TECNOVAP HYDROBOX 10.7 User manual

HYDROBOX

Pag. 2 TECNOVAP 36/18

HYDROBOX

Pag. 3 TECNOVAP 36/18

Understanding the symbols on the appliance

BEFORE USING THIS APPLIANCE, READ AND COMPLY WITH THESE USER INSTRUCTIONS.

KEEP THESE INSTRUCTIONS FOR FURTHER CONSULTATION AS NEEDED AND PROVIDE THEM TOGETHER

WITH THE APPLIANCE TO THE SUBSEQUENT OWNER.

BEFORE USING THE APPLIANCE FOR THE FIRST TIME, YOU ABSOLUTELY HAVE TO READ THE SAFETY

REGULATIONS GIVEN IN THIS MANUAL.

ANY DAMAGE CAUSED DURING TRANSPORTATION HAS TO BE PROMPTLY NOTIFIED TO YOUR RETAILER.

WARNING!

READ THE OPERATOR’S MANUAL

OPERATOR’S MANUAL;

USING INSTRUCTIONS

WARNING!!

DO NOT DIRECT THE STEAM JET TOWARDS PEOPLE, ANIMALS,

ELECTRICAL OUTLETS AND APPLIANCES.

HYDROBOX

Pag. 4 TECNOVAP 36/18

Understanding the command symbols on the appliance

Environmental protection

ALL PACKAGINGS ARE RECYCLABLE.

THE PACKAGING MUST NOT BE DISPOSED OF IN THE

HOUSEHOLD WASTE AND HAS TO BE DELIVERED TO AN

AUTHORISED COLLECTION CENTRE.

DISMISSED APPLIANCES CONTAIN PRECIOUS RECYCLABLE

MATERIALS AND SHOULD THEREFORE BE DELIVERED TO A

COLLECTION CENTRE. ELECTRICAL AND ELECTRONIC

APPLIANCES, BATTERIES, OIL AND SIMILAR SUBSTANCES MUST

NOT BE RELEASED TO THE ENVIRONMENT. PLEASE DISPOSE OF

THESE USING APPROPRIATE SEPARATED WASTE COLLECTION

SYSTEMS.

SUBSTANCES SUCH AS ENGINE OIL, DIESEL, PETROL OR OTHER

FUELS MUST NOT BE RELEASED TO THE ENVIRONMENT.

PROTECT THE SOIL BY DISPOSING USED OIL IN COMPLIANCE

WITH ENVIRONMENTAL LAWS.

DANGER OF SCALDING!

OBLIGATION TO WEAR PROTECTIVE GLOVES.

THE USER MAY RETURN THE APPLIANCE FOR DISPOSAL TO THE RETAILER WHEN PURCHASING A

NEW EQUIVALENT APPLIANCE; ON A ONE-TO-ONE BASIS.

HYDROBOX

Pag. 5 TECNOVAP 36/18

TABLE OF CONTENTS

1. SAFETY REGULATIONS

2. CONNECTION TO THE WATER SUPPLY

3. INTRODUCTION

4. TECHNICAL FEATURES

5. NOMENCLATURE

6. TECHNICAL DRAWINGS

7. USING INSTRUCTIONS

8. MAINTENANCE

9. BEFORE CONTACTING THE SERVICE CENTER

10. DECLARATION OF CONFORMITY

1. SAFETY REGULATIONS

▪Do not open or remove parts of the machine for any reason. Should the appliance have an operating

fault or malfunction, do remove the power plug and contact an authorized technical assistance center

or the point of sale where the appliance was purchased.

▪The connection of the appliance to the main power has to be done by a qualified electrician and has

to be conform to the contents of the IEC 60364-1 norm.

▪If the power cable is damaged, it has to be replaced by the manufacturer or a technical assistance

center, or in any case by a person with similar qualifications, in order to prevent all risks.

▪Make sure that the power supply to this appliance is fitted with a differential device which can cut off

the power supply if the leakage current to earth exceeds 30 mA for 30 ms, or a checking device of the

earth circuit.

▪SAFETY VALVE This appliance is fitted with two safety valves designed to ensure the safety of the

appliance if any other primary control elements were inefficient (due to a fault). Due to the extreme

importance of these components and to avoid compromising the safety of the appliance, they should

be replaced (by an authorized technical assistance center) every 2 years from the date of purchase.

▪DISCHARGE OF BOILER SLUDGE (DRAINAGE) The appliance automatically signals the need of

boiler sludge draining on the display; in this case the wording “C A L C”will flash alternately with the

current screen displayed.

▪WARNING. Use a set of new connectors, pipes and seals every time the appliance is connected to

the water supply.

▪WARNING. Do not use the machine if there are persons standing within its range of action.

▪WARNING. High-pressure jets can be hazardous if used improperly. Do not direct the jet towards

persons, live electrical equipment or towards the appliance itself.

▪Do not direct the jet towards yourself or other persons to clean clothing or footwear:

HYDROBOX

Pag. 6 TECNOVAP 36/18

▪WARNING. Water that has passed through backflow prevention devices is considered non-potable.

