TECNOTER N Series User manual

ILKF – ILKFB (PE)

ILKF – ILKFB (PE)

S

SAFETY

AFETY

VALVES

VALVES

RETROFIT

RETROFIT

KIT

KIT

FOR

FOR

FRONT

FRONT

LOADER

LOADER

AND

AND

TILT

TILT

H

HYDRAULIC

YDRAULIC (

(STANDARD

STANDARD)

) AND

AND

ELECTRONIC

ELECTRONIC

CONTROL

CONTROL (PE)

(PE)

B

BASIC

ASIC

VERSION

VERSION

SERIES

SERIES

N

N

HOST

HOST

MACHINE

MACHINE

CAT 938K

CAT 938K

Insta ation manua

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 1/22 Rev: 1.20_En –

01/02/2020

ATTENTION:

Some parts are supp ied a ready assemb ed and can be insta ed as “group”

More then one hose connected on a same port means the presence of an externa Tee.

Any kit connected to the main contro er needs the corresponding computer set up.

Refer to SIS for any specification

IMPORTANT NOTICE:

to prevent unauthorized use or distribution of caterpillar manuals and intellectual propert

rights, in accordance with the rules defined with Caterpillar Work Tool inc., this manual is

printed WITHOUT drawings.

WARNING:

Before using this manual, please access SIS and print the following documents:

Electric schematic

H draulic schematic

333-6538

347-8236

523-4260

333-6920

523-4245

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 2/22 Rev: 1.20_En –

01/02/2020

Index

INTRODUCTION................................................................................................................................4

Scope of the manua .........................................................................................................................4

How to read the manua ...................................................................................................................5

Preservation of the manua ..............................................................................................................6

Update of the manua .......................................................................................................................6

Addressees.......................................................................................................................................6

GENERAL INFORMATION...............................................................................................................7

Manufacturer identification.............................................................................................................7

INSTALLATION PROCEDURE.........................................................................................................8

Line gp Lift cy inder........................................................................................................................9

Testing and adjusting.................................................................................................................13

Line gp Ti t cy inder (SP version) .................................................................................................15

Testing and adjusting.................................................................................................................19

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 3/22 Rev: 1.20_En –

01/02/2020

INTRODUCTION

Scope of the manual

This instruction manua is part of the machine and it provides a the necessary information to:

•manipu ation of the machine, packed and unpacked in safety conditions

•correct assemb y of the machine

•thorough know edge of its operation and its imits;

According to the current regulations, the responsible of the departments where this s stem

will be assembled must read carefull the content of this instruction manual and make sure

that the emplo ees read it.

Time spent for this purpose will be rewarded b the correct functioning of the machine and b

its use in safet conditions.

This document assumes that the p ants where this system wi be set comp y with the current safety

regu ations and hygiene conditions.

Instructions, drawings and documentation contained in this manua are reserved and inte ectua

property of the manufacturer, and they cannot be fu y or partia y reproduced.

If the manufacturer made any change in this manua , the customer must verify that on y updated

versions of it wou d be present in site where the machine is used.

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 4/22 Rev: 1.20_En –

01/02/2020

How to read the manual

Manua is divided into autonomous chapters, and it is addressed to assemb ers with the necessary

ski s to operate on the machine in safety conditions.

The instruction manua is composed by a cover, a tab e of contents and a series of chapters

(sections).

PAGE NUMBERING

Compan Logo Product Name Model Serial no. Page no. Revision no.

TABLES NUMBERING

Every tab e is numbered progressive y

Numbering starts from “1” at every section.

Numbering is composed as fo ows:

ABBREVIATIONS

Sect. = Section

Ch. = Chapter

Par. = Paragraph

Pag. = Page

Fig. = Figure

Tab. = Tab e

UNIT OF MEASURE

Units from the Internationa System of Units (SI)

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 5/22 Rev: 1.20_En –

01/02/2020

LOGO NAME MODEL S/N and YEAR 5/36 REV. - DATE

Preservation of the manual

Instruction manua shou d be carefu y preserved and it has to accompany the machine in every

change of ownership. Preservation shou d be faci itated by a carefu hand ing, with c ean hands and

it shou dn't be put on dirty surfaces.

You don't have to e iminate, tear or change any part. Manua has to be fi ed in an environment

without humidity and heat and near the machine it refers to.

Manufacturer can supp y further copies of the instruction manua on demand of the User.

Update of the manual

Manufacturer has the right to modify and make improvements to the machine without

communicating it to the customers, and without updating the manua a ready in hands of the user.

