Enya 36-4CD AL-CHROME TN User manual

36-4CD AL-CHROME TN tffiltmmill önye

OPERATING INSTRUCTIONS

nENGINEX lset

L-ü An attachment for engine, each lset

lMain needie, hollow serew, needle seal" each I pcs)

lHead cover & set screw X I set. push rod tube X 2J

n M534C MUFFI-ER X 1 set

ü 55065 HEAD GASKET X 2 pcs

ü TS534C TOCIL SET x 1 set

lsme{r driver (-) x 1. open-end y{rench X }, ailen mench X 3l

N IN$TRUCTICINS

lGeneral c*ta]ogue,this manual for engine]

TYPE; 4 strake cycle, diesel: *eltlignition, with overhead

valves driven try push rods and twin camshafuts.

36*4CD A{-*tHRÖh{H TN

Ilisnlacement 5.89 cc (0.359 cu.in.)

BorcXStrohc 2l.0Xl?.0 mrn

Max power s.6 lrF

Rr*ational eneed 1,800*9,000 rpm

Weieht 360 s {wüfio$t müffler)

$izn ofrroüol$r t?*l{X8*5 in,

Weieht of airnlane ?.0*3.6 kc

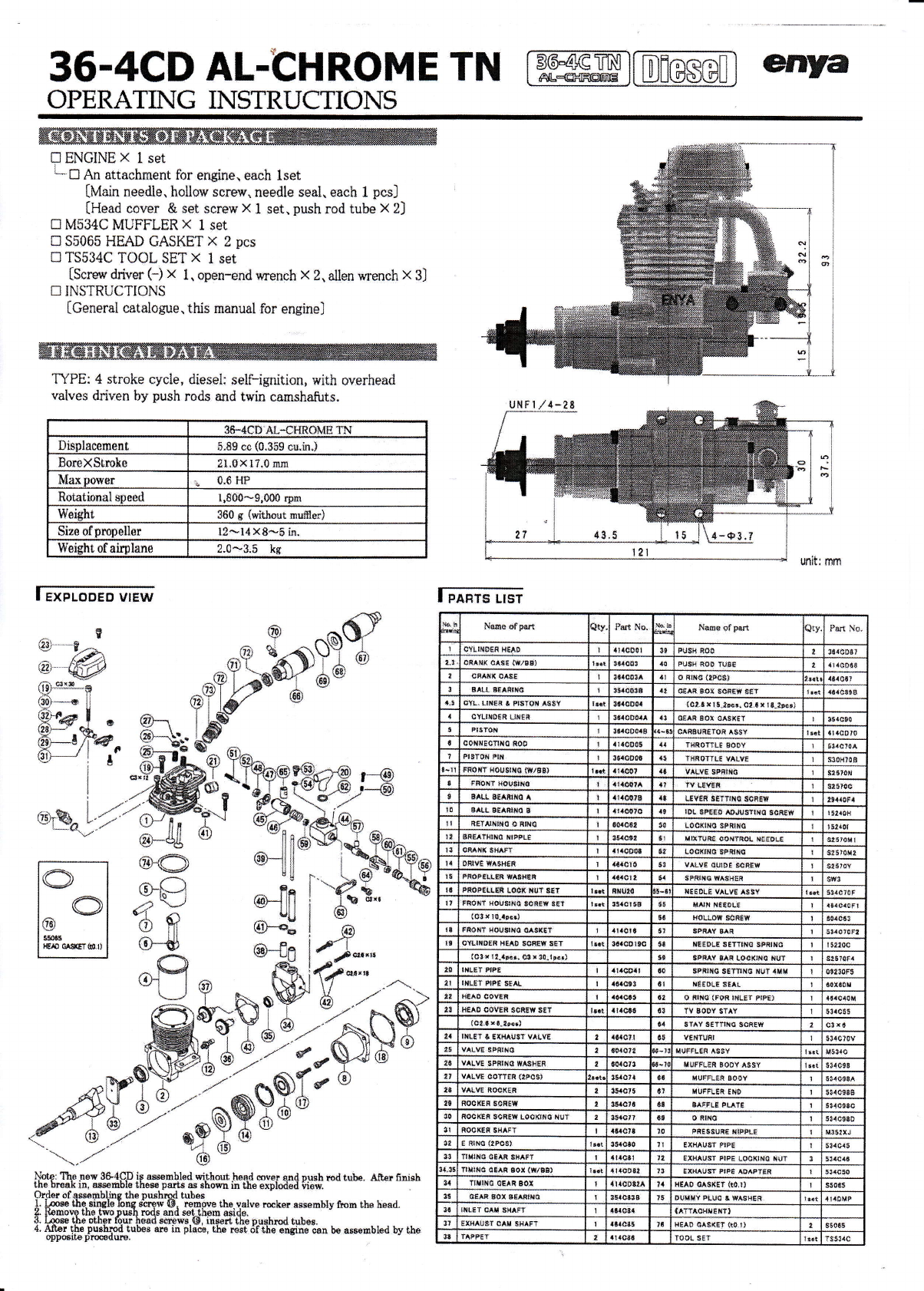

I äxpLoDEo vrEw .s?YS

n.TS4*-

.ru'Ld^

Y;: W

-*L*w,*'ry

Ft ffi#Äw

lff*,,,l ffi ffi: irt

*Mwsffi

,4fläffi$ter

ia

Not€: The .new 3&4$p ig awmbled wi_thout hoqd wet and Dush md tube. After linish

the break in, ssmble thös parts ru ehown in the exoloded view

Order of asscmblinc the nwhmd tuboe