▪Disconnect the main power by removing the plug from the power socket before carrying out any

maintenance to the appliance.

▪WARNING. This appliance is not intended to be used by children or unqualified persons.

▪Watch over children to make sure that they cannot play with the machine.

▪To ensure the safety of the appliance, do use only original spare parts supplied or approved by the

manufacturer.

▪WARNING. The hoses, accessories and couplings are very important for the safety of the appliance.

Use only hoses, accessories and couplings recommended by the manufacturer.

▪WARNING. Do not use the appliance if the power cable or other important parts have been

damaged, for example safety devices, high pressure hoses or trigger gun.

▪WARNING. When using an extension cable, the plug and socket must be watertight.

▪WARNING. Inappropriate extension cables may be hazardous.

▪WARNING. Risk of explosion. Do not spray flammable liquids.

2. CONNECTION TO THE WATER SUPPLY

The connection of the appliance to the water supply has to

be carried out by qualified staff. Use a set of new pipes and

couplings suitable for food use, do not reuse this set

(couplings, pipes, seals, adapters, etc.) for a new

connection.

As the appliance is mobile, it is not supplied with a water

connection pipe due to the variable position and distance of

the appliance to the water connection point.

HYDROBOX

Pag. 7 TECNOVAP 36/18

3. INTRODUCTION

Dear Customer,

Congratulations for choosing this appliance.

With the aim of continuously improving and updating its range and offering increasingly innovative models,

TECNOVAP has developed, designed and constructed HYDROBOX, a cleaning appliance with

superheated high-pressure water.

