Tecnoclima WIMBLEDON 145 Manual

- 1 -

TECHNICAL INFORMATION

ASSEMBLY, USE AND MAINTENANCE

AUTONOMOUS MONO-BLOCK

AIR TREATMENT UNIT

WIMBLEDON

MODEL

GB

- 2 -

Dear Customer,

Thank you for choosing an AUTONOMOUS MONO-BLOCK AIR TREATMENT UNIT,

WIMBLEDON series, an innovative, modern, high-quality and high-performance product, which

will ensure your wellbeing and which will be noiseless and safe in the long term; especially, if

you are supported by TECNOCLIMA Technical Assistance Service, which is specifically skilled

and trained to maintain the highest efficiency level of the machine at the lowest operating costs

and which can provide you with original spare parts, if needed.

This User Manual includes important instructions and recommendations that should be

complied with, in order to easily install and to better use the AUTONOMOUS MONO-BLOCK

AIR TREATMENT UNIT, WIMBLEDON series.

Thank you, once again.

TECNOCLIMA S.p.A.

COMPLIANCE

The air treatment unit, WIMBLEDON series, comply with:

•Machinery directive 2006/42/EC

•Low Voltage Directive 2006/95/EC

•Regulation UE 2016/426 for Gas equipment

•Electromagnetic Compatibility Directive 2004/108/EC

PIN NUMBER

The PIN number is specified on the technical data plate.

RANGE

Throughout this manual, reference is made to the TYPE. The table hereunder indicates the range or

products and relation between TYPES and TRADE NAMES.

TYPE

TRADE NAME

1

WIMBLEDON 145

2

WIMBLEDON 245

WARRANTY

The warm air heater is covered by a SPECIFIC WARRANTY, as from the date of purchase of the

appliance, to be documented by the Purchaser; if she/he cannot do this, the warranty shall apply as from

the data of manufacture of the appliance. The warranty terms are specified in detail in the WARRANTY

CERTIFICATE, delivered together with the appliance, which should be read with great care.

GENERAL INFORMATION

- 3 -

CONTENTS

GENERAL INFORMATION:

Compliance 2

Pin number 2

Range 2

Warranty 2

Contents 3

General instructions 4

Basic Safety rules 5

Disposal information 5

Appliance description 6

Identification 8

Structure 9

Heat exchanger scheme 10

Dimension and weight 11

Technical data 12

Information requirements 2016/2281 13

INSTALLATION AND SETTING INSTRUCTIONS:

Product receipt 14

Movement and transport 14

Transport locks 15

Position 15

Clearance area 16

Fuel connection 16

Smoke exhaust 16

Condensate drain connection 18

Condensate drain siphon (supplied with the machine) 19

Level switch (supplied with the machine) 20

Air outlet-intake connection 21

Combustion air 22

Gas supply line 22

Fixed protections 22

Gas burner and relevant supply ramp 22

Air outlet temperature probe 23

Safety thermostats 24

Wiring diagram 26

Electric connection 32

Start-up and stop of the treated air fan 33

Fan speed setting 33

Controls 34

Electric panel controls 35

Failures and troubleshooting 35

TECHNICAL ASSISTANCE INSTRUCTIONS:

Maintenance 36

Gas burner cleaning 36

Condensate drain system cleaning 36

Fan unit maintenance 36

LIMIT thermostat maintenance 37

Maintenance of safety devices 37

Exchanger cleaning 37

Assistance 38

Modulating thermal power regulator (RWF 40) 38

Notes 39

In the manual, the following symbols are used:

WARNING = operations requiring appropriate care and preparation

FORBIDDEN = operations that MUST NOT be performed, in any case

This manual comprises 40 pages.

GENERAL INFORMATION

- 4 -

GENERAL INSTRUCTIONS

This instruction manual is an integral part of the equipment and delivery, and must be preserved with care. In case o f equipment resale, the

manual must be delivered to the new owner or user. In case of loss of or damages to this manual, you are kindly requested to contact the

Manufacturer or the Technical Assistance Service of your area.

After removing the packaging, check that its content is in good condition and complete. If it is non-conforming, please contact the Organisation

that sold the appliance.

Air treatment units must be installed by a qualified company, which at the end of the work must provide the owner wi th a declaration of

conformity stating that the installation complies with the best practice and the applicable national and local regulations, a s well as the indications

of this instruction manual.

This equipment has been designed for room heating and must never be used for other purposes that are not compatible with its functioning

characteristics.

Any contractual or extra-contract liability of the Manufacturer in respect of damages caused to people, animal or things by mistakes in

installation, setting or maintenance or by the improper use of the machine is excluded.

A too high temperature is unhealthy and it is a pointless waste of energyDo not leave the rooms closed for a long time. Regularly

open windows to facilitate a proper air renewal.

Smells and fumes may be produced during the first start-up, due to the evaporation of the liquid that protects the heat exchanger during

storage; this event is normal and disappears after a short period of operation. Air the room properly.

If you plan not to use the machine for a long time, carry out at least the following operations:

•

turn the appliance’s master switch and the plant’s master switch to “OFF”

•

close the central cock that feeds the fuel

If the air treatment unit is shut down for long periods of time, it is recommended to inform the Technical Assistance Service or a professional

staff qualified to restart it.

The appliance must be equipped exclusively with original accessories. The Manufacturer shall not be held liable for any damag e caused by

improper use of the equipment or by the use of non-original materials or accessories.

References to Laws, Regulations, Directives and Technical Rules mentioned in this manual are made only for information

purposes and as they are in force when the manual is printed.

If new regulations or amendments to current laws go into effect, this

shall not oblige the Manufacturer with regards to third parties.

Servicing or maintenance operations shall be carried out by the After-sales Service or by qualified personnel, as provided for by this handbook.

Never modify nor tamper with this equipment, since this might cause hazardous situations, and the Manufacturer shall not be h eld liable for any

consequent damage.

The systems that shall be prepared (gas piping, power supply etc.) shall be properly secured and shall never become obstacles, involving the risk

of stumbling.

The Manufacturer is responsible for the product compliance with Laws, Directives or Construction Standards in force when the product

is marketed. Knowledge and compliance with the laws and regulations concerning plant design, installation, operation and

maintenance of the plant are the exclusive responsibility of the Designer, Installer and User, respectively

The Producer shall not be held responsible for failure to comply with the instructions of this manual, for the consequences of any

operations carried out and not specifically provided for or for translations open to misinterpretation

.

The equipment functions with airflow and variable thermal power and works with combustion fuels condensate.

BASIC SAFETY INSTRUCTIONS

GENERAL INFORMATION

- 5 -

Bear in mind that if you use products powered trough electric power, gas, etc., you should comply with some basic rules,

such as:

Children and non-assisted disabled persons should not use the air treatment unit.

It is forbidden to activate electric devices or appliances, such as circuit breakers, domestic appliances etc. if you notice a smell of fuel or unburnt

products. In this case:

•

Open the doors and windows to ventilate the room;

•

Close the fuel supply device;

•

Call the Technical Assistance Service for quick intervention, or contact professionally qualified personnel.

It is forbidden to touch the appliance barefoot and with wet limbs.

It is forbidden to perform any cleaning and maintenance operations before disconnecting the appliance from the power supply by turning the

system’s master switch to “OFF”, and before shutting off the fuel.

