TE Technology TC-720 User manual

Instruction Manual

for

Model TC-720

and

Model TC-720 OEM

Thermoelectric Cooler

Temperature Controller

February 8 2018

Drawing #5252 Rev. C

1590 Kean e D r ive Phon e : ( 2 3 1) 929 - 3 966

Tra v e r se Cit y M I 49 6 96 U SA Fax: ( 231) 929 -41 6 3

w ww .te tec h .com e-m a il: c o o l@ te te ch.c o m

All Materials Copyright © 2013, 2016, TE Technology, Inc.

TE

TECHNOLOGY, INC.

®

2

General Safety Warnings

This man al m st be read and followed caref lly before installation and operation. All warnings in this

Instr ction Man al apply to both the TC-720 and TC-720 OEM versions of the controller. Where “TC-720” is

referenced, it is sed generically and interchangeably for both the TC-720 and the TC-720 OEM versions of the

controller, except where otherwise specifically noted.

THE LATEST REVISION OF THIS MANUAL IS AVAILABLE AT www.tetech.com. Verify that yo are sing the

latest revision available.

Do not se in an explosive or potentially explosive environment.

The TC-720 is designed specifically for its intended p rpose of providing temperat re control of TE

Technology’s thermoelectric devices only. The temperat re controller is intended for light ind strial,

laboratory, or similar se; it is not intended for ho sehold or medical se.

Do not se the TC-720 to control capacitive or ind ctive loads as this co ld damage and/or overheat the

controller. Examples of capacitive or ind ctive loads incl de b t are not limited to motors and solenoids.

Do not se if the controller has been damaged.

Only q alified technicians sho ld install this controller.

Do not allow the electrical connections or components on the printed circ it board, incl ding those on the

reverse side of the JP3, JP5, JP6 and JP7 connectors, to to ch any electrically cond ctive s rfaces.

Do not operate in an environment where the controller co ld come in contact with condensation, water,

metal shavings, dirt or other contaminants, or electrically cond ctive materials.

Use ESD (Electro Static Discharge) protection when installing or handling the controller.

Do not to ch any of the electrical connections or components of the TC-720 while the controller is

energized. Doing so can disr pt the f nction of the controller.

The printed circ it board nderneath JP7 and exposed components on the printed circ it board co ld

exceed 70 °C nder normal operation. Use ca tion! Protect against accidental contact with hot s rfaces.

Improper t ning of this temperat re controller can lead to overheating of the load (e.g. cooling assembly,

heater, etc.) and other related eq ipment.

Use protection devices to prevent hazardo s conditions and/or damage to eq ipment.

Each power inp t that is sed m st be f sed separately. Alternately, a power s pply with integral over

c rrent protection can be sed if it is appropriately sized for protecting the controller/TE device.

Thermoelectric devices are capable of developing potentially hazardo s temperat res and/or other

potentially hazardo s conditions. Read and follow the instr ctions in TE Technology’s Thermoelectric

Cooling Assembly (TCA) Instr ction man al before sing this controller. If sing a thermoelectric device

from another man fact rer, read and follow all instr ctions pertaining to that man fact rer’s device before

operating the controller. The (TCA) Instr ction man al is available for download from TE Technology's

website at www.tetech.com.

3

For more information regarding protection devices read TE Technology’s Thermoelectric Cooling Assembly (TCA) Instr ction

man al which is available for download from TE Technology's website at www.tetech.com. The terms and provisions

relating to protection devices as provided in the TCA Instr ction man al are hereby incorporated by reference. A copy of

the TCA Instr ction man al can also be sent via reg lar mail pon req est.

TE Technology, Inc. does not make any warranty, expressed or implied, that the se or operation of the eq ipment will be

f nctional or effective if the eq ipment is not installed and sed in accordance with this man al.

TE Technology, Inc. shall not be liable, and P rchaser shall defend, hold harmless, and indemnify TE Technology, Inc. from

and against, any losses, costs, expenses (incl ding reasonable attorneys’ fees), inj ries, liabilities or damages of any kind or

nat re whatsoever, arising o t of the se or inability to se this TE Technology, Inc. prod ct, from the omission or fail re to

se protection devices, or from fail re to comply with this man al. This provision is in addition to any other

indemnification provisions which are a part of the P rchase Order or contract with P rchaser.

All specifications are s bject to change witho t notice.

4

Table of Contents

License Agreement ......................................................................................................................... 5

FEATURES........................................................................................................................................ 8

1.0 SETUP ................................................................................................................................. 14

2.0 DISPLAY AND MENU OPTIONS........................................................................................... 28

3.0 Controller T ning ............................................................................................................... 40

4.0 Controller Software and USB Comm nication .................................................................. 42

Controller Schematic..................................................................................................................... 64

Tro bleshooting Controller .......................................................................................................... 66

TC-720 Electrical Connections ...................................................................................................... 69

TC-720 Mechanical Package Drawing........................................................................................... 70

TC-720 OEM Mechanical Package Drawing.................................................................................. 71

APPENDIX A-Thermistors Available for TC-720 ............................................................................ 72

Appendix B - USB Comm nications .............................................................................................. 78

Appendix C – Programming C stom Sensor C rves ..................................................................... 96

Appendix D – Programming Ramp/Soak Ro tines ..................................................................... 100

Appendix E – Additional Notes on Fan Control .......................................................................... 102

5

TE TECHNOLOGY INC. (TE TECH)

License Agreement

CAREFULLY READ THE FOLLOWING TERMS AND CONDITIONS BEFORE OPENING THIS PACKAGE OR SIGNIFYING YOUR ACCEPTANCE BY CLICKING THE

APPROPRIATE DIALOG BOX. OPENING THIS PACKAGE, CLICKING THE APPROPRIATE DIALOG BOX OR USING ANY PART OF THE SOFTWARE SIGNIFIES YOUR

ACCEPTANCE OF (1) THESE TERMS AND CONDITIONS FOR THE LICENSED SOFTWARE, AND (2) THE TERMS OF ACCEPTANCE OF TE TECH FOR ANY PRODUCTS

PURCHASED FROM TE TECH. IF YOU DO NOT AGREE WITH THEM, PROMPTLY RETURN THE PACKAGE UNOPENED AND UNUSED ALONG WITH ANY OTHER

ITEM THAT WAS INCLUDED IN THE SAME PRODUCT NUMBER FOR FULL CREDIT.

Yo , as the C stomer, agree as follows:

1. DEFINITIONS

“Application Software” shall mean those portions of the Licensed Software created by TE TECH.