l. lmea the.singl€ long rbrew €l, remgva ths.qalve rtrker mrembly ftom lhe head.

a ltßmove the lwo Duslr rods md sgt, thom asde.

3. lm the otfier four hsad swwe C). iumrt lhe nushnd tubc.

4. Äft,€r thä puthrod tubes ue in plsm, the rest df the angina can be asmmbled by the

@P6lt€ PrcduB.

fFAFTs Ltsr

Nsms ofpüt ,lty Psrt Ns, Fiana sf p{rt JIy Pörl Nü"

CTLIEBEfl IIGAü I{ltco0r 9e pusH göü JircD6l

1,3 oRA|\l]( Orsg lw/6gt 3gct3 {o PUSH EON TU9C { l4soü3

c8ttx oÄ88 3CtCSSt o RrN6 (zPCAl 4tlet]

SALT BEIRIilC 35r6StS at OEAR BOX SOFEW iEI {ras{ta

t.5 oYL LrtER t RStOil ÄSSr Srico0r {gt.i ! i5-3ro!, C2., I tq-:r.r}

CYLINOSR Ufl5ä 96460041 at oEln gox 6^a,(81 I354C00

pr$Toil sroD0.6 c aoua€rofr ^$5e tt tqolt

!col{ffEtnxc Röo 1rqt03 4{ rflf,Ö;TLE sooY 934d:0A

F'$IOX Hfl ,!1CS0! ts TI.iRÖfilr 'ALY6 E3OX?!E

l*l lFFoNr Hö|]$]te {ffsa) 4r{ö0? 4a VALV€ SPitt{i s2s?oft

räotT HotJ$*6 at{0ö}A *t YY LEVifi gr9lco

süALt AEAntfiö n41a0s7a *l LtvlR $Efirßq ssnät tt440F4

tü tl|f' aE^fitr*6 Ir4c0lg {t r0r" sFggo AöJu5r|üq süfißft l 5:40H

It RETXNIftö O ANC ooaoöt 30 LOC|(INo tpRf+o t5zrs

gR€At,tlitc tt}plt ?540t, xrxluät coilTmL rlEbl€ a!5r0Ml

gRlrix fll Fl rr 4cosN 62 LOGXIIc BpÄlüü 6?StüE!

