MU

3010

CONTENTS

INTRODUCTION

AND

IMPORTANT

SAFETY

PRECAUTION.....................................

i

ELEOTHICALADUUSTMENT..........---.-........-.....

EA-1

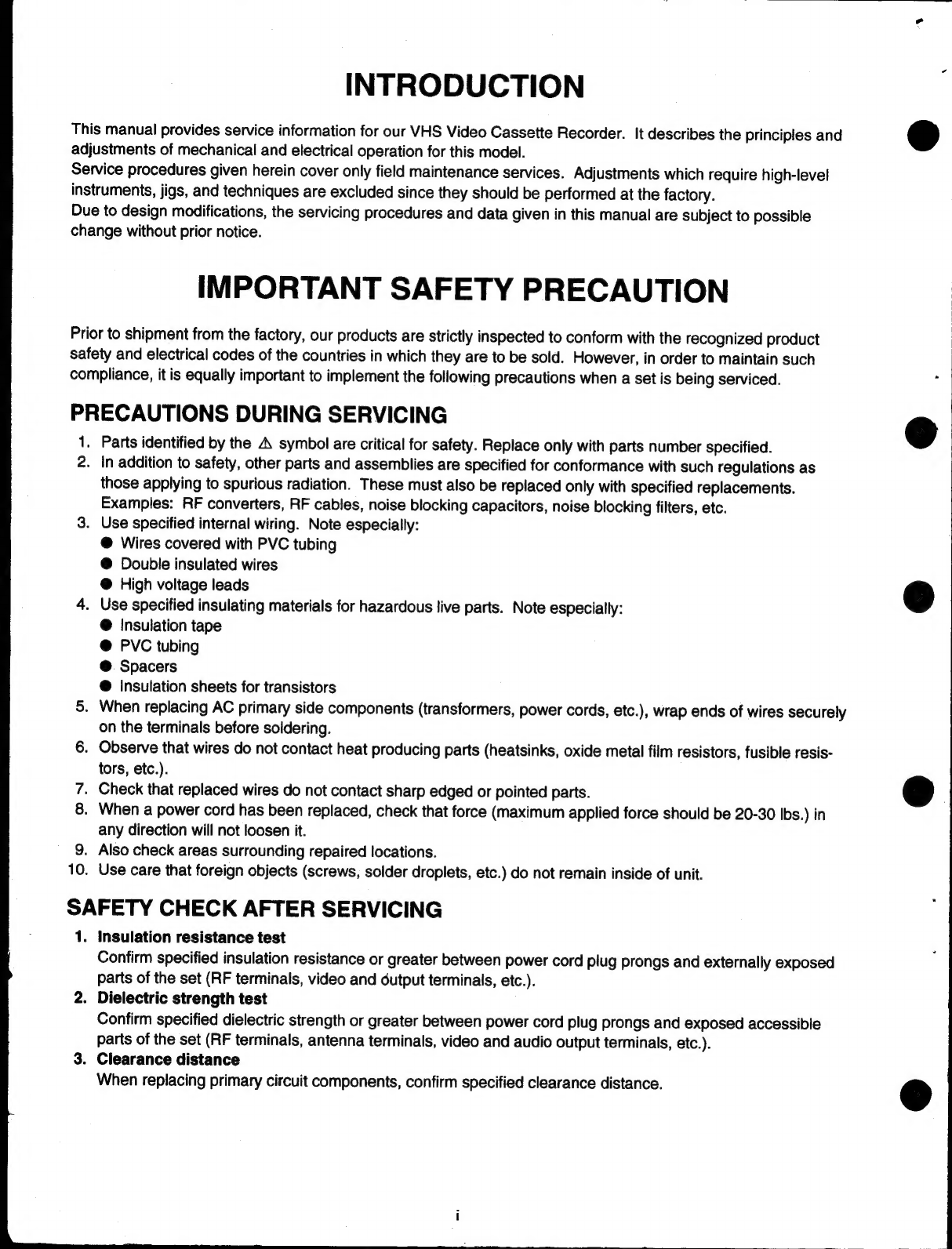

1.

PLAYBACK

SWITCHING

POINT

ADJUSTMENT

een

EA-1

MECHANICAL

ADJUSTMENT

...............................................................

MA-1

DECK

ADJUSTMENT

POINTS

ен

citer

tore

пони

dates

MA-1

1.