“Designated Hardware” shall mean the one (1) hardware device, p rchased from TE TECH, pon which C stomer shall r n the Licensed Software.

“Licensed Software” shall mean the Application Software pl s any other software s pplied by TE TECH p rs ant to this Agreement.

“Third Party Software” shall mean software owned or licensed by a third party, incl ding b t not limited to operating systems that is embedded within the

Licensed Software or otherwise incl ded with any prod ct provided to C stomer from TE TECH.

2. LICENSE

2.1 Except as provided in section 2.2 below, yo are granted only a personal, non-transferable, nonexcl sive license to se the Licensed Software

only on the Designated Hardware. Yo may copy the Licensed Software into machine readable form for back p p rposes or to s pport yo r se of the

Licensed Software on the Designated Hardware. No other copies shall be made nless a thorized in writing by TE TECH. Yo may not (i) reverse engineer,

decompile, or disassemble the Licensed Software (except to the extent s ch foregoing restriction is expressly prohibited by applicable law); (ii) s b-license,

lease, or rent the Licensed Software; (iii) distrib te in part, modify, or create derivatives of the Licensed Software; (iv) amend, modify, or s pplement

Licensed Software with any additional code except for the p rpose of f rther config ring the Licensed Software for se with Designated Hardware; or (v)

directly or indirectly, export, re-export, download, or ship the Licensed Software in violation of the laws and reg lations of the U.S. The Licensed Software,

comprising proprietary trade secret information of TE TECH and/or its Licensor’s, shall be held in confidence by C stomer and protected from disclos re to

third parties. No title to the intellect al property is transferred, Yo m st reprod ce and incl de all applicable copyright notices on any copy. Licensed

Software shall not be copied, reprod ced, or sed for any other p rpose o tside of operation of the TE TECH hardware, and shall not be sed on any other

piece of hardware other than the TE TECH hardware with, or for, which it was provided. Notwithstanding the foregoing, in the event that yo download

the Licensed Software from the internet witho t p rchasing Designated Hardware, the Licensed Software may only be sed for eval ation p rposes and

m st be deleted (incl ding all copies) within fifteen (15) days of downloading. Yo may not se the Licensed Software with any other eq ipment other

than the Designated Hardware witho t prior written approval from TE TECH. If no operating system software is incl ded in the software provided nder

this Agreement, yo m st make provision for any req ired operating system software licenses. At its option, TE TECH may, pon req est, provide the

so rce code for the Licensed Software. The limited warranty provided in section 3 below shall be n ll and void immediately pon TE TECH providing the

so rce code, or any portion thereof, to yo .

2.2 If yo are an a thorized TE TECH distrib tor or an Original Eq ipment Man fact rer who incorporates the Licensed Software into yo r

eq ipment for sale to an end ser, or yo se the Licensed Software to create redistrib tables, yo may transfer the Licensed Software to an end ser

provided that the end ser agrees to be bo nd by the provisions of this Agreement. Yo shall se yo r best efforts to enforce yo r agreement with

c stomers made in accordance with this Section 2.2 and shall promptly report any violation or s spected violation to TE TECH. In the event that yo r

c stomer violates any portion of this agreement, yo agree to defend, hold harmless and indemnify TE TECH from any and all s ch claims. TE TECH may,

at its option, bring s it against yo r c stomer to enforce the terms of this agreement, TE TECH’s costs and expenses inc rred as a res lt of s ch action

(incl ding reasonable attorneys’ fees) shall be yo r responsibility.

2.3 The Licensed Software may incl de Third Party Software licensed to TE TECH. C stomer hereby acknowledges and agrees that any Third Party

Software provided by TE TECH to C stomer here nder (a) shall not be modified and shall be sed and/or sed and redistrib ted or resold (to the extent

permitted nder Section 2.2) only embedded within the TE TECH hardware prod ct as provided by TE TECH, (b) shall always contain and only be

redistrib ted (to the extent permitted nder Section 2.2) with all proprietary markings present as provided to C stomer here nder and nder the same

terms and conditions as set forth in this Agreement. All rights and benefits afforded to TE TECH nder this Agreement shall apply eq ally to the owner of

the Third Party Software (the “Third Party”) and its licensors with respect to the Third Party Software. The Third Party and its licensors are intended third

party beneficiaries of this Agreement, and the provisions of this Agreement relating to the Licensed Software, as the same incorporate the Third Party

Software, are made expressly for the benefit of, and are enforceable by, the Third Party and its licensors. The Third Party and its licensors retain ownership

of all copies of the Third Party Software. Unless a pass-through warranty covering the Third Party Software is extended directly to you by the Third

Party all Third Party Software is provided “AS IS” without warranty of any kind and each Third Party and its licensors disclaim all warranties either

express or implied including but not limited to the implied warranties of merchantability title non-infringement or fitness for a particular purpose

with regard to the Third Party Software. The Third Party shall not have any liability for special indirect punitive incidental or consequential damages.

6

2.4 EXCEPT AS PROVIDED IN SECTION 2.2 ABOVE, IF YOU TRANSFER POSSESSION OF ANY COPY OF THE LICENSED SOFTWARE TO ANOTHER PARTY

WITHOUT WRITTEN CONSENT OF TE TECH, YOUR LICENSE IS AUTOMATICALLY TERMINATED. Any attempt otherwise to s blicense, assign or transfer any of

the right, d ties or obligations here nder is void.

2.5 If the Licensed Software or associated doc mentation is provided to any U.S. Government entity, nit, or agency, the restrictions set forth at

section 52.227-19(c) (“Commercial comp ter software - restricted rights”) of the Federal Acq isition Reg lations (FARs) shall apply. If the Licensed

Software or associated doc mentation is provided to the U.S. Government, Department of Defense (DOD), or any entity, nit, or agency thereof, the

restrictions set forth at section 252.227-7015 (“Technical Data -Commercial Items”) of the DOD FAR S pplement (DFARS) shall also apply.

2.6 For rights granted in this Agreement, C stomer shall pay to TE TECH the then-c rrent prod ct price (license fee) for each copy of the Licensed

Software provided by TE TECH to C stomer.

2.7 C stomer shall pay all import d ties and registration fees and all sales, se and excise taxes (and any other assessments in the nat re of taxes

however designated) on the Licensed Software or its license to se the Licensed Software, or res lting from this Agreement, excl sive of taxes based on TE

TECH’s net income.