It is forbidden to modify safety or control systems without the authorisation and the instru ctions of the Manufacturer of the appliance.

It is forbidden to pull, detach, twist the power cables from the appliance, even if it is disconnected from the power supply.

It is forbidden to open the doors providing access to the interior of the appliance before turning the system’s master switch to “OFF”.

It is forbidden to dump, abandon or leave the packaging materials (cardboard, staples, plastic bags etc.) within the children ’s reach, as they

could be a potential source of hazard.

It is forbidden to install the appliance near flammable material or in rooms characterised by the presence of aggressive atmospheres.

It is forbidden to put any objects on the equipment or insert them into the cover grid or into the fuel products discharge pi pes.

It is forbidden to touch the exhaust duct for combustion products, as during normal operation it may reach high temperatures, hazardou s by

contact.

It is forbidden to use adapters, multiple jacks and extensions for connecting the appliance.

It is forbidden to install the equipment beyond its operational and functioning limits indicated in this manual.

The warm air heater shall not be directly installed in small areas lacking proper ventilation, since the air intake might

cause a remarkable depression within the room, causing serious problems

.

DISPOSAL INFORMATION

Disposal of the appliance must be done by an authorized company and in compliance with the

Local and Current Laws.

Before giving the waste to the Authorized Collection Centers, the various materials that compose

it must be dismantled and separated:

•ferrous materials;

•aluminum;

•electric wire;

•seals;

•insulating materials;

•plastic materials;

•electronic boards.

GENERAL INFORMATION

- 6 -

DESCRIPTION

The air treatment unit essentially represents a thermal group that exchanges the combustion products of a

forced-air gas burner with an air flow generated by a group of highly efficient fans.

The air to be heated is sucked by the latter and when it touches the hot surfaces of the heat exchanger, the

air temperature rises; the air can be distributed both directly and through special ducts.

The characteristics of the centrifugal fan make the equipment suitable to be installed on plants needing the

distribution of hot air through ducts or, in general, when it is necessary to have static pressure.

This heating system makes it possible to remarkably reduce the plant costs and ensure savings in operating,

being particularly suitable for discontinuous and occasional use.

The special configuration of the counter-current flow heat exchanger optimises the heat exchange and

makes the equipment to work with condensate.

Besides, the equipment is realised in a way that it can operate with variable heating power and air flow, in

order to adapt to the real heating requirements of the environment.

In summer it is possible to operate the ventilating unit only.

GENERAL DESIGN AND FUNCTIONAL CHARACTERISTICS:

Heat exchanger:

It is made of a welded steel sheet, easy accessible for cleaning and maintenance. It is made up of:

•Combustion chamber made of AISI 430 STAINLESS STEEL, with a low thermal load, with

ovoidal shape and suitable volume.

•Patented, modular exchange elements of AISI 304 STAINLESS STEEL, wide surface, with

whirlpooling marks and counter-current position, in order to optimize the thermal exchange. The

exchange elements are inclined to facilitate the drainage of combustion product condensate.

•Exhaust manifold of AISI 304 STAINLESS STEEL, with shutters for inspection.

Supporting frame:

The supporting frame is made of press-folded, powder-painted and galvanised steel.

The mitre joints are made of strong and die-cast aluminium and are fully designed by the Manufacturer.

Closing panels:

The closing panels are made of coated galvanised steel or of pre-coated sheets; they are thermally insulated

with a mineral fibre mat, and are provided with galvanised counter-panel sheets. These panels can be

removed to perform the ordinary internal inspection.

Ventilation unit

The unit is made up of a centrifugal fan with backward blades and low noise emission and high efficiency;

they are powered by an electric motor connected by means of a belts and pulleys driven transmission

system, which provides this product with high reliability of the plant it is to be used with.

“LM” safety thermostat:

The air treatment unit is equipped with a safety thermostat whose sensors is placed on the air outlet. It

stops the burner if the air is anomalously overheated. It has to be manually reset, after removing the cause

that has caused its intervention.

GENERAL INFORMATION

- 7 -

“TR” Safety thermostat :

The air treatment unit is equipped with a safety thermostat whose sensor is placed on the air outlet. It stops

the burner if the air is anomalously overheated It has to be manually reset, after restoring normal operating

conditions.

“FAN”function:

To adapt the machine to the air treatment unit of pressure-static structures, the fan group operates

continuously.

Smoke exhaust opening

The equipment is fitted with a circular opening, to which the combustion products exhaust ducts is safely

connected and fixed. The stove to be used must conform to standards and is to be certified

Condensate drain connector.

Due to the fact that the equipment operates with combustion products condensate, the appliance is fitted

with a threaded condensate drain union to be connected in compliance with the relevant Regulations in

force.