HYDROBOX

Pag. 8 TECNOVAP 36/18

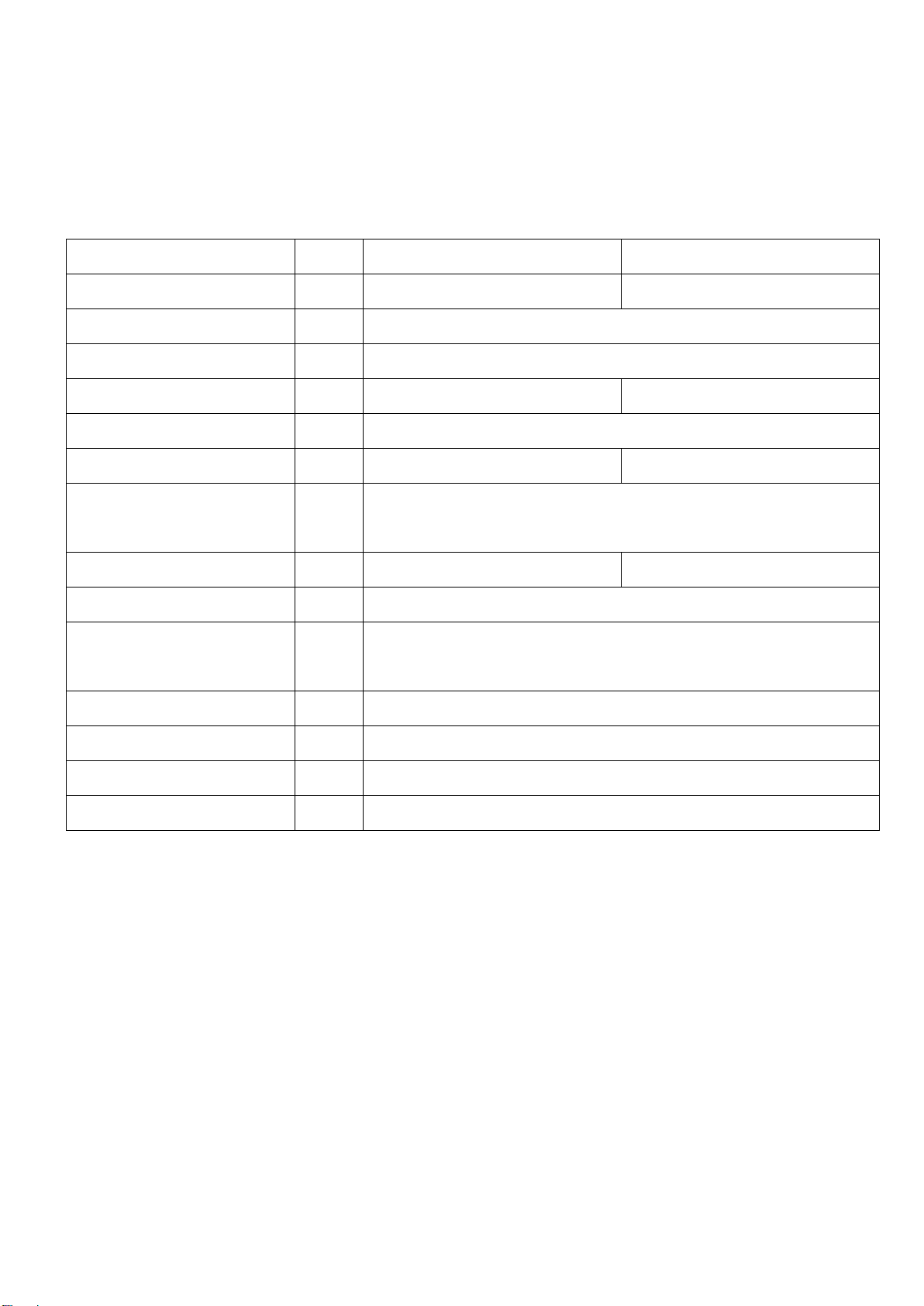

4. TECHNICAL FEATURES

FACTORY: TECNOVAP SRL VIA DEI SASSI 1A 37026 PESCANTINA VERONA ITALY

Model

10.7

14,4

Code

H100200

H400000

Rated voltage

V

400/230

Current type

Hz

50/60 3~

Rated power boiler

kW

9,1

14,5

Power pump module

kW

1.5

Max rated power

kW

Rated water pressure

kPa

bar

15’000

150

Max. water rated flow

l/m

2

4

Max temperature

°C

90°

Max. inlet water pressure

KPa

bar

600

6

Kickback forces

N

< 20

Vibration hand-arm

m/s²

< 2,5

Sound pressure level LPa

dB

< 70

Mass

kg

55

HYDROBOX

Pag. 9 TECNOVAP 36/18

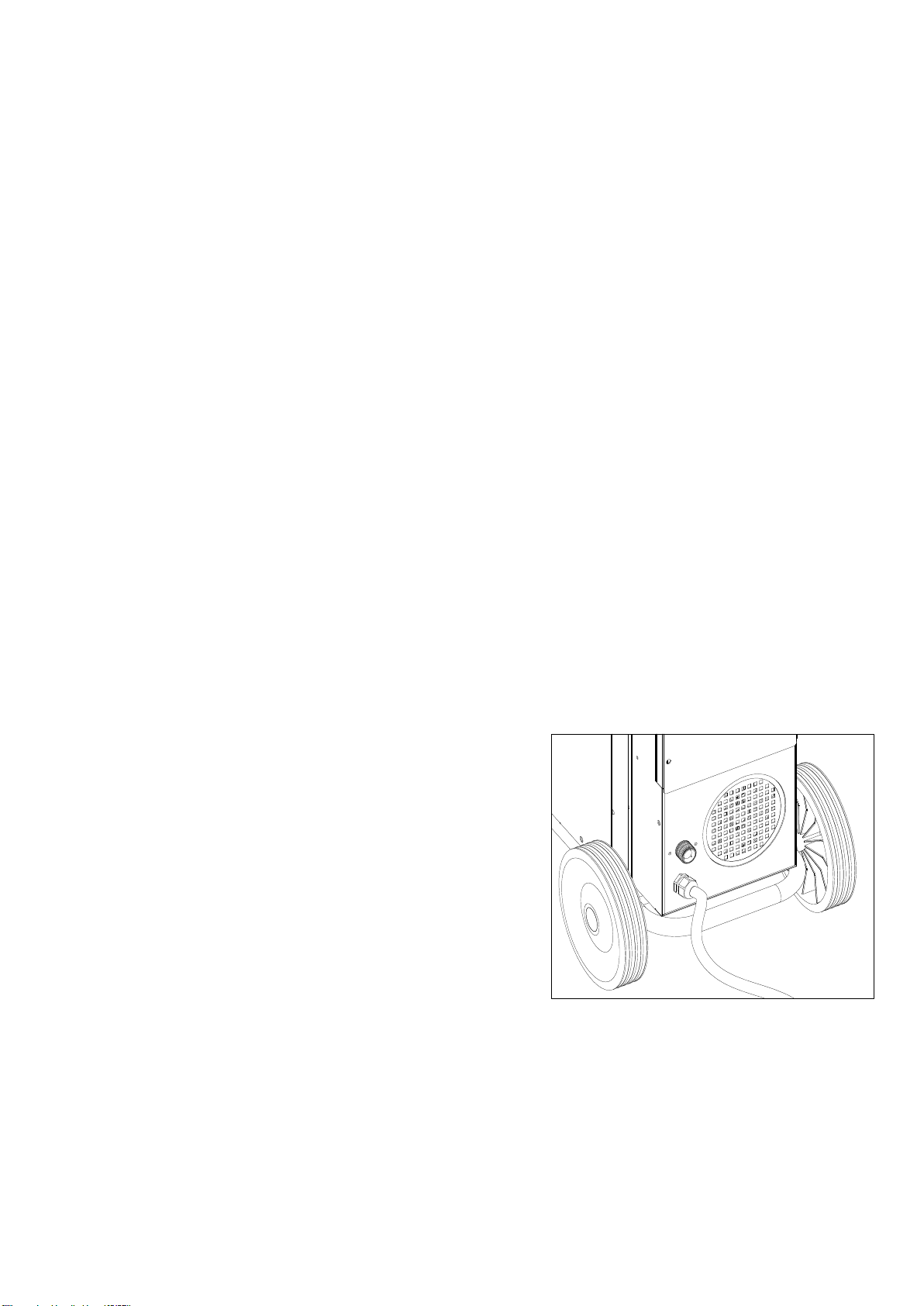

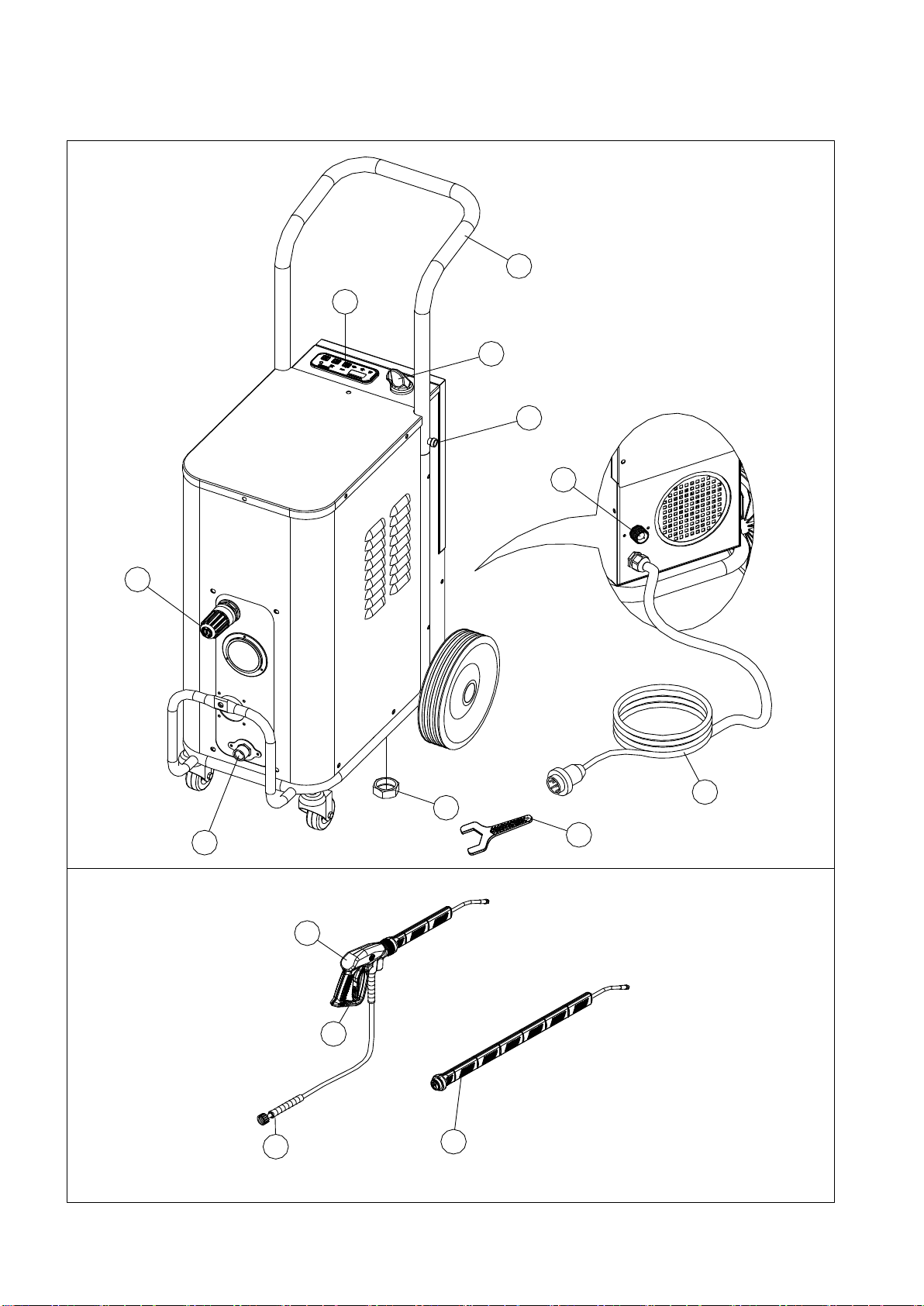

5. NOMENCLATURE

HYDROBOX