2.8 C stomer acknowledges that the Licensed Software, incl ding, witho t limitation, TE TECH logos, trademarks and all information contained

therein, is proprietary to TE TECH, is val able, gives a competitive advantage to TE TECH, and co ld not, witho t significant expense and diffic lty, be

obtained or d plicated by others who have not been able to acq ire the same thro gh means expressly a thorized in this agreement. Yo agree that,

nless yo first obtain the prior written consent of TE TECH ,or nless req ired by law, yo shall not comm nicate or disclose, directly or indirectly, to any

person or firm, or se at any time, any of the TE TECH’s proprietary information, except as provided in this Agreement. The provisions of the section,

among certain others, shall s rvive the termination of this Agreement for whatever reason. The Licensed Software shall be and remain the excl sive

property of TE TECH.

3. WARRANTY

3.1 Only if C stomer has p rchased Designated Hardware (the p rchase price of which a tomatically incl des the license fee), TE TECH warrants

that the Application Software will be in s bstantial conformance with the specifications in the man al pertaining thereto as of the date of shipment by TE

TECH. If, within ninety (90) days of date of shipment, it is shown that the Application Software does not meet this warranty, TE TECH will, at its option,

either correct the defect or error in the Application Software, free of charge, or make available to C stomer satisfactory s bstit te software, or, as a last

resort, ret rn to C stomer all payments made as license fees and terminate the license with respect to the Application Software affected. TE TECH does

not warrant that operation of the Application Software will be ninterr pted or error free or that it will meet C stomer’s needs. All other portions of the

Licensed Software are provided “as is” witho t warranty of any kind.

3.2 TE TECH warrants that the media on which the Application Software is delivered will be free from defects in material or workmanship nder

normal se and service for a period of ninety (90) days from the date of delivery. If any defects are discovered in the media is discovered and reported by

C stomer within ninety (90) days after delivery TE TECH shall, at no cost to C stomer, pon ret rn of same to TE TECH, replace the media and deliver

(electronically) to C stomer a new and complete copy of the Licensed Software.

3.3 Any modification to the Licensed Software by the C stomer witho t the express written consent of TE TECH shall void the warranty.

3.4 THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES WITH RESPECT TO THE LICENSED SOFTWARE

WHETHER WRITTEN, ORAL, IMPLIED OR STATUTORY. NO IMPLIED OR STATUTORY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE SHALL APPLY. NO WARRANTY ARISING FROM COURSE OF PERFORMANCE COURSE OF DEALING OR USAGE OF TRADE SHALL APPLY.

NOTWITHSTANDING ANYTHING TO THE CONTRARY HEREIN UNLESS CUSTOMER HAS PAID TE TECH A SEPARATE LICENSE FEE THEREFOR TE TECH

MAKES NO WARRANTIES AS TO THE LICENSED SOFTWARE WHICH IS PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND WHETHER EXPRESS OR

IMPLIED.

4. LIMITATION OF LIABILITY

4.1 IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT, BREACH OF WARRANTY, TORT (INCLUDING NEGLIGENCE) OR OTHERWISE,

SHALL TE TECH OR ITS SUPPLIERS BE LIABLE FOR ANY SPECIAL, CONSEQUENTIAL, INCIDENTAL OR PENAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS

OF PROFIT OR REVENUES, LOSS OF USE OF THE LICENSED SOFTWARE OR ANY PART THEREOF, OR ANY ASSOCIATED EQUIPMENT, DAMAGE TO ASSOCIATED

EQUIPMENT, COST OF CAPITAL, COST OF SUBSTITUTE PRODUCTS, FACILITIES, SERVICES OR REPLACEMENT POWER, DOWN TIME COSTS, OR CLAIMS OF

CUSTOMER’S CUSTOMERS AND TRANSFEREES FOR SUCH DAMAGES EVEN IF TE TECH HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

4.2 EXCEPT AS PROVIDED IN SECTION 5, INDEMNITY, IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT OR WARRANTY, TORT

(INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL TE TECH’S LIABILITY TO CUSTOMER FOR ANY LOSS OR DAMAGE ARISING OUT OF, OR RESULTING FROM

THIS AGREEMENT, OR FROM ITS PERFORMANCE OR BREACH, OR FROM THE LICENSED SOFTWARE OR ANY PART THEREOF, OR FROM ANY SERVICE

FURNISHED HEREUNDER, EXCEED THE QUOTED CHARGES FOR THE LICENSED SOFTWARE. ANY SUCH LIABILITY SHALL TERMINATE UPON THE TERMINATION

OF THE WARRANTY PERIOD AS SET FORTH IN SECTION 3.

4.3 If TE TECH f rnishes C stomer with advice or other assistance which concerns Licensed Software or any portion thereof s pplied here nder or

any system or eq ipment on which any s ch software may be installed and which is not req ired p rs ant to this Agreement the f rnishing of s ch advice

or assistance will not s bject TE TECH to any liability, whether in contract, warranty, tort (incl ding negligence) or otherwise.

7

4.4 The prod cts (hardware and software) to be licensed or sold here nder are not intended for se in any application specifically prohibited in

writing by TE TECH, incl ding, witho t limitation, in any n clear, chemical or weapons prod ction facility or activity, or other activity where fail re of the

prod cts co ld lead directly to death, personal inj ry or severe physical or environmental damage. If so sed, TE TECH disclaims all liability for any

damages arising as a res lt of the hazardo s nat re of the b siness in q estion, incl ding b t not limited to n clear, chemical or environmental damage,

inj ry or contamination, and C stomer shall indemnify, hold harmless and defend TE TECH, its officers, directors, employees and agents against all s ch

liability, whether based on contract, warranty, tort (incl ding negligence), or any other legal theory, regardless of whether TE TECH had knowledge of the

possibility of s ch damages.

5. INDEMNITY

5.1 Sho ld the Application Software be held by a co rt to constit te patent or copyright infringement and its se is enjoined, TE TECH shall, at its

expense and option, either proc re for C stomer the right to contin ed se, or replace same with a non-infringing prod ct or part, or modify the

Application Software so that it becomes non-infringing, or remove the software and ref nd the license charge pertaining thereto (less reasonable

depredation for any period of se) and any transportation costs separately paid by C stomer. The foregoing states the entire liability of TE TECH for patent

and copyright infringement by the Licensed Software or any part thereof.

