3

T-154 0-240°C protection relays

TECSYSTEM S.r.l ®

AUXILIARY POWER SUPPLY

•Rated voltage 24-240 Vac-dc

•Maximum ratings 20-270 Vac-dc

INPUTS

•3 or 4 inputs RTD Pt100 sensors-3

wires

•removable rear terminals

•input channels protected against elec-

tromagnetic noises and spikes

•sensors length cables compensation up

OUTPUTS

•2 alarm relays (ALARM-TRIP)

•1 alarm relay for fan control (FAN)

•1 alarm relay for sensor fault or working

anomaly (FAULT)

•output contacts capacity: 5A-250 Vac

res.

TEST AND PERFORMANCES

•Assembling in accordance with CE

rules

•Protection against electrical and mag-

netic noises: CEI-EN50081-2/50082-2

•Dielectric strength: 2500 Vac for 1 min.

from relays to sensors, relays to power

supply, power supply to sensors

•Accuracy: ± 1% full scale, ±1 digit

•Ambient operating temperature: -20°C

to 60°C

•Humidity: 90% non-condensing

•ABS self-extinguishing housing-NORYL

94VO

•Opt. Frontal plastic protection

•Opt. Protection treatment of electronic

part

•Frontal polycarbonate-IP65

•Burden: 3VA

•Data storage: 10 years minimum

•Digital linearity of sensors signal

•Self-diagnostic circuit

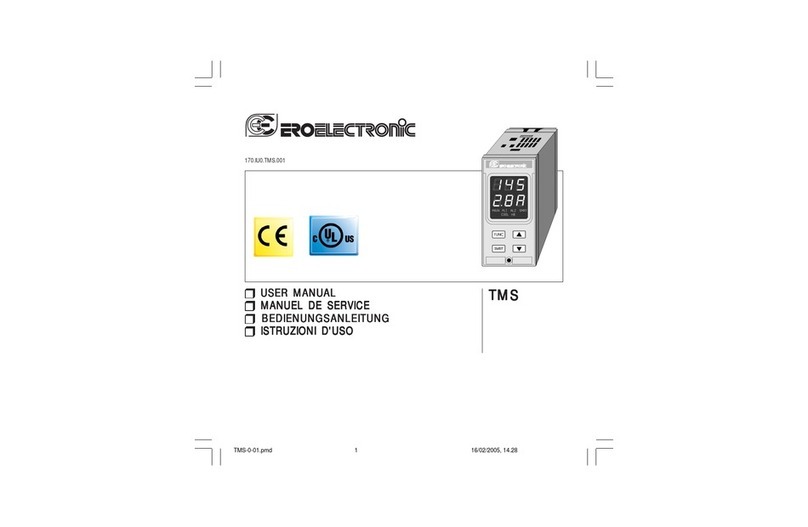

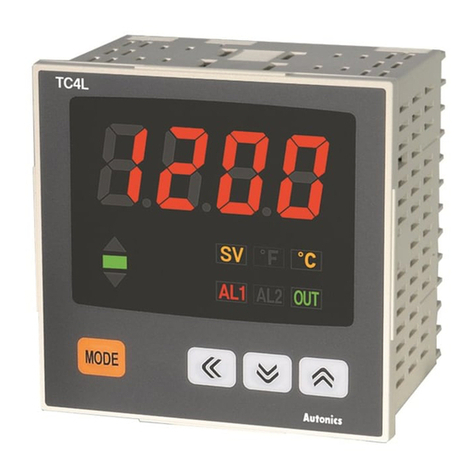

DISPLAYING AND DATA MANAGEMENT

•1 display 13 mm high with 3 digits for

displaying temperatures

•LED for displaying reference channel

•LED indicating alarm or trip channel

•LED indicating fault

•Temperature monitoring from 0-240°C

•2 alarm thresholds

•2 alarm ON-OFF thresholds for fan con-

trol

•Sensors diagnostic (Fcc-Foc-Fcd)

•Entering the programming by frontal

push button

•Automatic output from programming cy-

cle after 1 minute of no operation

•wrong programming automatic display

•Programmed data call out

•Possibility of setting automatic channel

scanning, hottest channel, manual scan-

ning

•Maximum temperatures and alarms stor-

age

DIMENSIONS

•96x96 mm-DIN43700 – depth 140mm

(with rear terminals)

•panel cutout 92x92 mm

1) TECHNICAL SPECIFICATIONS