Techni Mobili RTA-B005 User manual

SIT-TO-STAND ROLLING ADJUSTABLE

LAPTOP CART WITH STORAGE

MODEL RTA-B005

ASSEMBLY INSTRUCTIONS

REV.OL-6941-0922

Thank you for purchasing our product

Scan to view full

assembly video

•Please be kind to our planet, when done with the assembly,

recycle any of the packaging materials that is accepted by

your city or recycling service. Thank you!

P.1 P.1

RTA-B005

•Please read carefully the assembly instructions before the installation.

• Do not discard this manual or any of the packaging

material until the unit has been completely assembled.

•Scan this QR code to view the complete assembly video online.

•For individual Step videos - please use the QR code found on

the corresponding step within the manual. SAMPLE - DO NOT SCAN

P.2 P.2

RTA-B005

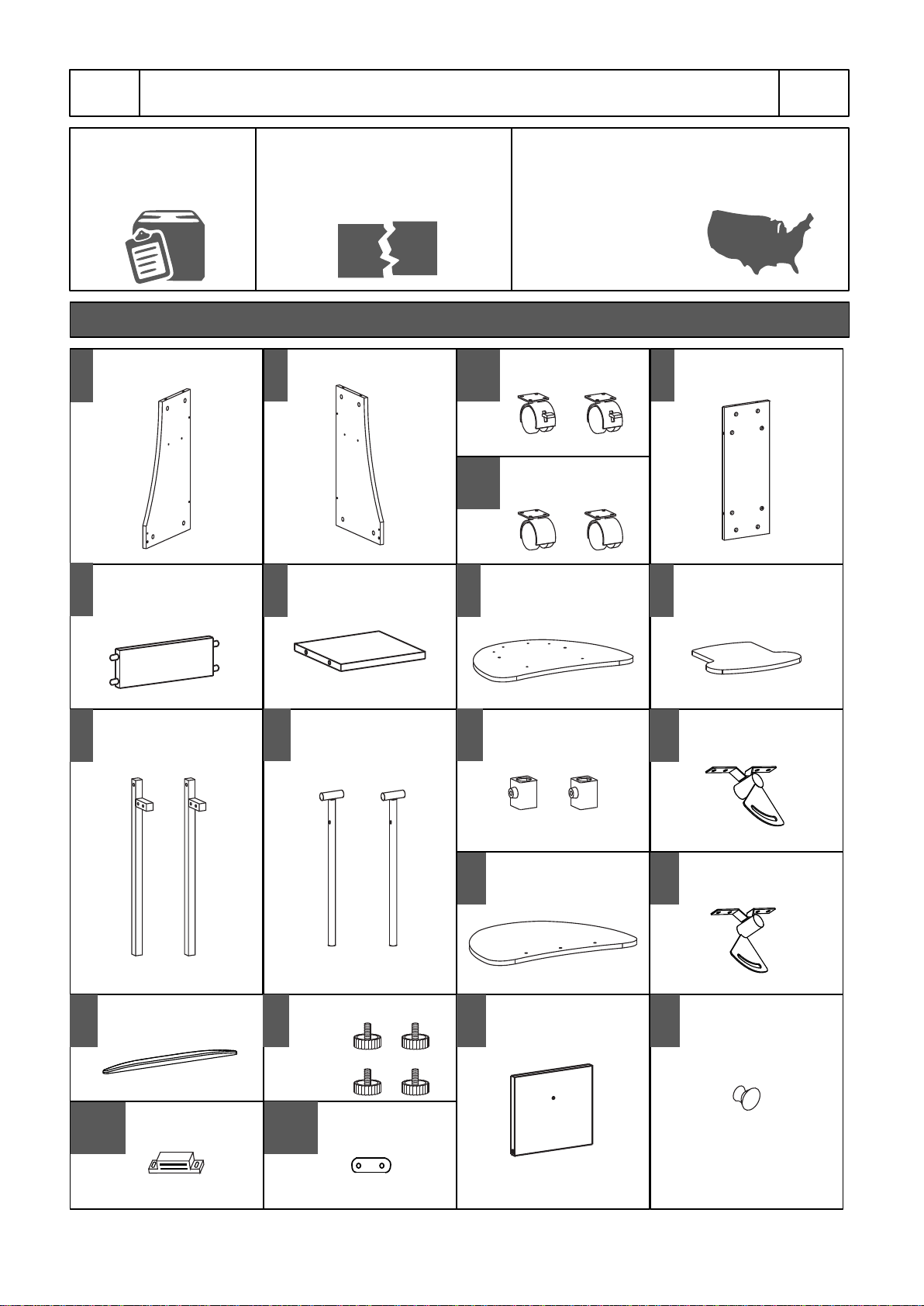

1

x1 2

x1 3-L

x2 4

x1

Left side panel

The replacement parts service is limited to

the 48 contiguous United States.

If you reside in AK, HI, PR, U.S. territories

or other countries,

please contact the

supplier from where

the unit was purchased.

Missing, damaged and defective

parts can be replaced at no cost

to you. Please refer to the last

pages on this manual.