GENERAL INFORMATION

- 8 -

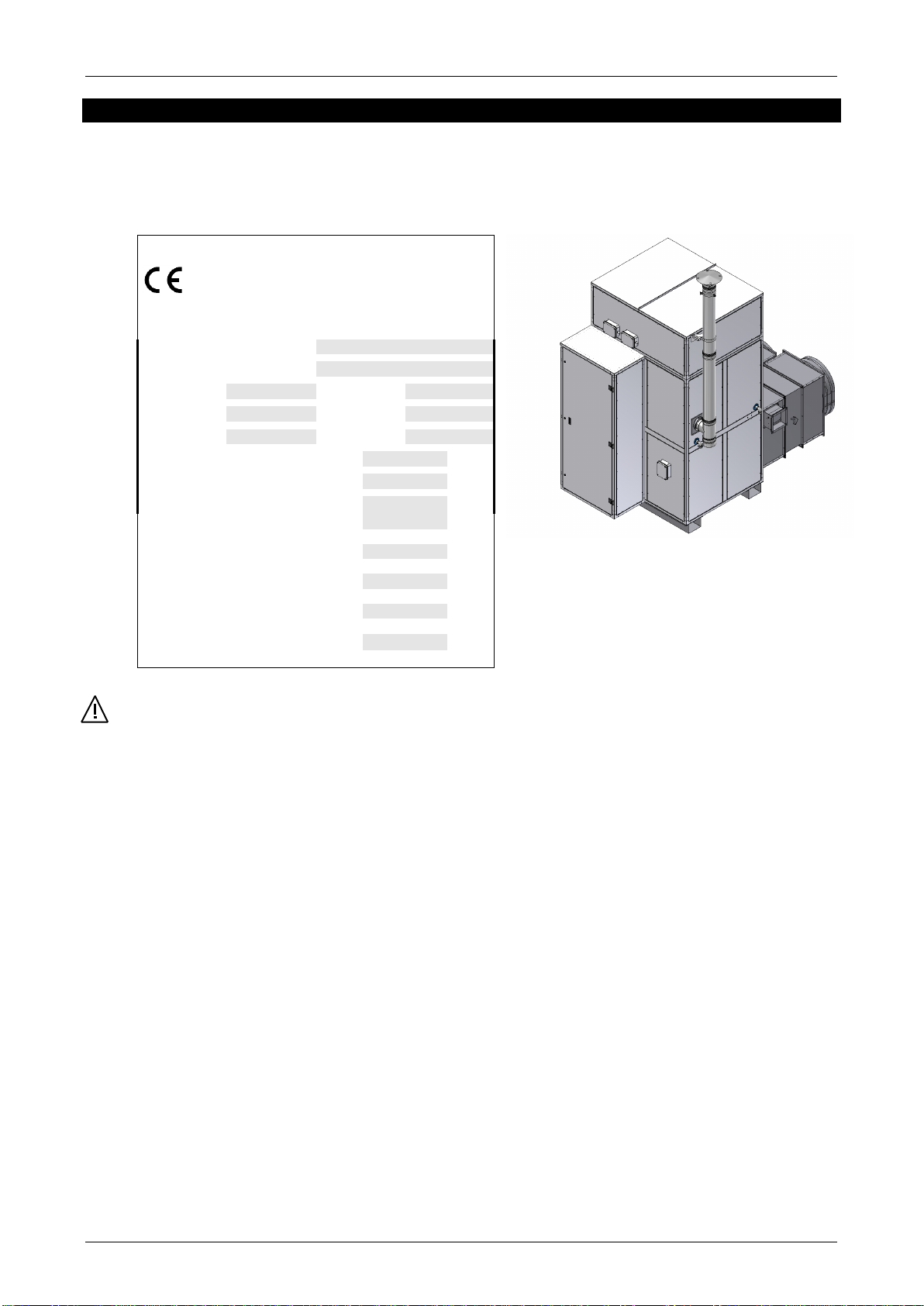

IDENTIFICATION

The warm air heaters can be identified through:

•The Technical Plate, applied to the equipment, and indicating its technical/performance data.

If the plate is lost or damaged, request a duplicate to the Technical Assistance Service,