öFtvü wA5HgR .td1ct0 VALYE 6UDC $CRf[ $1S)0V

PfiÖPiLLEi SIDIIET aa,tctt 5{ spittrg rl^sHcn ss3

t! pRoFerrtt Lodl( rlut ü6t Rlt{rt0 t-ü xs60LE VALV€ AäSV tslci0F

IrRÖilT HOUSIil6 ICR€X SET rrGtSa 8aN trl€t0Lq it{ct0fl

(O3 I lo-ar{i} 5t HSLLOX SCRSS todci!

t8 fn4ßr HOUS${o $r$'(tl {raclt $pRAY Srn 5t4010f2

It oY{lroEn xEs ss:* sET $a@1rc 6a trEEDU SETTNC SPf,IIC I sxt&

(Ct' l2-1!a.. ö1x30 l!..1 t9 SPNAY gAR LOdKIIiT NUI s2570F.

a0 II{TET PIPE 4lacDt ImsPF$io sETTrNc rtlt 4ru 0$:toFg

2l II{IET PIPE SEAL [4913 cl AEgOLT SEAL t0xttc

rlEA0 covEa 4n4Cti ,2 q RIN€ IFOf, IdLEI PIPä) {!4Cr0t

tz hEÄo covEh scäEw sEt l$ai at aqtc f3 TY OOOY STA' sSre!ä

{C2.! , n b.r) ta STAY STTTINC SCf,EW c3 xi

t{ IXL€T T IX|{^ilgT VALV{ attc?l 05 v€'lTURr 33t6?0Y

VALY! 8PfrIXG !01c?g {II}FFLEN A6SY [83{O

26 vaLv€ sFntilo flÄsHER to{ctt !-l IIUFFLEi BÖOY ASSY 53{S3t

2: yALVE OOtT€i {}pCSt t5{cil 6t T.IUFFLEF I6'Y iS,icsst

1ü y Lvr ft001{En lg.Grt a? &UFFLER !NÖ 5t4CS8B

29 ROOXE6 SÖn€lI ltr6It ü8 g^FFLE PLATE !34098C

äocx€f; $cREw Loci{ltio t{t TgS{Ett to Rlr{o 5i{OS80

ROCX:R 3'{AFT .iactt lo PRF*IUR€ TlPPTE XJgIXJ

32 E flilG (TPcs} 334C8! EX|J USr $pE 53{C{$

TITIffG CEAN 8HÄFl I+t +cl EXHAUST FIPE LOE(INO XUT 53{Cd6

4.t! nxtt{o eE^a 60t {ff/€g) I 5at { r 4co& ?a €XMUST PIP$ ADAPT'R 534C50

3{ nrr{6 oGi.i got lriöüütJl i,. HE,^b eA*t(ti ttd.r) 850!5

It GEAR 5OX BEMiTG 3'{G'IB DVI'MY PLUO T IIASHER a ttoMp

lttET cÄt sHtFt {aact{ (ÄTTrsHrFXr,

EXH^ü$T CÄI StrFT {t4e{5 7A HEAD CA8Xff (!0 J) 3506i

35 IÄPP81 41tO8! TOOL FTT ts534C

"S $PEGIALATTENTIOH

1. In general, model engine is very powerful and rune at lery

high speed. Never handle it, carelessly. "Safety lirst" ie most

important in all reepects when you run model engine.

2" When fhe 86-4CD ie new, you may feel that the pistoat doe*n't

work $üssthly (tight) near the top dead center. However, it i$

no problem because the 86-4CD is "AAC" *pecilications not to

have a piston ring.

3. The 36-4CD is re$lated to the euitable compresaio* rstio at

factory shipmant. So, at Sret you ehould start running täe en-

gine just as it is"

4. The diesel engine hae eelf-ignition system. Never idly ftip the

propeller, beearrse it could start sudenly. I{andle iü with great

I ff; you run tbe 36.4CD, take care of the following points.

O Tighten the engine mounting ecrewe and propetlei nut once

again.

O Make eure thai there are nobody near around {except your ae-

eretant).

O lt is most irnportant to coafirm that, your rad:o control equip-

ment works well. If you find a defective point on il you muct

never fly your plane. And then repair it pirfectly.

+ FUEL

The 36-4CD will start aud rua on commerciallv-available model

dieeel fuel of high quality. Tbe recomnended foimula is 4gYa ker-

oeene, 3S% ethyl ether, and 25% castor oil, t L% tß 8% amyl ni-

trite or amyl nitrate added to the fuel uray make for slightly

smoother running.)

+ PROFELLER

The 36-4CD will perform best with the pmpellere of high quality

which run 6,ä00 * ?,6ü0 r.p.m. on the ground.