Do a quick inventory

of all the parts and

hardware listed below

MAIN PARTS LIST

Right side panel Locking Casters Back panel

5

x1 6

x1 7

x1 8

x1

Front bottom panel Middle lower shelf Bottom base panel Middle upper shelf

9

x2 10

x2 11A

x2

12

x1

Lateral support bar Lifting "T" tube Tightening plastic

cover

Main top panel

13

x1

15

x1 16

x4

17-A

x1

Right tilting

mechanism

Protection rail Tightening screw

knob

Magnet

3-N

x2 Non-Locking

Casters

14

x1 Left tilting

mechanism

17-B

x1

Small steel

plate

18

x1 Shelf door 19

x1 Door handle

16

P.3 P.3

RTA-B005

PART QTY SIZE

MAIN PARTS LAYOUT (For reference)

HARDWARE LIST

16 M4x14

A

ITEM

3

B

6

C

20

D

8

E

PART QTY SIZE

4M3x15

F

ITEM

1

G

2

H

2

Sets

I

INCLUDED TOOLS

1Phillips Screwdriver

M5x16

M6x35

M6x40

Bolt

M6x12

M4x20

Ø5x17

Ø8x19 Curved

connector

__________

12

13

14

16

8

12

7

5

9

18

11

15

10

10

4

3-L

Ø10x28

Plastic washer

P.4 P.4

RTA-B005

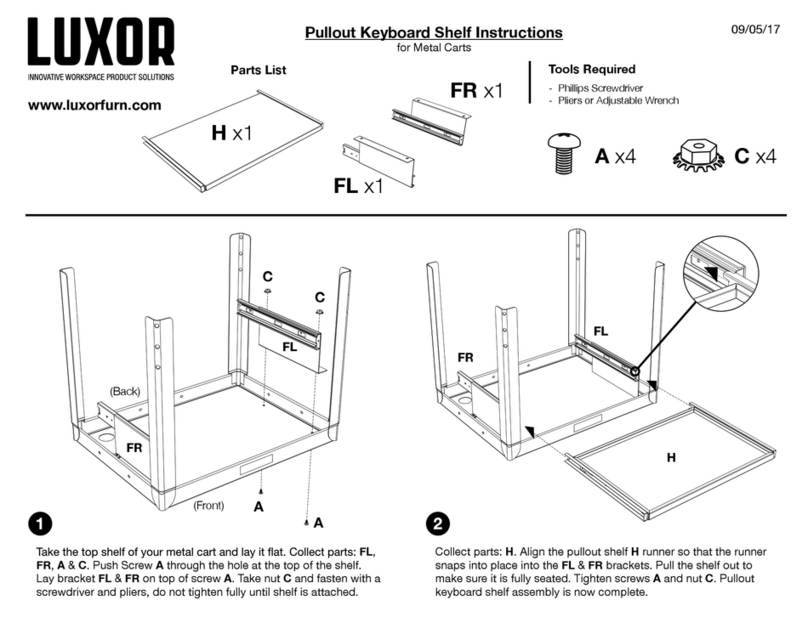