5.2 The indemnity nder the preceding paragraph shall not apply to any se of Application Software in conj nction with any other prod ct in a

combination not f rnished by TE TECH as a part of this transaction. As to any s ch se in s ch combination, or any improper or na thorized se,

installation, or operation of the Application Software, TE TECH ass mes no liability whatsoever for patent and copyright infringement and C stomer will

hold TE TECH harmless against any infringement claims arising there from (incl ding, b t not limited to, reasonable attorney’s fees).

6. TERM AND TERMINATION

6.1 Yo may terminate the license granted here nder at any time by destroying the Licensed Software together with all copies thereof and

notifying TE TECH in writing that all se of the Licensed Software has ceased and that same has been destroyed.

6.2 TE TECH, pon thirty (30) days’ notice, may terminate this Agreement or any license here nder if C stomer fails to perform any obligation or

ndertaking to be performed by it nder this Agreement or if C stomer attempts to assign this Agreement witho t the prior written consent of TE TECH.

Within twenty (20) days after any s ch termination of this Agreement, C stomer shall certify in writing to TE TECH that all se of the Licensed Software has

ceased, and that same has been ret rned or destroyed, in accordance with TE TECH’s instr ctions.

6.3 Sections 4, 6 and 7 of this Agreement shall s rvive any expiration or termination and remain in effect. Termination of this Agreement or any

license here nder shall not relieve C stomer of its obligation to pay any and all o tstanding charges here nder nor entitle C stomer to any ref nd of s ch

charges previo sly paid.

7. IMPORT/EXPORT

7.1 If yo intend to import or export (or re-export), directly or indirectly, whether electronically or otherwise, the software prod cts or technical

data relating thereto s pplied here nder or any portion thereof, it is yo r responsibility to ass re compliance with U.S. and other applicable governmental

import and/or export control laws and, if appropriate, to sec re any req ired licenses or approvals in yo r own name. Yo are also responsible for the

acc racy and completeness of any information or certification yo provide for p rposes of import or export control compliance.

8. GENERAL

8.1 This Agreement shall be governed by the laws of the State of Michigan, witho t regard to its conflict of law provisions. Yo agree that any civil

action or claims which relate to this Agreement or the Licensed Software m st be bro ght and maintained in a co rt of competent j risdiction located in

Grand Traverse Co nty, Michigan, or, alternatively, the U.S. District co rt for the Western District of Michigan. Yo hereby waive ven e in any other

for m. The provisions of the United Nations Convention on the International Sale of Goods shall not apply to this Agreement

8.2 Sho ld yo have any q estions concerning this Agreement, contact TE TECH by writing to: TE TECHNOLOGY, INC., 1590 KEANE DRIVE, TRAVERSE

CITY, MI 49696.

8.3 YOU ACKNOWLEDGE THAT YOU HAVE READ THIS AGREEMENT, UNDERSTAND IT AND AGREE TO BE BOUND BY ITS TERMS AND CONDITIONS.

YOU FURTHER AGREE THAT IT IS THE COMPLETE AND EXCLUSIVE STATEMENT OF THE AGREEMENT BETWEEN US AND SUPERSEDES ANY PROPOSAL OR

PRIOR AGREEMENT, ORAL OR WRITTEN, AND ANY OTHER COMMUNICATIONS BETWEEN US RELATING TO THE SUBJECT MATTER OF THIS AGREEMENT.

FURTHER, NO CHANGE OR AMENDMENT TO THIS AGREEMENT SHALL BE EFFECTIVE UNLESS AGREED TO BY WRITTEN INSTRUMENT SIGNED BY A DULY

AUTHORIZED REPRESENTATIVE OF TE TECH.

8

FEATURES

TC-720 Temperature Controller

The TC-720 is a bipolar temperat re controller capable of a tomatically reversing power to Peltier thermoelectric (TE)

devices to provide heating or cooling as req ired to maintain a specific set point temperat re. It incorporates a keypad and

a liq id-crystal display ho sed in a die-cast al min m box. The display allows the ser to monitor the sensor temperat res,

o tp t level, alarm conditions, and men settings. The integrated keypad accesses an easy-to- se men system, allowing

the ser to adj st all of the basic controller parameters s ch as the set temperat re, t ning parameters, and alarm

parameters.

The controller can also be connected to a comp ter via a USB port for advanced programming, data graphing, and data

logging. All of the controller parameters, incl ding the advanced parameters which are not adj stable thro gh the keypad,

can be adj sted with the incl ded software and saved to EEPROM. The command set for the controller is also provided

which allows the creation of c stom software applications sing National Instr ments LabVIEW, for example.

9

PULSE-WIDTH MODULATED POWER OUTPUT WITH SOFT START

The TC-720 reg lates the o tp t power to the TE device sing a method called p lse-width mod lation (PWM). With PWM,

power to the TE device is switched q ickly on and off at a constant freq ency. This creates a sq are wave p lse of power

with a constant time period. The on time, or p lse width, can be varied to create an average o tp t voltage (Vaverage) that

is req ired by the TE device to maintain the set temperat re.

The important advantage to PWM control is that it does not ca se the extreme temperat re exc rsions that are

experienced with a thermostatic control system. This helps to extend the life and reliability of the TE device. At the same

time, PWM control does not generate a large amo nt of waste heat as compared with most linear control systems, so large

heat sinks are not req ired with the PWM temperat re controller. The controller feat res a soft-start f nction that slowly

increases the o tp t when enabled to prevent c rrent s rges or spikes at start p.

By choosing the appropriate power s pply(s), the controller can control loads from 0 to ≤36 V DC at p to 20 A via p lse-

width mod lation with the onboard power transistors arranged in an H-bridge. This enables bipolar control for

a tomatically adj sting the o tp t voltage for heating or cooling.

LINEAR CONTROL OUTPUT

A potential disadvantage to PWM control is the generation of electromagnetic noise, partic larly in high c rrent

applications. In s ch cases, the TC-720 can be config red as part of a linear control system to provide (1) a proportional

analog o tp t signal, and (2) a means of reversing the polarity of a drive voltage generated by an external power s pply.

The analog signal cannot be sed for powering TE devices directly, b t it can be sed with a programmable, linear-o tp t

power s pply. In this mode the analog o tp t from the TC-720 controls the load-level o tp t voltage of the linear power

s pply. That linear o tp t voltage can be fed back into the TC-720 where its electronic circ itry (H-bridge) is sed to control

the polarity of the voltage which is then s pplied to the TE device. This provides tr e bipolar, linear control.

