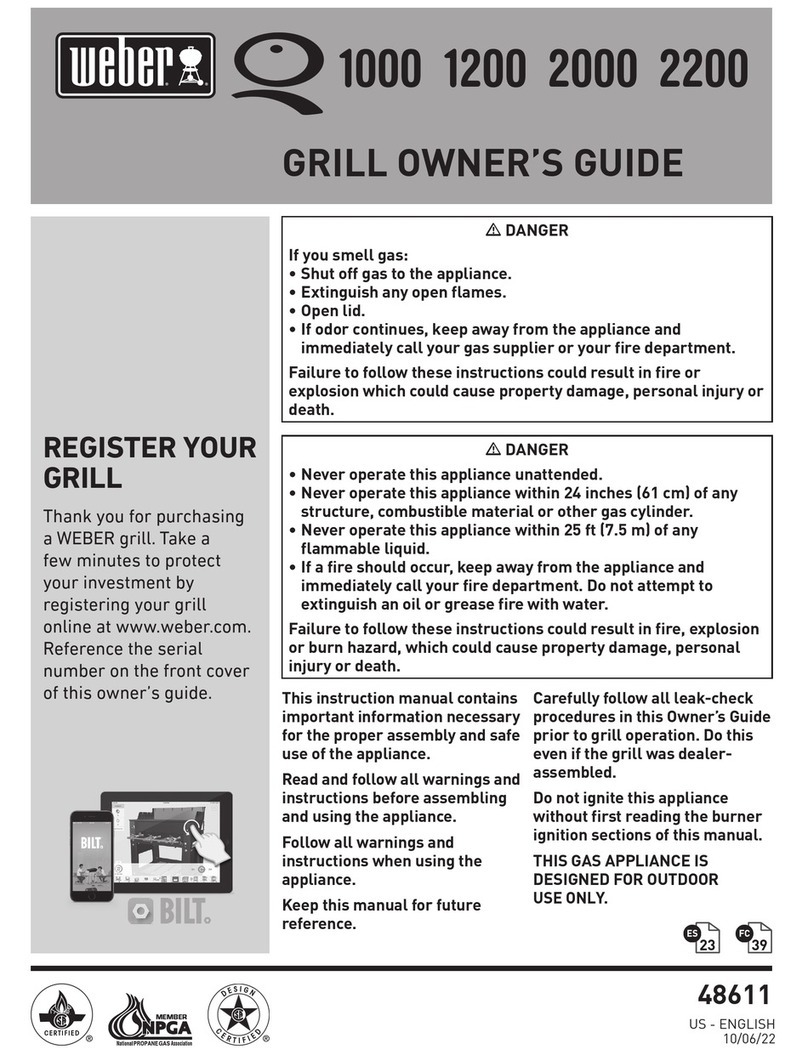

Tecnoinox GD4FG9 User manual

GD4FG9

FREESTANDING GAS GRILL WITH WATER AND CA ST IRON GRID ON CLOSED

CABINET

333112

CODE

DESCRIPTION

MODEL

03-03-2023 12:30

EN - 1

5410.495.01

Part 1

Installation

DIRECT OR LAVA STONE GRILL

General warnings

The appliance described in this manual was

manufactured in compliance with the

standards. This appliance is intended only for

cooking food professionally and must be used

by qualified personnel. Any other use is

improper.

The appliance must be used only under

surveillance. Moreover, the appliance should

be checked once a year by a qualified

technician.

Switch the appliance off in the event of a fault

or malfunction.

Care must be taken when using the appliance because the tank and the cooking surfaces are

very hot.

The appliance must be installed, connected and serviced by qualified personnel according to

the regulations and directives in force in the country where it is installed, as well

as the

instructions in this manual.