Moreover, the manufactures has to send the updated manua for any agreed change of the machine

at the customer's site.

User is responsib e for changing the o d chapters, the cover and the tab e of contents with the new

ones in every owned copy.

Addressees

This manua addresses to the operator, the assemb er and the maintenance technicians.

OPERATOR: one or more peop e that assemb y or do the maintenance of a machine;

QUALIFIED PERSONNEL OR OPERATOR: peop e that attended specia ization courses and

that have experience in assemb y and maintenance of the machine.

Qualification of addressees

The machine is intended for industria and therefore professiona use, so its use is addressed to

qua ified technicians that:

•are of age;

•are physica y and psychica y apt to do technica y difficu t jobs;

•have been proper y instructed on use and maintenance of the machine;

•are judged by the emp oyer as suitab e to do the designed job;

•have the ski of assemb y and operating the specific type of equipment;

•have fami iarity with the specific regu ations of the matter.

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 6/22 Rev: 1.20_En –

01/02/2020

GENERAL INFORMATION

Manufacturer identification

Manufacturer

Tecnoter sr a socio unico

VAT: IT13072070157

Head office

P.zza E eonora Duse 3

20121 Mi ano

Ita y

Production site

Via Car o A berto da a Chiesa 6

20098 San Giu iano Mi anese (MI)

Ita y

After sales service / Spare parts

Via Car o A berto da a Chiesa 6

20098 San Giu iano Mi anese (MI)

Ita y

CONTACTS:

Tel: +39 029824.8180 / .9339 /.9305

Fax: +39 029824.7605

www.tecnotergroup.com

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 7/22 Rev: 1.20_En –

01/02/2020

INSTALLATION PROCEDURE

TOP IMPORTANT

This system is not identica to the standard CAT system.

Any reference to CAT pict or documentation has to be considered as an indication on y.

Carefull follow this manual to install the s stem on the host machine

Attention:

Be sure to have understood the insta ation manua before the insta ation of the system.

Doub e check each hydrau ic insta ation before operate the system.

Attention:

In case of oca aws or restrictions were app icab e on the use of this upgrade kit, the

operator must strict y observe them.

IMPORTANT NOTICE

This s stem has been designed to fit the specific host machine onl and it is the result of

accurate engineering process. The presence of parts not identical to the expected one (e.g.

supports having different shape, bolts having different grade then expected, etc.) is

intentional.

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 8/22 Rev: 1.20_En –

01/02/2020

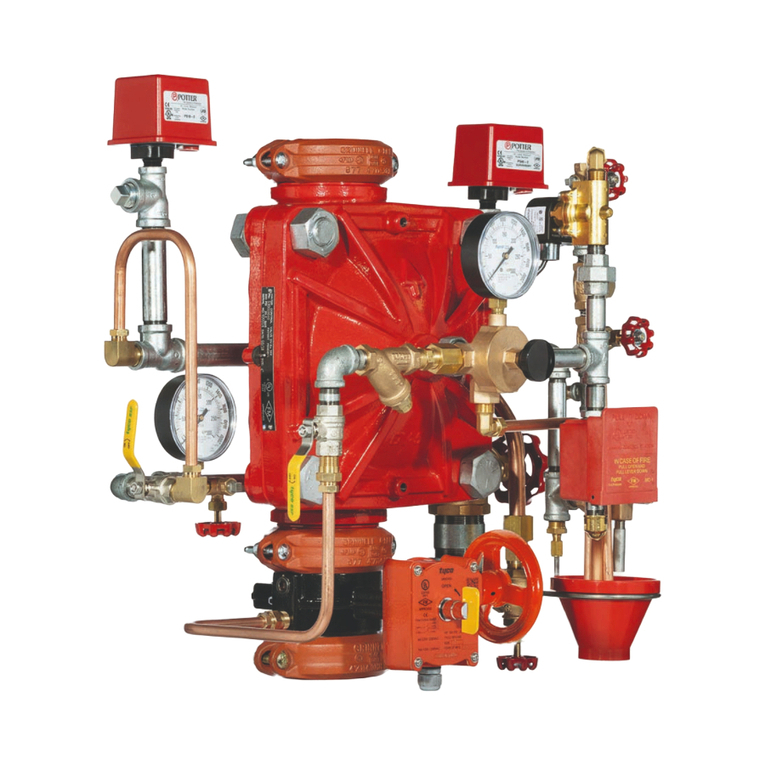

Line gp Lift cylinder

WARNING

A ways set the va ves before operate the machine.

