1

CONTENTS PAGE

PRECAUTIONS........................................................................... 1

ACCESSORY .............................................................................. 1

INSTALLATION ........................................................................... 2

WIRING ....................................................................................... 6

SPECIFICATION PARAMETER ................................................ 10

KRE APPLICATION................................................................... 11

MAINTENANCE AND UPKEEP ................................................ 11

TRAIL RUN................................................................................ 11

ERP INFORMATION. ................................................................ 12

1. PRECAUTIONS

To prevent injury to the user or other people and property

damage, the following instructions must be followed. Incorrect

operation due to ignoring of instructions may cause harm or

damage. The appliance should be installed by a professional in

accordance with the specied instructions.

The safety precautions listed here are divided into two categories. In

either case, important safety informations are listed which must be

read carefully.

WARNING

Failure to observe a warning may cause electric shock,

re hazard or personal injury

CAUTION

Failure to observe a caution may cause injury or damage

to the equipment.

WARNING

● Ask your dealer or qualied personnel to carry out installation

work. Do not try to install the machine by. Incorrect installation

may result in leakage, electric shocks or re.

● Installation should be done by following the installation manual

and no changes should be made to the unit. Incorrect installation

may cause leakage, electric shock, or re. If the KRE falls, it may

cause damage and injury.

● Install the unit on a foundation that is strong enough to withstand

the weight of the unit.

A foundation of insufcient strength may result in the equipment

falling and causing injuries.

● Do not allow exhaust air to enter the outside air inlet.

This may cause the air of the room to become contaminated,

harming the health.

● Locate the outside air intake vent so that it does not take in

exhaust air which contains combustion air, etc.

Incorrect installation may cause a loss of oxygen in the room,

leading to serious accidents.

● Make sure that a separate power supply circuit is provided for

this unit and that all electrical work is carried out by qualied

personnel according to local laws and regulations and this instal-

lation manual.

Insufcient power capacity, improper electrical works, or incorrect

wiring may cause electric shock or re.

● Make sure Earth Leakage Breaker is the type of all poles drop-out.

● Be sure to ground.

Do not connect the ground wire to gas or water pipes, lightning rod

or a telephone ground wire.

Incomplete grounding may result in electric shocks.

● Make sure that all wiring is secured, the specied wires are used,

and no external forces act on the terminal connections or wires.

Improper connections or installation may result in overheating or

fore.

● When wiring the power supply and connecting the remote control-

ler wiring and transmission wiring, position the wires so that the

electric parts box lid can be securely fastened.

Improper positioning of the electric parts box lid may result in

electric shocks, re or the terminals overheating.

CAUTION

● Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric

shocks.

● Install the indoor and outdoor units, power supply wiring and

connecting wires at least 1 meter away from television or radio

in order to prevent image interference or noise. (Depending on

the radio waves, a distance of 1 meter may not be sufcient

enough to eliminate the noise.)

● Install the two outdoor ducts with down slope to prevent rainwa-

ter from entering the unit.

If this is not done completely, water may enter the building, may

damage furniture, etc.

● Insulate the duct and the wall electrically when a metal duct is to

be penetrated through the metal lattice and wire lattice or metal

lining of a wooden structure wall.

Improper duct work may cause electric shocks or short circuits.

● Make sure that a snow protection measure is taken. If no pro-

tection snow may enter through the outdoor ducts, and cause

damaging furniture and electric shock and re.