At first choose the well-balanced 13 x 6 or 1ä x $ propeller cf

t_righ Ouality. You can get *mooth running and good idling with

the propellera made of glass fiber ae they perform ae an ade-

the propellera-made of glaas frber as tliey perforn as an ade-

quate {ly-wheel. When yo'$ use a wooden prq)eller ofrather light

werght, it is re*omare*ded to u$e a spinner al a fly-whoel.

-T. FUEL TUBE

The 36-4CD must not use the eili{on based fuel tube and rubber

parte qf the filler cap. Chocse the goods made of vinyl or neo.

prene for the gasohne engine.

.t FUEL TAf'lK

A fuel tank of about 150 - 900 cc is resom'mended for normal

Ilight,._ For eaeiest engine etarting, set tbe fuel tank at nearty

same lev€l ag ühe carburetor.

* PROTECTI\IE GLOSE

Hand.atarting i.s recomneuded fsr tlre $6-4Cn, so prq)ere the

errong reätner glovet.

-E FREPARÄTTON$ BEFORE STARNNG

1. Connect a pieg of vinyl pipe of about 10 cm length ou the

breatlring nipple, to lead tLe excees oil in the crankia*e out of

the frrselage.

l" Add üh* various exhauet and mufller bodv to the cvlinder

head, qp shg* io tJre,exploded view Tighteä these firä1y, be.

- Salrse they have a kndency to loose as tf,e eng:iae rults.

3. lt is unnecessary to pressurize the fuel tsnk*witÄ the mulTler

pree"re q: a 1ule.Jt ie gCIod to stop the pressure nipple of ex-

haust mulller by a hoee nlip.

4. Set prqeller with double rock nut, tighdy. At that time, chooee

the- best setting angle of pr4eller at the compressioa stroke

to flip it with your finger.

.{" STARIII*G A}ID RUI{NII|G

{he^following process ie xccommended ta 6tayt a new engine at,

tbe flrst time.

1. Fill the tanh with dieeel fuel, and close the 6l1er cap.

2. Don't adjru-t the rnixture ccntrol needle. It, ie irüporüant to

keen it the factof,v default eettins.

Ieep i! the factory dehult eetting.

)pen the.main needle 2.5 turns fiom tÄe fully cloaed poeiüion.

?. The engine will start, keep running it whiie 20 * 30 seconds

wit!,rout adjusting the throttle valve. The engine will etall

easily that its own isn't warming enough.

8. Open tlre throttle valve fully, then close the needle valve slow-

ly to the beet running poeition. But it is irnportant to run the

engine with a slightly rieh mixtrrre to get the best perform-

&nt8.

9. Cioee the throttle lve slowly, and set ihe idling epeed. Relia-

ble idling speed i€ f800 * 1200 rpm.

10. I-astly, check the medium epeed range lo open and cloee (low-

high, high-low) the throttle vahe repeatedly.

Ifthe thm-ftle resposs€ is siovg-moving, cioee the uixtirre con-

trol needle 1/3 - 1l{ turns to mean some rieh nixiurc.

U tbs throttle response is quick-moving , olea tbe mixture

eontml needle U3 - U4 tums to meen some weak mixture.

Ia any ease waürh the resultcarefuIl3r

11, If you lost adi-ustment, stert again from the factory default

settings fi.rst of all.

X Strndard sf neüdlr retting I ritlnut tha uuffler prasslr* )

Ordtr of a,iusutncrl Ranrü of äJtAünlnt 0*frult Efttk in R6l rün

lldln ne{Sr 1älrd llith rffid Ittount 2 5 tufN ÄSölnl 2 trrffi

l" Uixtüru on$d redh 1.5 tum! l-i lürß I 5 fum!

+ BA€AK ll'l

Run your eagine about W - L hour on the gxound.

Dqriog this period the engine running is Äomeiimes unsmooth

and unstead;r But a,s you eoutinue thä breaking in, ttre ensine

running will become amoother and more powerfi.rl. usually, itlvil

take 1 *I hours fsr the engine ts reach its peak in power and

smoothness.