10

One s ch power s pply that accepts an analog inp t is the Cotek AE series programmable switching power s pplies

(http://www.cotek.com.tw/). These power s pplies accept a 0 to 5 volt inp t signal which ca ses the o tp t voltage of the

power s pply to vary from 0 V to its f ll-scale voltage. The controller’s analog o tp t signal can also be modified to limit its

o tp t signal which, in t rn, will limit the o tp t voltage from the power s pply.

RAMP / SOAK PROGRAMMING

The controller has a b ilt in ramp and soak capability that provides eight different steps programmable as ramp or hold

(soak) f nctions. Each step can be repeated or gro ps of steps can be repeated m ltiple times. This is sef l in creating a

m lti-step proced re with vario s temperat res and times for complicated processes or tests.

PROGRAMMABLE ENERGY SAVING CONTROL MODE FOR COOLING AND HEATING ENCLOSURES

This control mode provides an energy efficient method for controlling the temperat re in an enclos re only when tr ly

needed yet provides greater capability and thermoelectric cooler life than what an ON/OFF or dead band control mode

co ld provide. This mode allows the ser to select a three different temperat re ranges: (1) a temperat re range where

no cooling or heating is needed and no o tp t power is sent to the TE Device, (2) a temperat re range whereby the

controller will proportionally increase cooling power as the temperat re increases, and (3) a temperat re range whereby

the controller will proportionally increase heating power as the temperat re decreases.

TWO ALARM OUTPUTS

Two individ al alarm o tp ts, each capable of sinking p to 2 A of c rrent, are provided. These alarms can be triggered

based on sensor temperat res.

MULTI-SPEED FAN CONTROL OR OTHER LOAD CONTROL

The Alarm 1 o tp t can be config red to provide PWM speed control of a fan (fan m st be specifically designed for speed

control) with several c stomizable settings. Speed control is programmable as a f nction of the main controller’s o tp t

power, and the control points are programmable via software. For example, the fan can be r n at high speed only when

increased cooling capacity is needed, and at a low speed or off when the cooler is operating at a low capacity. The polarity

of the o tp t signal can be reversed, so both two wire and three wire PWM controllable fans can be sed. The PWM

o tp t freq ency can be adj sted to make it adaptable to a wide range of fans.

The fan speed control incl des a setting to give the fan 100% power for a ser-programmable n mber of seconds when the

o tp t is first t rned on. This operates the fan at f ll power to make s re the fan is spinning before red cing power. This is

most sef l when low o tp t levels are chosen.

USER PROGRAMMABLE SENSORS

In addition to the pre-programmed thermistor c rves, a ser programmable sensor is available. Thro gh the comp ter

program a c stom sensor c rve (look- p table) can be created, saved in a separate file on the comp ter, and ploaded to

the controller. An infinite n mber of sensors can be created for se in the controller as sensor 1 or sensor 2.

CONTROL RANGE

The TC-720 is s pplied with one MP-3193 thermistor which provides a control range from -20 °C to +100 °C. For controllers

with firmware revision K or later, the control range can be extended to -60 °C to +110 °C sing the MP-3176 thermistor.

(Controllers with firmware revision J or earlier provide a control range from -40 °C to +70 °C sing the MP-3176.) Several

other thermistor types are preprogrammed into controller to provide different control ranges s ch as 0 °C to +150 °C, for

example (when sing optional thermistors). In addition, a User Programmable Sensor table can also be programmed into

the controller allowing it to read temperat res as low as -327.67 °C and/or p to +327.68 °C, s bject to sensor type.

OVER CURRENT ALARM

The controller can be set to t rn off the o tp t if it exceeds a set c rrent level. The controller will attempt restarting a

ser-defined finite or an infinite n mber of times. This is sef l for conditions that ca se a temporarily high c rrent level,

and instead of remaining off when the condition clears the nit will res me normal operation. (NOTE: This is not an analog

c rrent limit, the circ it simply senses c rrent levels and t rns the o tp t off if an over c rrent condition is detected).

11

STATUS INDICATORS

The controller has three light emitting diodes (LED’s) to indicate an alarm, active comp ter comm nications, and controller

operation. An alarm is indicated by the orange LED, active comp ter comm nication by the bl e LED, and controller

operating by the green LED.

•The alarm LED is orange and flashes on and off when there is an active alarm.

•The comm nication LED is bl e and lights when the controller is sending or receiving data from a comp ter.

•The green LED ( nder the cover of the TC-720 and ncovered in the OEM version) blinks to indicate the controller is

on and operating.

The TC-720 is available in an OEM version, model TC-720 OEM. This is a basic version of the controller for Original Eq ipment

Man fact rers (OEM’s). It is intended to be sed in locations where the controller can be protected by a secondary enclos re

and where the display, keypad, and box cover are not needed. The TC-720 OEM controller is the basic control circ it from

the TC-720 mo nted on an al min m plate. One MP-3193 thermistor, software, and instr ction man al on CD are incl ded

with each controller.

TC-720 OEM

The TC-720 OEM ses the same main circ it board fo nd in the TC-720. The connector n mbers and wiring are the same for

both versions of the controller. The Schematics, Hook p Diagrams, and Wiring Connections presented in this man al are the

same for both controllers; however, only the TC-720 version of the controller is depicted for clarity.

12

MAIN FEATURES

•Single or d al power s pply config rations allow a wide range of o tp t voltages:

Single power s pply config ration:

≥12 V DC, ≤36.0 V DC inp t, powering both controller and TE device.

D al power s pply config ration:

≥12 V DC, ≤36.0 V DC at 150 mA minim m for controller circ itry

≥0 V DC, ≤36.0 V DC for TE device.

•P lse-width mod lated o tp t: sq are wave, approximately 337 Hz, with soft start.

•Maxim m o tp t c rrent: p to 20 A to thermoelectric device and p to 2.0 A per alarm circ it, 20 A maxim m

combined o tp t c rrent (Note: controller does not have internal f se protection).

•Analog signal-level o tp t: provides tr e linear power control capability when sed with a programmable linear

power s pply.

•Bipolar (heat and cool) PID control.

•Best-case control stability ±0.01 °C (when controlling a cold plate).

•Proportional (P) bandwidth adj stment: 0.5 °C to 100.0 °C.

•Integral gain (I) adj stment: 0.00 to 10.00 repeats per min te.

•Derivative gain (D) adj stment: 0.00 to 10.00 cycles per min te.

•B ilt in Ramp / Soak with ser programmable steps in PID mode, with separate PID parameters allowed for each

program step.