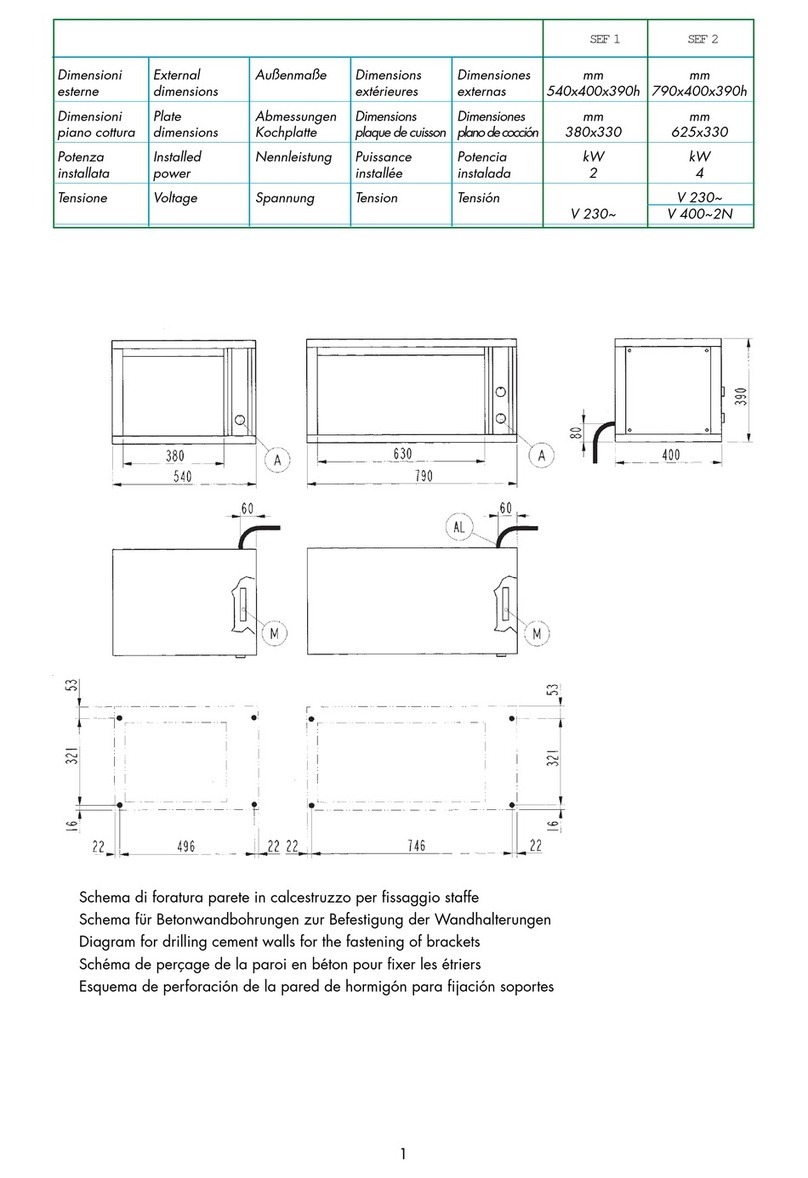

Characteristics of the appliance

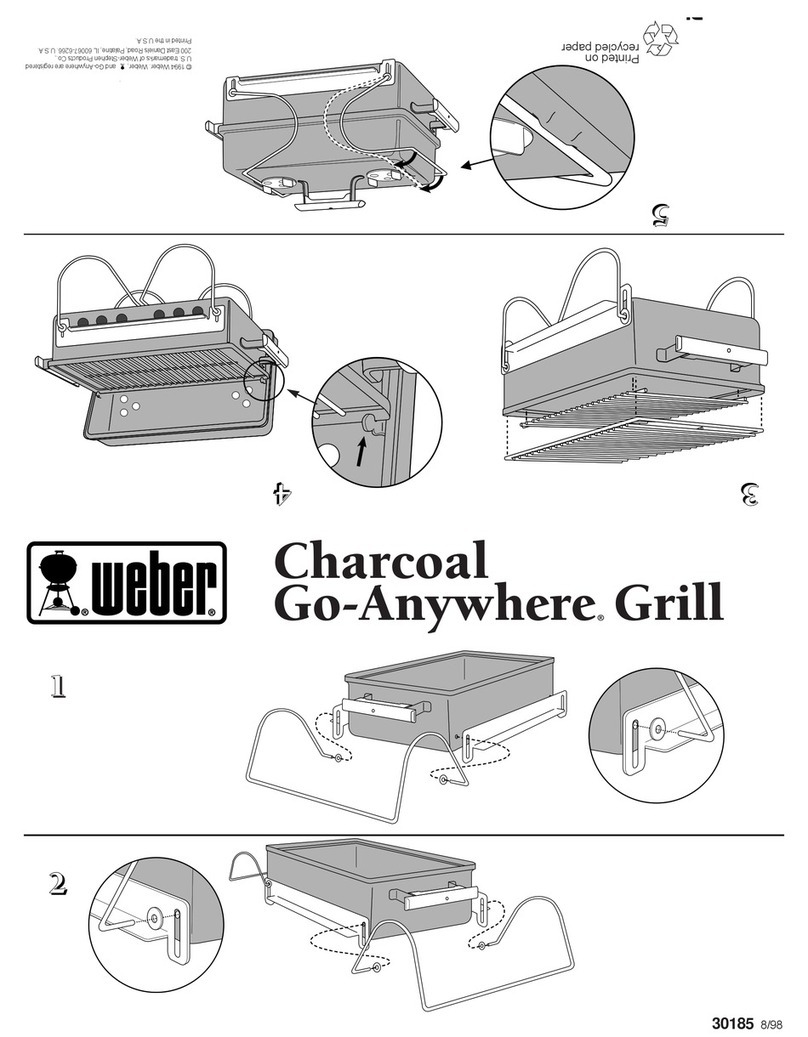

The serial number plate “T1” (fig.1) is behind the control panel

(inside the appliance). This plate contains the following data:

The supplementary plate is also made of self-adhesive polyester

and is affixed near the data plate; it contains all information

regarding the appliance arrangement.

The supplementary plate is also made of self-adhesive polyester

and is affixed near the data plate; it contains all information

regarding the appliance arrangement.

Appliances measuring 35 cm or 40 cm wide are equipped with a

burner and a gas connection fitting. Appliances measuring 70 cm

or 80 cm wide are equipped with two burners and a gas

connection fitting.

The gas distribution network fitting meets EN10226-1 standards

and is situated on the back of the appliance. The appliance

structure is made of stainless steel and the burners are made of

steel.

All models have height-adjustable feet.

The main gas pipe is made of galvanised steel. The pipes between

the shut-off cock and the burner are made of copper.

Place a shut-off valve between the

appliance and the gas distribution

network.

EN - 2

5410.495.01

Connecting to the distribution network

Before you install the appliance, make

sure that the gas supp

lier company has

authorised the installation,

subsequently compare the appliance

data (data plate) with the local supply.

Remove the appliance packaging as well as the protective plastic

sheet. If necessary, remove any glue with a suitable solvent. For

information on disposing of the packaging, please consult the

local regulations in force (for more details, please refer to the

chapter “ECOLOGY AND THE ENVIRONMENT”. Prior to connecting

the unit to the gas network, check the data plate to see if the unit

has been set and tested for the type of gas available. If the gas