MANUFACTURER’S IDENTIFICATION DATA

AIR TREATMENT UNIT

Model

Production number

Country

PIN

Category

Codes

Type

Year

Max thermal capacity

kW

Max thermal power

kW

Max air capacity

m³/h

Useful static pressure

Pa

Three-phase power supply

Fan engine power

kW

Fan engine max power

A

Electric protection degree

IP

GENERAL INFORMATION

- 9 -

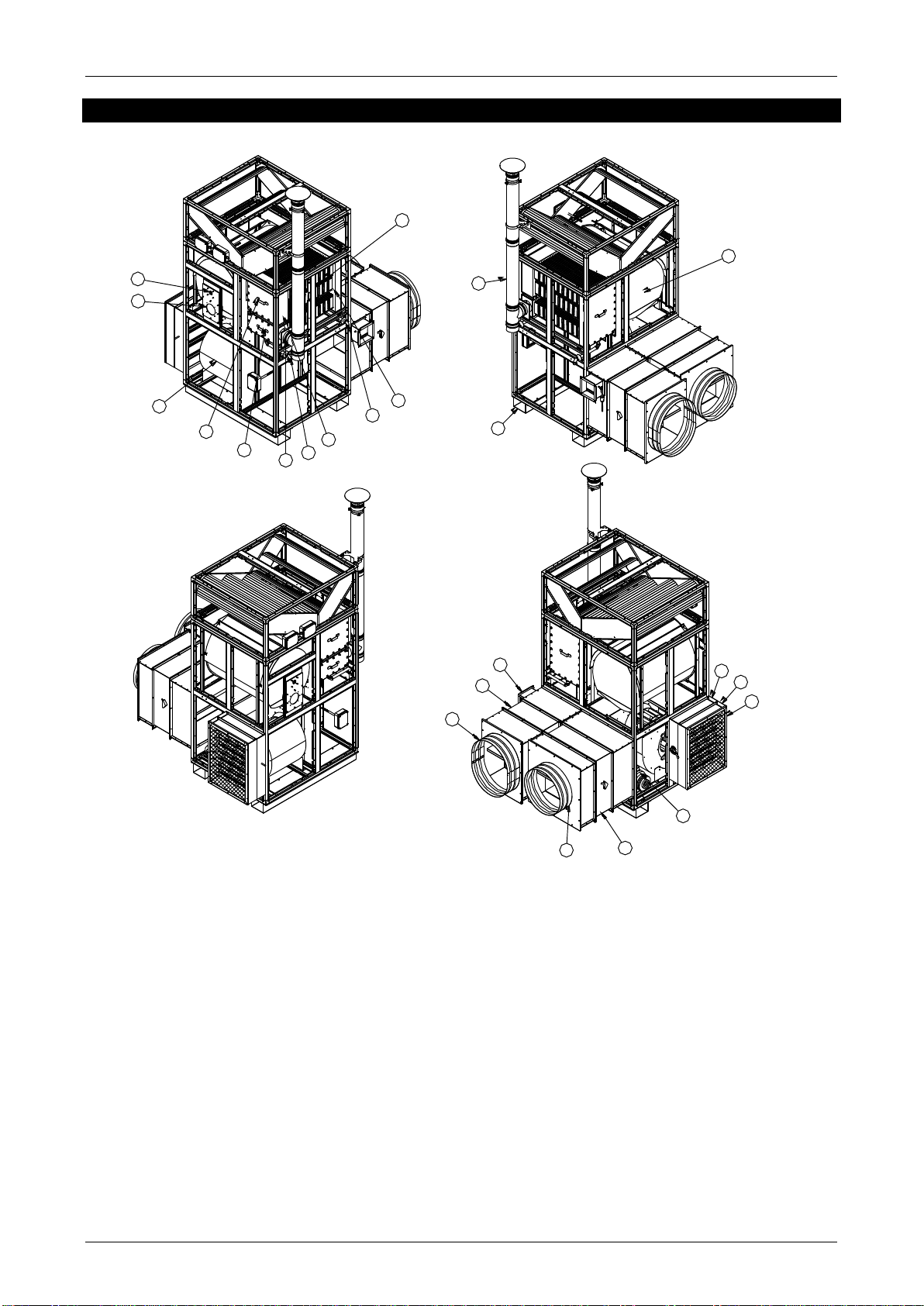

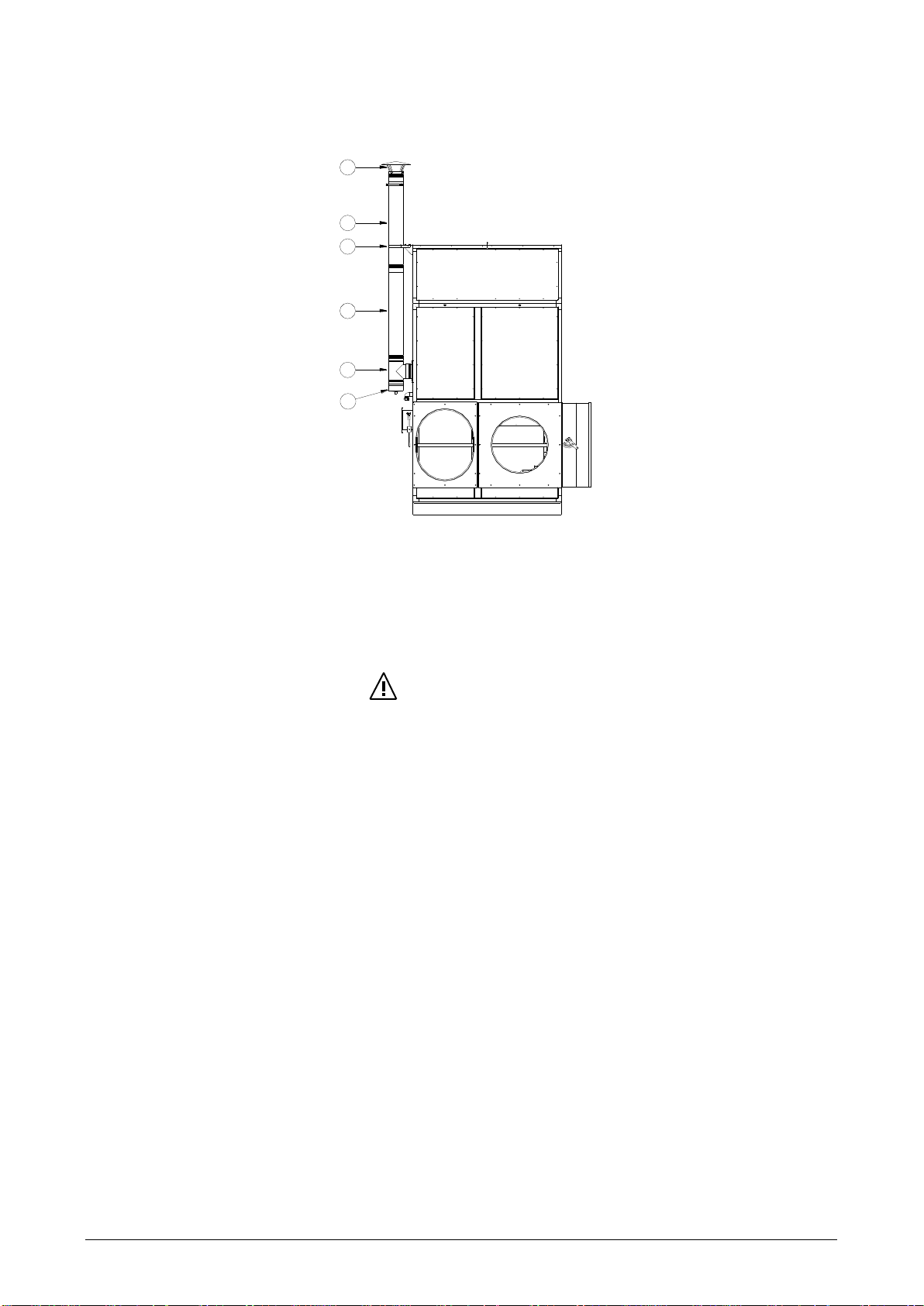

STRUCTURE

1

2

3

4

5

5

6

7

8

9

10

11

11

17

18

20

18

19

15

16

13

12

14

1) Smoke pipe

2) Combustion chamber

3) Front fume manifold

4) Rear fume manifold

5) Heat exchanger inspection shutters

6) Fume exhaust fitting

7) Burner head

8) Flame inspection window

9) Centrifugal fan

10) Fan electric engine

11) Condensate drain fitting

12) Smoke discharge Kit

13) Lower struts

14) Outside air controlling shutter

15) Gravity shutter on outside air

16) Protection net

17) Overpressure shutter

18) Fire protection shutter

19) Recirculation air suction fitting

20) Hot air outlet fitting

Note:

In order to make the internal parts visible, the drawing represents the equipment without the housing of the

burner and electrical panel.

INSTALLATION AND SETTING INSTRUCTIONS

- 10 -

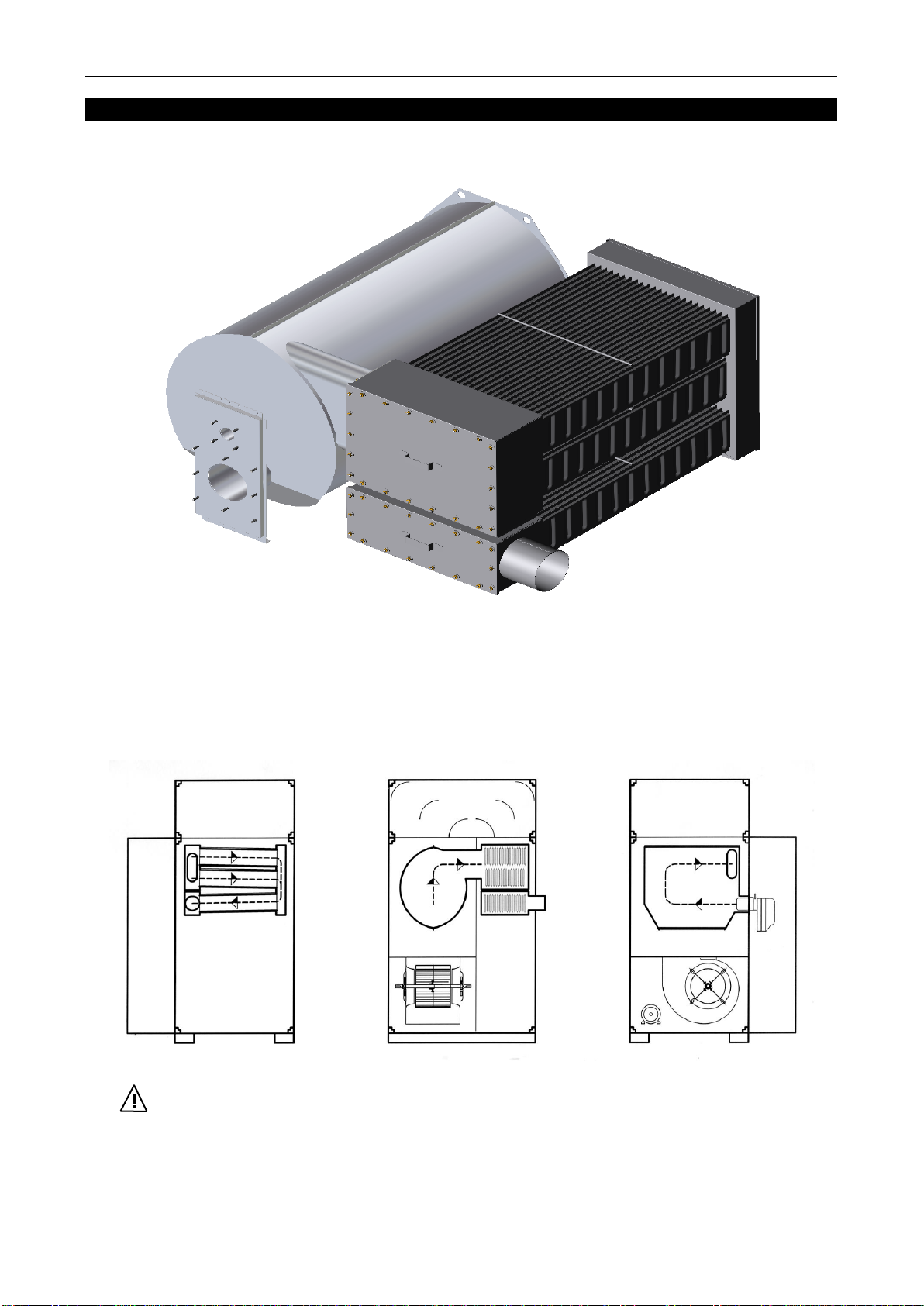

HEAT EXCHANGER SCHEME

Axonometric image of the heat exchanger:

Combustion products

•create an inversion in the combustion chamber;

•are transferred into the first smoke collector and then flow into the first row of exchanging

elements;

•arrive to the second smoke collector and then flow into the second row of exchanging elements;

•are discharged from the equipment through the circular junction.