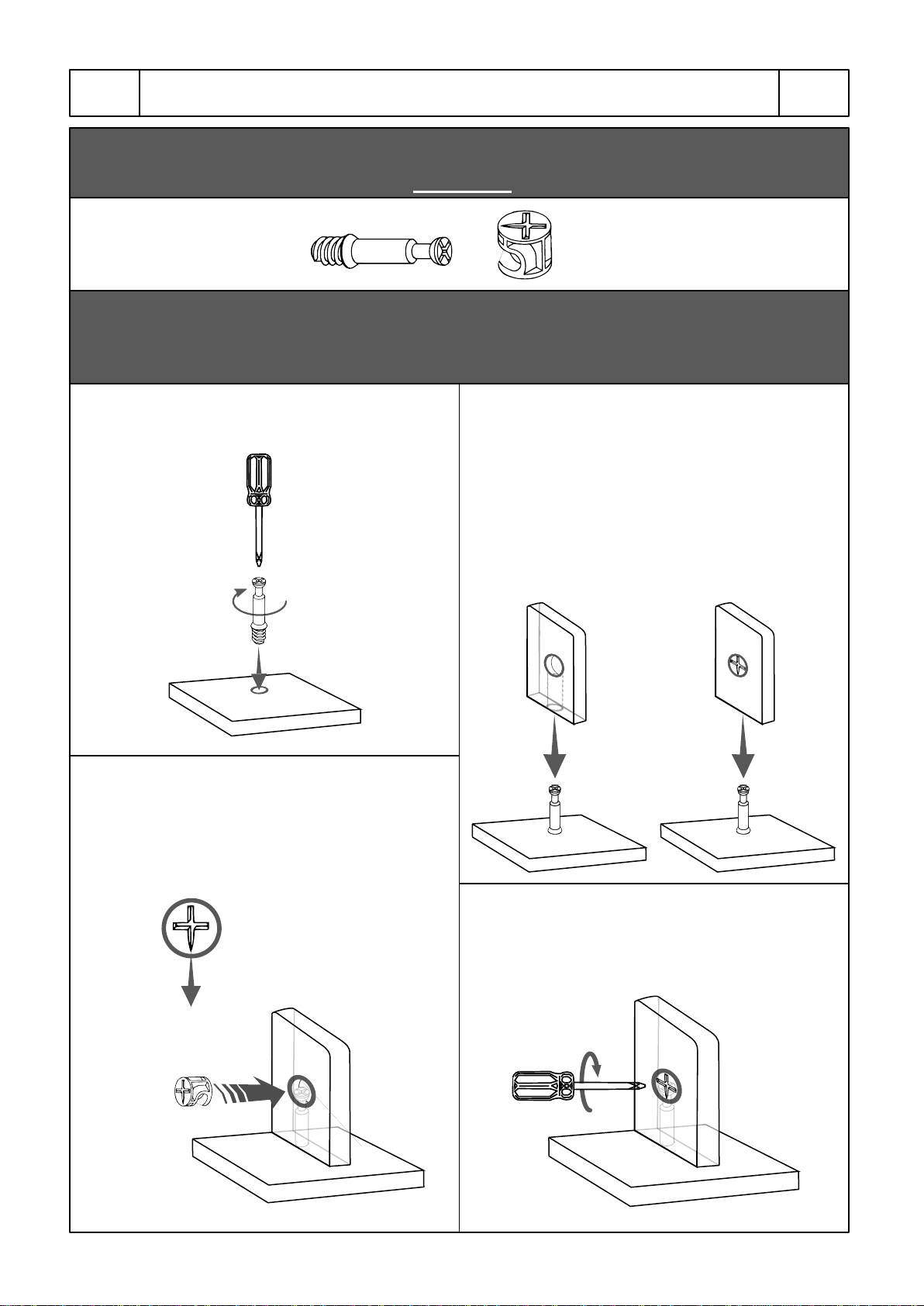

1. Screw the bolt into the indicated hole on the

panel indicated in the assembly step.

CAM BOLT AND CAM LOCK TUTORIAL

THE INSTRUCTIONS BELOW ARE NOT ACTUAL ASSEMBLY STEPS

This unit uses cam bolts and locks (also known as mini fixes).

If you are not familiar with this kind of hardware, the below is a tutorial

that explains how to use them on the steps where they are required.

2. Join the other panel (with the big hole) to the

panel with the bolt. If it comes with the cam

locks already pre-installed, make sure to align

them to receive the bolt's head (refer to point

3). There might be a very small gap between

the panels which is normal.

3. Insert the cam lock on the panel with the big

hole making sure it goes aligned to receive the

bolt's head.

4. Use a Phillips screwdriver to turn the cam

lock clockwise. This will lock the panels

togheter and also will close any gaps.

Cam lock

alignment

If the cam locks come

pre-in stalled, make sure they

are aligned (see point 3).

