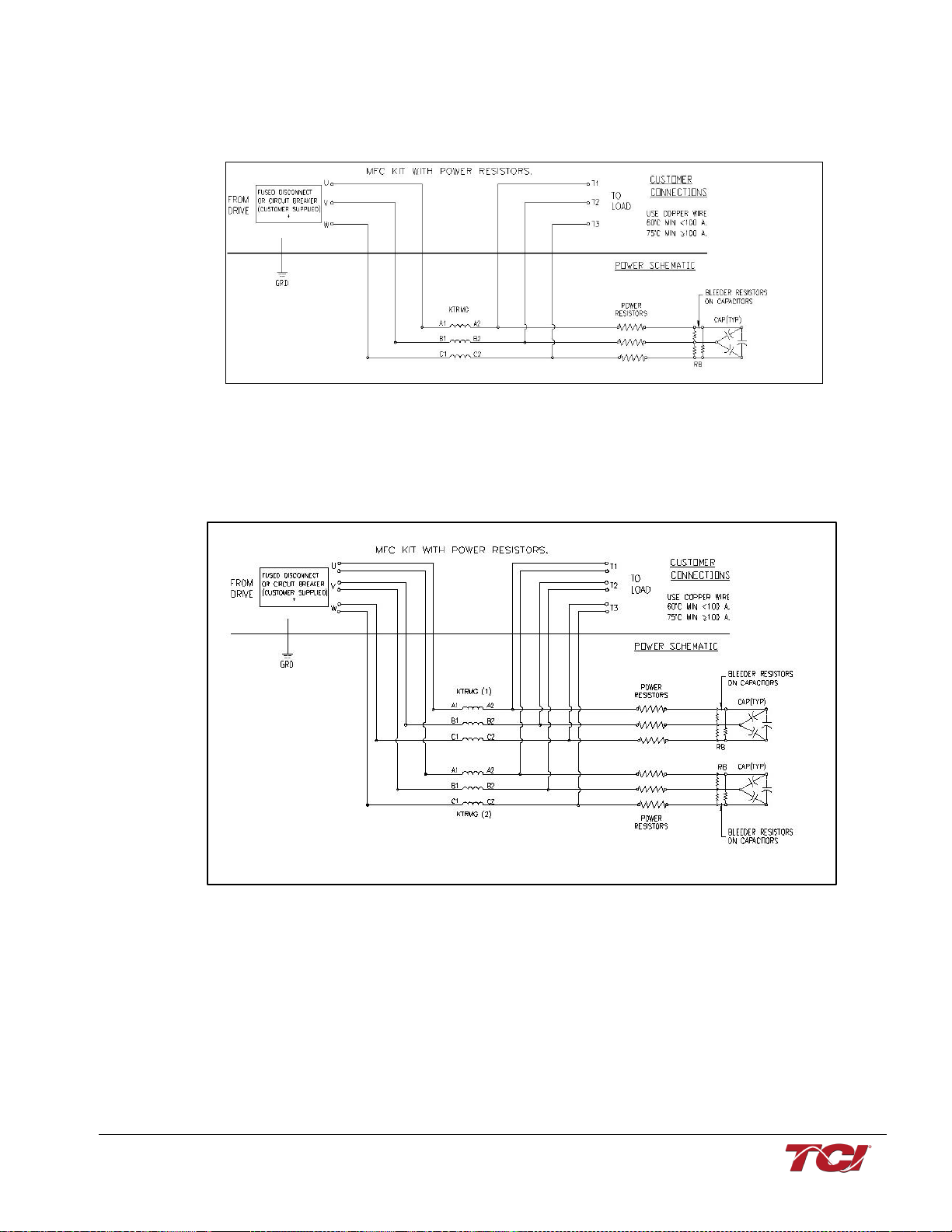

Filter Schematic

The schematic shown in the figure below is an illustration of a typical MFC filter wiring.

Figure 2: Typical MFC “A” Filter Kit Wiring

*DISCONNECT NOT REQUIRED BY UL IF FILTER SUPPLIED BY LOAD SIDE OF POWER

CONVERSION EQUIPMENT (VFD)

For horsepower ratings 480 V/ 900 HP and larger the series line reactor is comprised of two parallel

KTRMG reactors, as illustrated in the schematic below.

Figure 3: Typical MFC “A” Filter Kit Wiring for 480 V/900 HP and larger with two reactors

*DISCONNECT NOT REQUIRED BY UL IF FILTER SUPPLIED BY LOAD SIDE OF POWER

CONVERSION EQUIPMENT (VFD)

MFC Kit Instructions 3.0 Pre-Installation Planning

15

The schematic shown in the figure below is an illustration of a typical resistor-less MFC (AR, CR)

filter wiring.