01) Manoeuvring handle

02) Fixing screw

03) Hose coupling

04) Coupling for water supply

05) Power cable

06) Main switch

07) Control panel

08) Pressure regulator of pump

09) Boiler drainage cap

10) Boiler drainage key supplied

Hand grip

20) Hand grip

21) Hydraulic coupling

22) Releasing lever for water under pressure

23) Water lance 500 / 700 / 900 / 1200 mm with nozzle

HYDROBOX

Pag. 10 TECNOVAP 36/18

6. TECHNICAL DRAWINGS

22

21 23

20

03

04

05

07

06

09

01

10

02

08

HYDROBOX

Pag. 11 TECNOVAP 36/18

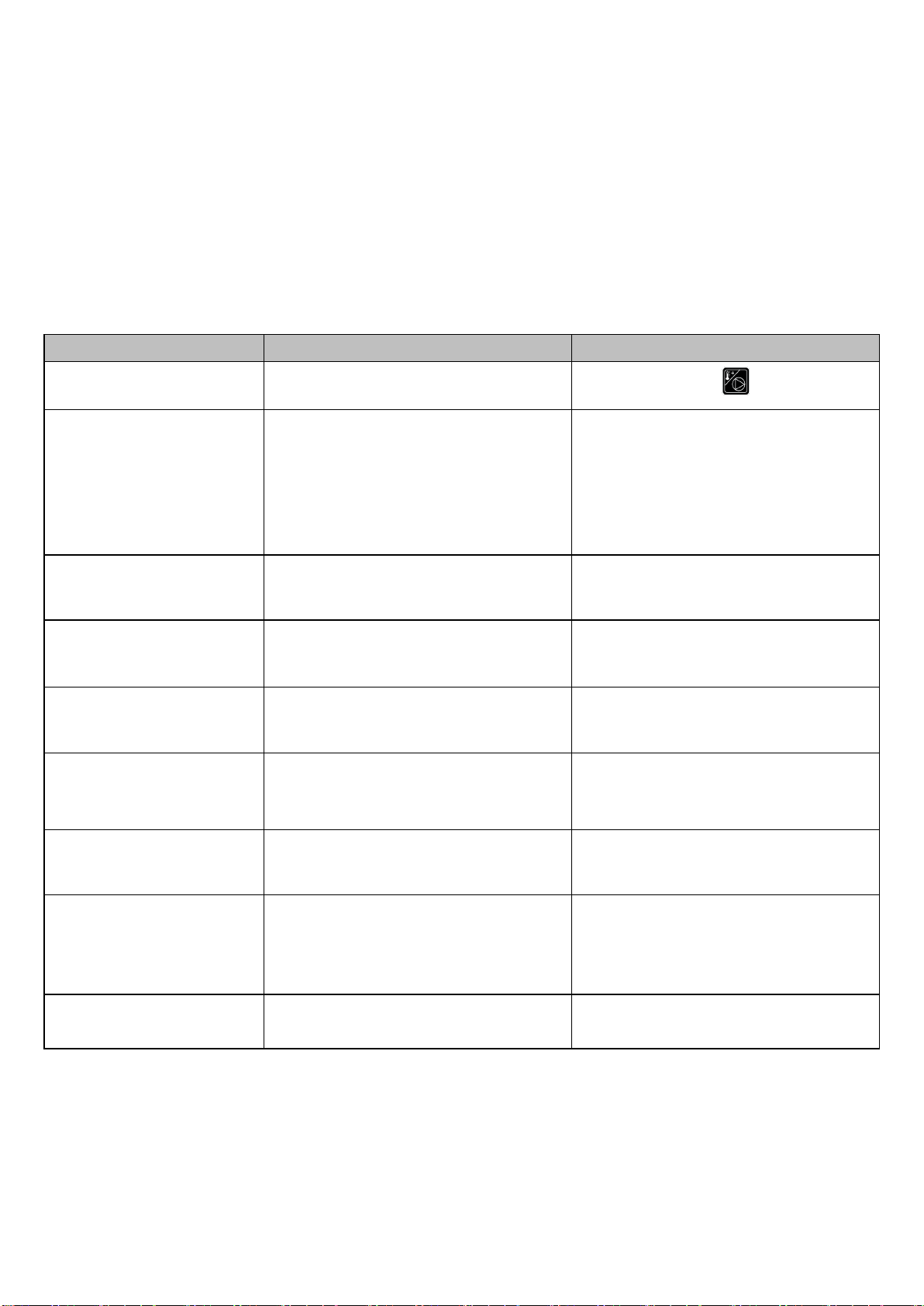

CONTROL PANEL FUNCTIONS

Indicator for pump in standby

Indicating pump operation: if blinking the pump is in standby mode (occurs after about 40

seconds of inactivity).

Temperature switch

Activates/disactivates: possibility of temperature regulation.

Indicator for lack of water

Indicating lack of water in the boiler: blinking with simultaneous intermittent acoustic signal.

Boiler switch/ Temperature reduction

Activates/disactivates the heating elements of the boiler.

If the temperature switch is activated, the operating water temperature can be reduced.

Indicator for Boiler switched ON

Indicating that the boiler is switched on.

Pump switch / Temperature rise

Activates/disactivates the high-pressure pump.

If the temperature switch is activated, the operating water temperature can be increased.

Indicator for high-pressure pump switched ON

Indicating that the high-pressure pump is switched on.

