TECSYSTEM NT538 User manual

http://www.tecsystem.it

INSTRUCTION MANUAL

TECSYSTEM S.r.l.

Via Cristoforo Colombo, 5/C

20094 Corsico (Milan)

phone +39-0248601011 / 024581861

Fax: +39-0248600783

NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

R.1 08/09/05

NT538

Cross Reference RA Part Number PP8704

2NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

INNOVATIONS INTRODUCED WITH THE NT538

1. New hardware and software for a further improvement of immunity to disturbances.

2. Reading rate increasing, indispensable for applications where fast temperature

variations must be monitored.

3. Intelligent control of alarm detecting relays which is able to exclude possible

overtemperatures caused by an external disturbance without causing working prob-

lems or manual reset conditions.

4. Detecting of possible corruption of data stored in the memory (Ech) and default

value reset for security.

5. Storage in T. Max mode of possible alarms occurred from last reset and recording of

possible sensor failures.

6. Error detecting in case of wrong programming with specific indication of the wrong

value couple.

7. Possibility to return to previous programming step for a faster value modification.

8. Safer programming block which can be activated just through the closing of an inner

jumper.

9. SCAN display mode to see, in sequence, the temperature and the state of the

alarms for all channels

10. 8 channels with two programmable thresholds in an independent way.

11. Fan contact to check a cooling system.

12. More compact sizes compared with T538 version1.

13. Options with serial output to control the expansion module such as:

a) EXT 4.20-8: module with 4-20 mA outputs for each channel

b) EXT RL-8: module with 2 relays (alarm and trip) for each channel

c) EXT RS485 Modbus: module for connection on a Modbus network

14. Possibility to connect many expansion module on serial output in order

to have many expanding options simultaneously.

3

NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

1) TECHNICAL SPECIFICATIONS

POWER SUPPLY

• Rated values 24-240 Vac-dc

• Highest tolerable values 20-270 Vac-dc

• Vdc with reversible polarity Vdc

COMMUNICATION

• option

INPUTS

• 8 inputs RTD Pt100—3 wires

• Removable rear terminals

• Input channels protected against electro-

magnetic noises and spikes

• Sensor length cable compensation up to

500 m (1 mm² )

OUTPUTS

• 2 alarm relays (ALARM-TRIP)

• 1 alarm relay for fan control (FAN)

• 1 alarm for sensor fault or working anom-

aly (FAULT)

• Outputs contacts capacity: 5A-250V ac

resistive.

TESTS AND PERFORMANCES

• Assembling in accordance with CE rules

• Protection against electrical noises

CEI-EN50081-2/50082-2

• Dielectric strength 2500 Vac for 1 minute

from relays to sensors, relays to power

supply, power supply to sensors

• Accuracy ± 1% full scale value ± 1 digit

• Ambient operating temperature from –20

°C to +60°C

• Humidity 90% no-condensing

• ABS self-extinguishing housing NORYL

94VO

• Frontal in polycarbonate IP65

• Absorption 3VA

• Data storage 10 years minimum

• Digital linearity of sensor signal

• Self-diagnosis circuit

• Option protection treatment of elec-

tronic part

DISPLAYING AND DATA MANAGEMENT

• 1 display 13mm high with 3 digit for dis-

playing temperatures and messages

• 8 leds to show selected channel

• 4 leds to display the state of the alarms

for selected channel

• Temperature monitoring from

0°C to 240°C

• 2 alarm thresholds (alarm/trip) for each

channel

• 2 ON-OFF thresholds for fan control

• Sensors diagnostic (Fcc-Foc)

• Data storage diagnostic (Ech)

• Programming access through front key

• Automatic output from programming cycle

after 1 minute of no-operation

• Wrong programming automatic display

• Possibility of setting automatic channels

scanning, hottest channel, manual scan-

ning

• Maximum reached temperatures, alarm

storage and sensor fault.

• Frontal alarm reset push button

DIMENSIONS

• 96 x 96 mm-DIN43700– depth 140 mm

(terminal box included)

• Panel cut-out 92 x 92 mm

SOFTWARE RELEASE

• P8 V4-R.1.4

4NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

2) MOUNTING

Make a hole in the panel sheet with dimensions 92x92 mm.