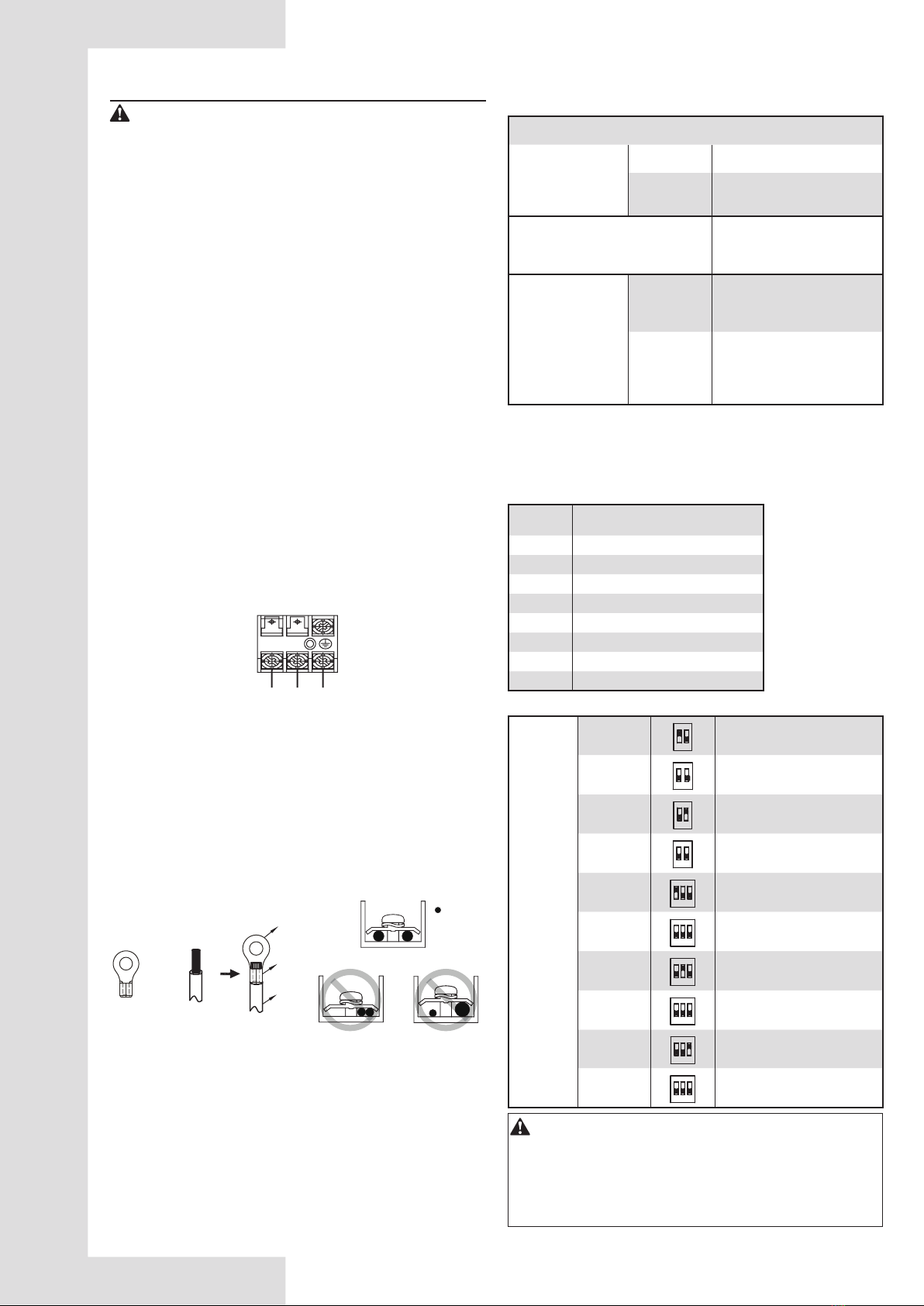

2. ACCESSORY

Table 2-1

Name Qty. Shape Purpose

Installation and

owner’s manual 1 This manual must be delivered to the

customer

Notes: Wired controller should be purchased separately.

Prepare the following on site.

Table 2-2

Name Purpose

PVC drain pipe

For connecting unit’s drain pipe, which length is

selected according to your actual requirement

(Only required for Model 1500 and 2000

Damper For vibration damping, when lift the unit.