In order to keep the combustion products speed at an optimal level, the section of the smoke

passage has a decreasing gradient.

The smoke duct elements are slightly inclined to facilitate the condensate drain.

The two fluids (air \ combustion products) are in counter-current.

These are some of the design specifications that make this innovative heat exchanger

extremely efficient.

- 11 -

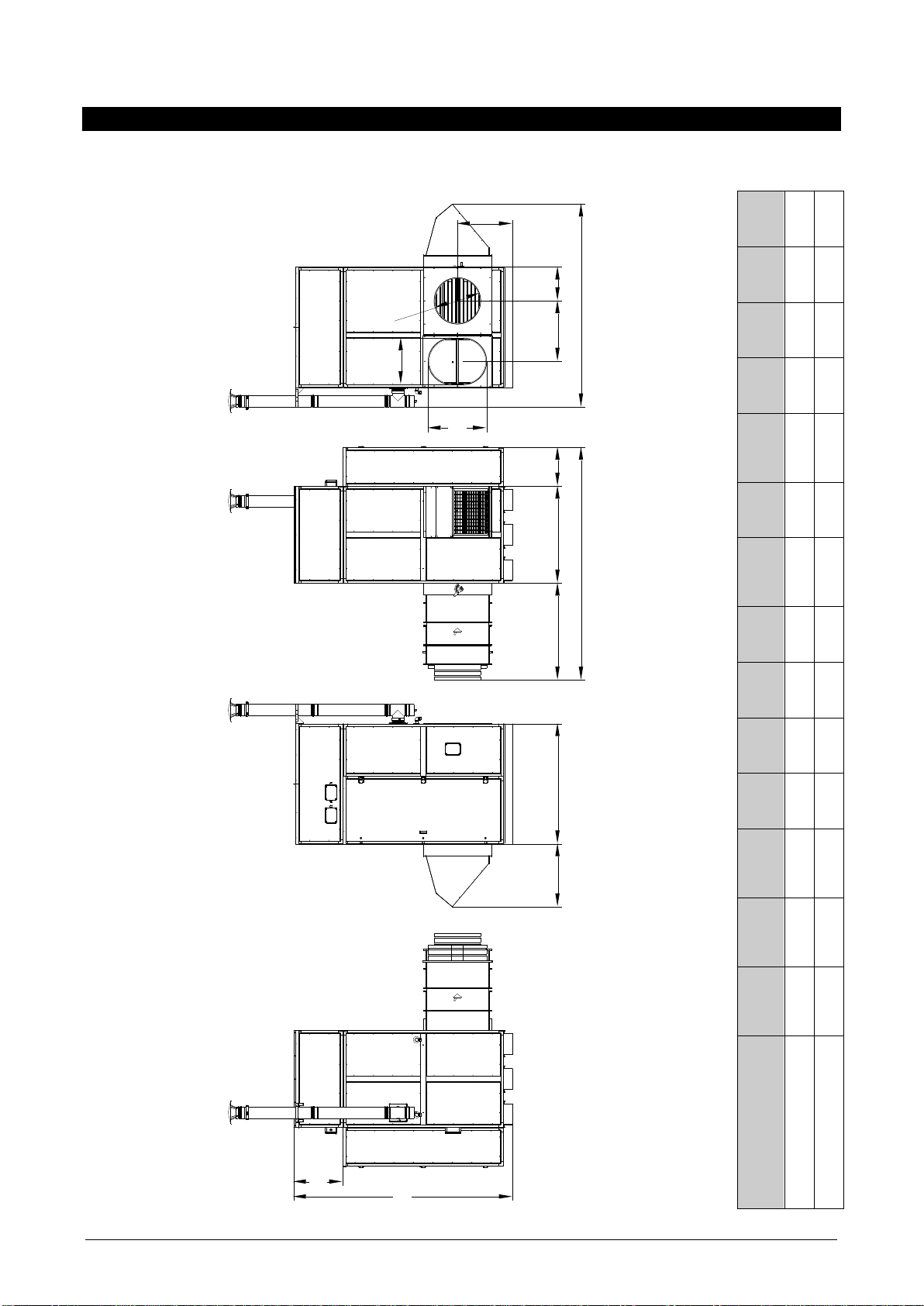

DIMENSIONS AND WEIGHT

I

F

K

M

D

B

1250 C

A

812

G

H

J

E

L

WEIGH

T

(kg)

1200

1500

M

(mm)

600

800

L

(mm)

600

600

K

(mm)

750

914

J

(mm)

2616

2935

I

(mm)

709

559

H

(mm)

2815

2620

G

(mm)

632

651

F

(mm)

435

430

E

(mm)

780

930

D

(mm)

500

700

C

(mm)

3000

3450

B

(mm)

1250

1500

A

(mm)

