TECSYSTEM MM453 User manual

INSTRUCTION MANUAL

MM453

TECSYSTEM S.r.l.

20094 Corsico (MI)

Tel.: +39-024581861

Fax: +39-0248600783

http://www.tecsystem.it

R. 1.2 09/02/17

ENGLISH

1MN0130 REV. 0

operates with ISO9001 certified quality system

“Translations of the original instructions”

2MM453 SERIES

CONTENTS

PAGE

1) SAFETY REQUIREMENTS ………………………………….. 4

2) ACCESSORIES ………………………………….. 5

3) TECHNICAL SPECIFICATIONS ………………………………….. 6

4) FRONT PANEL ………………………………….. 8

5) MOUNTING ………………………………….. 9

6) ELECTRICAL CONNECTIONS ………………………………….. 10

MM453 BACK ………………………………….. —

POWER SUPPLY ………………………………….. —

WIRING NOTES ………………………………….. 12

PROGRAMMED DATA DIAGNOSTICS …………………………………... —

SENSOR CONNECTION ………………………………….. —

TEMPERATURE SENSOR DIAGNOSTICS ………………………………….. 13

TEMPERATURE DIAGNOSTICS ………………………………….. —

DISPLAY MODE ………………………………….. —

USE AND WORKING OF MM453 CONTROL UNIT ………………………………….. —

7) PROGRAMMING ………………………………….. 14

PROGRAMMING MENU ' ………………………………….. —

PROGRAMMING OF CHANNELS SETTING PAGE ………………………………….. —

PROGRAMMING MM453 SETTING PAGE ………………………………….. 15

FACTORY DEFAULT SELECTION ………………………………….. 16

FACTORY DEFAULT SETTINGS ………………………………….. —

RELAYS LOGIC (AL/AUX). ………………………………….. —

8) MODBUS OPTION ………………………………….. 18

OPERATING NOTES ………………………………….. —

DATA TRANSMISSION ON MODBUS NETWORK ………………………………….. —

RS485 ELECTRICAL CONNECTIONS ………………………………….. —

INTRODUCTION

First of all we wish to thank you for choosing to use a TECSYSTEM product and recommend you read this instruction

manual carefully: You will understand the use of the equipment and therefore be able to take advantage of all its func-

tions.

ATTENTION! THIS MANUAL IS VALID AND COMPLETE FOR THE MM453 / MM453 MODBUS INSIDE /

MM453 AD MONITORING UNIT.

3

MM453 SERIES

PAGE

DATA FRAME ………………………………….. —

DATA PACKET ………………………………….. —

FUNCTION CODE ………………………………….. —

CODE 3(10). ………………………………….. —

CODE 16(10). ………………………………….. 19

NOTES FOR REMOTE PROGRAMMING ………………………………….. —

ERROR CODES (exception code) ………………………………….. —

POLLING FREQUENCY ………………………………….. —

CRC CALCULATION ………………………………….. —

PARAMETER DESCRIPTION ………………………………….. —

ALGORITHM …………………………………... —

MODBUS PARAMETER PROGRAMMING ………………………………….. 20

MODBUS TEMPERATURE MAPPING ………………………………….. —

CHANNEL STATE AND SETTING MAPPING ………………………………….. 21

AL0 MAPPING ………………………………….. 22

AL1 MAPPING ………………………………….. 23

AL2 MAPPING ………………………………….. 24

121-125 MAPPING ………………………………….. —

9) 4.20mA OUTPUT ………………………………….. 25

10) WARRANTY CONDITIONS ………………………………….. 27

11) TROUBLESHOOTING ………………………………….. 28

12) EQUIPMENT DISPOSAL ………………………………….. —

13) USEFUL CONTACTS ………………………………….. —

4MM453 SERIES

SAFETY REQUIREMENTS

ATTENTION :

Read the manual carefully before starting to use the control unit. Keep the instructions for future reference.

Do not open the device, touching any internal components can cause electric shock. Contact a voltage over 50

Volts can be fatal. To reduce the risk of electric shock, do not dismantle the back of the device for any reason.

Moreover its opening would void the warranty.

Before connecting the device to the power supply, make sure that all the connections are correct. Always

disconnect the unit from the supply before any cabling modification.