Firmly tighten the device with the enclosed fixing blocks.

3) POWER SUPPLY

NT538 control device has an UNIVERSAL supply, i.e. it can be indifferently fed from 24 to

240 Vac-dc, regardless of polarities in Vdc.

This peculiarity is obtained using a new-concept and new-designed tested feeder, which

relieves the technician of each concern for the correct supply Vac or Vdc.

To terminal 41 must always be connected the ground.

When the control device is directly fed from secondary winding of the transformer to be

protected, it can be damaged by high-intensity over voltages.

These problems occur if the main switch is connected without load.

Above mentioned problems are much more evident when the voltage is 220 Vac is directly

taken from the transformer secondary bars and there is a fixed capacitor battery to phase

the transformer itself.

4) ELECTRICAL CONNECTIONS FOR ALARMS AND FAN

Carry out the electrical connections on the removable rear terminals, after having removed

them from the device.

ALARM and TRIP relays switch only when the set temperature limits are reached.

FAULT relay (Fault) switches when the meter is fed, while gets de-energised when a fault

occurs to Pt100 sensors, data memory fault (Ech) or when supply voltage is lacking.

FAN contact can be used to check the cooling fans or it can be inserted in a transformer

room conditioning circuit.

5) TEMPERATURE SENSOR CONNECTION

Each temperature sensor Pt100 has a white wire and two red wires (CEI 75.8 standards).

Fig. 1 shows the position inside the terminal box of monitoring unit connection cables.

Each channel can be independently programmed with two alarm thresholds (alarm and trip).

To protect the control device from line over voltages, we suggest to use the elec-

tronic discharger PT73-220, designed by TECSYSTEM S.r.l. for this specific pur-

pose.

As alternative we suggest to use supply voltages from 24 Vac or, much better, 24

Vdc.

5

NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

6) MEASURING SIGNAL TRANSFER

All the measuring signal transfer cables for Pt100 must absolutely:

• be separated from the power ones

• be made with shielded cable and twisted conductors

• have at least 0,5 mm² section

• be twisted if there is no shield

• be firmly fixed inside the terminal boxes

• have tinned or silvered conductors

All “NT” series control devices have the sensor signal linearization, with a maximum error

of 1% of full scale value.

7) TEMPERATURE SENSOR DIAGNOSTIC

In case of breaking of a temperature sensor mounted on the machine to be protected,

FAULT relay immediately switches with the relevant indication of defective sensor on the

corresponding channel.

• Fcc for short-circuited sensor.

• Foc for interrupted sensor

To eliminate the message and reset Fault switching, it is necessary to verify Pt100 con-

nections and, in case, replace the defective sensor.

8) PROGRAMMED DATA DIAGNOSTIC

In case of breaking of the internal storage or corruption of programmed data, just after

switching on, it appears Ech indication with the relevant reporting of the Fault contact.

In this case, for safety reasons, the default parameters: NCH=8, Alarm Ch1-2-3-4-5-6-7-

8= 90°C, Trip Ch1-2-3-4-5-6-7-8= 119°C, Fan= YES, Fan-on= 70°, Fan-off= 60°,

HFn= 000 are automatically loaded.

Eliminate Ech indication by pressing RESET and run programming to insert desired val-

ues.

Finally turn off and turn on again the unit to verify the correct memory working; in case it

is damaged and Ech still appears, please return the monitoring unit to TECSYSTEM for

repair.

9) TEMPERATURE DIAGNOSTIC

If one of the temperature sensor detects a temperature higher than 1°C compared to set

value as alarm limit, after approximately 5 seconds ALARM relay switches together with

turning on of channel reference LED ALARM (CHn).

When the release temperature limit is passed, TRIP relay switches together with turning

on of channel reference LED TRIP (CHn).

As soon as taken temperature returns to equal or lower values than set limit for ALARM

and TRIP relays switching, they de-energise with consequent turning off of relevant

LED’s.

