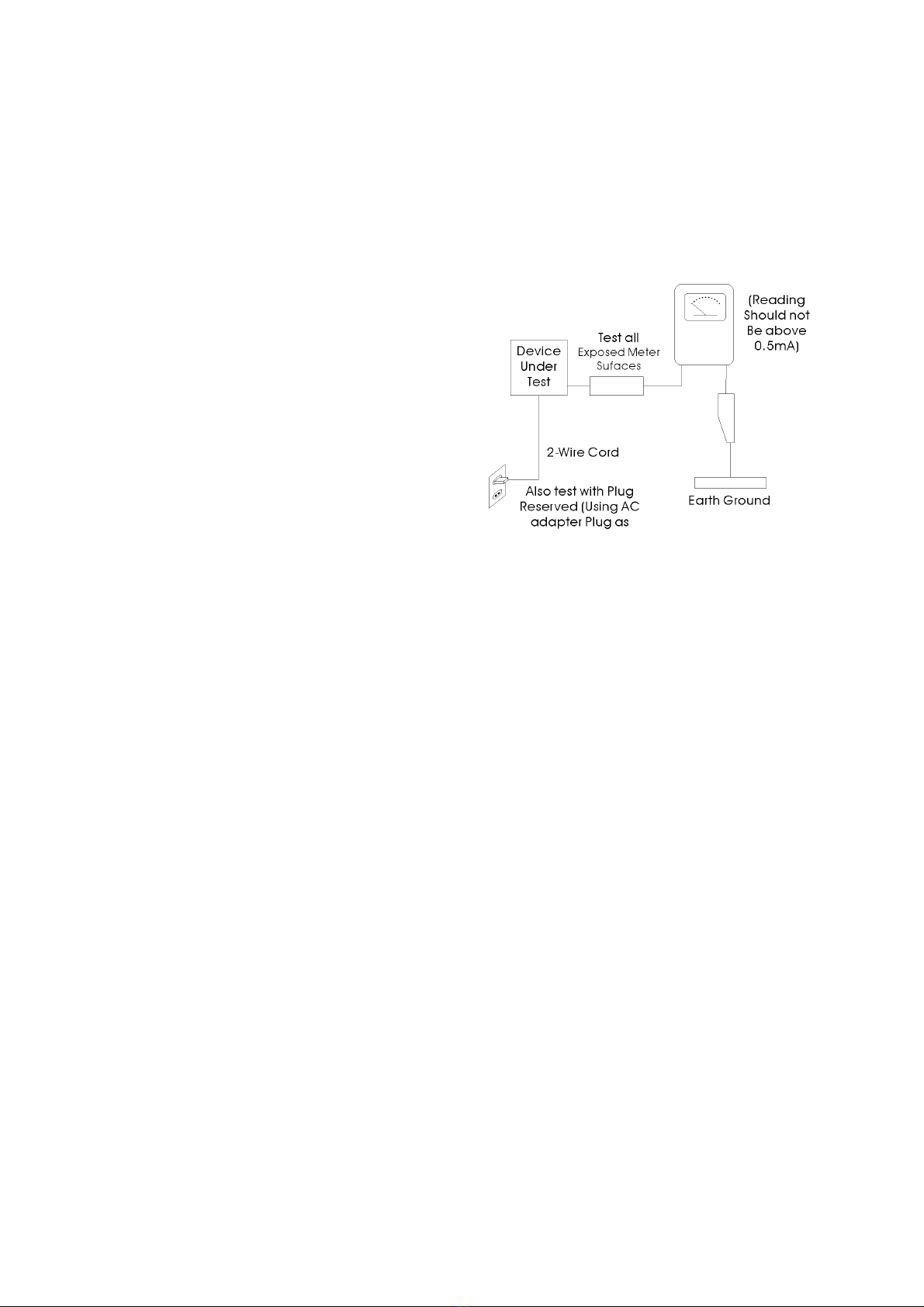

Insulation Resistance Test

2) Read and comply with all caution and safety related

notes non or inside the cabinet, or on the chassis.

3) Design Alteration Warning-Do not alter of add to the

mechanical or electrical design of this instrument.

Design alterations and additions, including but not

limited to, circuit modifications and the addition of

items such as auxiliary audio output connections,

might alter the safety characteristics of this instrument

and create a hazard to the user. Any design alterations

or additions will make you, the service, responsible

for personal injury or property damage resulting there

from.

4) Observe original lead dress. Take extra care to assure

correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts (be

sure that leads and components do not touch

thermally hot parts), (3) the AC supply, (4) high

voltage, and (5) antenna wiring. Always inspect in all

areas for pinched, out-of-place, or frayed wiring. Do

not change spacing between a component and the

printed-circuit board, Check the AC power cord for

damage.

5) Components, parts, and/or wiring that appear to have

overheated or that are otherwise damaged should be

replaced with components, parts and/or wiring that

meet original specifications. Additionally determine

the cause of overheating and/or damage and, if

necessary, take corrective action to remove and

potential safety hazard.

6) Product Safety Notice-Some electrical and mechanical

parts have special safety-related characteristics which

are often not evident from visual inspection, nor can

the protection they give necessarily be obtained by

replacing them with components rated for higher

voltage, wattage, etc. Parts that have special safety

characteristics are identified by shading, an ( ) or a

() on schematics and parts lists. Use of a substitute

replacement that does not have the same safety

characteristics as the recommended replacement part

might created shock, fire and/or other hazards.

Product safety is under review continuously and new

instructions are issued whenever appropriate.

1-2 Servicing Precautions

CAUTION: Before servicing Instruments covered by this

service manual and its supplements, read and follow the

Safety Precautions section of this manual.

Note: If unforeseen circument create conflict between the

following servicing precautions and any of the safety

precautions, always follow the safety precautions.

Remember; Safety First

1-2-1 General Serving Precautions

(1) a. Always unplug the instrument’s AC power cord from

the AC power source before (1) removing or

reinstalling any component, circuit board, module or

any other instrument assembly. (2) disconnecting

any instrument electrical plug or other electrical

connection. (3) connecting a test substitute in

parallel with an electrolytic capacitor in the

instrument.

b. Do not defeat any plug/socket B+ voltage interlocks

with which instruments covered by this service

manual might be equipped.

c. Do not apply AC power to this instrument and/or any

of its electrical assemblies unless all solid-state

device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting the

test instrument positive lead. Always remove the test

instrument ground lead last.

Note: Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed on the

cabinet, chassis or components. When servicing,

follow the printed or indicated service precautions

and service materials.

(3) The components used in the unit have a specified flame

resistance and dielectric strength.

When replacing components, use components which