MECHANISM

CONTROL

..............

diiit

Qa

ke

nt

аниа

идэн

MA-2

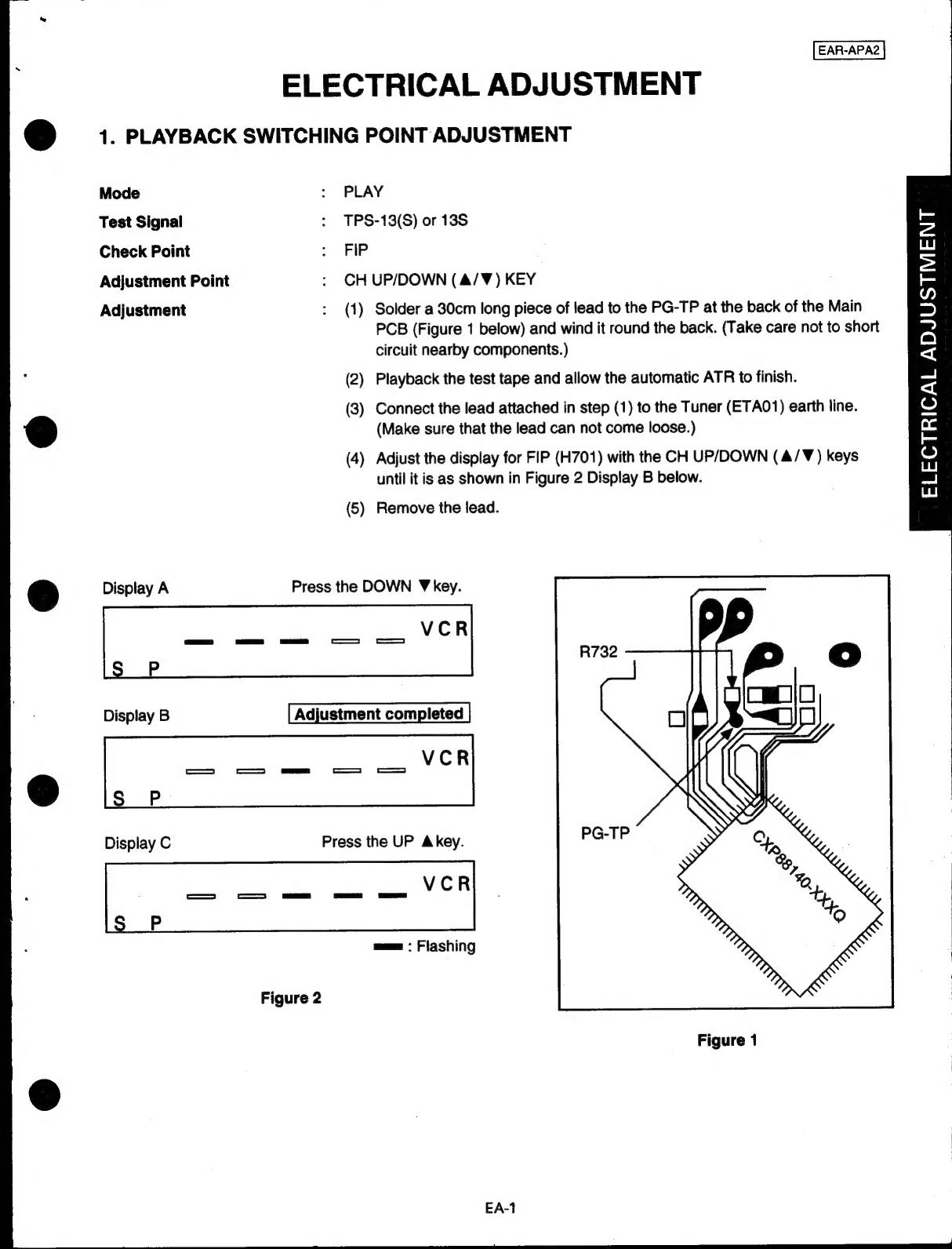

2.