TECSYSTEM S.r.l. has designed an own special cable to transfer the measur-

ing signals, according to CEI standards, with all the protection requirements

provided for : mod. CT-ES

6NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

10) COOLING FAN CONTROL

NT538 monitoring unit, if opportunely programmed, can control ON-OFF of transformer

fans, according to set temperatures.

Fans on machine are driven using the temperatures taken from enabled channels.

11) FAN TEST

It is possible, through programming (hFn), to lay down that fans are activated for 5 minutes

each “xxx” hours, regardless of column or room temperature values (ex.: with hfn=001 fans

are activated for 5 minutes each hour).

This function has the aim to periodically verify the working of the fans and their control ap-

paratus during long idle periods.

Loading 000 value, this function is inhibited.

12) DISPLAY MODE

Pressing MODE key, display mode is loaded:

• SCAN: control device displays in scansion all activated channels (each 2 seconds)

• AUTO: control device automatically displays the hottest channel

• MAN: channel temperature manual reading of channel through cursor keys

• T.MAX: monitoring unit displays the highest temperature reached by the sensors and

possible alarm or fault situations occurred after last reset.

Select channels with

Sand T, delete values with RESET.

13) WORKING PROGRAM CONTROL

To check the programmed temperature values, shortly press PRG key. VIS indication ap-

pears for 2 seconds, confirming entering in program vision mode.

By repeatedly pressing PRG key, all the previously loaded values are rolled in sequence.

After 1 minute of keyboard no-operation, display-programming procedure will be automati-

cally left.

To end display, press ENT key.

14) LAMP TEST

We suggest to regularly carry out monitoring unit LED test.

For this operation, shortly press TEST key; all displays turn on for 2 seconds.

If one of the LED’s should not work, we kindly ask you to return the monitoring

unit to TECSYSTEM (Led RS is not available on monitoring units without optional

module)

7

NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

15) ALARM RELAY TEST

This function allows to carry out a test on relays working without having to use further de-

vices.

To start test procedure you have to keep pressed TEST key for about 5 seconds;

TST indication appears for 2 seconds, confirming entering in Relays Test mode.

Blinking led shows the relay to test; using the cursors you can select the desired one.

Press SET and RESET keys to energise and de-energise the relay to test; display will show

ON-OFF.

After 1 minute keyboard no-operation, RELAYS TEST procedure will be automatically left.

To end RELAYS TEST procedure, press TEST key.

16) ALARM RELAY EXCLUSION

If you want to exclude the ALARM signal press RESET key: relay de-energises itself and

LED ALARM, which was fixed, will start to blink.

Exclusion system is automatically disconnected when the temperature goes under the

ALARM threshold.

17) IMPORTANT NOTICE

Before carrying out the insulation test on the switchboard where the monitoring unit

is mounted, you have to disconnect it from the mains in order to avoid serious dam-

ages.