1550

1800

TYPE

1

2

- 12 -

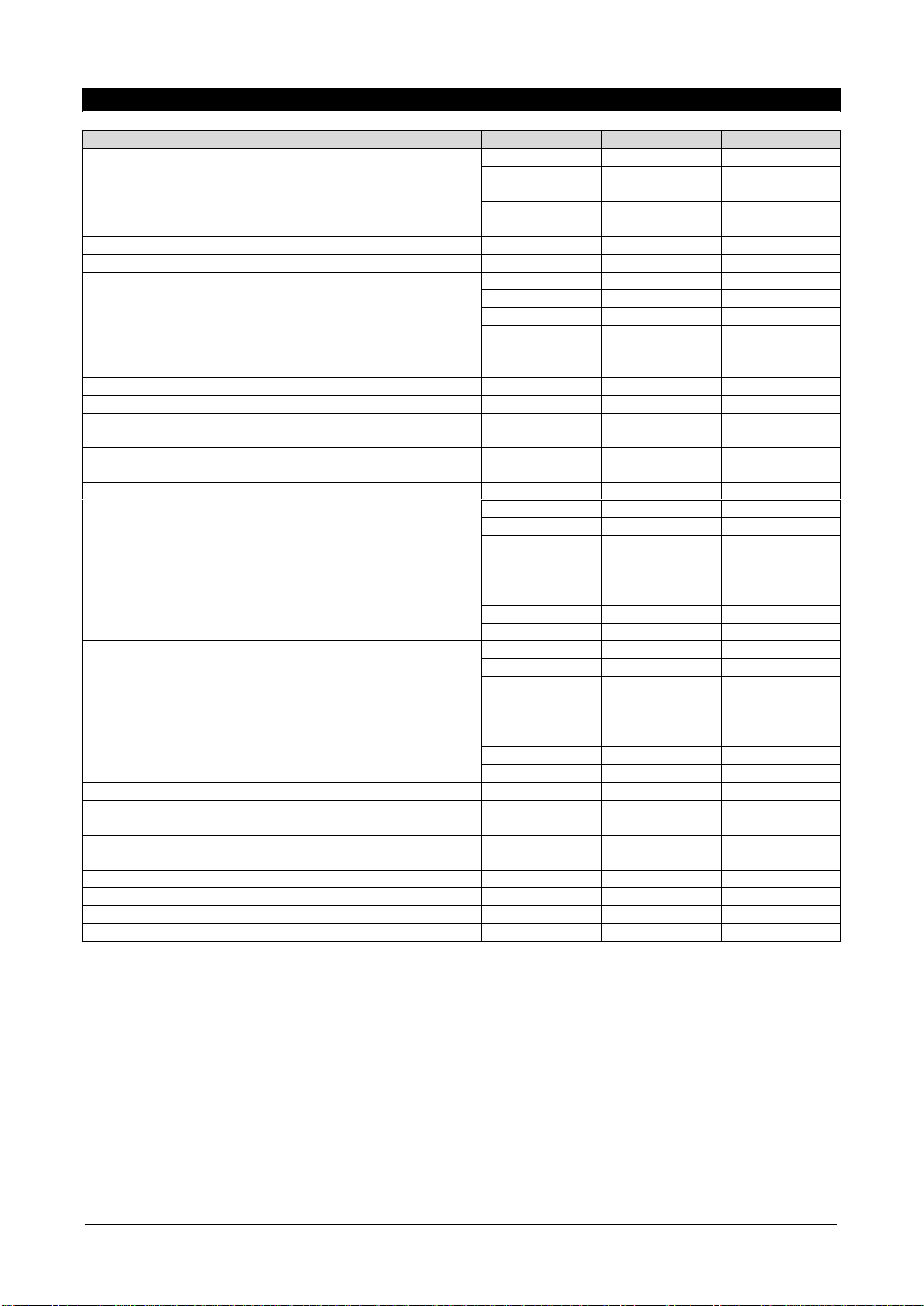

TECHNICAL DATA

TYPE

1

2

MAX NOMINAL THERMAL POWER

kW

152,3

247,5

(burned)

Kcal/h

130.980

212.850

MAX NOMINAL THERMAL POWER

kW

148,2

240,0

(useful)

kcal/h

127.450

206.400

PERFORMANCE AT MAX. THERMAL POWER 1)

%

97,3

96,9

MAX. PRESSURE IN COMBUSTION CHAMBER

mbar

0,6

0,7

GROSS SMOKE TEMPERATURE (2)

°C

80

90

CONSUMPTION AT NOMINAL THERMAL POWER (3)

- G20 methane gas

Nm3/h

16,1

26,2

- G25 methane gas

Nm3/h

18,7

30,5

- G31 propane gas

Nm3/h

6,2

10,1

- G30 butane gas

Nm3/h

4,7

7,7

NOMINAL AIR CAPACITY

m3/h

14.000

23.000

USEFUL NOMINAL STATIC PRESSURE

Pa

150

200

NOMINAL AIR THERMAL GRADIENT (t)

°K

31

31

PRE-CALIBRATION OF THE SAFETY THERMOSTAT (MAN.

RESET)

°C

90

90

PRE-CALIBRATION OF THE SAFETY THERMOSTAT (AUTO.

RESET)

°C

70

70

TREATED AIR FAN

- brand

NICOTRA

NICOTRA

- quantity

N°

1

2

- model

RDH 450 L

ADH 315 L

TREATED AIR FAN ENGINE

- polarity

N°

4

4

- quantity

N°

1

2

- unit electric power

kW

4,0

5,5

- max. design absorbed unit power

A

8,4

11,5

TRASMISSION

Driving pulley (engine)

- model

mod.

PRC 187 2B

PRC 178 2B

- pitch

mm

148180

139171

Driven pulley (fan)

- model

mod.

D 150 2B

D 160 2B

- pitch

mm

150

160

Driving belts

mod.

B 68

SPB 1450 LW

GENERAL ELECTRIC POWER SUPPLY

Three-phase

400V 50Hz 3N

400V 50Hz 3N

RECCOMENDED USE CONDITIONS

- outside air temperature range

°C

-15/+35

-15/+35

- nominal suctioned air temperature

°C

+15

+15

- suctioned air temperature range

°C

-15/+35

-15/+35

NOx CLASS

4

4

DESTINATION COUNTRY

ITALIA

ITALIA

TYPE

B23

B23

CATEGORY

See burner

See burner

1) Referred to a lower heating power (Hi)

2) Referred to a comburent air temperature of +15°C

3) G20 methane gas: Hi = 34,02 MJ/Nm3

G25 methane gas: Hi = 29,25 MJ/Nm3 (not available in Italy)

G31 propane gas: Hi = 88,00 MJ/Nm3

G30 butane gas: Hi = 116,09 MJ/Nm3

- 13 -

INFORMATION REQUIREMENTS 2016/2281

TYPE

1

2

Type of installation:

B23

B23

Type of fuel:

Gassoso

Gassoso

Capacity:

P rated,h

kW

148

240

P min

kW

74

123

Useful efficiency(1):

nom

%

93

92,5

pl

%

95,4

95,4

Electric power consumption:

el max

kW

0,18

0,18

el min

kW

0,18

0,18

el sb

kW

0,01

0,01

Other items:

F env

%

1

1

P ign

kW

-

-

s,flow

%

94

94

s,h

%

86,7

86,6

1) Refferd to the high heating value (Hs):

•Gas : gas G20 (37,78 MJ/Nm³);

Definitions:

P rated,h

Rated heating capacity

P min

Minimum heating capacity

nom

Useful efficiency at rated heating capacity

pl

Useful efficiency at minumum capacity

el max

At rated heating capacity

el min

At minimal capacity

el sb

In standby mode

F env

Envelope loss factor

P ign

Ignition burner power consumption

s,flow

Emission efficiency

s,h

Seasonal space heating energy efficiency

Note:

The data in the table is referred to the high heating value of the fuel (Hs), nominal air flow rate and a 15

mm of mineral wool

- 14 -

PRODUCT RECEIPT

The air treatment unit is supplied together with:

•Document envelope including:

oUser guide

oWarranty certificate

oSpare parts catalogue

oBarcode tags

oCondensate discharge syphon

oLevel switch

MOVEMENT AND TRANSPORT

The machine is used through a forklift:

GENERAL INSTRUCTION TO MOVE AND TRANSPORT THE APPLIANCE

WARNING!

The appliance should be moved by adequately equipped persons and with tools suitable for the appliance

weight.

The machine should be extremely carefully transported and moved, so as to prevent damages to the

machine and dangers for those performing the operation.

While the machine is being transported or moved, do not stay near it.

The forks to be used should be at least as long as the machine width.

A lifting beam (not included in the shipment) must be employed, if belts and ropes are used in the handling,

in order to avoid damaging the equipment structure by the pressure of the latter.

If it is necessary to line up several machines, the stacking index (written on the packaging) should

compulsorily be complied with and the boxes should be lined up so as not create unstable stacks.

We suggest using protection gloves.