type indicated on the data plate is not the same as that supplied,

please refer to the section “CONVERSION AND ADAPTATION”.

Connect the appliance to the gas distribution network using

metal pipes with a suitable diameter and interposing an

approved shut-off valve. Flexible pipes can be used, provided that

they are made of stainless steel in compliance with the

regulations in force. When installing the appliance, all the

regulations in force must be observed such as

Safety standards.

Regional and/or local regulations such as building regulations.

Accident-prevention regulations in force.

Fire-prevention regulations.

Applicable IEC regulations (only in Italy).

We recommend installing the appliance in a well-ventilated

environment, or under an extractor hood in order to remove the

fumes or steam produced during cooking. The appliance has an

equipotential earth terminal at the back “ ” (fig.1). The appliance

can be installed as a standalone unit or in combination with other

appliances. Keep a minimum distance of 80 mm between the

appliance and any walls made of flammable material, partitions,

kitchen furniture or adjacent equipment. The adjacent surfaces

must be covered with non-combustible heat-insulating material.

Once the appliance is installed, check the seal of the fittings. To

detect any leaks, use non-corrosive foam-based products such as

a leak-detection spray.

Do not use naked flames during the leak test.

The manufacturer is not responsible for damage resulting from failure to comply with the

installation and use instructions or improper use. Moreover, the manufacturer is not

responsible for connections made that do not comply with the regulations in force and fire-

prevention provisions.

Evacuating unburned gases

This appliance belongs to construction type classification A1, therefore connection to a flue is not necessary.