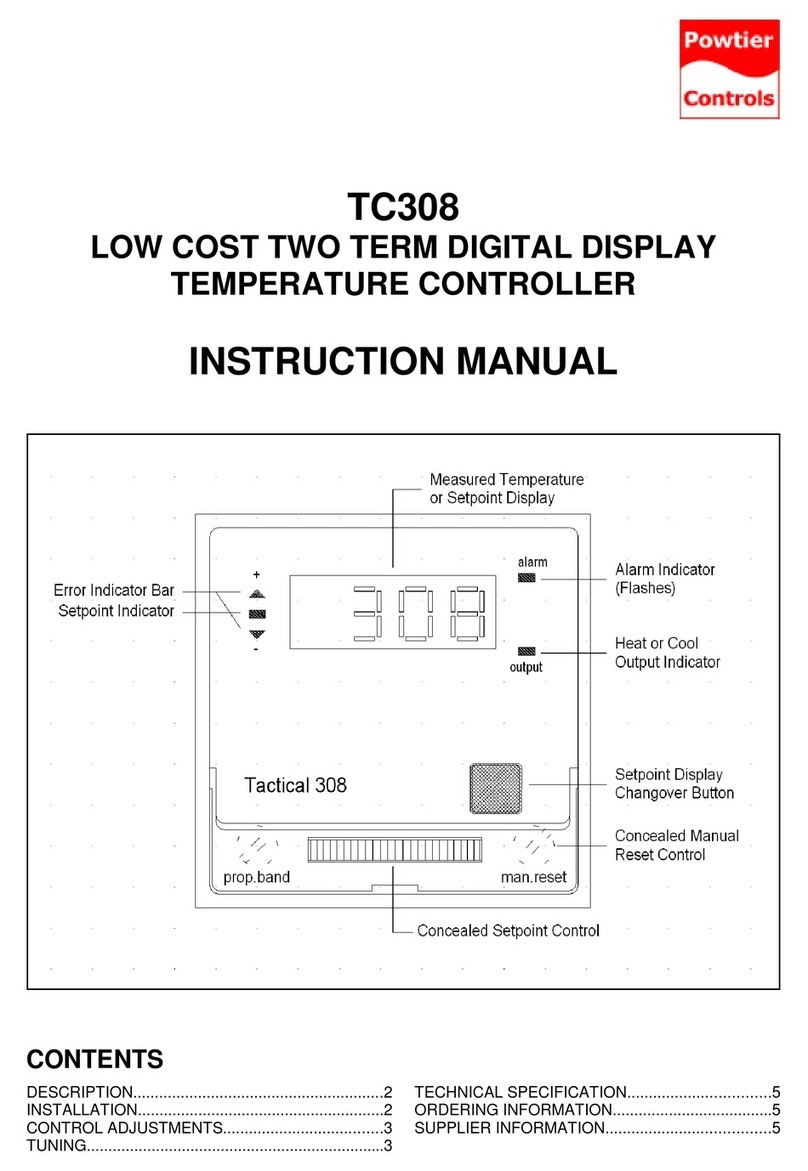

18) FRONT PANEL

Alarm

selected

channel

Display mode

Selected

channel

Message and tem-

perature display

Prg/RelaysTest

mode

Keyboard

Data

transmission

(option)

8NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

19) PROGRAMMING

NOTE: LED PRG-ON OFF:PROGRAM DISPLAY .

LED PRG-ON ON: PROGRAM MODIFICATION

1) It is possible to return to previous step by pressing MODE key.

2) if pressing ENT it appears “ERR”, it means that one of the following mistakes has been

made: ALARM ≥TRIP or FAN-OFF ≥FAN-ON. Press PRG to return to step 1 and correct

the data.

3) After 1 minute of keyboard no-operation, programming is left without data storage.

N° PRESS EFFECT NOTES

1 PRG/SET Keep pressed PRG key until PRG-ON led

turns on. After PRG indication, it appears

NCH indication (number of channels)

If NOP appears please see

“Programming block” paragraph

2 Load number of desired channels Refer to channel leds

(from 1 to 8)

3 PRG/SET It appears ALARM threshold for CH 1

4 Load desired threshold

5 PRG/SET It appears TRIP threshold for CH 1

Follow the same procedure for the number of channels chosen at step 2

6 PRG/SET Fan led blinks

7 Set: YES or NO NO: disabled fan

YES: enabled fan

8 PRG/SET Display shows ON FAN turning on

9 PRG/SET It appears ON threshold for FAN

10 Load desired threshold

11 PRG/SET Display shows OFF FAN turning off

13 Load desired threshold

14 PRG/SET Display shows HFN Fan cyclic test for 5 minutes

each “n” hours

15 Load desired number of hours 000= disabled function

22 PRG/SET Display shows END Programming end

23 ENT Loaded data storage and programming exit Err(2): wrong programming for

values indicated by leds

24 PRG/SET Return to step 1

16 PRG/SET Display shows n.o./ n.c.

and Alarm led blinks Alarm relay working logic

19 Set n.o. or n.c. n.o.: normally open

n.c.: normally closed

17 Set n.o. or n.c. n.o.: normally open

n.c.: normally closed

18 PRG/SET Display shows n.o./n.c.

and Trip led blinks Trip relay working logic

20 PRG/SET Display shows FCD <> “threshold” Fault for fast temperature

increase (°C/sec)

21 Load desired threshold

(see page 10) From “no” up to 30 °C/sec

(no: disabled function)

12 PRG/SET It appears OFF threshold for FAN

9

NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

20) PROGRAMMING RE-ENABLING IN CASE OF BLOCK (Prg no)

If pressing PRG to enter programming (step 1) “NOP” indication appears, it means that

programming access jumper inside the unit has been removed and therefore this func-

tion is blocked. To reset programming access, mount the jumper as shown in the figure

below.