HYDROBOX

Pag. 12 TECNOVAP 36/18

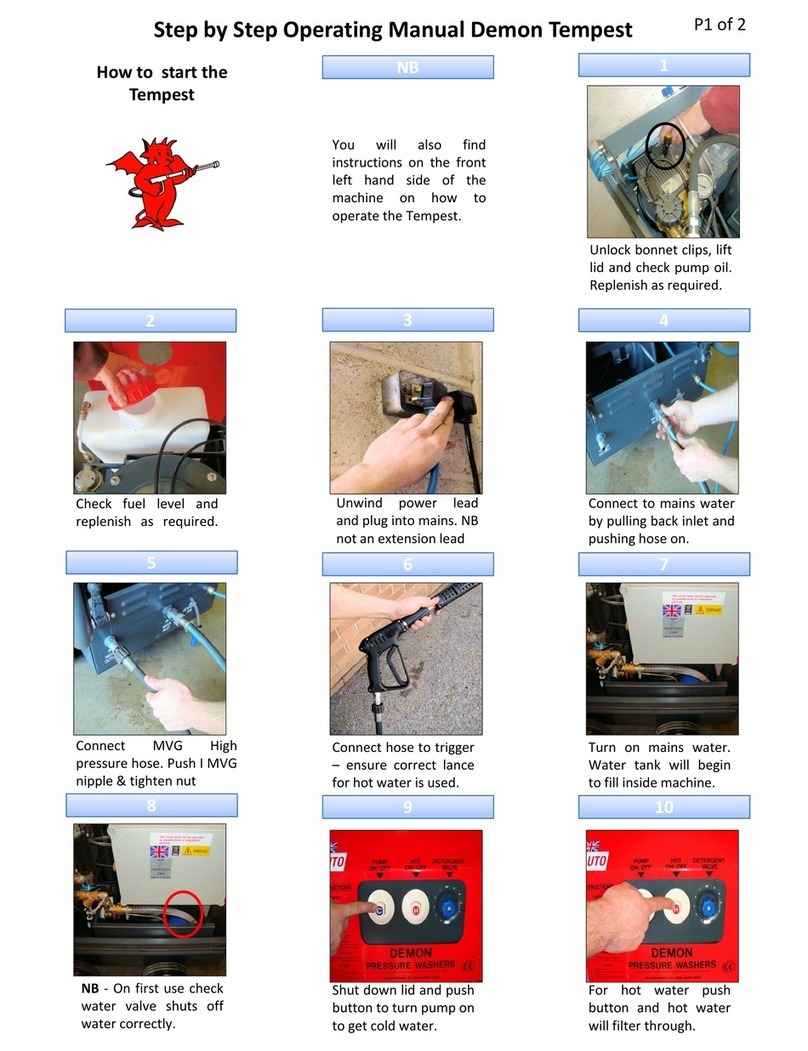

7. USING INSTRUCTIONS

(a) After opening the packaging, insert the manoeuvring handle (01) in the relative seat and secure in

place with the fixing screw (02).

(b) Connect the hand grip to the appliance (03) and insert one of the available lances (23) by screwing

the fixing ring to secure everything;

(c) Connect the appliance to the water supply (04) as indicated in chapter 3;

(d) Insert the power cable (05) in a power outlet, making sure that the voltage and amperage

correspond to the values provided on the machine data plate;

(e) Switch on the appliance by turning the main switch (06) to ON position and activate the boiler switch

as well as the pump switch .

Warning!!

Operating the lever (22) on the hand grip (20) will cause the release of superheated high-

pressured water with up to a temperature of 90°C, be very careful that this lever is not

activated inadvertently and that the water jet is never directed towards persons or animals.

Partial counter reset

The switched-on appliance (ON) should be in standby mode (OFF on the display), then press and

hold the temperature switch until the wording “C L R”appears on the display.

“C A L C”signal reset

After maintenance, carried out by the user, switch on the appliance and activate the boiler switch

as well as the pump switch . Press and hold the boiler switch and press the pump switch

, the wording “C L R”will immediately appear on the display and the appliance is thus resetted.

HYDROBOX

Pag. 13 TECNOVAP 36/18

8. MAINTENANCE

8.1. Boiler maintenance

WARNING

DISCONNECT THE POWER SUPPLY BEFORE CARRYING OUT ANY MAINTENANCE.

WARNING ! DANGER OF SCALDING

Cleaning of the appliance absolutely has to be carried out when cold (i.e. generator switched off

for at least 5 hours), in the following way: (we therefore do advise to perform maintenance at the

start of the next use, provided that at least 5 hours have passed since the former use).

The appliance is equipped with a maintenance warning system which informs the user of the need to

clean the boiler. The system is programmed to signal this condition after every 100 effective working

hours while showing the wording “C A L C” on the display.

When this warning is displayed, the machine can in any case be used until the started operation has

been completed. Then switch off the appliance with the main switch (06) and remove the power plug

(05).

Place a suitably sized basin under the appliance and remove the drainage cap (09) underneath, then

wait for the boiler to be completely empty.

Clean any dirt off the cap with running water, check that the seal on the bottom of the cap is in good

condition, replace if necessary (contact your supplier for spare parts), then screw the cap back on the

machine.

If the used water has a hardness of over 10 French degrees (depending on product use,> 2 hours/day)

water should be treated with special water softeners, these devices can reduce the calcium carbonate

content in the water to below 4 French degrees significantly improving the reliability of the generator.

(For further details or to purchase a softener filter, please do contact the manufacturer).

