distributed by

7

1 General

1.1 Standards and regulations

There are dierent international standards for electrical machines, e.g.

• the international“IEC” standard or

• the North American“NEMA”-standard and others.

The motors covered by this catalogue are designed and manufactured according to the latest IEC standards.

Furthermore they full the relevant regulations of the European Community (“EC Regulations”).

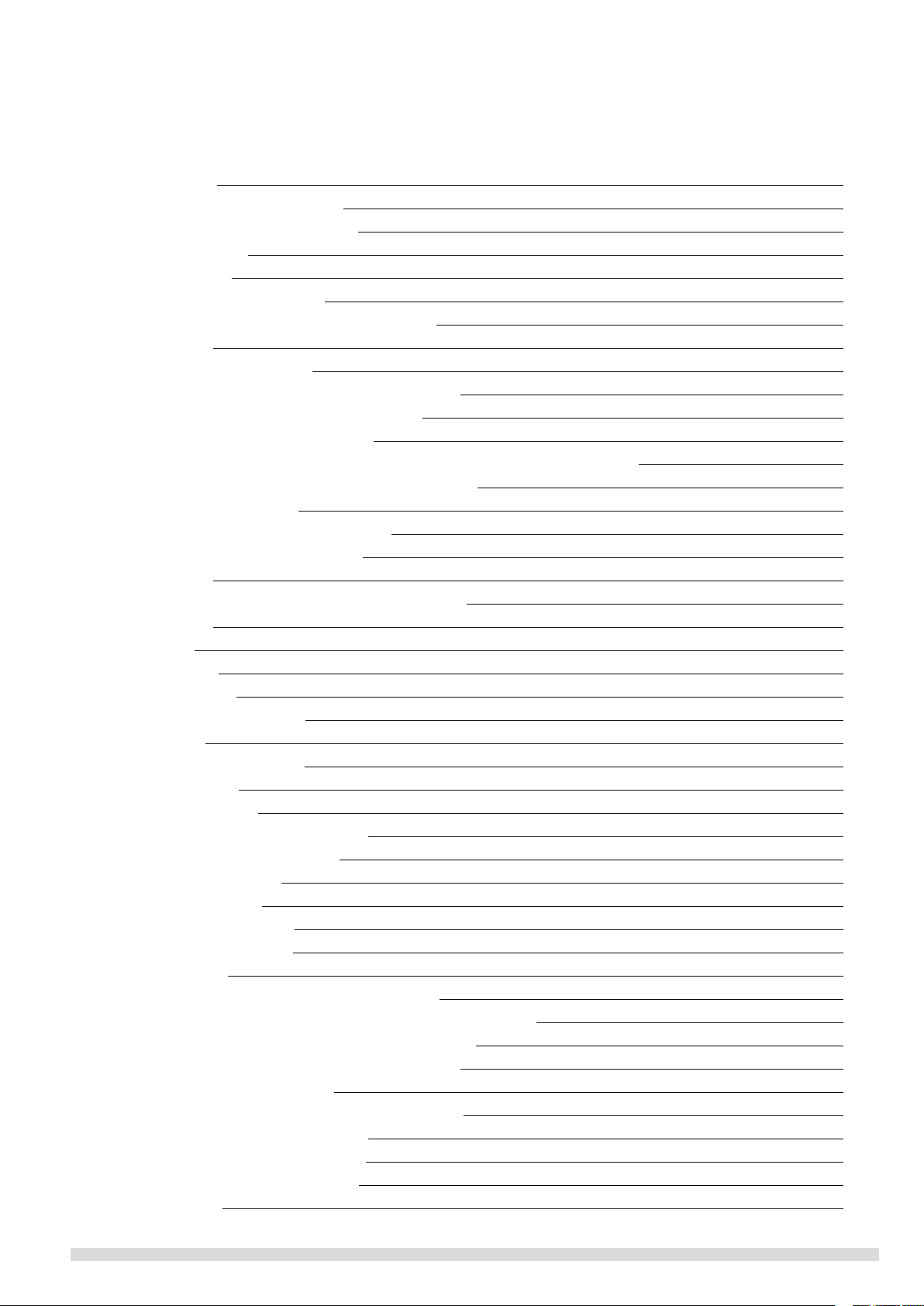

List of national and international standards and regulations applied:

Title International IEC Europe EN/Directive Germany DIN/VDE

Rotating electrical machines – Part 1:

Rating and performance 60034-1 60034-1 DIN EN 60034-1

VDE 0530 Part 1

Rotating electrical machines – Part 2-1:

Standard methods for determining losses

and eciency from tests

60034-2-1 60034-2-1 DIN EN 60 034-2

VDE 0530 Part 2

Rotating electrical machines –

Part 5: Degrees of protection provided by

the integral design of rotating electrical

machines (IP code) – Classication

60034-5 60034-5 DIN EN 60 034-5

VDE 0530 Part 5

Rotating electrical machines –

Part 6: Methods of cooling (IC Code 60034-6 60034-6 DIN EN 60034-6

VDE 0530 Part 6

Rotating electrical machines –

Part 7: Classication of types of

construction, mounting arrangements and

terminal box position (IM Code

60034-7 60034-7 DIN EN 60034-7

VDE 0530 Part 7

Rotating electrical machines –

Part 8: Terminal markings and direction of

rotation

60034-8 60034-8 DIN EN 60034-8

VDE 0530 Part 8

Rotating electrical machines –

Part 9: Noise limits 60034-9 60034-9 DIN EN 60034-9

VDE 0530 Part 9

Rotating electrical machines –

Part 11: Thermal protection 60034-11 60034-11

Thermistors, PTC - - DIN 44081:1980-6

Rotating electrical machines –

Part 12: Starting performance of single-

speed three-phase cage induction motors

60034-12 60034-12 DIN EN 60034-12

VDE 0530 Part 12

Rotating electrical machines –

Part 14: Mechanical vibration of certain

machines with shaft heights 56 mm and hi-

gher – Measurement, evaluation and limits

of vibration severity

60034-14 60034-14 DIN EN 60034-14

VDE 0530 Part 14

Cage induction motors when fed from

converters-Application guide TS 60034-17 - -

Mechanical vibration; balancing shaft and

tment key convention - - DIN ISO 8821

Mechanical vibration – Balance quality

requirements for rotors in a constant (rigid)

state – Part 1: Specication and verication

of balance tolerances

- - DIN ISO 1940-1:

2004-04