Refer the paragraph Testing and adjusting for detai s

1. Disconnect the two ift cy inders 495-6000 and ocate them on a c ean working tab e

2. On the Rh cy inder, dismount the tube 346-5073 with hose 346-5078 and c amps. Be sure

to keep c amps, b ocks, p ates and strips for reuse

3. Dismount the corresponding parts from the Lh cy inder. Be sure to keep c amps, b ocks,

p ates and strips for reuse

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 9/22 Rev: 1.20_En –

01/02/2020

Print SIS pages

333-6538

347-8236

WARNING: illustration for reference onl .

Some parts have been replaced b Tecnoter parts

Strictl follow this manual

4. Execute the fo owing steps on both Rh and Lh ift cy inders:

4.1. rep ace the existing e bow 148-8357 with the provided e bow

4.2. Insta the tube 523_4251TEC (148-8357TEC in certain versions) on the e bow

4.3. Using the support 526-9202TEC, fit the safety va ve (port C2) to the tube

Note: use the va ve KF34D (0849250304400D) on the Rh cy inder and KF34S

(0849240344000D) on the Lh cy inder

4.4. Insta the tube 523-4257/8TEC on the port V2 of the va ve

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 10/22 Rev: 1.20_En –

01/02/2020

148-8357TEC

523-4251TEC

KF34D

KF34S

525-9202TEC523-4257TEC

4.5. Insta the provided e bows on the tube 523-457 and the ports T and Pi as shown

4.6. Fix the support 526-9202TEC using the provided c amp-hose

4.7. Using the hose 523-4259TEC, connect the tube 523-457 to the ine Gp Lift

4.8. Adjust the present c amp-hoses according to the new arrangement

4.9. Insta the provided hose guard on the origina hose connected to the rod port of the

cy inder (see the pict in previous page for reference)

4.10. Insta again the cy inder in the frame

WARNING

Doub e check the correct c earance between cy inder's components and frame before actuate the

cy inder itse f

5. Insta the Tees 148-8439TEC and the shutt e 387-1096 with Tee on the support PSTPSP

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 11/22 Rev: 1.20_En –

01/02/2020

6. Temporary disconnect the hose 350-7587 to the tube 508-4258, then remove the nut 6V-

9172 from the tube 508-4258 (ref. 24 SIS page 347-8236)

7. Insert the ho e of the support PSTPSP in the nipp e of the tube 508-4258 then fix it with the

nut 6V-9172 just removed

8. Reconnect the hose 350-7587 to the tube

9. Using the hoses 523-4235TEC, connect the side ports of Tee 148-8439TEC to the e bow on

the pi ot ports of the safety va ves

10. Insta the provided nipp e (148-8326TEC) on the port G of the va ve 565-0113 then, using

the hose 577-7715TEC, connect the port G to the one shutt e va ve side port

11. Using the hose 523-4237TEC, connect the ast shutt e va ve side port to the port V9 of the

main contro va ve (refer the hydrau ic schematic M0107766-01) trough the second nipp e

148-8326TEC

IMPORTANT NOTE: PE option (Aux ECM with PRV valves) shall be ordered and

added on machines without port V9

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 12/22 Rev: 1.20_En –

01/02/2020

Print SIS page

523-4260

WARNING: illustration for reference onl .

Some parts have been replaced b Tecnoter parts

Strictl follow this manual

12. Connect the two hoses F04F-F90B-FDOB-A1050 to the T ports of the safety va ves then

pu them ti the support PSTPSP

13. Connect the hoses to the side of the free Tee

14. Using the second hose 523-4237TEC, connect the centra port of the Tee to the return

manifo d 433-1417. The provided spare Tee EGIL-FDOB-MDOB-MDOB and e bow can

be uses on certain arrangements for an easier insta ation.

WARNING

Doub e check the correct c earance between hoses and frame before actuate the cy inder itse f