The boiler cleaning is done. Insert the power cable (05) back into the power socket, connect the

appliance to the water supply and activate the main switch (06). Remember to also activate the lever

(22) on the hand grip to bleed out the air from the empty boiler.

After completing boiler maintenance, proceed by following the instructions described in paragraph (c) of

chapter 7.

HYDROBOX

Pag. 14 TECNOVAP 36/18

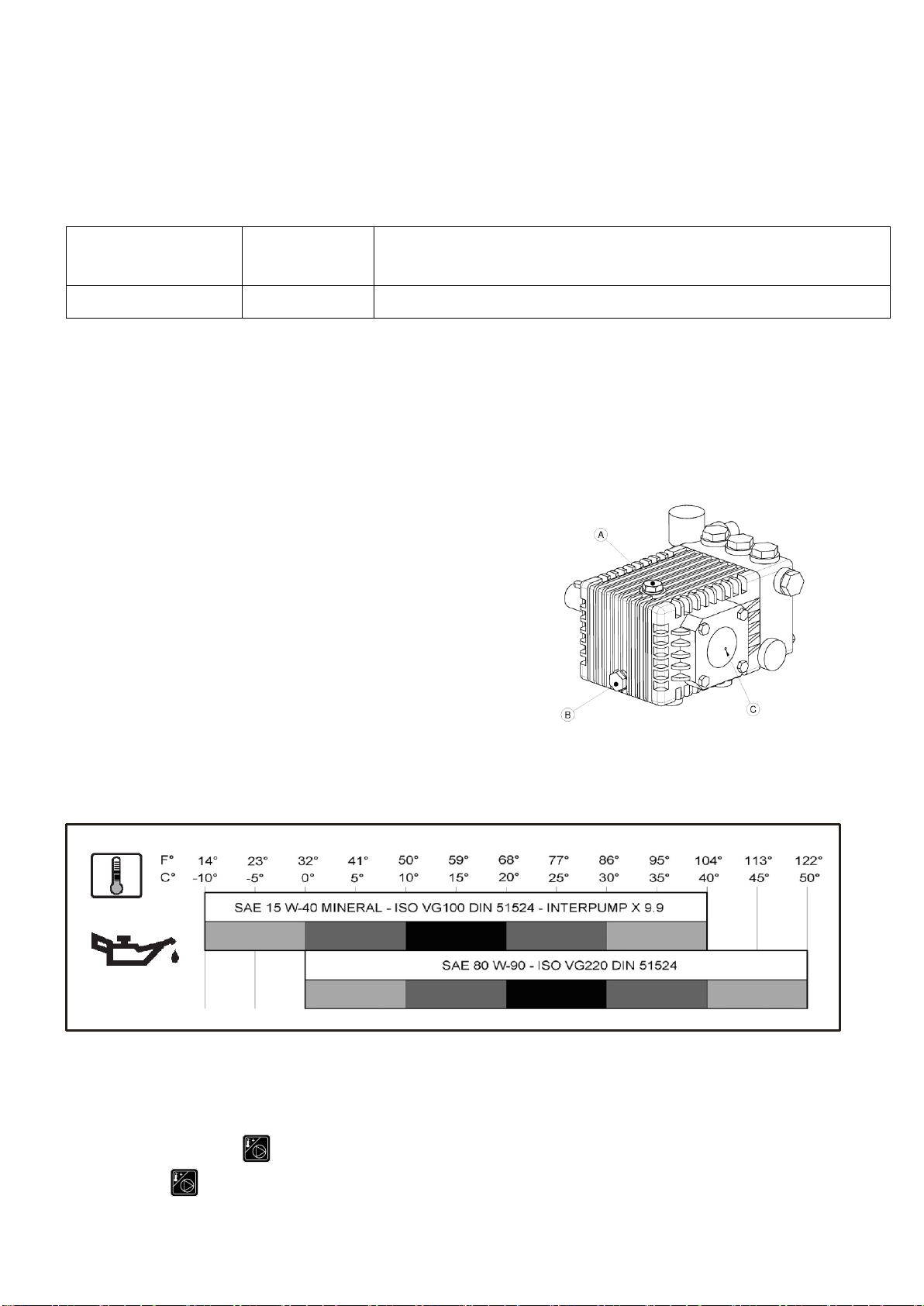

8.2. High-pressure group maintenance

Maintenance always has to be undertaken by specialized and authorized staff.

The oil change of the pump, the valve group and the pumping seals has to be carried out according to

the scheduled maintenance described in the table below.

After the first 50

hours

Every 500

hours

Every 500 hours (average interval, to be reduced with heavy-duty

uses)

Oil change

Oil change

Check/Replace: valve group, pumping seals

After achieving the first 50 working hours, when switching on the pump, the wording “P U M P” will

appear on the display to indicate the need of the first oil change. Subsequently this warning will appear

every 500 working hours, as indicated in the table.

Observe the replacement of the valve groups etc. as described, according to the working hours of the

pump visualised on the display.