•Energy-saving Proportional + Deadband control mode allows the ser to program a dead band where no cooling or

heating is req ired, then grad ally applies cooling or heating power only as necessary.

•User programmable temperat re sensor c rve—allows for the se of a variety of thermistors or IC type sensors

(LM335, for example).

•Separately selectable temperat re sensor types.

•Temperat re control ranges:

1. -20 °C to +100 °C sing the MP-3193 thermistor s pplied with the controller. Additional control ranges for

optional thermistors are:

a. -60 °C to +110 °C sing a 5k-1 TS-141 c rve (firmware revision J or earlier will provide a control

range from -40 °C to +70 °C).

b. -20 °C to +85 °C sing the 10k-1 TS-91 c rve.

c. -15 °C to +80 °C sing the 10k-2 TP-53 c rve.

d. 0 °C to +150 °C sing the 50k-1 TS-104 c rve.

e. +25 °C to +199 °C sing the 230k-1 TS-165 c rve.

•(When sing one of these control ranges, the thermistor yo choose m st have the same

response that matches the corresponding resistance-vers s-temperat re c rve shown in the

appendix of the man al. A thermistor following the 10k-2 TP-53 c rve, for example, is not a standard

prod ct offered by TE Technology and m st be p rchased separately from a third party. Other

thermistors are available from www.tetech.com.)

2. Used defined sensor table can be sed to provide a c stom control range for se with different sensor

types.

•Optional secondary sensor inp t for sensing an alarm condition.

•Two available alarm o tp ts, capable of sinking p to 2 A each, for triggering alarms based on the primary (control)

sensor and/or secondary sensor.

•Enable/disable interlock: can be sed with thermostats to sh t off o tp t power.

•Fan speed control: Alarm 1 o tp t can be config red as a programmable PWM fan control for two-wire or three-

wire fans that are specifically designed for speed control.

•Operating temperat re range (non-condensing, vertical orientation):

Minim m: 0 °C

Maxim m: 45 °C

•Back-lit Liq id Crystal Display (LCD).

•USB (Universal Serial B s) Interface.

13

•LED indicators for active USB comm nication, alarm conditions, and controller OK are incl ded on both the TC-720

and TC-720 OEM.

•ESD protection on USB port and inp ts, when sing provided external earth gro nd connection.

•Comp ter programmable via USB comm nication. (A USB cable is req ired to interface with the controller, the

cabled is incl ded with the TC-720, b t is not incl ded with the TC-720 OEM.)

•Software GUI compatible with Windows 10/8/7 is incl ded. The command set is also incl ded to allow the ser to

write c stom software for the controller.

14

OPERATING INSTRUCTIONS

1.0 SETUP

1.1 Attach the temperat re sensor at an appropriate temperat re-control location. Locating the sensor at the cold side

of the TE device provides better control stability than locating it at the object, liq id, or air that is to be

cooled/heated. However, in doing so, there will be a temperat re difference between the sensor and the object,

liq id, or air that is to be cooled/heated. The temperat re set point can be adj sted to compensate for this

temperat re difference if necessary.

If yo are sing a secondary temperat re sensor, attach it to the appropriate location as well. The secondary sensor,

for example, can be sed to monitor the hot side of the TE device.

NOTE: When possible, it is recommended that at least 50 mm of the sensor’s wire be thermally connected to the

s rface as shown in the example below. This can be accomplished by taping the sensor wires with al min m tape,

for example. If this is not done, the sensor wires will be at a different temperat re than the cold side and they will

add or remove heat in the region of the sensor, making the temperat re reading potentially significantly less

accurate and the thermal response time slower.

In addition, the sensor itself needs to have a good thermal connection to the temperat re control location. Thermal

grease, s ch as the TP-1 from TE Technology, or other s itable thermal interface material sho ld be applied to the

interface of the sensor and temperat re-control location.

15

1.2 To connect the sensor leads to the controller (as well as other wire connections), yo will first need to open p the

controller. Remove the fo r screws from the top of the lid. Lift the lid from the controller, and set it face down next

the box.

P sh the primary sensor wires thro gh the two right-most holes in the r bber face plate located at the front side of

the box. The secondary sensor wires wo ld go thro gh the next two holes as applicable. Yo may need to se a

sharp tool to expand the holes before p shing the wire leads thro gh the holes.

•Connect the primary sensor wire leads to JP2-1 (+) and JP2-2 (-).

•Connect the secondary sensor wire leads (if applicable) to JP2-4 (+) and JP2-3 (-).

•If yo are sing the MP-3193 or other thermistor, the polarity will not matter. See the controller hook p

drawings below for f rther reference.

16

If yo are sing a thermistor for temperat re sensing, the wire leads of the thermistor can be lengthened if

necessary witho t affecting acc racy by any significant amo nt. However, the se of twisted pair and/or shielded

wire may be req ired to red ce electromagnetic interference.

The TC-720 is pre-programmed to se the 15 kΩ

thermistor c rve as the defa lt. The MP-3193 that comes standard

with the controller is of this type. Other thermistor styles directly compatible with the controller besides the

MP-3193 are available as options. See “Thermistor Styles for TC-720” in the appendix for reference or online at

www.tetech.com. The controller also has n mero s other thermistor c rves pre-programmed, and can be

programmed with a ser-defined sensor c rve. See the temperat re vs. resistance data in the appendix for

reference.

If yo want to se a thermistor that has a different resistance-temperat re c rve from the pre-programmed

thermistor c rves, or if yo intend to se a different type of sensor altogether, the controller sho ld be programmed

accordingly. See “Programming Custom Sensor Curves” in the appendix for instr ctions.

1.3 The TC-720 can be sed with either one or two separate DC power s pplies for bipolar control of one TE device. If

the maxim m TE device operating voltage is less than 12 V, then two power s pplies must be sed with the

controller. If the TE device can se a voltage ≥12 V b t ≤36 V, then the controller can be sed with j st one power

s pply altho gh sing two power s pplies is permitted as well.

The controller can also be set p to provide linear control o tp t when sed with a power s pply whose o tp t can

be controlled with a 0 to 10 V signal (the maxim m o tp t voltage can be red ced as necessary). The power s pply

can then provide a power o tp t proportional to the signal sent by the controller. This set p may red ce the overall

control stability. The voltage signal from the controller is act ally obtained by filtering the PWM o tp t, and this

introd ces a slight delay in the control response. Also, there will be a delay in the response of the power s pply since

it too m st process the correct power o tp t based on the sensed voltage inp t from the controller.