Any work on the equipment must be entrusted to a qualified engineer.

Failure to comply with these instructions can cause damages, fires or electric shock, and possible serious

injuries!

POWER SUPPLY

The MM453 series control unit has UNIVERSAL power supply, i.e. it can be supplied by 24 to 240 Vac-Vdc, irrespectively

of polarity in Vdc.

Before using it, make sure the power cable is not damaged, knotted or pinched. Do not tamper with the power cable.

Never disconnect the unit by pulling the cable, avoid touching the pins. Do not carry out any connecting/disconnecting

with wet hands. To disconnect the device, do not use objects such as levers. Immediately disconnect the device if you

smell burning or see any smoke: contact technical service.

LIQUIDS

Do not expose the equipment to splashes or drops, do not position it in places with humidity exceeding 90% and never

touch with wet or humid hands during storms. If any liquid penetrates the control unit, disconnect it immediately and

contact technical service.

CLEANING

Disconnect the power cable before cleaning the control unit, use a dry cloth to dust it, without any solvent or detergents,

and compressed air.

OBJECTS

Never insert any objects into the cracks of the control unit. If this happens, disconnect the control unit and contact an

engineer.

USE RESERVED TO QUALIFIED PERSONNEL

The purchased goods are a sophisticated electronic device that is totally unsuitable to be used by non-qualified person-

nel. Any work must be carried out by a specialist engineer.

ACCESSORIES

The use of non-original accessories or spare parts can damage the unit and endanger users' safety. In the event of

faults, contact technical service.

LOCATION

Install the control unit indoors, in a place protected from water splashes and sun rays. Do not place near heat sources

exceeding the parameters stated in this manual. Position on a stable surface, far from any possible vibrations. Position

the unit as far as possible from any intense magnetic fields.

REPAIRS

Do not open the control unit. For any fault, always use qualified personnel. The opening of the control unit and/or the

removal of the series identifying label entails the automatic forfeiture of the warranty. The Warranty seal is applied to all

devices, any attempt to open the unit would break the seal and cause the consequent automatic forfeiture of the

warranty.

TECHNICAL INFORMATION

Mail: ufficiotecnico@tecsystem.it —tel: 02/4581861

5

MM453 SERIES

ACCESSORIES

The following objects are present inside the box:

ATTENTION: Always install the device using the terminals included in the pack.

The use of terminals other than those included with the control unit might cause malfunctions.

1MN0030 REV. 0

Control unit

Start Guide and QR code

2 blocks for panel mounting

2/3 supply terminal 3 poles pitch 5 Supply/Relay/RS485

Code: 2PL0367 - Screws tightening torque 0.5Nm

1 relay terminal 15 poles pitch 5

Code:2PL0362 - Screws tightening torque 0.5Nm

1-6 sensor terminal 12 poles pitch 5

Code: 2PL0361- Screws tightening torque 0.5Nm

1 sensor terminal 4.20mA output 4 poles pitch 5

(optional) Code: 2PL0095 - Screws tightening torque

0.5Nm

6MM453 SERIES

TECHNICAL SPECIFICATIONS MM453

POWER SUPPLY

Supply rated values 24-240

Vac-Vcc

50/60HZ

Maximum and minimum supply values 20-270

Vac-Vcc

50/60Hz

Vdc with reversible polarities ●

INPUTS

1-24 inputs configurable : sensor inputs RTD Pt100 3-wires

sensor inputs RTD Pt1000 3-wires

sensor inputs TCK

●

Connections on removable terminal strips ●

Input channels protected against electromagnetic interference ●

Cable compensation for Pt100 or Pt1000 500 m (1 mm²)

Compensation for TCK with cable a terminal compensated 100 m

OUTPUTS

5 alarm relays (AL0-AL1-AL2-AUX1-AUX2) SPDT ●

1 sensor or operating failure (FAULT) SPDT ●

Output relays with 5A-250Vca-res COSФ = 1 contacts ●

RS485 Output Modbus RTU Optional (*)

Scanning 4.20mA output with synchronism signal Optional (**)