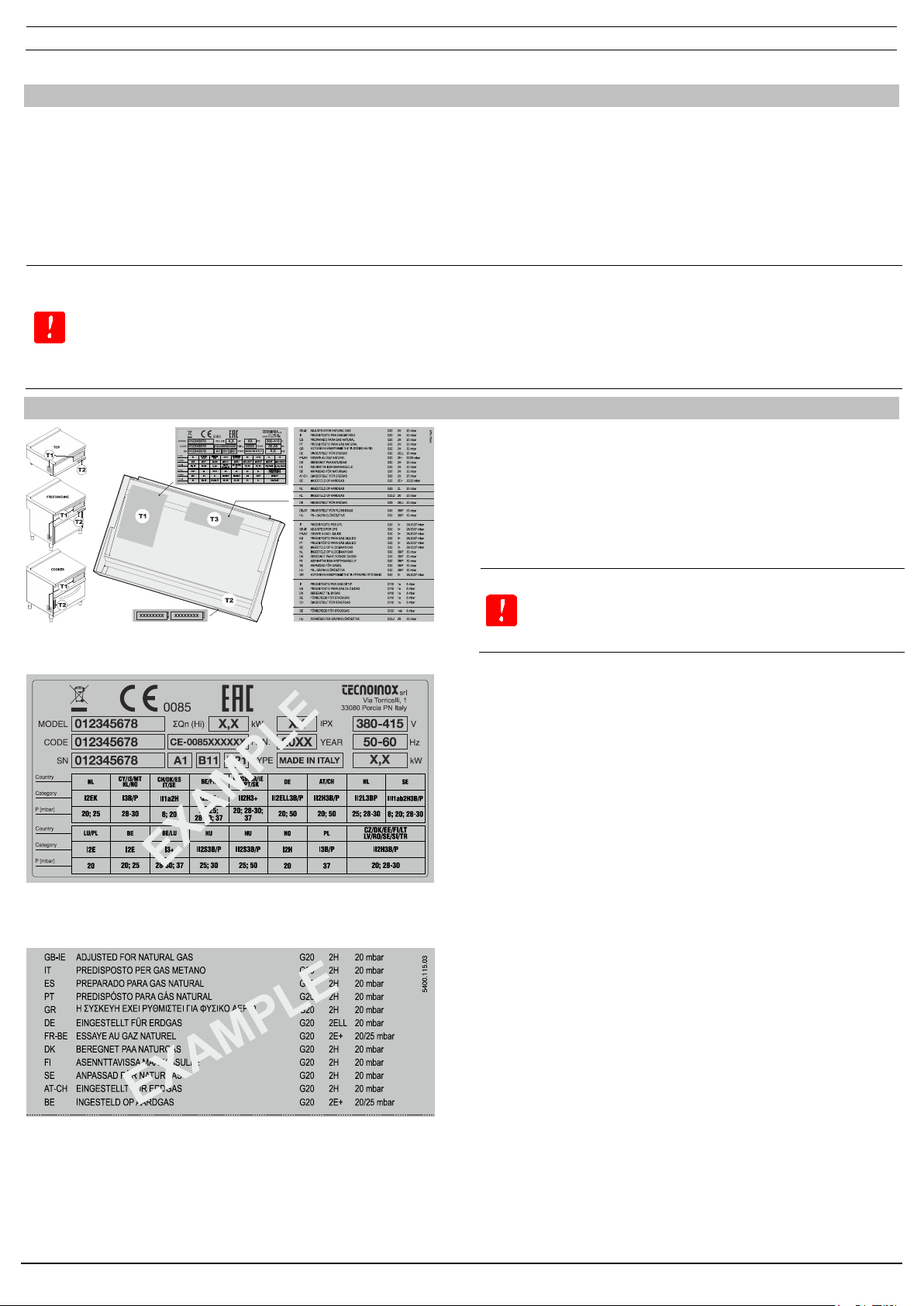

Checking the pressure

The mains pressure must comply with the

values reported in the nozzle table

according to the type of gas supplied.

shown above, please inform your utility company. Do not start up

the appliance until the cause has been found and the problem

solved.

The distribution network pressure can be taken using a U-tube

manometer (min. value 0.1 mbar), connected to the pressure

outlet at the base of the appliance “P” (fig.6).

1. Remove the screw and sealing washer “Y” (fig.6) from the

pressure outlet and connect the manometer.

2. Turn the appliance on following the enclosed instructions

and check that the pressure is within the permitted pressure

range.

3. Disconnect the manometer and replace the screw “Y” (fig.6)

and the sealing washer in the pressure outlet.

EN - 3

5410.495.01

Part 2

Conversion and adaptation

Changing the gas supply - Conversion

If the gas supply to the room where the appliance is to

be installed is different from the gas it is set up for, the

appliance must be converted from one type of gas to

another, e.g. from natural gas to LPG. In this case, the

nozzles of the main burner, the by-pass and the pilot

light need to be changed.

