412-10100

Rev A

4.8Point to Point (P2P) / FFT Sensitivity .................................................................................................. 27

4.9 Sample................................................................................................................................................. 28

4.10 Calibrate .............................................................................................................................................. 29

4.11 Learn.................................................................................................................................................... 30

5Production .................................................................................................................................................... 32

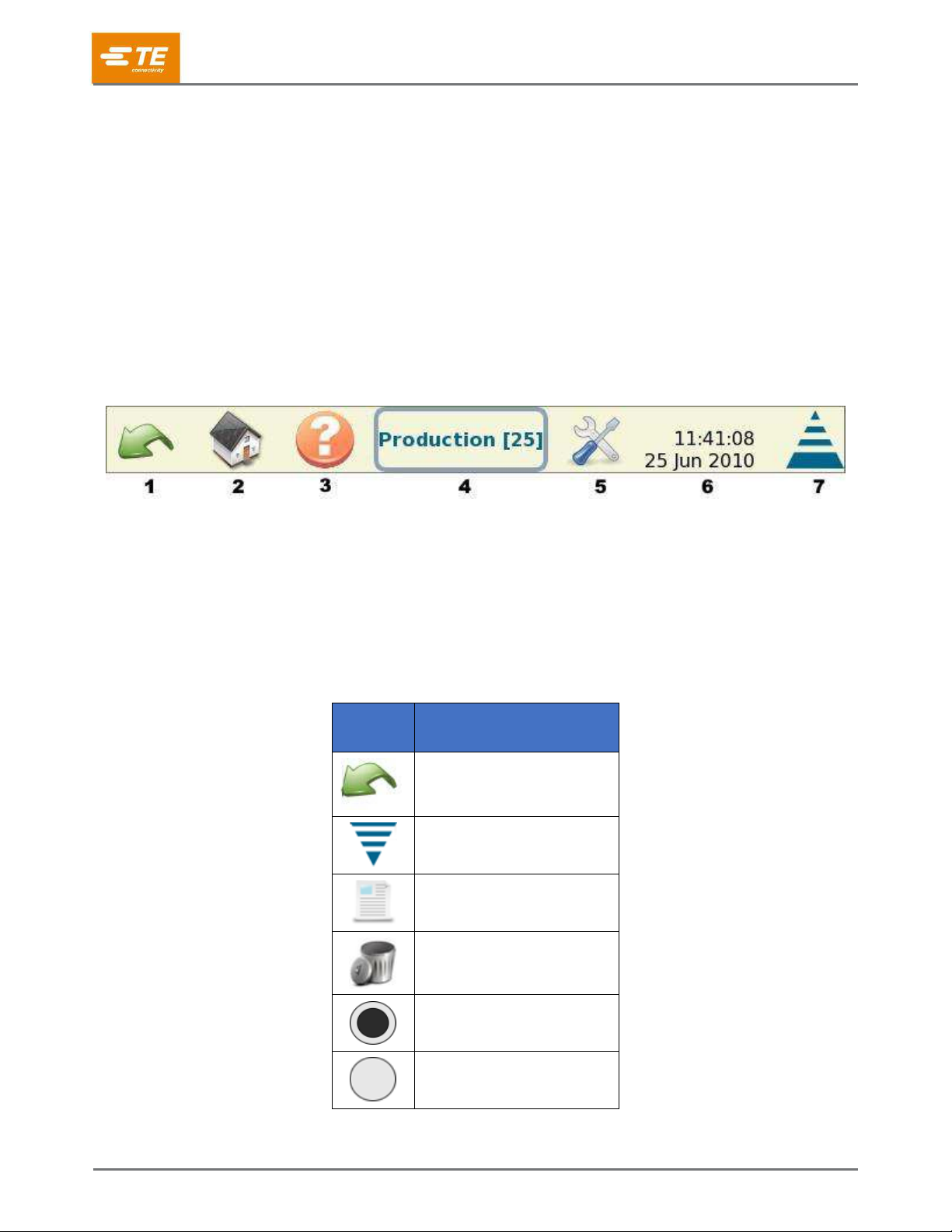

5.1 Basic Screen........................................................................................................................................ 33

5.2 Status................................................................................................................................................... 34

5.3 Crimp Height........................................................................................................................................ 35

5.4 Work Index........................................................................................................................................... 36

5.5 Peak Force .......................................................................................................................................... 37

5.6 P2P ...................................................................................................................................................... 38

5.7 FFT ...................................................................................................................................................... 39

6Control panel ................................................................................................................................................ 40

6.1 Language icon ..................................................................................................................................... 40

6.2 Login/Logout ........................................................................................................................................ 40

6.3 Users ................................................................................................................................................... 41

6.3.1 Add New User.................................................................................................................................. 41

6.3.2 Change Password ........................................................................................................................... 41

6.3.3 Delete .............................................................................................................................................. 41

6.3.4 Permission Settings ......................................................................................................................... 42

6.4 Locale Settings .................................................................................................................................... 44

6.4.1 Date/Time Settings .......................................................................................................................... 45

6.4.2 Reports ............................................................................................................................................ 46

6.4.3 Report Setup.................................................................................................................................... 53

6.4.4 Curve History Graph ........................................................................................................................ 53

6.4.5 Network............................................................................................................................................ 54

6.4.6 Display Settings ............................................................................................................................... 56

6.4.7 Calibrate Touchscreen..................................................................................................................... 57

6.4.8 Maintenance .................................................................................................................................... 58

6.4.9 Diagnostics ...................................................................................................................................... 62

6.4.10 Error Log Viewer.......................................................................................................................... 66

6.4.11 Demo ........................................................................................................................................... 67

6.4.12 Printer Icon .................................................................................................................................. 67

7Troubleshooting............................................................................................................................................ 69

7.1 Additional information for specific sensors .......................................................................................... 70

7.1.1 Linear Encoder ................................................................................................................................ 70

7.1.2Analog Height Sensor...................................................................................................................... 70

7.1.3 Base Plate Strain Gage (Force Sensor) .......................................................................................... 71