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 13/22 Rev: 1.20_En –

01/02/2020

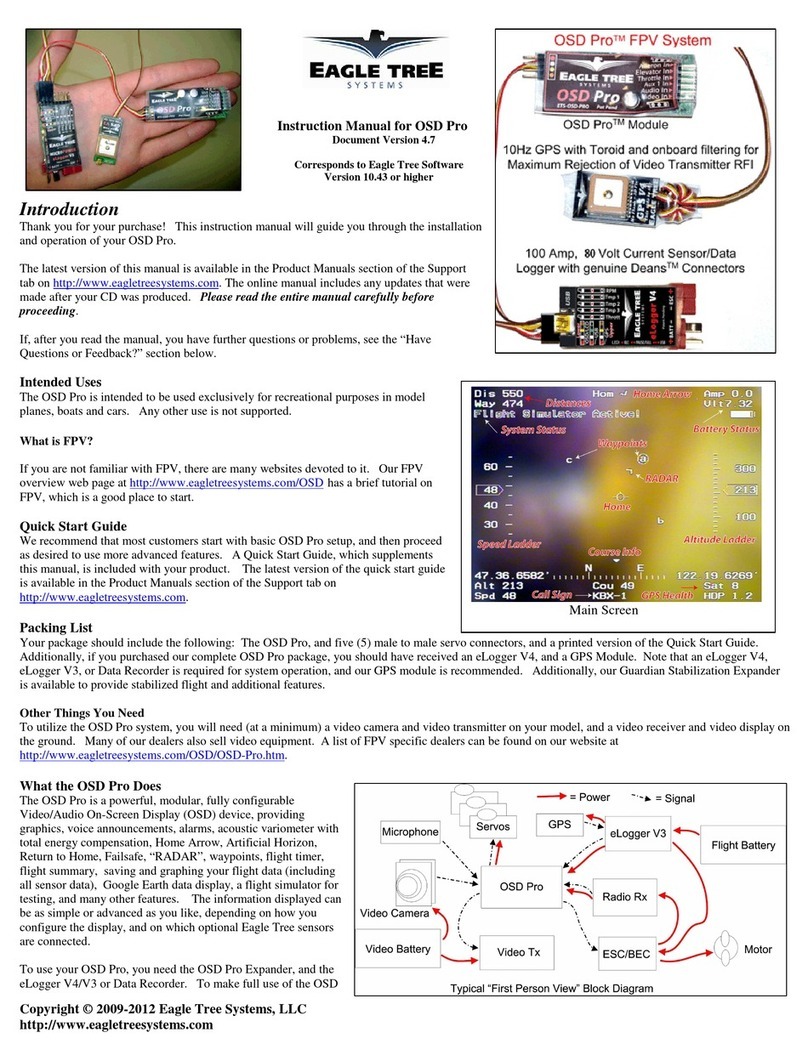

Testing and adjusting

P ease note schematic and component position of the ift cy inders safety va ves

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 14/22 Rev: 1.20_En –

01/02/2020

IMPORTANT NOTICE

The Factor sealed “E” screw can be used for Emergenc spool opening and boom lowering,

in case of pilot pressure failure; once the emergenc boom lowering is completed, the “E”

screw must be restored to its original position and locked

Pilot ratio adjusting:

The va ve (1) – Pi ot – is preset at the va ue of 7,5 bar (109 PSI) cracking pressure.

This setting is the resu t of severe ab and on-the-fie d tests and it represents the idea va ue

to ensure the best operator experience.

In case of particu ar necessities, this setting can be changed by ski ed technicians to modify

the va ve sensibi ity.

Va ve (1) range: 7 – 20 bar (102 / 290 PSI)

Va ve (1) sensibi ity: approx 3.2 bar / turn (51 PSI)

Screw c ockwise to increase.

Overload setting:

The va ve inc udes an anti shock re ief (2) which senses C2 pressure and opens under

over oad or shock conditions in order to pi ot wide open the metering spoo and to a ow

cy inder pressure to be re ieved downstream through the main hose (V2) and through the

main contro va ve.

The cartridge (2) sha be adjusted during insta ation according to the host machine setting.

Va ve (2) range: 300 – 460 bar (approx 4350 / 6650 PSI)

Va ve (2) standard setting: 350 bar (approx 5000 PSI)

Va ve (2) sensibi ity: approx 228 bar / turn (approx 3300 PSI)

Screw c ockwise to increase.

WARNING

Alwa s set the valve (2) to the appropriate value before operate the host machine.

Safet valves supplied in the kit are pre set at the value of 350 bar!