Oil change

▪Place a basin underneath the cap (B);

▪Remove the oil drainage cap (B);

▪Unscrew the cap with graduated shaft (A);

▪Let the oil drain into the basin;

▪Screw back the cap (B);

▪Insert new oil through the cap (A) according to the

table below;

▪Observe the graduated shaft and the reference (C) on

the window for the correct oil level.

Oil type to be used

Cancellation of the maintenance warning “P U M P”

After having done the oil change etc. on the switched-off appliance (main switch (05) OFF) press and

hold the pump switch , then switch on the appliance (main switch (05) ON) and keep pressing the

pump switch until the wording “C L R”appears on the display.

HYDROBOX

Pag. 15 TECNOVAP 36/18

8.3. Filter maintenance

Check periodically the filter inside the coupling for the water supply connection (04) by grasping the

provided tab in the centre of the filter with a gripper. Clean and put the filter back into place.

9. BEFORE CONTACTING THE SERVICE CENTER

INCONVENIENTE

CAUSA POSSIBILE

RIMEDIO

Lacking of high pressure.

The high-pressure pump is not powered.

Check if the pump switch is activated.

The pump is making no noise when

activated.

The pump is not primed and is dry-running.

There is no water supply.

The flow line is blocked and does not allow the air

outlet from inside the pump.

Check the coupling to the water supply.

Check the water supply connection (04) and the water

tap.

Turn the regulator (08) anticlockwise on the high-

pressure lance.

The pump does not reach the due

flow capacity (see machine data

plate) and is excessively noisy.

Cavitation due to: supply lines and/or filter, insufficient

flow, high temperature of the water, blocked filter.

The incoming water should not have a temperature

exceeding 25 °C.

The pressure delivered by the pump

is insufficient.

The water use is oversized compared to the due one

or the nozzle is worn out.

Replace the nozzle on the lance, with an adequate

one. (see flow/pressure on the label of the high-

pressure pump group).

The pump is overheating.

The oil level inside the carter pump is insufficient or

the oil type is not suiting to the recommended oil

types.

Add or replace oil.

Water is leaking at the junction point

of the various accessories.

Check the deterioration of the O-rings.

Clean and lubricate the O-rings.

If necessary, replace the O-rings with the supplied

spares.

Visualisation of the wording “A L L 2”.

Exceedance of temperature threshold, missing boiler

drainage, pressurized boiler after discharge of the

sludge.

Insert the drainage cap, bleed out the air from the

boiler by activating the water release lever on the

supplied hand grip.

Noise inside the generator.

After cooling down (6-7 hours) an internal depression

is created inside the boiler, which causes vibrations

when switching on again.

Wait for the pressure to be stabilized inside the boiler

(about 2-3 minutes), the noise disappears.

The accessories do not fit perfectly.

Dirt has deposited on the O-rings and the couplings.

Clean and lubricate the joints of the accessories.

HYDROBOX

Pag. 16 TECNOVAP 36/18

10. DECLARATION OF CONFORMITY

DICHIARAZIONE DI CONFORMITA’ CE

(EC DECLARATION OF CONFORMITY)

TECNOVAP S.R.L. con la presente dichiara che:

la macchina per pulizia a vapore modello:

(Certifies that the steam cleaning machine model:)

Hydrobox

Risulta conforme alle specifiche delle direttive

(conforms to the specifications of directives)

2014/35/UE 2014/30/UE 2011/65/UE 2006/42/UE

Per il controllo della conformità alle sopraindicate direttive, sono stati seguiti i seguenti standard:

(For the checking of cconformity to the above directives, the following standards have been used):

Riferimento alle norme armonizzate:

(Reference to harmonized standards):

EN 60335-1

EN 60335-2-79

EN 55014-1

EN55014-2

EN 61000-3-2

EN 61000-3-3

PESCANTINA –VERONA (ITALY) 19-10-2018

HYDROBOX

Pag. 17 TECNOVAP 36/18

Routine Maintenance

Working hours of

the generator

Frequency of

intervention

Notes

HYDROBOX

Pag. 18 TECNOVAP 36/18

Non-Routine Maintenance

Working

hours of the

generator

Date of

intervention

Description of intervention, replaced components etc.

HYDROBOX

Pag. 19 TECNOVAP 36/18

NOTES

HYDROBOX

Pag. 20 TECNOVAP 36/18

THE MANUFACTURER RESERVES THE RIGHT OF TECHNICAL AND STRUCTURAL MODIFICATIONS AS

WELL AS IMPROVEMENTS WITHOUT PRIOR NOTICE.

This manual suits for next models

3

Table of contents

Popular Pressure Washer manuals by other brands

Greencut

Greencut JET260X instruction manual

Spitwater

Spitwater HP25400DE operating & maintenance manual

Kärcher

Kärcher K 3.67 M Operator's manual

Kärcher

Kärcher K 360 operating instructions

GreenWorks Pro

GreenWorks Pro GPW2200-1 Operator's manual

Nilfisk-Advance

Nilfisk-Advance MH 5M E Instructions for use