All the nozzles are marked with a number that indicates the

diameter in 1/100, and are supplied in a bag.

After each conversion or adaptation, the appliance must

undergo an operating test and the supplementary plate

must be updated according to the conversion or

adaptation carried out.

All appliance connection, installation and maintenance operations must only be carried out by

qualified technicians and in compliance with all applicable regulations.

For further details refer to the nozzle table.

Replacing the nozzles and adjusting the air

BURNER:

Detach the knobs.

Remove the control panel by unscrewing the fixing

screws at the bottom.

Replace the nozzles (fig.5) with suitable ones for the

new type of gas indicated in the nozzles table section

“Technical data”.

ADJUSTING THE AIRFLOW:

Unscrew the fixing screw on the primary air adjustment

bush.

Move the bush the distance “H” (fig.7). indicated in the

nozzles table

Block the bush by tightening its fixing screw. PILOT:

Unscrew and remove the closing nut (fig.3).

Replace or adjust the pilot nozzle “D” (fig.3) as per the

indications in the nozzles table.

Refit the closing nut.

MINIMUM:

Replace or adjust the minimum nozzle “Um” (fig.6) as

indicated in the nozzles table.

Reassemble the panel and the knobs.

EN - 4

5410.495.01

Part 3

Use

Fat recovery drawer

Before operating the appliance and

starting cooking, always fill any recovery

tank(s) “V

” (fig.2) with clean water. Do

not use the appliance with empty tanks;

the tanks must always hold a minimum

of 2 litres of water.

After cooking or at the end of the day

and only after the appliance has cooled

down, empty the tanks “V” (fig.2).