+ }IEAD GASKET

The compreseiog ratio is adequate for ncrrnal running. But in

qa^se you use a big propeller and find sone tendenry of engine

knocking, it is recommended io r,ree the extra head sasket (en-

closed in tle box, 2pcs). Disassemble the cylinder häad, iruert

tÄe gasket between cylinder head and liner. The compression ra-

tio becomee low, and the knocking tendency will vanisb.

.e MAtl,tTE!{ltittE

1. Qol't screw the cylinder head of 36-4CD tighfly to awid the

deformation of cylinder liner

?. p.ry* ühe-cylinder head Lo erank caee when the engine i* co1d.

3. It is uually needlese to supply some oil ro the inlner mecha-

niem, bacawe the oil contained in fuel lubricatee oil of the

parts.

+ ADJU$TMET{T OF VALVE CLEARAI{CESE

fh* -1oqg$ valve clearances of Valve clearance

3;^31;1c9:: 9'1 ;tr?- n: öiäi:ä

when the engine is cold. It ie rec-

3. Opan the aain needle 2.6 turus

omraended to make tlre first sd"

jwtmeni of valrm clearance after

{rst 112 * t hour of rururing wit}r

the wreneh and drivrr encloee in

tlr. bof.Also addurg or removrng

the rylinder head iasket will afl

the cylinder head fasket wil] af 4]ms;; sl. wsß trffi""l

fec't the valve clearance setting. Be sur€ fo re-adjust it. It is im-

fect the valve eleareffie $etting. Be sur€ ro re-adju.ot it. It ie im-

portant that,.the.adjustrnent is to be made wheä the engine ia

po"{ant that_the adjustrnent

cold. (The-valve clearances begome wider when the eaginäis hoi

becau$e of the expansion of cylinder block.)

+ METHOD OF EHGAGI}IG TIIIIING GEAR WITI{ CAM

SI{AFTS

The disassembline and aeeeglbiine of

ihe 36-4CD is noiso difficult. But-do

it, carefuLly:

1. lVhen you assedle thc tim"iag

gear bax, prrt the pisüo* at the top

dead wnter, and th€n cümbine the

uotches cf gear sbäfts and the

uarks of carn sha$s &s sh$wil in

the ägure on the right.

The standard timing of valves are

as hllaws"

Inlet valve open 20' B.'llD.C.

Inlet, valve clü$e 6{J' A.B^U.C.

Exhaustvalve open 60" B.B.n.ü"

Exhaustvalveclose g0' A.T"D.ü,

2. The 86-4CD of nor:nal rctatiorr cs.rr

be modified inta t"he revergäl en-

gine.

Rebuild to move each (inlet and

exhauqt) cana ehafts ?0 degreee to

the left or righl ae ehowü in the

figure on the right,

HOSIIAL ROTATICIN

lhEbl'o{i|l[ {gweatffilh!

aoüel FoEi[ofis of tinlifig 06'r qirn

*E pirton k st lhs bp dad csbl

lfitüt Extrrurt

ftEVERSE RüTATTOII

ld{t Exhüurt

(!5r grg the tanL is pressurized, Z turne.)

4. Chokeby cloeing the ialet port ofcarburetor with your finger.

Tbrn the propeller very elowly until the fuel in the hose reacb"

ee to lhe carburetor. Then, in additiorr türn the propeller

about 5 timee. The fuel as priming will be sueked-isü) the

crank caee and blown up into the-Wliüder and combustion

cbamber,

5. Open the throttle valve by {0 * 50 X.

6. ni*.tbe propeller counler-clockwiee quiekly by your hand

with the protective glove.

ENYA ITETAL PMH.|CT]S CrI., LTD.

1&3 RKUMASAWA-HIGASHI IRUMA-CUN MIYOSHI-CHO SAITAMA. 354.M4O JAPÄN

Popular Engine manuals by other brands

KSB

KSB IE4 Installation & operating manual

BAFANG

BAFANG MAX Drive System Dealer's manual

GRÖNINGER

GRÖNINGER MR Series instruction manual

Briggs & Stratton

Briggs & Stratton 310000 VERTICAL SERIES Operator's manual

MTU

MTU 12 V 2000 S96 operating instructions

Nice

Nice RDF-140-20 Instructions and information for installation and use