DIMENSIONS

192 x 96-mm DIN43700-depth 220mm (terminal block included) Hole 188 x 92 mm

TESTS AND PERFORMANCE

Construction in compliance with CE regulations ●

Protection from electrical interference EN 61000-4-4 ●

Dielectric strength 1500 Vac for 1 min. between output relays and sensors, relays and power supply, power

supply and sensors ●

Accuracy ± 1% full scale value, ± 1 digit ●

Ambient operating temperature from -20 ° C to +60 ° C ●

7

MM453 SERIES

TECHNICAL SPECIFICATIONS MM453

Front polycarbonate IP54 ●

Humidity 90% non-condensing ●

Black anodized aluminum housing ●

Absorption 10VA ●

Data memory 10 years minimum ●

Digital linearity of sensors signal ●

Self-diagnostic circuit ●

Protection treatment of the electronic part Optional

DISPLAY AND DATA MANAGEMENT

1 LCD display with 4 lines of 20 characters to show operative data and program parameters ●

6 LEDs indicated the status of the relay (AL0-AL1-AL2-AUX1-AUX2-FLT) ●

Temperature reading from :-40°C to 240°C PT100

0°C to 300°C PT1000

-40°C to 1000°C TCK

●

Alarm settings from:0°C to 240°C PT100

0°C to 300°C PT1000

0°C to 1000°C TCK

●

3 alarm thresholds for each input ●

Sensor diagnostics (Fcc-Foc) ●

Access to programming through front keyboard ●

Automatic exit from programming after 1 minute’s inactivity ●

Selection between channel automatic scanning, hottest channel or manual scanning ●

Storage of maximum temperatures reached by channels and alarm status (memo) ●

Front key to reset the alarms ●

* Only for Modbus inside and AD versions.

** Olny for AD verdion

8MM453 SERIES

FRONT PANEL

1) LCD display 10) AUX1 relay (red) LED

2) Control unit series 11) AL2 relay (red) LED

3) UP key 12) AL1 relay (red) LED

4) RIGHT key 13) AL0 relay (red) LED

5) DOWN key 14) Enter / Reset key

6) Fixing block 15) Programming / Setting key

7) LEFT key 16) ESC / Functions F1 key

8) Fault relay (red) LED 17) Fixing block

9) AUX2 relay (red) LED 18) Mode / Functions F2 key

1 2

3

4

5

6

7

89101112

14 13

15

16

17

18

1MN0130 REV. 0

NOTE: Due to its own characteristics, the LCD data update speed may be reduced when operating at temperatures lower

than 0°C. Anyway this condition doesn’t affect the correct working of the monitoring unit.

CH 1 2 P T 1 0 0 S C A N

T E M P 23 °C AL 0 O F F

T m a x 1 1 0 ° C AL 1 O F F

T m i n 8 0 ° C A L 2 O F F

HOME PAGE

SENSOR TYPE CH

CHANNEL CH

TEMPERATURE CH

TEMPERATURE MAX CH

TEMPERATURE MIN CH

SELECTED VIEWING

STATUS AL0

STATUS AL1

STATUS AL2

9

MM453 SERIES

Drill a 188 x 92 mm hole in the panel sheet.

Fix the unit securely with the blocks supplied.

1) Control unit 3) Fixing screw

2) Fixing block 4) Cross-head screwdriver # 1X100mm

1 2 3 4

1) Control unit 2) Panel hole dimensions (± 0.8 mm tolerance )

3) Identification label

1

MOUNTING

1MN0076 REV. 0

1MN0065 REV. 0

2

3

Note: Do not install the device in too hot or humid places; low frequency and high intensity vibration can cause damage to the

mechanical structure.

10 MM453 SERIES

ELECTRICAL CONNECTIONSELECTRICAL CONNECTIONS

1) Pt100 sensors

Card 1 CH1-CH2-CH3-CH4

5) Pt100 sensors

Card 5 CH17-CH18-CH19-CH20

9) AL0 Relay

2) Pt100 sensors

Card 2 CH5-CH6-CH7-CH8

6) Pt100 sensors

Card 6 CH21-CH22-CH23-CH24

10) 4.20mA (Optional) page 25.

3) Pt100 sensors

Card 3 CH9-CH10-CH11-CH12

7) Relays

(AL1-AL2-FAULT-AUX1-AUX2)

11) RS485 (Optional) page 18.