INSTALLATION AND SETTING INSTRUCTIONS

- 15 -

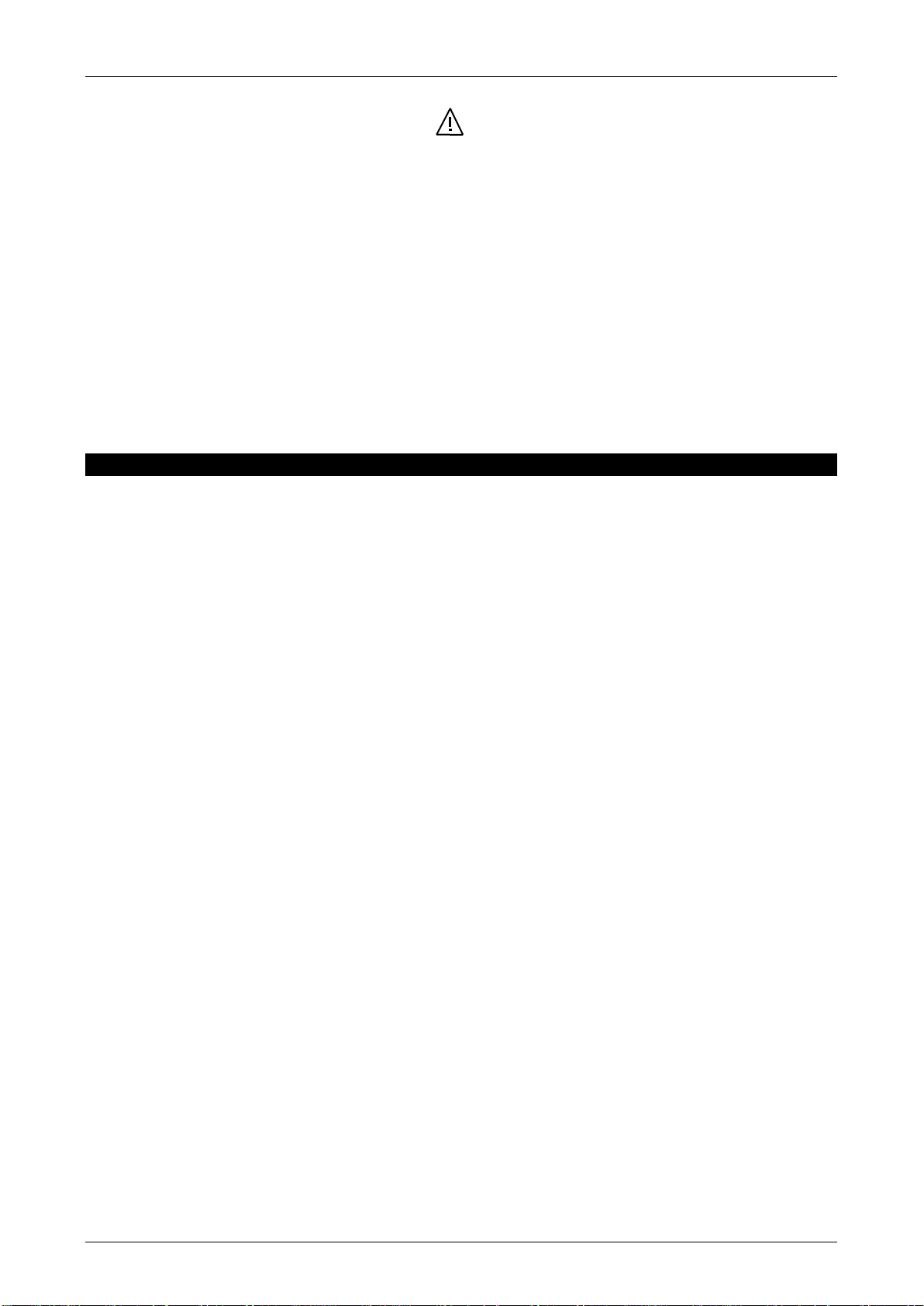

TRANSPORT LOCKS

To prevent damage to the appliance during transportation, some red mechanical locks can be used, limiting

the movement of some internal elements. Their identification and the instructions to remove them are

specified on a self-sticking tag placed on the appliance.

THE LOCKS MUST BE REMOVED BEFORE THE FIRST COMMISSIONING.

POSITION

The installation setting should be defined by the plant designer or by a competent person and it should take

into account the technical needs as well as the relevant laws and regulations in force; specific authorizations

are usually required. (e.g.: regulations concerning city planning, architecture, fire prevention, environmental

pollution, noise level, etc.)

Therefore, we suggest requesting and obtaining the relevant authorizations before installing the machine.

If the appliance is to be installed in sport facilities, specific skills and experience are required

since the following requirements should be met: highest quietness, limited air stratification, air

distribution uniformity, without generating unpleasant currents. If you have any doubt, pleas

ask the Manufacturer to receive the appropriate technical support.

To be properly installed, the air treatment unit should:

•be laid on all the lower frame rang;

•be placed on a flat, non wet surface, capable of bearing its weight;

•be placed on a surface that is high and solid enough to avoid transmission of vibrations to the premises

underneath;

•be placed in compliance with the specified distances so that air can properly flow and that ordinary

cleaning and maintenance operations can be performed;

•be placed in compliance with the specified distance from inflammable substances;

•be easily connected to the gas grid;

•be placed close to a power socket;

•be close to the duct which discharges the combustion products out of the premises;

•be such that all the maintenance and control operations can be easily performed;

•be fitted with the ventilation openings required by the relevant regulations.

We suggest not installing the machine :

•in places with aggressive atmosphere;

•in narrow places where the heater noise level can be magnified by reverberation and resonance;

•in corners where leaves can deposit or any other materials might obstruct the air opening, thus

decreasing the heater efficiency;

•in places with an higher pressure;

•in places with a lower pressure;

INSTALLATION AND SETTING INSTRUCTIONS

- 16 -

CLEREANCE AREA

The machine shall be easily and safely reached without needing special equipment (ladders -

movable platforms -etc.). Around the machine, minimum distances shall be complied with so that the

control and/or maintenance operations can be performed and that no obstacles block the air flow.

WARNING!

Any Laws or specific regulations requirements (e.g. fire prevention) shall be complied with. Consult the plant

designer.

FUEL CONNECTION

The machine should be connected to the gas (GPL or butane) network by qualified personnel in compliance

with installation instruction.

For appliances fuelled by gas, we recommend installing a leakage detector controlling an electric valve that

stops the gas supply if any leakage is detected.

.

SMOKE EXHAUST PIPE

The height of the smoke exhaust fitting is as mentioned in the figure hereunder:

P

N

O

TYPE

N

(mm)

O

(mm)

P

(mm)

1

150

692

1474

2

180

879

1265

The smoke duct and chimney flue connection must be made in conformity with the Standards and

Legislations in force; they are to be made with rigid metal ducts, resistant to combustion mechanical,

thermal, and chemical stress

The smoke ducts connecting the equipment to the chimney flues must be easy to

dismantle; this is an indispensable condition to allow the checking and internal cleaning

of the heat exchanger.

- 17 -

Connection of the air treatment unit to the flue:

2

1

3

5

6

4

1. Condensate drain fitting.

2. T-shape joint

3. Flue.

4. Bracket.

5. Flue.

6. Terminal.

WARNING!

All stove components must be CEE certified.

There must be a condensate drain at the lowest part of the smoke duct (see diagram),

in order to avoid condensate backflow from the chimney flue to the air treatment unit.

The total weight of the smoke exhaust pipe must not weigh on the appliance.

It is mandatory to install a device (ex. level switch), which stops burner in case of

accidental clog of the condensate drain (see also the “condensate drain” paragraph).

Moreover, we recommend:

•avoid or however limit horizontal sections which in all cases should have a rising

gradient;

•use ducts having a smooth internal surface, made of material resistant to the flue gas

thermal and chemical stresses, with equal or higher diameter than the one of the

connection on the appliance;

•avoid tight curves and section reduction;

•have a cockpit for the combustion products sampling and analysis;

•adequately connect the smoke exhaust duct;

•have a suitable terminal to avoid rainwater infiltration into the equipment, and

simultaneously, to avoid high loss of load.