21) WARRANTY

“NT” series monitoring units are covered by a 12-month warranty starting from the deliv-

ery date on the device itself.

This Guarantee is valid if device should be damaged by causes which can be attributed

to TECSYSTEM S.r.l., such are manufacturing defects of improper calibration.

The warranty is not valid if the monitoring unit would be tampered or if it would be dam-

aged by supply voltages beyond the highest working limits (20÷270 Vac-dc). The war-

ranty is not valid if the device would be burnt out by too many transient voltage peaks.

In this case TECSYSTEM S.r.l. do not answer for damages caused by faulty or defec-

tive monitoring units. All the deliveries (go and back) as well as the repair and servicing

costs for the device will be at Customer’s expenses, reckoned according to ANIMA, Col.

C rates.

In case of contest may only be instituted the Milan court.

The warranty is always FREE OUR DOMICILE in CORSICO.

22) EXTENSION CABLE FOR Pt100 TECHNICAL SPECIFICATIONS

Cable 20xAWG 20/19 Cu/Sn

Section 0,55 mm²

Insulation PVC105 flame-retardant

Standards CEI 20.35 IEC 332.1

Max. working temperature : 105°C

Structure: 4 terns composed of three twisted and coloured wires

Shield in Cu/Sn

Sheath in flame-retardant PVC

External Diameter 9,0 mm

Standard packaging in skein of 100 m

Enabled program-

ming

Disabled pro-

gramming

10 NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

FAULT DIAGNOSTIC CAUSES AND REMEDIES

Monitoring unit doesn’t turn on, even if there is

power supply and the terminals are fed.

Connector not well placed inside its seat. Connec-

tion cables are not tightened in the terminal. Burnt

out feeder.

Take out and give supply again.

One of 8 channels is in FAULT for FOC/FCC

1) Check Pt100 sensor connections: possible de-

fective sensor.

Replace the damaged sensor.

2) Number of channels programmation different to

number of sensors connected.

Repeat programmation.

When turning on, indication “ECH” appears.

A strong disturbance damaged the stored data.

Please refer to paragraph 8.

If this problem should persist, please contact TEC-

SYSTEM S.r.l Technical Department.

All the sensors are in FCC. Wrong sensor connections. Terminal box connected

inside out.

Check connections and terminal box.

Temperature indicated by one or more channel is

wrong. Contact TECSYSTEM S.r.l. Technical Department.

Sudden trip of main switch. Temperature is on

standard levels. Just a channel caused the trip.

Verify through T.MAX function possible defective

sensors.

Replace the sensor. Check the measuring signal

terminal boxes.

23) NOTES ON FCD FUNCTION

NT device series have an innovatory control function combined with the Pt100 probes dynamic

state.

If a thermometric probe should by chance break down, the defect is highlighted with a fast in-

crease of its own resistance and therefore of the temperature recorded by the monitoring device.

It’s obvious that this increase is not directly resulting from the power increase of the machine to

be protected, whether it is a motor or a dry or encapsulated transformer.

Therefore it is necessary to know the state of the probe and send a Fault signal instead of an

Alarm signal or, worse still, a Trip signal.

In case of temperature control on electrical motors, the fast rise in temperature could be caused

by the working with a stalled rotor and not by a defective probe; in this case Fault relay, once

energised, makes clear this anomalous condition for motor working.

Activating FCD function it is possible to have, on contacts 7-8-9, a Fault signal when temperature

recorded by a Pt100 rises with a speed higher than “n” °C/sec (loadable from 1 to 30).

According to the loaded value, you can have a different sensitivity which can be useful for differ-

ent applications:

- from 1 to 10: high sensitivity, for instance useful to immediately detect stalled of a motor rotor.

- From 10 to 20: average sensitivity, useful to get information relevant to possible noises which

affect probe reading, connection problems or defective probes.