P.5 P.5

RTA-B005

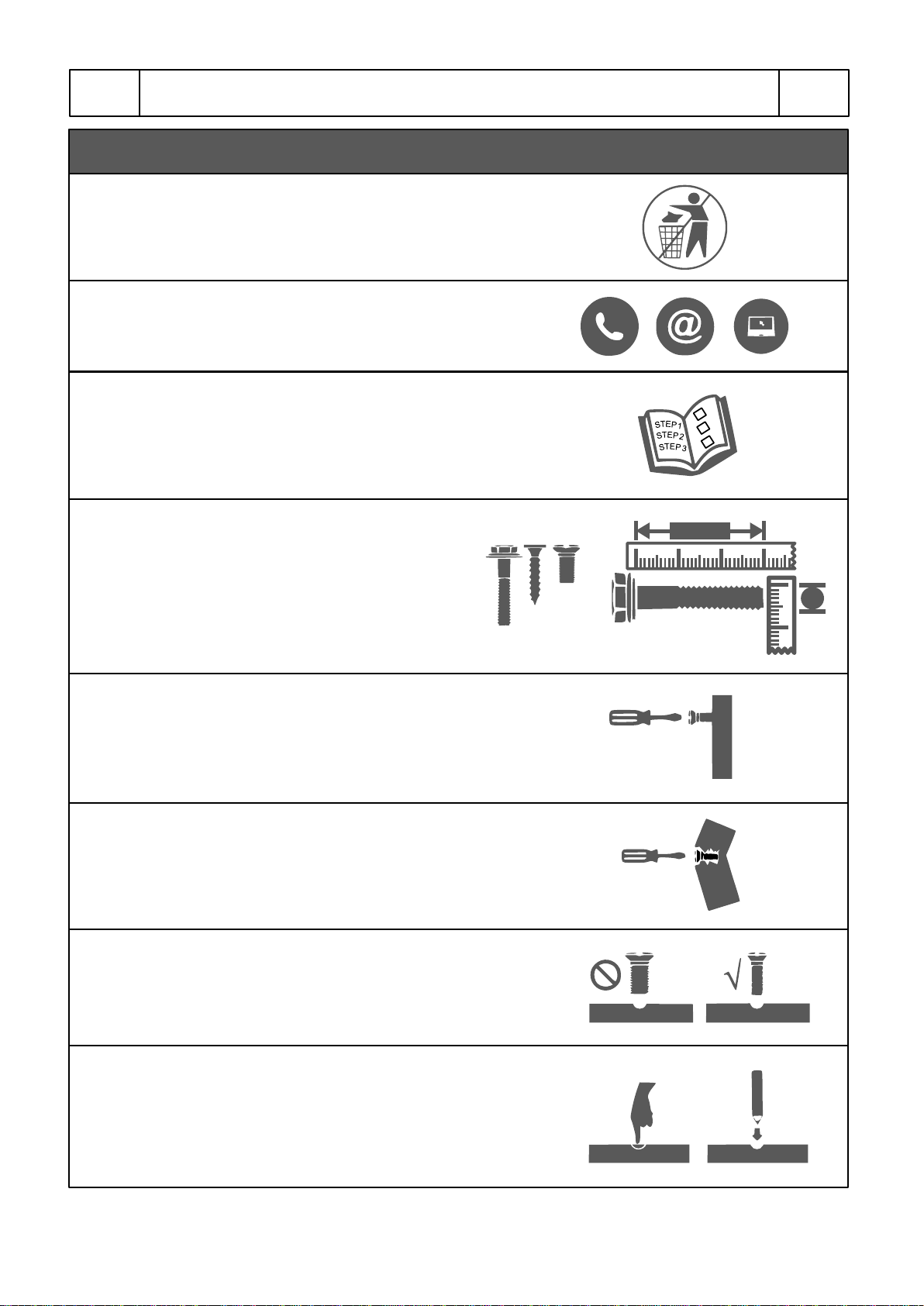

BEFORE YOU START THE ASSEMBLY, PLEASE READ THE FOLLOWING TIPS AND WARNINGS.

• If during assembly you find an issue or need clarification,

please contact our Customer Service for assistance.

Please refer to the last pages on this manual.

• On each step read the instructions thoroughly and

analyze the illustrations before proceeding to do the

assembly.

• Follow the instructions step by step and do not skip any

unless our Customer Service advises it is OK to do so.

• Do not overtighten or force the screws as they might

break, strip, damage the threads of the holes or get stuck

inside the part.

• Make sure you understand which hardware will be

used on each step. Using the wrong size of screw,

bolt or pin might strip the threads or cause damage

to the part in which it is being used.

• To avoid misalignments, always leave the screws loose

and tighten them until all pieces are positioned correctly.

• If the hole seems too small for the screw, make sure you

are using the correct size of screw and/or that you are

installing it in the correct hole.

• Do not discard this manual or any of the packaging

material until the unit has been completely assembled.

√

√

M6

30mm

M6x30

•Sometimes on the panels the laminate or material might be

covering the hole partially or entirely. If there is no visible

hole or it seems too small, pass and press the tip of your

finger over the area where the hole should be located to feel

its indentation, and once found, carefully pierce the laminate

to uncover the hole underneath.

