ENGLISH

31

COMUNELLO ®Copyright 2021 - All rights reserved

PRESCRIPTIONS

• The control unit does not have any type of 230 Vac power line sectioning device; it will therefore be the installer’s responsibility to install a

sectioning device in the system. An omnipolar switch with overvoltage category III must be installed. It must be positioned so as to be protected

against accidental reclosing in accordance with the provisions of point 5.2.9 of EN 12453. The wiring of the various electrical components

external to the control unit must be carried out in accordance with the prescriptions of the EN 60204-1 standard and the modications to this is

made from point 5.2.7 of EN 12453. The power supply cables can have a maximum diameter of 14 mm; the xing of the power and connection

cables must be guaranteed through the assembly of cable glands, available as optional.

• 5.2.7 of EN 12453. Power cables can have a maximum diameter of 14 mm and the Ø of power supply and connection cables must be

guaranteed by assembling the “optional” cable glands.

• For power cables it is recommended to use exible cables in insulating sheath in harmonized polychloroprene (H05RN-F) with a minimum

conductor cross-section of 1 mm2.

• When installing, use only double-insulated cables (sheathed cables) both for mains voltage connections (230V) and for SELV safety extra-low

voltage connections. Use only plastic channels, separate for low voltage wiring (230V) and for extra low voltage wiring (SELV).

• The conductors with very low safety voltage must be separated (at least 4 mm in air) from the mains voltage conductors, or they must be

adequately insulated with additional insulation having a thickness of at least 1 mm.

• Provide a device that ensures complete omnipolar disconnection of the network upstream of the automation power supply network, with

a contact opening distance at each pole of at least 3mm. These disconnection devices must be provided in the power supply network in

accordance with the installation rules and must be directly connected to the power supply terminals.

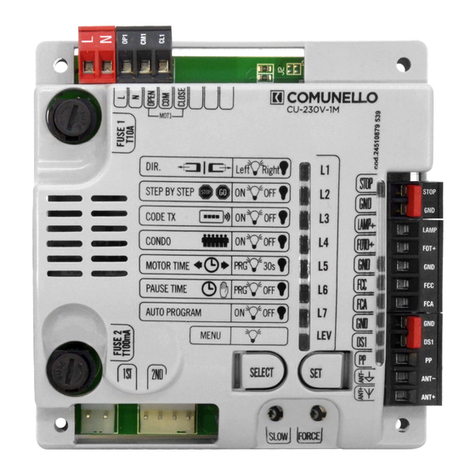

• In the case of installation inside a QUAD control panel, be careful when drilling the external casing to pass the power supply and connection

cables, and the assembly of the cable glands, to install everything so as to keep the IP rating of the box as unaltered as possible. Also pay

attention to the cables so that they are anchored in a stable manner, and not to damage the board with the puncture (g. 3B).

• The casing in the back is provided with suitable predispositions for xing to the wall (predisposition for holes by means of plugs or holes for xing

by screws). Predict and implement all the precautions for an installation that does not alter the IP rating.

• The possible assembly of a push-button panel for manual control must be done by positioning the push-button panel so that the user is not in

a dangerous position.

• The gearmotor used to move the gate must comply with the requirements of point 5.2.7 of EN 12453.

• The FOTO + output (CN2) is necessarily dedicated to powering the photocells, they cannot be used for other applications.

• The control unit can perform the photocell operation test at each cycle of operation, guaranteeing protection against the failure of Category 2

anti-crushing devices according to the provisions of point 5.1.1.6. of EN 12453. Therefore if the safety devices are not connected and / or are

not working the control unit is not enabled for operation.

The device cannot be used by children under the age of 8 or by persons with reduced physical, sensory or mental abilities, or lacking in

experience or the necessary knowledge, if not under supervision or after they have received instructions relating to safe use of the appliance

and understanding of the dangers inherent in it.

USER CAUTION

Do not allow children to play with the device and keep remote controls away from them. Cleaning and maintenance intended to be carried out

by the user must not be carried out by children without supervision.

Do not allow children to use the device as a toy and keep remote controls out of reach.

NOTE: keep this instruction manual and respect the important safety instructions contained in it. Failure to comply with the regulations could

cause damage and serious accidents.

Examine the system frequently to detect any signs of damage.