4) Pt100 sensors

Card 4CH13-CH14-CH15-CH16

8) Power Supply (LINE 40-41-42)

24 to 240 Vac-Vcc, 50/60Hz

1) Pt1000 sensors

Card 1 CH1-CH2-CH3-CH4

5) Pt1000 sensors

Card 5 CH17-CH18-CH19-CH20

9) AL0 Relay

2) Pt1000 sensors

Card 2 CH5-CH6-CH7-CH8

6) Pt1000 sensors

Card 6 CH21-CH22-CH23-CH24

10) 4.20mA (Optional) page 25.

3) Pt1000 sensors

Card 3 CH9-CH10-CH11-CH12

7) Relays

(AL1-AL2-FAULT-AUX1-AUX2)

11) RS485 (Optional) page 18.

4) Pt1000 sensors

Card 4CH13-CH14-CH15-CH16

8) Power Supply (LINE 40-41-42)

24 to 240 Vac-Vcc, 50/60Hz

MM453 ex. Pt100 12

9 1MN0130 REV. 0

7

PT100 CONNECTION

WHITE

RED

RED

8

3

11

4

5

6

10

MM453 ex. Pt1000 12

9 1MN0130 REV. 0

7

WHITE

RED

RED

8

3

11

4

5

6

10

PT1000 CONNECTION

11

MM453 SERIES

Note:the relays status showed when the device is off. When the unit is powered, the FAULT relay switches, contacts 27-28

open (NO) and 26-28 closed (NC), see below image fault contact switching.

FAULT 27-28 NC: ALARM FAULT OR POWER OFF FAULT 26-28 NC: NO FAULT POWER ON

FAULT CONTACT

26 27 28 26 27 28

POWER SUPPLY

The MM453 control unit has UNIVERSAL power supply, i.e. it can be supplied by 24 to 240 Vac-Vdc, 50/60 Hz irrespec-

tively of polarity in Vdc (terminals 40-42).

This is obtained thanks to the use of a tested power supply unit, newly designed and manufactured, that frees installers

from worrying about the correct Vac and Vdc supply.

The ground must always be connected to terminal 41.

When the unit is supplied directly by the secondary of the transformer to protect, it can be burnt out by strong overvoltages.

This happens if the main switch is closed and the transformer has no load (blank test).

The above-mentioned problems are much more evident when the 220 Vac voltage is taken directly from the

transformer secondary bars and there is a fixed capacitor battery to phase the transformer itself.

1) TCK sensors

Card 1 CH1-CH2-CH3-CH4

5) TCK sensors

Card 5 CH17-CH18-CH19-CH20

9) AL0 Relay

2) TCK sensors

Card 2 CH5-CH6-CH7-CH8

6) TCK sensors

Card 6 CH21-CH22-CH23-CH24

10) 4.20mA (Optional) page 25.

3) TCK sensors

Card 3 CH9-CH10-CH11-CH12

7) Relays

(AL1-AL2-FAULT-AUX1-AUX2)

11) RS485 (Optional) page 18.

4) TCK sensors

Card CH13-CH14-CH15-CH16

8) Power Supply (LINE 40-41-42)

24 to 240 Vac-Vcc, 50/60Hz

MM453 ex. TCK 12

9 1MN0130 REV. 0

7

TCK CONNECTION

YELLOW +

RED -

8

3

11

4

5

6

10

PT100-PT1000-TCK INPUTS.

At the customer's specific request you can combine different sensor input cards in the following order

TCK - PT100/PT100 - PT100/PT1000

12 MM453 SERIES

If an existing control unit must be replaced with a new one, to guarantee its correct and safe operation, the sensor/

relay/supply connecting terminals must be replaced with the new terminals supplied.

ATTENTION: the monitoring unit must not be turned off during the starting phase (boot) in order to avoid

configuration data loss. In case of configuration problems, enter in PROGRAMMING and select the option “factory

default” to restore the factory settings.

WIRING NOTES

Connect the terminal on the removable terminal blocks as shown at page 10-11

AL0 alarm relay switches when the set threshold value is reached, enabling is available on all channels, see programming

step 3 on page 14.

AL1-AL2 / AUX1-AUX2 alarm relays switch when the set threshold values are reached according to the selected

intervention logic (Mode Alarm: 1-2-3-4) as shown at page 16-17.