P.6 P.6

RTA-B005

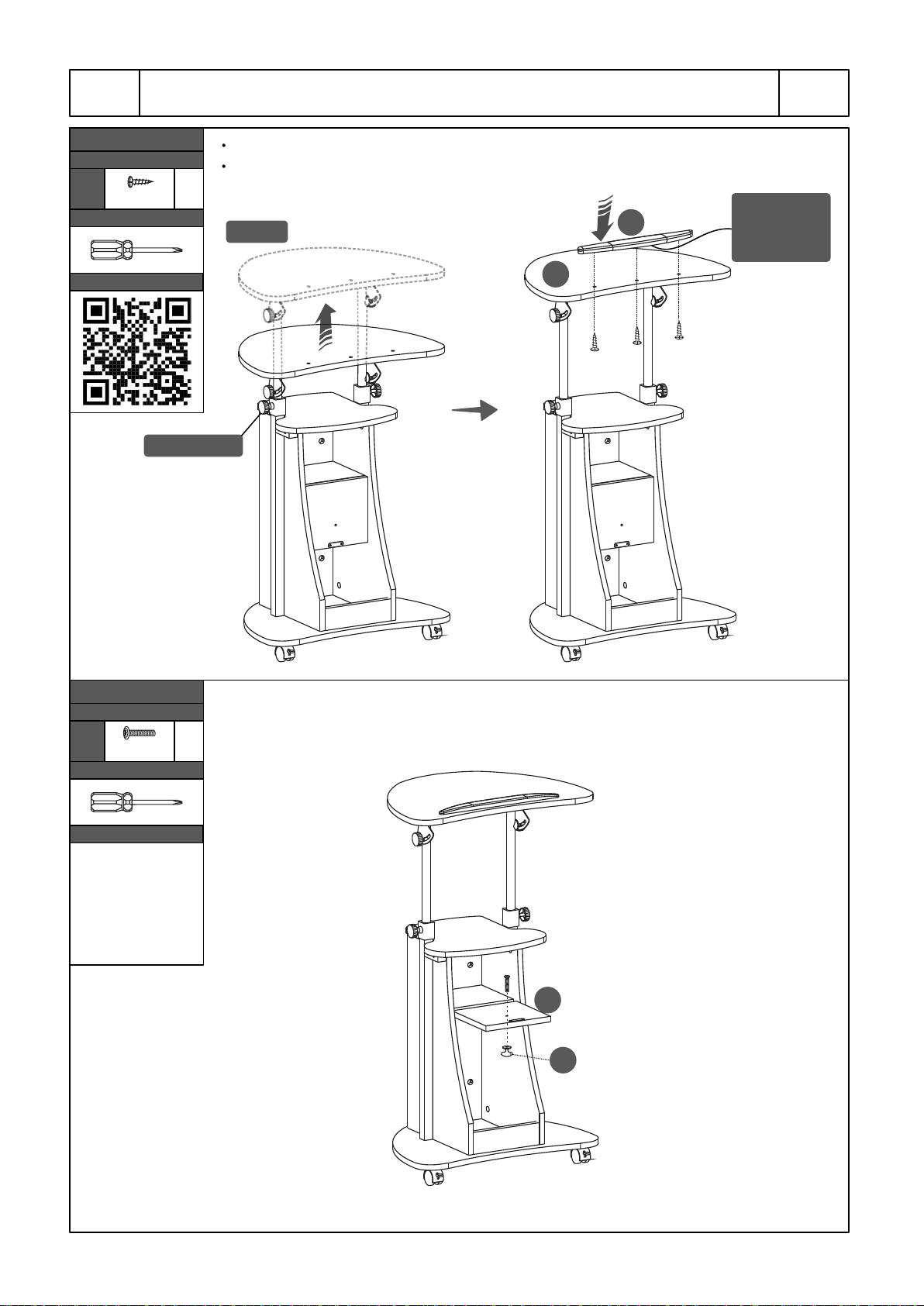

Attach the magnet 17-A to the bottom surface of the middle upper shelf 8with

screws F.

Attach the small steel plate 17-B to the inside surface of the shelf door 18 with

screws F.

STEP 1

Hardware

FM3x15 4

Pcs

17-A

ASSEMBLY STEPS

1

4

5

6

8

Tools (included)

Scan QR to view step

5

(Bottom face)

(Inside face)

Screw the bolts Dinto panel 1.

Join panel 4to panel 1and turn the cam locks as explained in page 4.

Assemble panel 6to panel 1in the same way making sure the surface with the

cam locks towards the BOTTOM.

Join panel 5to panel 1.

STEP 2

Hardware

DM6x40 4

Pcs

Tools (included)

Scan QR to view step Attach bolts to 1

(Front)

(Top)

(Front)

(Bottom)

(Top)

(Front)

Assemble 4 to 1

Cam locks

alignment

on 4 and 6

(Front)

Assemble 6 to 1

(Front)

Attach 5 to 1

17-B

18

11

1

(Bottom)

(Top)

Attach bolts to 2

(Top)

(Front)

P.7 P.7

RTA-B005

Insert the metal pin Hinto the corresponding hole on panel 1.

Attach the door panel 18 to the pin H, making sure the metal plate is visible as

shown.

STEP 3

Hardware

HDouble

sided pin

1

Pc

(Front)

(Bottom face)

3-N

H

Non-Locking

go at the back

46

7

18

Tools (included)

Scan QR to view step

1H

Attach the bolts Dto the right side panel 2into the indicated holes.

Insert the metal pin Hinto the door 18.

Assemble panel 2to panels 4, 5, 6 and 18 as shown and as explained in page 4.

STEP 4

Hardware

DM6x40

Bolt

4

Pcs

Tools (included)

Scan QR to view step

X2

X2

HDouble

sided pin

1

Pc

Insert H into 18

H

18

Attach 2 to 4, 5, 6

2

2

5

Cam locks

alignment

on 4 and 6 18

Use screws Ato assemble the casters 3to the bottom surface of the bottom

base panel 7in the following positions:

The Locking casters 3-L go at the front of the panel.

The Non-locking casters 3-N go at the back of the panel.

STEP 5

Hardware

AM4x14 16

Pcs

Tools (included)

Scan QR to view step

Locking

go at the front

3-L

Screw the bolts Dinto the indicated holes on the top surface of pa

nel 7.

Join the main frame to the base and lock the pieces together by turning the

cam locks on panels 1, 2 and 4 as shown and as explained in page 4.

STEP 6

Hardware

DM6x40 6

Pcs

Tools (included)

Scan QR to view step Attach bolts to 7

P.8 P.8

RTA-B005

(Front)

1

4

8

9

Cam locks

alignment

on 1, 2 & 4

7

2

Screw the bolts Dto the middle upper shelf 8.

Assemble the shelf 8to panels 1, 2and 4as explained in page 4.

STEP 7

Hardware

DM6x40 6

Pcs

Tools (included)

Scan QR to view step

Attach bolts to 8 8

1

4

2

Assemble the lateral support bars 9to the base panel 7with screws C from

underneath. The screws go through the base panel and into the bars.

Assemble the bars 9to the side panels 1and 2with screws Cfrom the side.

The screws go through the bars and into the side panels.