Figure 4: Typical MFC “R” Filter Kit Wiring

*DISCONNECT NOT REQUIRED BY UL IF FILTER SUPPLIED BY LOAD SIDE OF POWER

CONVERSION EQUIPMENT (VFD)

For horsepower ratings 480 V/900 HP and larger the series line reactor is comprised of two parallel

KTRMG reactors, as illustrated in the schematic below.

Figure 5: Typical MFC “R” Filter Kit Wiring for 480 V/900 HP and larger with two reactors

*DISCONNECT NOT REQUIRED BY UL IF FILTER SUPPLIED BY LOAD SIDE OF POWER

CONVERSION EQUIPMENT (VFD)

MFC Kit Instructions 3.0 Pre-Installation Planning

16

The schematic shown in the figure below is an illustration of a typical MFC kit with PQconnect (AP,

CP) filter wiring.

Figure 6: Typical MFC “P” Filter Kit Wiring

*DISCONNECT NOT REQUIRED BY UL IF FILTER SUPPLIED BY LOAD SIDE OF POWER

CONVERSION EQUIPMENT (VFD)

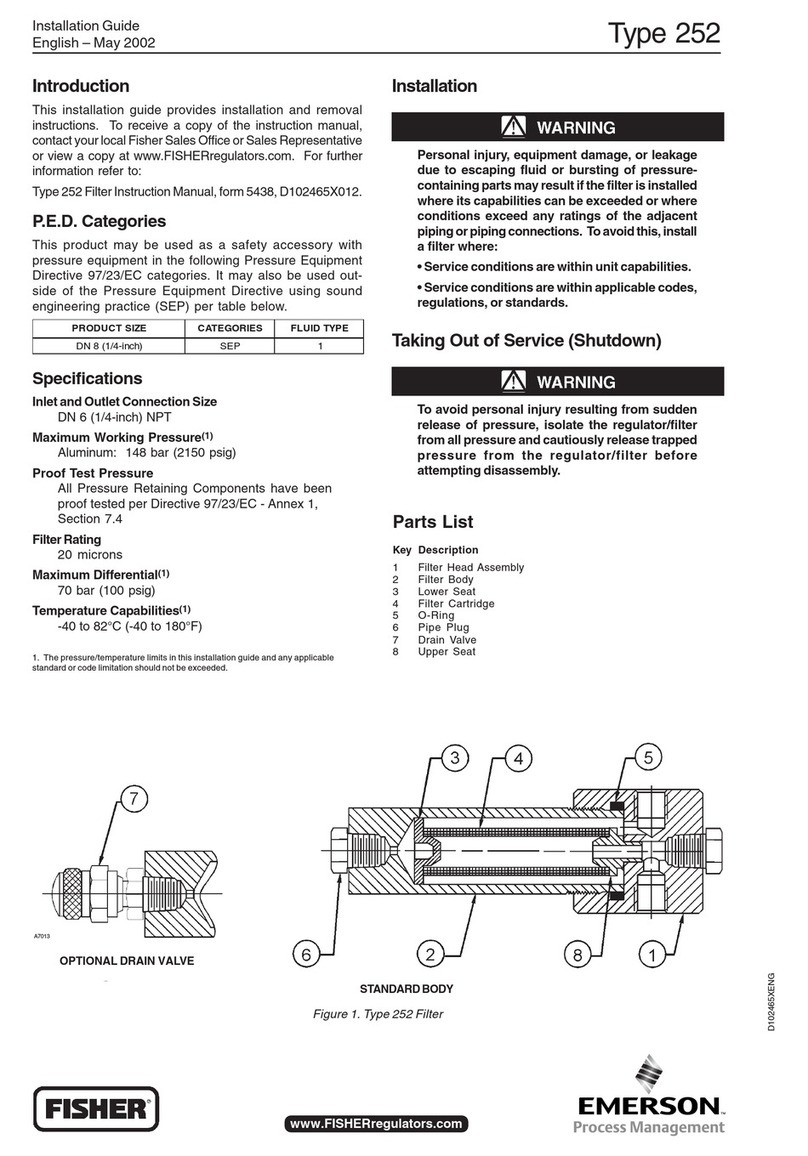

Capacitors

The high-endurance, PWM current ripple rated capacitors supplied in the MFC Filter kit are in

shunt with the load. In the case of the MFC “A” Filter Kit, the capacitors are wired in series with

the power resistors. If multiple capacitors are supplied with the kit, they are intended to be

connected in parallel with each other. Typically, the capacitors are three-terminal, three-phase

capacitors with the internal capacitive elements connected in delta. Each capacitor has a bleeder

resistor connected across the three input terminals to ensure voltage discharges in the time

required by UL.

Warning

Do not connect capacitors to power unless the bleeder resistors are

connected, otherwise, hazardous voltages will remain across the

capacitors after the power has been disconnected.