- From 20 to 30: low sensitivity, useful for applications where a higher sensitivity could cause a

fault for unwanted FCD’s.

- With “no” FCD function is disabled.

When a channel is in Fault for FCD, relevant Alarm and Trip signalling are inhibited in order to

report just the anomaly for the too fast rise in temperature.

Press Reset to cancel FCD signalling for all the channels and to reset relays fault.

11

NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

NT538 ELECTRICAL CONNECTIONS

13 14 15 16 17 18 19 20 21 22 23 24

CH 1 CH 2 CH 3 CH 4

1 2 3 4 5 6 7 8 9 10 11

Pt100 INPUTS

ALARM RELAY OUTPUTS

40

41

42 POWER SUPPLY

24-240 VAC-VDC WHITE

RED

RED

Pt100

FIG.1

ALARM TRIP FAULT FAN

25 26 27 28 29 30 31 32 33 34 35 36

CH 5 CH 6 CH 7 CH 8

ESPANSION MODULE OUTPUT

62

61

60

63

GND RX

RX

GND TX

TX 62

63

GND RX

RX

NT538 EXPANSION

MODULE

61

60 GND TX

TX

If TX is fore-

seen on the

module

12 NT538 P8 V4-R1.4 protection relays

TECSYSTEM S.r.l ®

TEST DECLARATION FOR NT538

Date: ……………

N° Description

1 Mounting card check

2 Input working check

3 Relay contacts and output check

4 Push-button working check

5 Check lamp

6 Calibration at 0 and 200°C

7 Software working check

8 Burn-in min. 24h

This device has passed a test at the origin, according to the following procedure:

Other manuals for NT538

2

Table of contents

Other TECSYSTEM Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

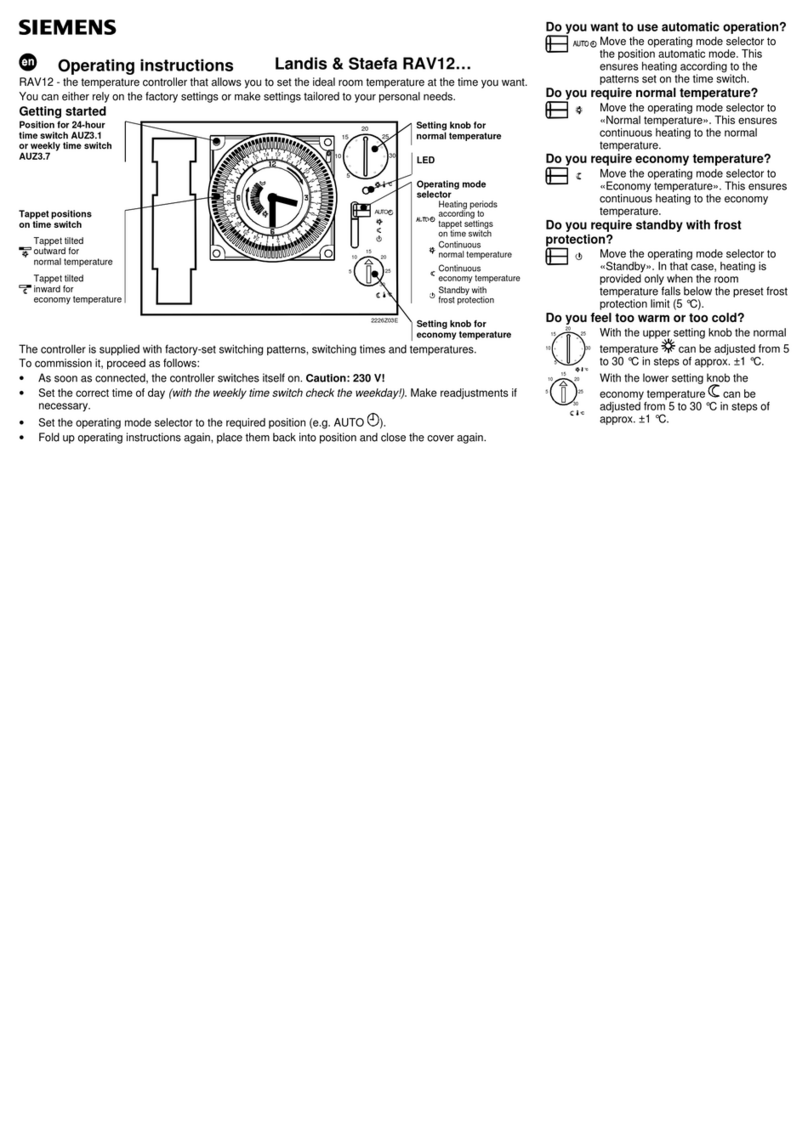

Siemens

Siemens Landis & Staefa RAV12 Series operating instructions

REGLOPLAS

REGLOPLAS 300L operating instructions

Drayton

Drayton LP20RF Installation & user guide

ATIM

ATIM TM2D-HP Series user guide

Johnson Controls

Johnson Controls System 350 A350A Technical bulletin

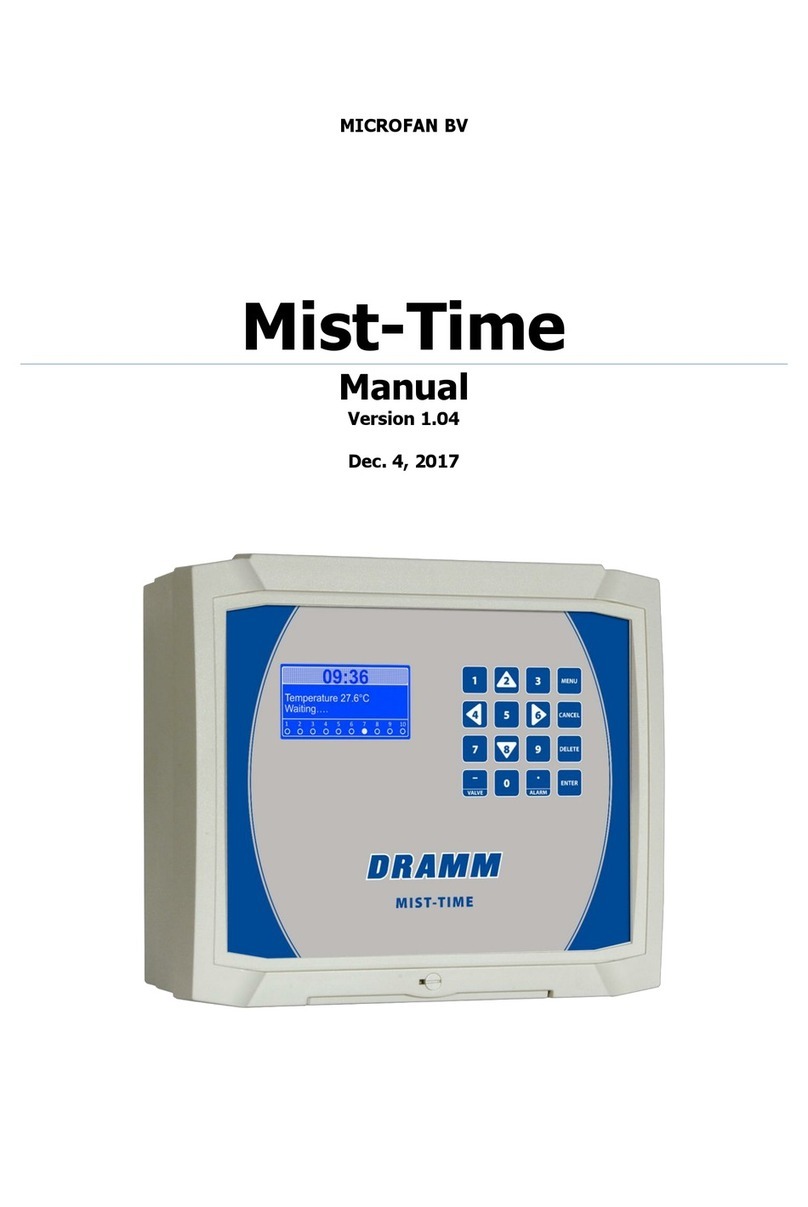

Microfan

Microfan Argos Mist-Time manual