STEP 8

Hardware

CM6x35 6

Pcs

Tools (included)

Scan QR to view step

9

7

12

99

(Front)

(Front)

Cam locks

alignment

on 1, 2 & 4

Secure all pieces

by tightening the

screw knob 16

into the tube 10

P.9 P.9

RTA-B005

Place the curved connectors I over the threaded holes of the lifting tubes 10.

Place the washer I over the connector I.

Connect the right tiltilg mechanism 13 to the tube 10.

Insert and screw the screw knob 16 into the tube 10. The screw knob goes

through the mechanism 13, the washer I, the connector I and into the tube 10.

Repeat the procedure for the left tilting mechanism 14.

THE SOFT PLASTIC WASHER MUST GO IN BETWEEN THE CONNECTOR

AND THE MECHANISM, AS IT PURPOSE IS TO CREATE THE NECESSARY

FRICTION THAT KEEPS THE MECHANISM FIRM WITHOUT MOVING.

DO NOT PLACE THE WASHER OVER THE MECHANISM, IT MUST GO

UNDER IT.

IF THE SOFT PLASTIC WASHER IS MISSING, DO NOT REPLACE IT WITH

ANY OTHER KIND; DO NOT USE METAL OR HARD PLASTIC WASHERS.

STEP 9

Hardware

IConnector 2

Sets

I

10

14

Soft plastic

washer

Scan QR to view step

REPEAT THE

PROCEDURE FOR

MECHANISM 14

EXTREMELY IMPORTANT!

Follow this step EXACTLY as instructed! An incorrect assembly leaves

the tilting mechanism and main panel prone to moving or sliding, and

even might flip down forwards unexpectedly under any weight.

Place Connector I

over tube 10

I

10

Place Washer I

over connector I

The washer goes OVER

THE CONNECTOR, NOT

over the mechanism.

10

Connect mechanism

13 to tube 10

If the soft plastic washers are

missing, DO NOT replace them

with metal or hard plastic washers.

13

16

16

I: Connector

I: Washer

10

Hollow

end

Tilting direction

13

Do not

tighten

P.10 P.10

RTA-B005

Assemble the tilting mechanisms 13 and 14 to the main panel 12 in their

respective sides with screws E.

STEP 10

Hardware

EM6x12 8

Pcs

12

13 14

16

Tools (included)

Scan QR to view step

Holefacingto

theoutside

(Front)

(Left)

(Right)

Place the plastic covers 11 over the lateral bars 9with their threaded holes

facing towards the outside.

Slide the lifting tubes 10 through the plastic covers 11 and into the bars 9.

Insert the screw knobs 16 into the plastic covers 11, but do not tighten yet.

STEP 11

Scan QR to view step

11

9

910

16

9

(Front)

P.11 P.11

RTA-B005

Lift the main panel 12 about 6inches and tighten the screw knobs 16.

Assemble the protection rail 15 to the main panel 12 with its curvature towards

the front with screws Bfrom underneath.

STEP 12

Hardware

BM5x16 3

Pcs

Tighten 16

12

15

18

19

Tools (included)

Scan QR to view step

Assemble the handle 19 to the door 18 with screw G.

STEP 13

Hardware

GM4x20 1

Pc

Tools (included)

Scan QR to view step

Lift 12 Curvature

towards

the front

Give yourself a nice pat on

the back, you did a great job!

P.12 P.12

RTA-B005

ALL DONE!

ENJOY YOUR NEW UNIT!