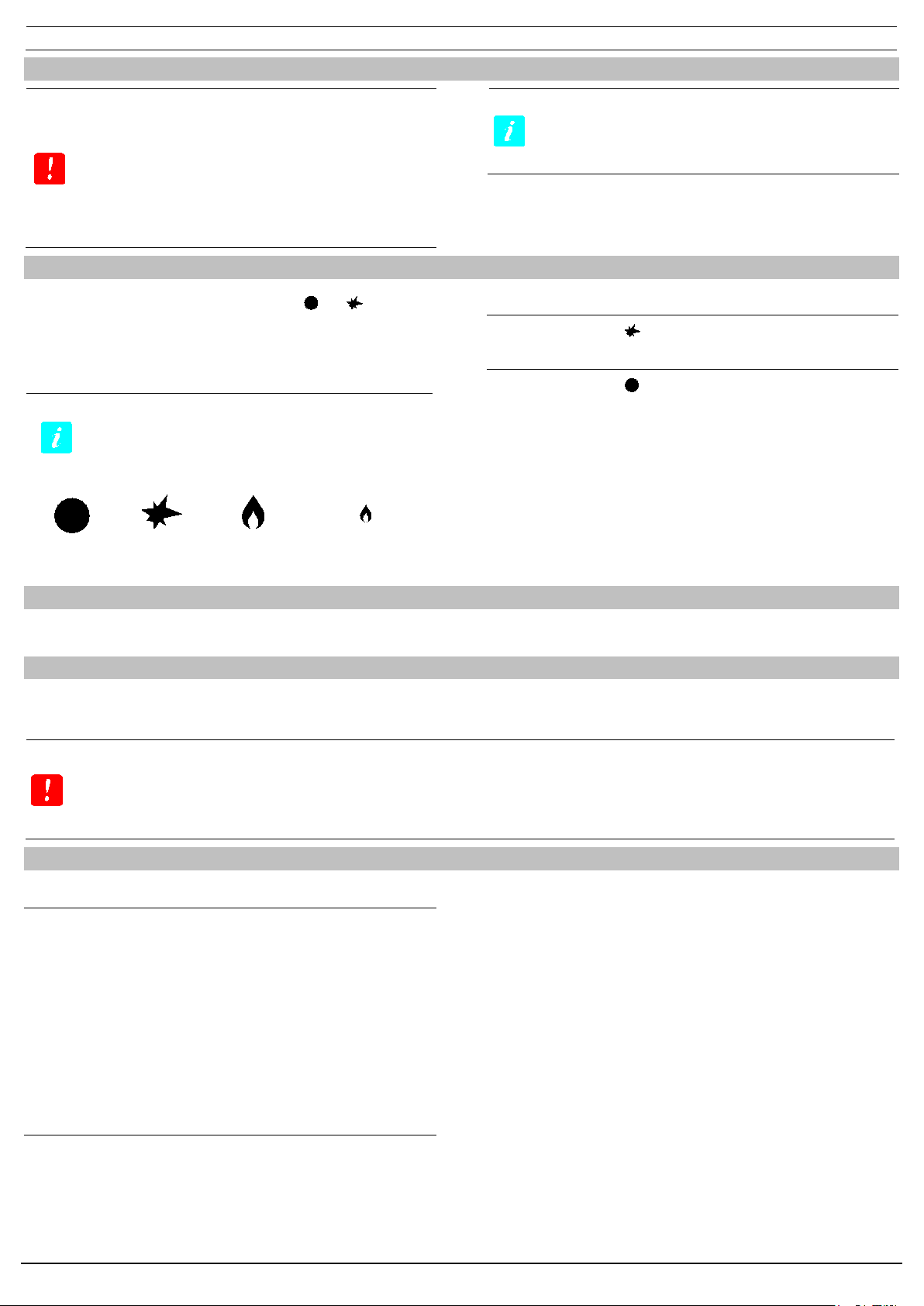

Turning on the burner and the appliance

Press and turn knob “A” (fig.4) from position “ ” to “ ”. At the

same time press ignition button “B” (fig.4) repeatedly to light the

pilot light. After the flame has lit, hold the knob down for roughly

10 seconds (count to 20), so the thermocouple heats up and

keeps the safety valve open.

If the piezoelectric device cannot be

u

sed, you can manually light the

flame using a match or a gas lighter.

Off Flame on pilot

light Burner max Burner min

TURNING THE BURNER OFF

Turn the knob to the “ ” position.

TURNING THE APPLIANCE OFF

Turn the knob to the “ ” position.

What to do when the appliance is not going to be used for a long time

Close the gas shut-off cock. Clean the appliance with soapy water, rinse it, dry it thoroughly

and apply a light layer of liquid paraffin.

What to do in the event of a malfunction

Malfunctions are not always caused by the quality of the

components used. These appliances are manufactured using top

quality components.

Failures may be caused by dust and dirt infiltrating the operating

components.

Unauthorised persons should never attempt to repair the appliance or carry out maintenance.

Tampering with the appliance voids the warranty.

If you suspect that there may be a fault, close the shut-off cock and inform the authorised

support service

.

Operational checks

THERMAL CAPACITY

Check that the gas type and group where the unit is to be used is

the same as that indicated on the plate. If it is not, follow the

conversion or adaptation procedure in the section “Conversion

and adaptation”.

Check that the right nozzles have been installed. Refer to the

nozzle table and check that the nozzles indicated in the table are

the same as those installed on the unit. As an additional check of

the thermal capacity, verify the gas consumed using the

volumetric method: start the burner and, after approximately 10

minutes (in working conditions), check that the gas flow (in m3/h

or in kg/h) corresponds to that in the nozzles table.

FLAME APPEARANCE AND PRIMARY AIRFLOW

Use the inspection hole “I” (fig.2) to check the flame.

The flame should be blue and there should be no yellow dots in

it; it must be stable at the base. If the colour of the flame is yellow,

it means the primary airflow is not adjusted properly. If the

primary airflow is too fast, the flame will be short and tend to burn

above the burner. The primary air capacity is fixed, therefore no

adjustment is required. The appearance of the flame must also be

checked 15 minutes after the appliance has been running at full

power. The flame must remain stable even when passing quickly

from minimum to maximum.

Any alterations made to the installation area

which may influence the amount of air needed

for combustion require appliance operation to

be checked again. When these checks have

been completed, test the appliance for leaks.

EN - 5

5410.495.01

Replacing parts

Faulty parts should only be replaced by

qualified personnel.

Disconnect the appliance from the gas

distribution network before doing any work.

After having removed the control panel, all the functional parts of

the appliance are easily accessible.

Only order spare parts from the

manufacturer or an authorised dealer.

EN - 6

5410.495.01

Part 4

Maintenance and cleaning

Cleaning and care

Cleaning operations must only be

carried out once the appliance has

cooled.

Only use products that are food safe.

To clean the appliance, disassemble it as per the steps shown in

figs “14” to “18”.

Keeping the appliance clean is very important for a long and

trouble-free product life. Wash the removable parts separately

with warm water and detergent, then rinse them under running

water. Do not use harsh or abrasive detergents to clean the

stainless steel parts. Iron cleaning pads should not be used as

they may cause rust to form. For the same reason, avoid contact

with ferrous materials.