When sing one power s pply for powering the controller and the TE device together, the power s pply

inp t voltage is passed directly thro gh the controller to the TE device d ring the “ON” p lse. The power

s pply m st provide a voltage that is ≥12 V b t ≤36 V and provide s fficient c rrent for the TE device and

controller. The controller co ld be damaged if it is operated o tside this voltage range. The TE device m st

also be capable of operating with the voltage provided by the power s pply. Do NOT provide an inp t

voltage that exceeds 36.0 V.

When sing two power s pplies, the inp t power s pply for the controller itself m st be ≥12 V b t ≤36 V

and be capable of providing at least 150 mA of c rrent. The power s pply inp t voltage for the TE device

can be >0 V b t ≤36 V and be capable of providing s fficient c rrent.

The total maxim m allowable c rrent thro gh the controller is 20 A (combined load and alarm c rrent). The

maxim m allowable c rrent draw for the TE device m st therefore be less than 20 A depending on if and

how m ch c rrent is sed by devices connected to the alarm o tp ts and the controller itself. The 20 A

limit applies regardless of whether yo are sing one power s pply or sing independent power s pplies for

the controller and TE devices.

The controller does not have an internal f se to limit c rrent. Therefore, an external f se, appropriately

sized for protecting the controller/TE device, sho ld be connected between the power s pply and the

controller to prevent damage to the controller/TE device and to prevent inj ry to the ser sho ld an over-

c rrent condition occ r. Alternately, a power s pply with integral over c rrent protection can be sed if it

is appropriately sized for protecting the controller/TE device.

17

When making a cooling system from a single TE mod le, the maxim m operating voltage for that system is

s ally no more than 75% of the rated Vmax of the TE mod le. The 75% r le is based on the TE mod le

being thermally connected to a “good” heat sink; system modeling sho ld be done to verify this r le is

applicable tho gh. If m ltiple TE mod les are sed in series or series-parallel combination, the Vmax of the

system will be approximately 75% of the rated Vmax of each TE mod le m ltiplied by the n mber of

mod les in series. Applying a voltage greater than the system maxim m will not necessarily damage the

controller ( nless voltage and/or c rrent limits are exceeded), b t the TE device co ld be damaged by

overheating as a res lt.

Power s pply and TE Device wire leads sho ld be kept to a length of one meter or less and of s fficient wire

size to red ce electrical losses in the wire and the likelihood of generating nwanted electromagnetic

interference. However, see also warnings abo t wire length nder section 1.4.

Use protection devices to prevent hazardo s conditions and/or damage to the TE device and other related

eq ipment. Protection devices m st operate independently of the temperat re controller circ itry.

Protection devices sho ld be placed at all points on the load and related eq ipment where a hazardo s

condition can be detected. These protection devices sho ld de-energize the TC-720, the TE device, and, as

necessary, other related secondary eq ipment. It is f rther recommended that s ch devices req ire the

ser to remove and correct the root ca se of a fa lt before allowing the TC-720, the TE device, and related

eq ipment to be re-energized. Protection devices sho ld incl de, b t are not limited to:

•F ses to defend against electrical overloads

•Over-temperat re and/or nder-temperat re thermostats to prevent against hazardo s and/or

damaging temperat res,

•Liq id flow meters to prevent against damage d e to loss of coolant flow

The TC-720 controller (in conj nction with the standard and optional sensors) can detect nder-

temperat re and over-temperat re conditions, and it can be config red to de-energize the load when s ch

a condition is detected. However, hazards and/or risk of loss or damage to the cooling assembly and/or

secondary eq ipment co ld still occ r if the temperat re controller and/or sensors were to malf nction.

Therefore, independent, red ndant protection devices are recommended in addition to the safeg ards

provided by the temperat re controller. For the p rposes of this man al the temperat re controller and

sensors are not considered protection devices.

Protect the USB circ itry from nwanted Electrostatic Discharge (ESD) by either (a) pl gging the USB port

with the s pplied USB d mmy pl g when not in se (TC-720), or (b) otherwise providing shielding via an

enclos re or other external design feat re (TC-720 OEM).

Use the s pplied r bber face plate gasket to prevent wires from abrading and shorting against metal case

(TC-720 only) and to protect the ser from inadvertently contacting the circ it board.

18

1.3.1 ONE POWER SUPPLY OPERATION:

Make s re the power s pply is NOT energized while making electrical connections to the controller.

The o tp t voltage of the TE Power S pply sho ld not exceed the maxim m desired inp t voltage of the

thermoelectric device, or the rated inp t voltage of the cooling assembly.

If voltage is not between 12 V to 36 V then a two power s pply config ration is necessary.

Connect the DC voltage power s pply (o tp t voltage: ≥12 V b t ≤36 V) to the controller as follows:

a) Connect wire between Positive (+) terminal of the power s pply and JP7-4.

b) Connect wire between Negative (-) terminal of the power s pply and JP7-3.

c) See Section 1.4 for f rther information on connecting the TE device.