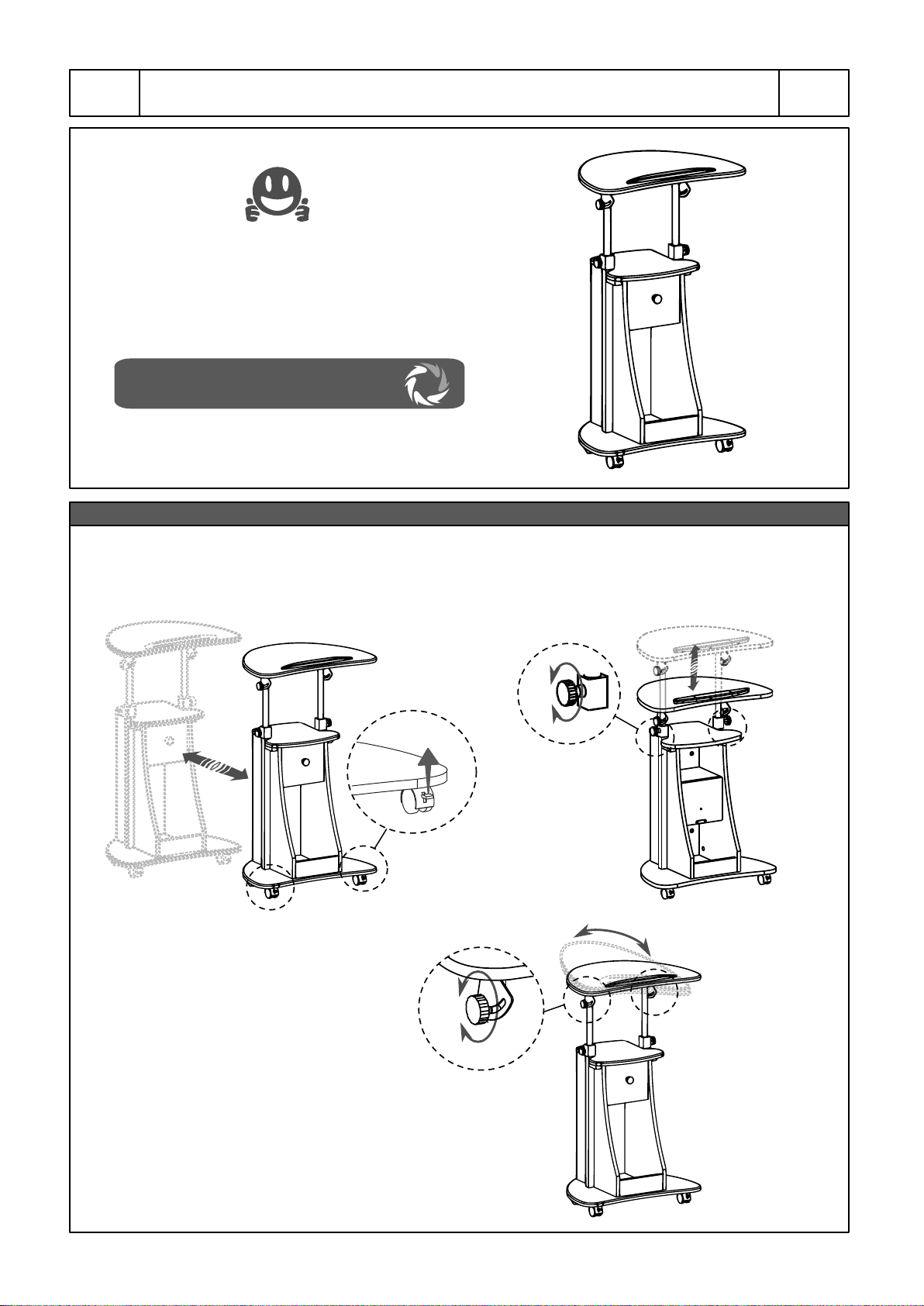

FUNCTIONS / ADJUSTMENTS

ROLLING:

Unlock the front casters to

allow free movement.

LIFTING:

Loosen the screw knobs to lift,

then tighten again.

TILTING:

Loosen the screw knobs to tilt,

then tighten again.

P.13 P.13

RTA-B005

Clean the surfaces preferable with a clean cloth damped in a solution of mild soap and water,

then dry with a clean towel.

If you decide to use a cleaning agent, test first on an area hidden from view such as

underneath the tabletop.

Every 4 months, inspect the unit completely and make sure that all screws are tighten.

When transporting the unit to places far away, protect and secure the unit to avoid damage in

transit.

Shall any part of the unit become defective during the warranty period, replacement parts

might be available to you at no charge. Please refer to the last pages on this manual.

The warranty does not extend to regular wear and tear, nor the manufacturer assumes liability

for damages or consequences due to accidents, incorrect assembly, negligence, improper

use, modifications, or not heeding the above warnings.

WEIGHT LIMITS

CARE AND MAINTENANCE

WARNINGS

Do not exceed the indicated weight limits.

Do not expose the surfaces to direct sunlight or to extreme environmental conditions.

Do not use solvents or abrasive materials to clean the unit.

Do not climb on the base of the unit.

Do not allow small children to play with the unit.

Before moving the unit, unlock the front casters and make sure to secure or remove any object

on it that might fall off.

Do not overtighten the screw knobs.

Make sure that the tilting mechanisms are properly assembled as instructed in page 9 step 9.

An incorrect assembly leaves the tilting mechanism unsecured, and the main top panel will not

hold enough weight on it and even might flip down forwards unexpectedly.

If you have objects or devices on or under the main panel, use caution when adjusting the

height or tilting angle.

It is recommended to first tilt the main panel, then place the objects or devices, but pay

attention to if they will be properly retained by the protection rail. If the object or device seems

that might tip over, reduce the tilting angle.

Do not use the unit if the plastic covers or screw knobs look cracked or if they are stripped.

20 Lbs

(9.1 Kg)

20 Lbs

(9.1 Kg)

20 Lbs

(9.1 Kg)