When cleaning, avoid using abrasive paper or cloth; instead, and

only in special cases, use pumice stone powder. For stubborn

deposits, use a sponge (e.g. Scotch-Brite). You can also use oven

and grill cleaning sprays, readily available on the market, to

remove stubborn deposits.

If you use spray products, please follow the manufacturer’s

instructions.

To minimise emissions of polluting substances into the

environment, clean the appliance with products that are at least

90% biodegradable.

Additional recommendations for cleaning, for gas grills only

Before turning on the appliance, frequent checks and cleaning of the inside of the appliance

are recommended. This is to prevent oil and grease residues from previous cooking being

burned.

For lava stone grills:

•Clean the burner holes regularly with a metal brush to prevent clogging and promote

good combustion;

•Remember that the lava stones must be distributed on the metal grid as uniformly as

possible, noting the following amounts:

GR35G/G6 - GR35G/0 - GR35G7

GR70G/G6 – GR70G/0 - GR70G7

3.3kg

6.6kg

EN - 7

5410.495.01

FAULTS

Malfunctions are not always explained by the quality of the

components used. These appliances are manufactured using top

quality components. Malfunctions may be caused by voltage

surges, or by dust or dirt infiltrating the components. If you

suspect that there may be a fault, ALWAYS turn the appliance off

and call the authorised support service.

These appliances are manufactured using high-quality

components. Malfunctions may be caused by voltage surges,

dust and/or dirt infiltrating the components.

Unauthorised persons should never

attempt to repair the appliance or carry out

maintenance. Tampering with the appliance

voids the warranty.