ADJUSTMENT

OF

BT

TORQUE

IN

PLAY

MODE

een

MA-3

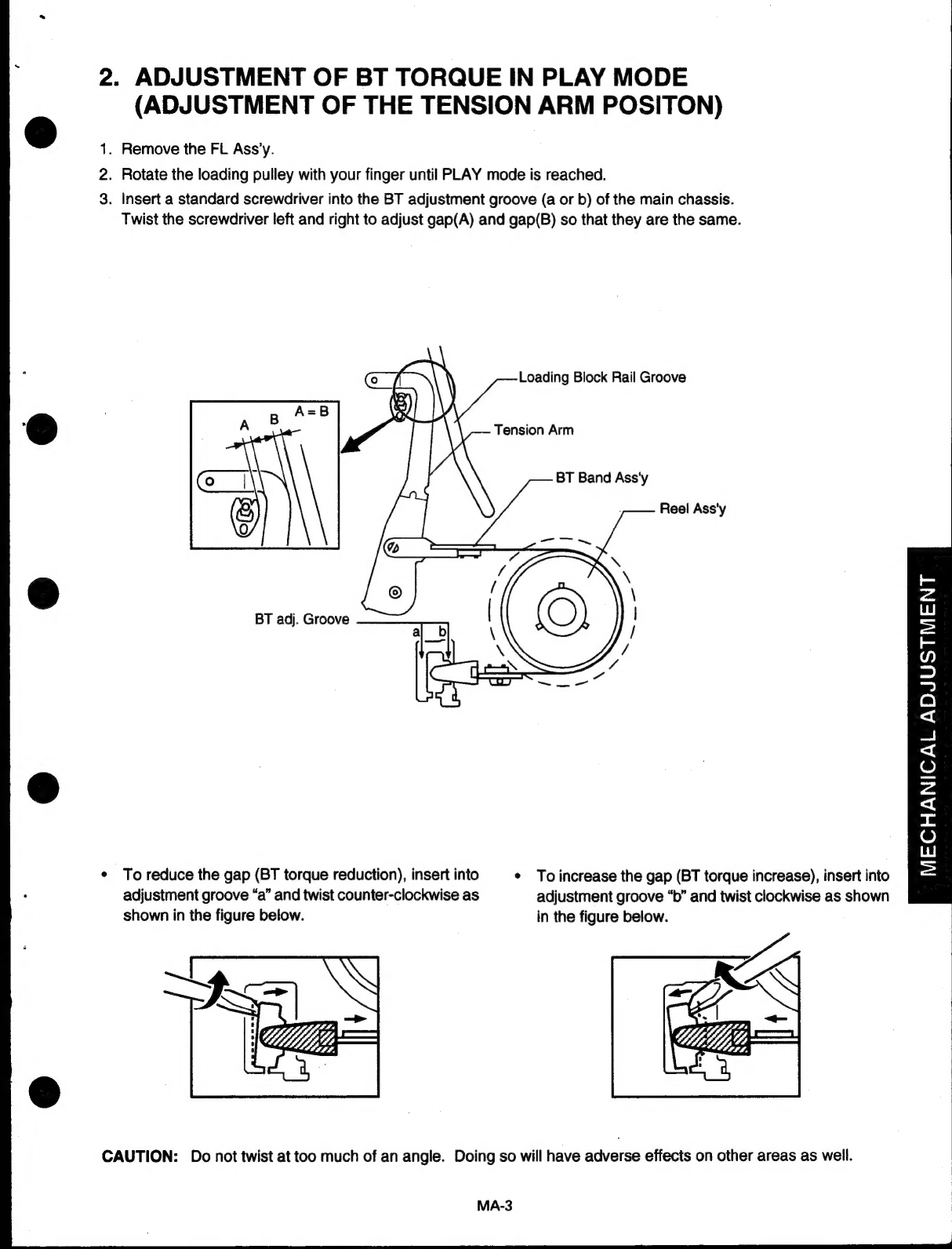

9;

AUDIOICTL

BEAD:

sisan

enn

A

ааа

a

sb

lina

oU

RR

рыны

Н

MA-4

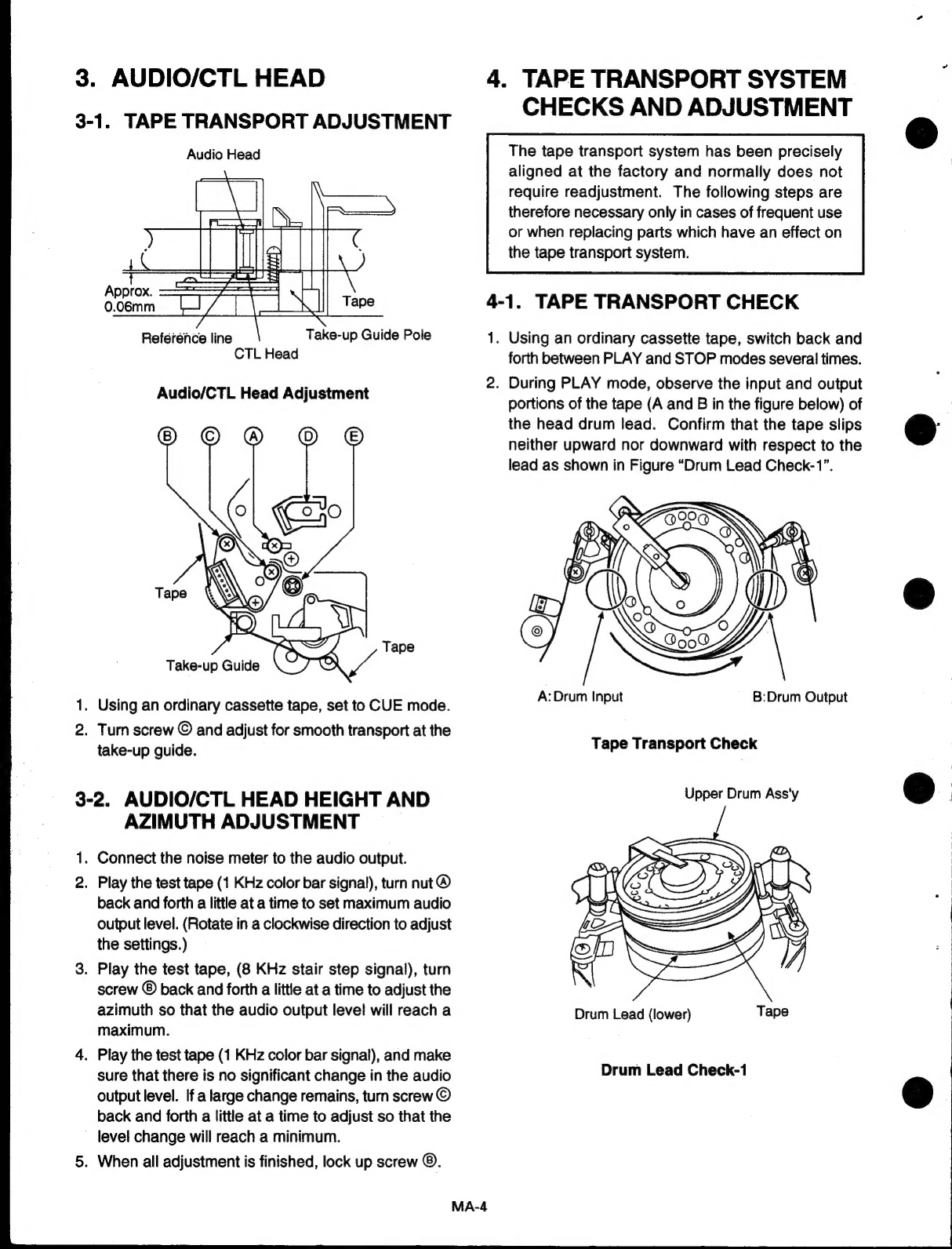

4.

TAPE

TRANSPORT

SYSTEM

CHECKS

AND

ADJUSTMENT

линеен

MA-4

5.

INTERCHANGEABILITY

ADJUSTMENT

eee

MA-6

6.

FRONT

LOADING

ASSEMBLY

ATTACHMENT

ttt

MA-10

7.

RG

POST

HEIGHT

ADJUSTMENT................

a

eed

iibi

ides

MA-11

PERIODIC

МАНТЕНАМСЕ........

niono

den

pobe

Ia

ansa

ak

Vaska

MA-12

EXPLODED

VIEW

OF

THE

CASSETTE

DECK

MECHANISM

...............

enn

MA-14

MECHANICAL

PARTS

LIST

=

ssp

reat

ананы

арады

санан

онай

leko

une

MP-1

DIAGBAM

ана

as

омар

lena

o

dolar

e

ань

1

1:

BLOCK

DIAGRAM

D

——~~T„=———-—-E

ETE

M

1

2.

TERMINOLOGY

REFERENGES.

spiso

to

nalsnno

ының

ud

ya

a

omara

afa

2

3.

SCHEMATIC

DIAGRAM)

нанына

Sa

E

make

4

4.

1C,

TRANSISTOR

LEAD

IDENTIFICATION

encens

6

5.

"ELECTRICAL

PARTS

LOCATION

ix

an

and

Skol

и

ene

8

6.

REMOVAL

OF

THE

DECK

MECHANISM

eee

11

7;

BRIEF

SERVICE

INSTRUCTION

u

азанны

ое

не

12

8.

CABINET

EXPLODED

VIEW

аннан

KE

er

UU

iU

tima

ын

erii

tnt

13

8:

ELECTRICAL

PARTS

LIST:

muki

анални

cdd

eja

kaa

at

ta

ai

e

a

a

a

a

PL-1