P.14 P.14

RTA-B005

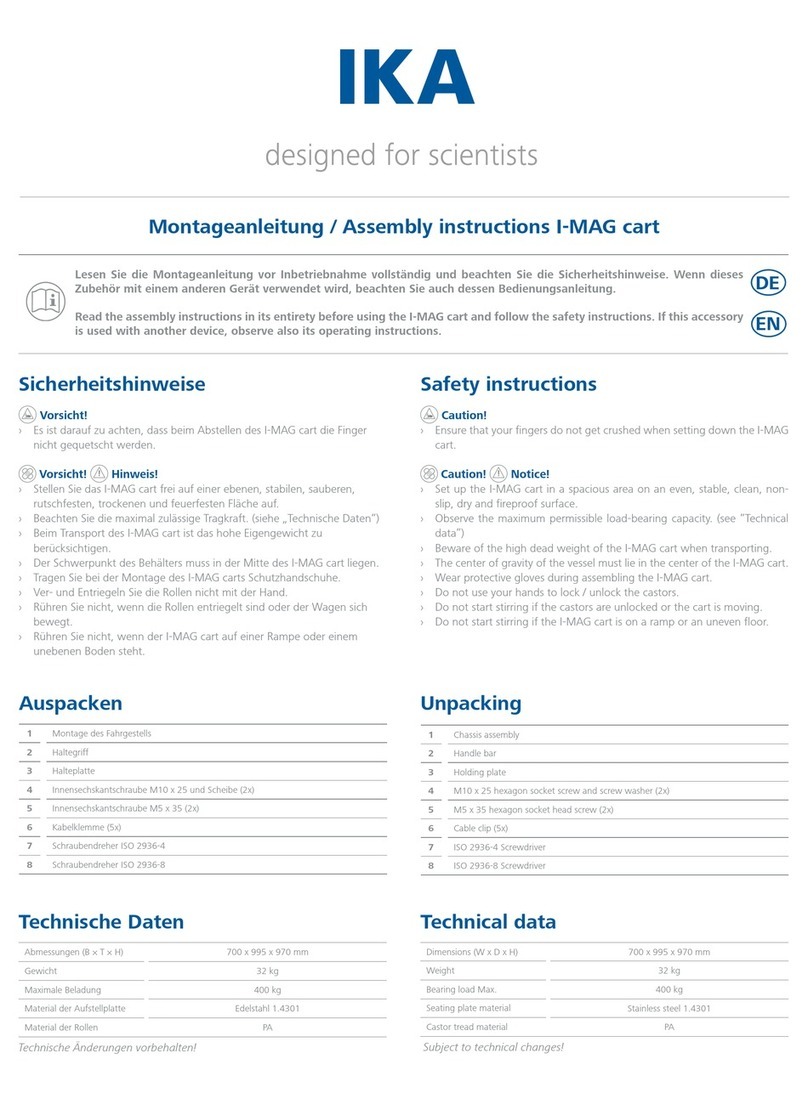

TECHNI MOBILI WARRANTY

RTA Products, LLC warrants to the Original Purchaser who acquired a new product from RTA

Products or its authorized resellers that this product will be free from defects in its workmanship

and materials, under normal use and service conditions, as described herein. "Defects" as used

in this warranty, is defined as any imperfections that impair the use of the furniture or product.

RTA Products LLC will replace any defective part, at its discretion, and without charge to the

original purchaser other than the freight from the end consumer to RTA Products.

Replacement parts can only be supplied if parts are available. Items out of production may be

unavailable. This warranty will be effective for the applicable time period beginning the date of

purchase on your original sales receipt. RTA product’s obligation under this warranty is limited to

repairing or replacing products or parts as provided herein. This product has been designed for

and is intended for office and home-office use only. This warranty is Original Purchaser’s sole

remedy for product defects, and this warranty does not extend to any product, or damage to any

product, caused by or attributed to abuse or misuse, products used for commercial or rental

purposes, use modifications of, or attachments to the product, and products or parts not used,

maintained, or extended hereunder is in lieu of any and all other warranties, express or implied,

including without limitations any implied warranty or merchantability or of fitness for a particular

purpose. Please note, all desks made with PVC Laminate surface should not be exposed to

direct sunlight, as it may damage the material. Damage of this nature is not covered under this

warranty.

RTA Products will not be responsible for indirect, special, incidental or consequential damages.

This warranty is limited to merchandise purchased in the Continental United States, excludes

AK, HI and PR. Some States do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights. You may also have other rights that may vary from state

to state.

RTA Products will advise you of the procedure to follow in making warranty claims. The following

are the procedures for warranty claims:

a. Call us Monday – Friday, from 9am-5pm (Eastern Time) at (866) 782-5520 to explain the

defect and give your name, address and phone number. Please have ready the model number

of our product, date and place of purchase. You can also write to us by e-mail to

b. If we determine that replacement will remedy the situation, and in order to determine the

extent or the cause of the defect, purchaser will need to send the part in question at purchaser’s

expense. Once we receive the part, we will examine it and determine whether the claim is valid

(or not), and then proceed to send the replacement. We will ship the replacement at our

expense.

DESKS/LAPTOP CARTS/FILE CABINETS: LIMITED 5-YEAR WARRANTY

FOR SEVERAL HELP OPTIONS

INCLUDING REPLACEMENT PARTS ORDERS

VISIT: WWW.TECHNIMOBILI.COM

AND CLICK ON SUPPORT TAB

Or scan the following QR Code:

Scan the following QR Code to order replacement parts:

EMAIL US:

Other manuals for RTA-B005

1

Table of contents

Other Techni Mobili Outdoor Cart manuals

Popular Outdoor Cart manuals by other brands

Vestil

Vestil CART-500-2033-FP instruction manual

Costway

Costway OP70393 user manual

EefaCo.Store

EefaCo.Store PROTEAK 701 Assembly instructions

Amity Technology

Amity Technology Concord 2250 Owner's operating manual

Black cat

Black cat MH1100-1 owner's manual

Gorilla Carts

Gorilla Carts GOR10-16 quick start guide