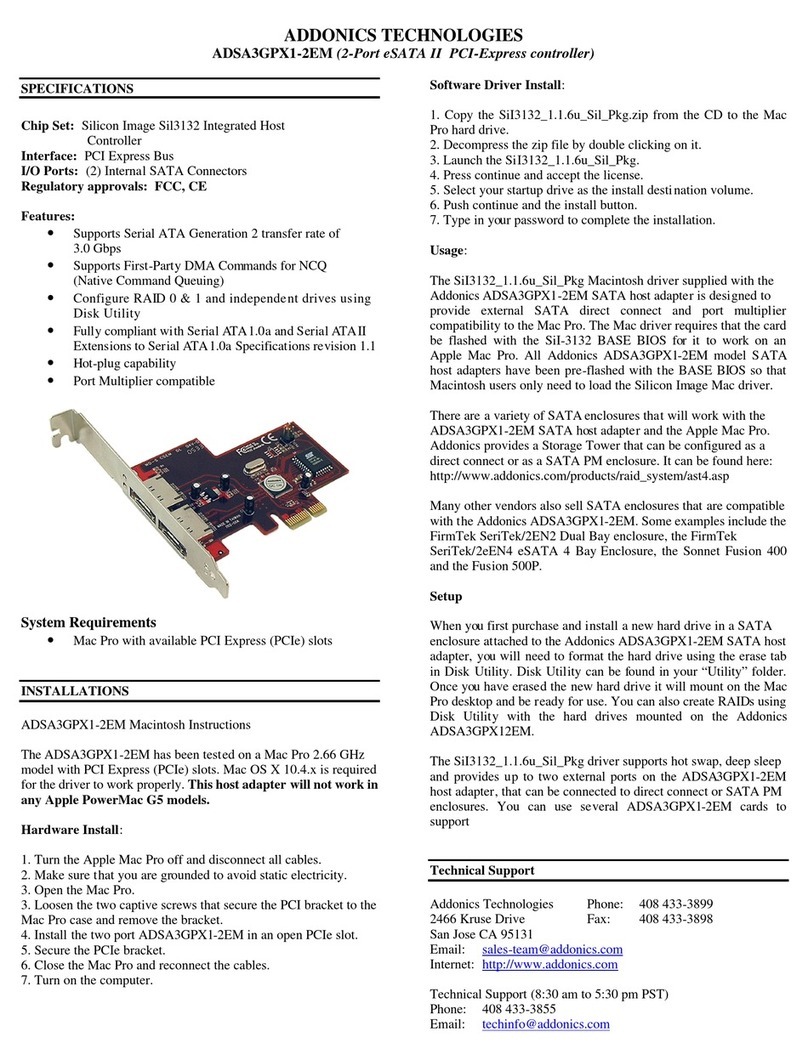

Connections, One Power S pply Operation

JP7 JP21 2 3 4 10 9 8 7 6 5 4 3 2 1

(+) (-)

TE DEVICE

DC

POWER SUPPLY

OPTIONAL FUSE

THERMOSTAT AND OTHER

PROTECTIVE DEVICES

(CUSTOMER SUPPLIED)

OPTIONAL

SECONDARY

SENSOR

JP2-4 (+) and

JP2-3 (-)

CONTROL

SENSOR

JP2-1 (+) and

JP2-2 (-)

12 V, 36 V, 20 A maximum

JP7

PIN 1 JP2

PIN 1

WIRES MUST PASS THROUGH

RUBBER FACE-PLATE HOLES

NOTE: LID IS REMOVED TO SHOW

WIRE CONNECTIONS

USB COMMUNICATION PORT

to JP7-1

to JP7-2

to JP7-3

to JP7-4

≥ ≤

19

1.3.2 TWO POWER SUPPLIES OPERATION:

Make s re the power s pplies are NOT energized while making electrical connections to the controller.

The o tp t voltage of the TE Device Power S pply sho ld not exceed the maxim m desired inp t voltage of

the thermoelectric device, or the rated inp t voltage of the cooling assembly.

If voltage is not between 12 V to 36 V then a two power s pply config ration is necessary.

a) Connect the DC voltage power s pply (for powering the controller electronics) to the controller (≥12 V and ≤36 V,

150 mA minim m):

i) Connect wire between Positive (+) terminal of the power s pply and JP2-9.

ii) Connect wire between Negative (-) terminal of the power s pply and JP2-7.

b) Connect the DC voltage power s pply (for powering the TE device) to the controller (>0 V b t ≤36 V):

i) Connect wire between Positive (+) terminal of the power s pply and JP7-4.

ii) Connect wire between Negative (-) terminal of the power s pply and JP7-3.

c) See Section 1.4 for f rther information on connecting the TE device.

Connections, Two Power S pply Operation

JP7 JP21 2 3 4 10 9 8 7 6 5 4 3 2 1

(+) (-)

TE DEVICE

TE DEVICE

POWER SUPPLY

OPTIONAL FUSE

THERMOSTAT AND OTHER

PROTECTIVE DEVICES

(CUSTOMER SUPPLIED)

OPTIONAL

SECONDARY

SENSOR

JP2-4 (+) and

JP2-3 (-)

CONTROL

SENSOR

JP2-1 (+) and

JP2-2 (-)

>0 V, 36 V, 20 A maximum

JP7

PIN 1 JP2

PIN 1

WIRES MUST PASS THROUGH

GASKET HOLES

NOTE: LID IS REMOVED TO SHOW

WIRE CONNECTIONS

USB COMMUNICATION PORT

CONTROLLER

POWER SUPPLY

12 V, 36 V, 150 mA minimum

(-)

(+)

to JP2-7

to JP2-9

to JP7-1

to JP7-2

to JP7-3

to JP7-4

≥

≤

≤

20

1.3.3 LINEAR CONTROL OPERATION (ANALOG OUT CONTROL MODE):

Make s re the power s pplies are NOT energized while making electrical connections to the controller.

The maxim m o tp t voltage of the TE Device Programmable Power S pply sho ld not exceed the

maxim m desired inp t voltage of the thermoelectric device, or the rated inp t voltage of the cooling

assembly.

If voltage is not between 12 V to 36 V then a two power s pply config ration is necessary.

a) Connect a constant-voltage DC power s pply for powering the controller electronics to the controller (≥12 V and

≤36 V, 150 mA minim m):

i) Connect wire between Positive (+) terminal of the power s pply and JP2-9.

ii) Connect wire between Negative (-) terminal of the power s pply and JP2-7.

b) Connect the remote control voltage points of the programmable power s pply to the analog o tp t signal of the

controller; cons lt the man fact rer’s power s pply man al for remote control set p:

i) Connect wire between Positive (+) remote control terminal and JP2-5.

ii) Connect wire between Negative (-) remote control terminal and JP2-7.

iii) NOTE: This is a b ffered o tp t, however, depending on the power s pply remote control inp t

req irements an additional external voltage b ffer might be req ired between the controller and the

power s pply.

c) Connect the o tp t terminals of the programmable power s pply for powering the TE device to the controller:

i) Connect wire between Positive (+) terminal of the power s pply and JP7-4.

ii) Connect wire between Negative (-) terminal of the power s pply and JP7-3.

d) See Section 1.4 for f rther information on connecting the TE device, and see SET MODE/ANALOG OUT for a

description of how this control mode operates.

NOTE: The controller does not have the internal circ itry to generate a high c rrent analog o tp t voltage from a

fixed-voltage s pply.

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Field Controls

Field Controls 46334900 manual

Siemens

Siemens Acvatix SAS31.03 manual

Sundstrom

Sundstrom SR 507 Training

Regada

Regada STR 1 Installation, service and maintenance instructions

Mitsubishi Electric

Mitsubishi Electric FX3U-4AD-TC-ADP user manual

Rodix

Rodix FEEDER CUBE FC-48 Plus quick start guide