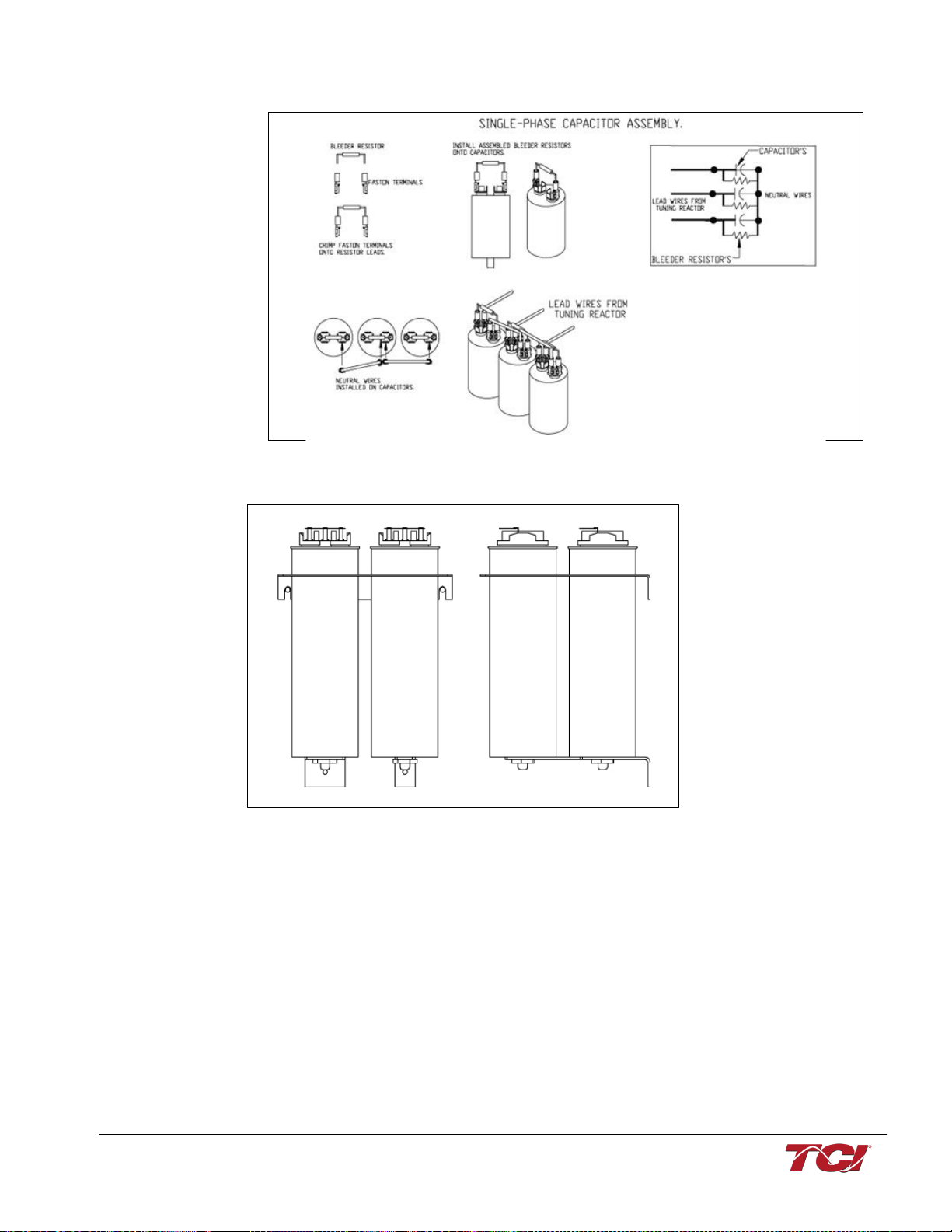

Kits below 50 Amps are supplied with single phase capacitors for each filter.

These capacitors are connected in wye, and the bleeder resistors are connected across the

terminals of each capacitor.

MFC Kit Instructions 3.0 Pre-Installation Planning

17

Figure 7: Bleeder Resistor Installation and Wiring for Single Phase

Capacitor Brackets

Figure 8: Capacitors and Brackets

Capacitor brackets supplied with the MFC kits (50 Amps and above) mount the three-phase capacitors

cansfromaright-anglebracket usingthestudsonthebottomofthecapacitors.Thebracketsurrounding

the capacitors is mounted near the top of the capacitor can. Grommet material is placed around the

large diameter holes to prevent the edges of the bracket damaging the capacitor cans. This hole does

not firmly clamp the capacitors and is not intended to do so: such a design would prevent the internal

capacitor pressure disconnection means from operating. This bracket prevents gross motion of the

capacitors during shipping vibration which could fracture the mounting bracket or allow the capacitors

to hit other components.

Recommendations for MFC Kit Usage

Panel design using a TCI MFC Filter Kit should be performed with appropriate engineering

supervision, so the design meets the requirements based on materials utilized in the construction

of the panel, wiring practices followed by your shop, and the actual ambient conditions of the

components for each application.

This manual suits for next models

2

Table of contents

Other TCi Water Filtration System manuals