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 15/22 Rev: 1.20_En –

01/02/2020

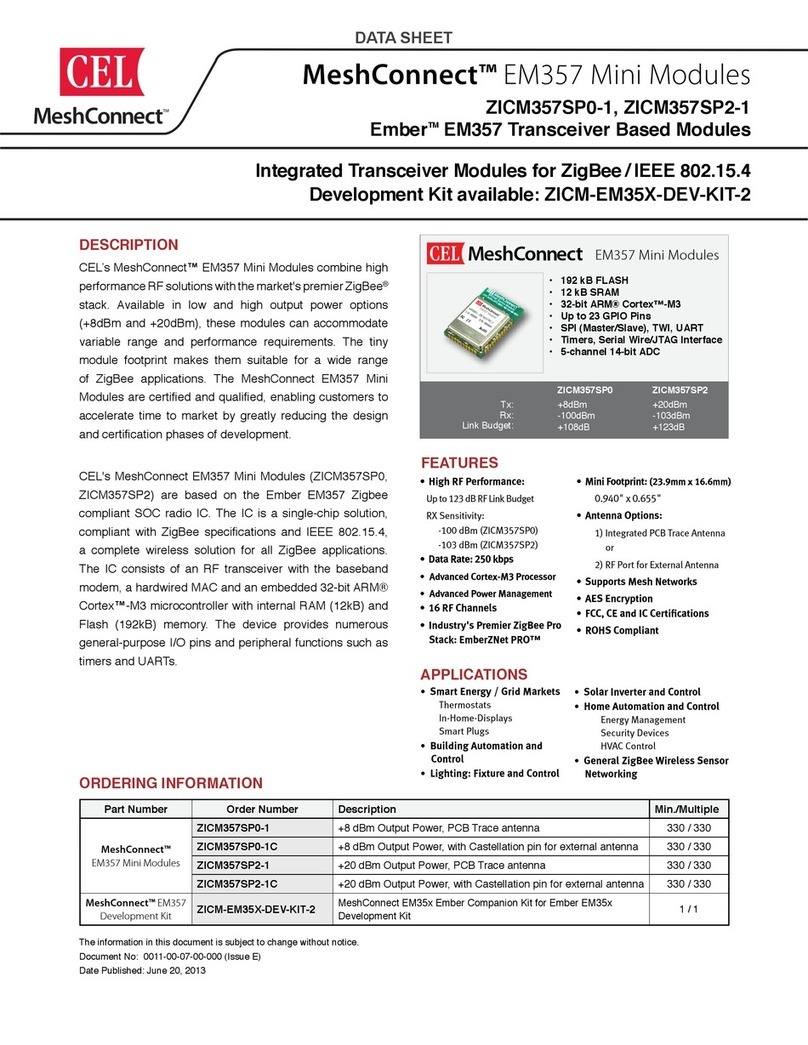

Line gp Tilt cylinder (SP version)

NOTE:

PE option (Aux ECM with PRV valves) shall be ordered for applications in EU market

15. Remove hoses and tube from the ti t cy inder

16. Keep hoses in a c ean compartment for reuse

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 16/22 Rev: 1.20_En –

01/02/2020

Print SIS page

333-6920

17. rep ace the e bow148-8356 with the provided 848-1356TEC

18. connect the tube 364-1545TEC to the e bow

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 17/22 Rev: 1.20_En –

01/02/2020

Print SIS page

523-4245

WARNING: illustration for reference onl .

Some parts have been replaced b Tecnoter parts

Strictl follow this manual

19. Using the provided c amp-hose, insta the support 523-4239TEC as in the fo owing

picture

20. Insta the safety va ve WCB17ISO on the support PSTVBL (523-4239TEC), then connect

the va ve (port C2) to the tube as shown

21. Using the provided e bow 148-8356TEC, reconnect the origina hose 393-0597 to the

safety va ve, port V2

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 18/22 Rev: 1.20_En –

01/02/2020

PSTVBL - 523-4239TEC

WCB17ISO

393-0597

C2

V2

22. Insta the provided Tee 148-8425TEC on the rod port of the cy inder

23. Using the hose 523-4248TEC (F04F-FDOB-FDOB-A350), connect the centra port of the

Tee to the pi ot port of the safety va ve

24. Connect the hose 393-0597TEC to the free port of the Tee

WARNING

Doub e check the correct c earance between cy inder's components and frame before actuate the

cy inder itse f

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 19/22 Rev: 1.20_En –

01/02/2020

148-8425TEC393-0597TEC 393-0597

364-1545TEC 523-4248TEC

Testing and adjusting

P ease note schematic and component position of the ift cy inders safety va ves

Tecnoter srl Safety va ves ILKF.N

ILKFB.N

CAT 938K Page 20/22 Rev: 1.20_En –

01/02/2020

Pi

C2

V2

2

2

This manual suits for next models

2

Table of contents

Popular Control Unit manuals by other brands

ALRIGHT DEVICES

ALRIGHT DEVICES Chronoblob2 user manual

Ross

Ross W74 Series quick start guide

Comunello Automation

Comunello Automation QUAD-24V-HP Installation and user manual

Wheelock

Wheelock MZC-RM installation instructions

Videx

Videx DK8K-1 installation instructions

Quectel

Quectel EC25 series user manual