INSTALLATION AND SETTING INSTRUCTIONS

- 18 -

The chimney flue must guarantee minimum depression, as provided for by Technical Standards in force,

taking into consideration that the pressure is “zero” at the joining point with the smoke duct.

Non-insulated exhaust ducts are a source of potential hazard.

Inadequate or wrongly sized chimney flues or smoke ducts may amplify the combustion noise and negatively

influence the combustion parameters.

The joints must be sealed with materials resistant to thermal and chemical stress caused by combustion

products.

Crossings through walls and/or roofs, if any, must be performed up to standard, in order to avoid hazards of

fire and/or water infiltration.

CONDENSATE DRAIN CONNECTION

The condensate drain system should comply with the relevant European, National and Local Standards, and

the need for a neutralisation treatment should be checked.

We provide the following instructions, for information purposes:

•the condensate drain system should be dimensioned and made in a such a way that liquids can flow out,

without leaking;

•all condensate drain unions should be independently connected, and they should not be combined in one

duct;

•smokes must be prevented from being discharged through the condensate drain system; therefore a

syphon should compulsorily be installed.

•Condensate that may accumulate in the chimney flue, must never be permitted to backflow into the

equipment. A specific condensate drain must be created;

•The system should have a proper gradient. Pipes should not be installed at the same level of the machine

nor in counter-inclination.

•In case of connection to the domestic sewage net, a suitable trap or equivalent device is to be used in

order to prevent any backflow from the sewage net;

•The system must be made in a way as to prevent the freezing of the liquids it contains, in all

expected operating conditions;

•The system is to be provided with a device that stops the burner in case of accidental clog of the

condensate drain system, in order to avoid hazard situations or unhealthy combustion;

INSTALLATION AND SETTING INSTRUCTIONS

- 19 -

Position of condensate drain fittings –air treatment unit:

R

Q

S

1" GAS

TYPE

Q

(mm)

R

(mm)

S

(mm)

1

120

1.235

968

2

138

999

1.185

The air treatment unit is provided with two condensate drain fittings, which must be connected to the drain

system. The fittings must never be clogged.

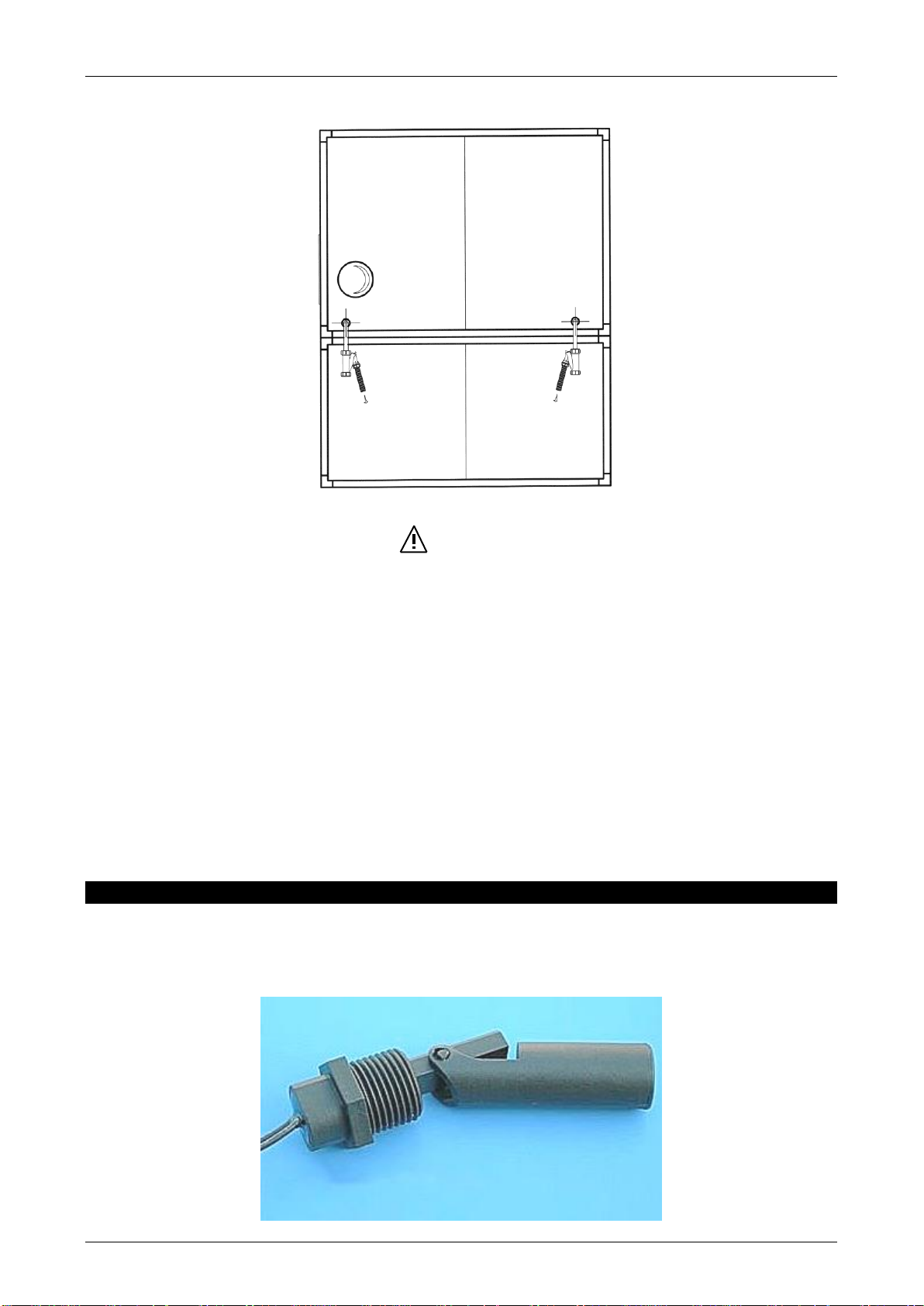

CONDENSATE DRAIN SYPHON (SUPPLIED WITH THE APPLIANCE)

In order to prevent leakage of combustion products from the condensate drain and the backflow of sewage

fumes, the siphons should be installed (one for each condensate drain system)

Condensate drain syphon image and section:

INSTALLATION AND SETTING INSTRUCTIONS

- 20 -

Connection to the condensate drain fittings

WARNING

Pipes with external diameter ranging between 24 and 30 mm are to be used in connecting the air

treatment unit to the syphon. The head must not be smaller than 25 mm.

The total weight of the condensate drain system must not weigh on the equipment, and must be

suitably and separately mounted.

The configuration of the condensate drain system must facilitate the removal of the inspection panels.

The condensate drain system must be easily disassembled to perform inspection and/or maintenance

operations.

The two-condensate drain systems of the unit should be separately connected.

LEVEL SWITCH (PROVIDED WITH THE APPLIANCE )

A level switch must compulsorily be installed in the chimney flue “T”-shaped fitting, in order to stop the

burner in case of accidental flooding of the heat exchanger (ex. in case of failure in the condensate drain

system)

condensate

drain

condensate

drain

This manual suits for next models

1

Table of contents