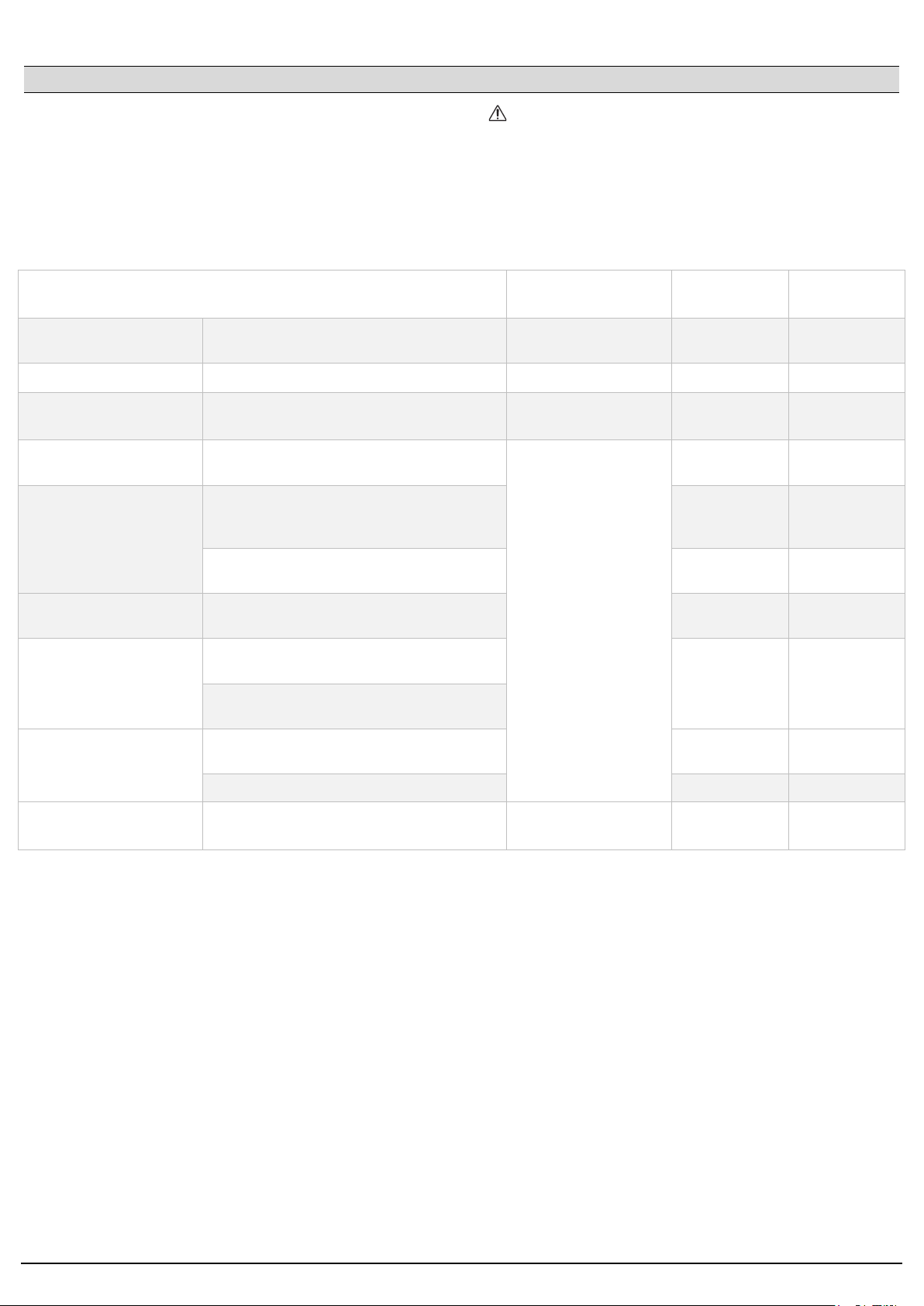

MAINTENANCE – TESTS – CHECKS – CLEANING FREQUENCY USER SUPPORT

SERVICE

Cleaning General cleaning of the appliance and the

surrounding areas

Daily or based on the

degree of use Yes -

Safety devices Check the safety devices function correctly Monthly Yes Yes

Mechanical protective

devices

Check condition. Check that there are no

deformations or loose/missing parts. Monthly Yes Yes

Controls Check the readability and condition of the

inscriptions and symbols. Repair if necessary.

Yearly

Yes Yes

Appliance structure

Check the mechanical part to make sure that

it is not broken or deformed. Check the screws

are tightened.

Yes Yes

Tighten the main bolts (screws, fasteners, etc.)

on the appliance - Yes

Safety signs Check the readability and condition of the

safety signs. Yes Yes

Electrical control panel /

electronics

Check the condition of the electrical parts

installed on the electrical control panel. - Yes

Check the wiring between the electrical panel

and the parts of the appliance.

Electrical connection

cable and plug socket

Check the condition of the connection cable

and plug socket. Yes Yes

Replace if defective. - Yes

Motor bearings (if

present) Replace motor bearings Every three years - Yes

EN - 8

5410.495.01

Safety precautions

REMEMBER THAT THE APPLIANCE

The appliance must never be left

unattended when in use.

When the unit is switched on, the surfaces

get very hot. Please take great care.

The appliance is intended for professional

use and therefore only qualified personnel

should use it.

Installation, as well as any conversion or

adaptation operations to a different gas

type, must be carried out in accordance

with current laws and only by qualified,

authorised personnel.

At least once a year, have the appliance

checked by qualified personnel.

All the parts that come into contact with oil

or fat during use should be cleaned

regularly, as indicated in the chapter

“Cleaning and Care”.

In the event of a fire, close the shut-off

cock immediately to cut off the gas

supply, then use a suitable fire

extinguisher.

Ecology and environment

Our appliances are studied and optimised via testing to provide

high performance and yields. To reduce energy consumption

(electricity, gas and water), do not use the appliance for long

periods of time without food inside or in conditions that may

compromise optimum yield.

All of the following materials are used for the packaging:

•Polyethylene: external packaging film and/or bubble wrap

•Polypropylene: straps

•Expanded polystyrene: corner pieces, protective sheets and

blocks

•Cardboard

•Wooden base frame

These materials are environmentally friendly and can be safely

stored or reused/recycled. Should you wish to dispose of them,

please adhere to the waste regulations in force in your country.

Dispose of the appliance responsibly at the end of its useful life.

In compliance with the regulations in force in your

country, dispose of the waste product by taking it

to an authorised collection and treatment site, after

removing the power cable.

This manual suits for next models

1

Table of contents

Other Tecnoinox Grill manuals

Popular Grill manuals by other brands

Outback

Outback Omega 100 Assembly and operating instructions

Fritel

Fritel TEPPANYAKI TY 1896 instruction manual

Weber

Weber Q 3200 Series owner's guide

One Fire Grills

One Fire Grills Lock'n Go 2010 user manual

Vulcan-Hart

Vulcan-Hart Vulcan VCCB25 Installation & operation manual

Ninja

Ninja SIZZLE GR101 Series owner's guide