FAULT relay switches when the monitoring unit is powered on and switches back only when the unit has registered one of

the following events:

Data memory fault (message DATA LOST / DATA ERROR) .

Sensors fault (FCC short-circuited sensor, FOC interrupted sensor) .

Insufficient supply voltage

NOTE: do not connect the FAULT relay to the transformer tripping circuit to avoid system interruptions.

The terminals 40-42 must be connected to the phases of power, while the terminal 41 must be connected to the GROUND

of the plant.

NOTE: always disconnect the unit before performing any electrical connection.

PROGRAMMED DATA DIAGNOSTICS

In case of corruption of programmed data, just after switching on, DATA ERROR appears on the display with the relevant

Fault contact. In this case, for safety reasons, the default parameters are loaded automatically (see pre-set default settings

on page 16). Eliminate DATA ERROR by pressing ENT / RST and run programming to enter the desired values.

Finally switch the unit off and back on to check the memory works correctly, if it is damaged DATA ERROR will be

displayed again (send the control unit to Tecsystem srl for repairs).

In case of failure of the internal memory, LOST DATA indication appears with the relevant Fault contact (send the control

unit to Tecsystem srl for repairs).

SENSOR CONNECTION

The PT100 sensors must be connected as shown on page 10-11, each card has 4 inputs.

All the cables transferring the sensors measurement signals must comply with the following under all circumstances:

be separated from the power cable

be made with shielded and twisted conductors

have a minimum cross section of 0.5 mm²

be firmly fixed in the terminal

cables and joints compensated for TCK probes

have tinned or silvered conductors (Pt100-Pt1000)

shielding must be connected with GROUND of the device together with the ground wire.

NOTE: to install the sensors and signal transferring cable correctly, read the sensor and SCS/SENSOR installation

rules manual.

What may happen when installation rules are not complied with.

1)The electrical field propagating from the power line of another circuit, couples capacitively with the conductors

(in particular with unscreened cables). The effect of this coupling creates a signal that overlaps the signal transmitted by

the nearby conductors, causing incorrect readings.

2) The variations in magnetic flux in the power lines may induce an electromotive force on the signal transferring cables

(in particular non-twisted cables), that, being a closed circuit, generates a current. This interference current, multiplied by

the circuit resistance, gives a voltage value that overlaps the signal to be transmitted, distorting the sensor measurement.

3) False contacts can alter the signal with the consequent variation in the temperature detected.

In specific cases, when the rules for connecting the Pt100 sensors are not complied with, the following anomalies can

occur between the SCS box and the temperature control unit:

a) incorrect temperature readings, alarms or anomalous tripping

b) mechanical / electrical fault of the sensors

c) damage to the inputs of the control unit.

13

MM453 SERIES

TECSYSTEM S.r.l. has designed its own special cable to transfer the measurement signals, CEI-compliant, with all

the protection requirements provided for: model CT-ES.

1MN0034 REV. 0

All "M" series control units have linearity of the sensor signal, with a maximum error of 1% of full scale value.

TEMPERATURE SENSOR DIAGNOSTICS

In case of failure or exceeded full scale value of one of the thermometric sensors installed on the machine to protect, the

FAULT relay opens immediately with the relative warning of faulty sensor on the corresponding channel.

Fcc indicates sensor short-circuited or minimum full scale value of the control unit exceeded

Foc indicates sensor interrupted or maximum full scale value of the control unit exceeded

To eliminate the message and reset the opening of the Fault contact, it is necessary to check the Pt100 connections and

replace the faulty sensor (if any). If the minimum/maximum full scale value has been reached, check that the ambient

conditions match the control unit reading.

Note: exceeding the minimum/maximum full scale value can also be caused by interference on the sensor lines; in this

case we recommend that you check: the correct installation of the sensors and above all of the extension cable (as

stated in the paragraph MEASUREMENT SIGNAL TRANSFER)

TEMPERATURE DIAGNOSTICS

When one of the temperature sensors senses a temperature 1°C higher than the alarm threshold, 5 seconds later the

ALARM relay switches and the AL/AUX LED turns on: the page of the channel which generated the alarm displays ON

near the passed threshold (AL0, AL1-AL2 or AUX1-AUX2).

When the taken temperature returns to equal or lower values than the set limit for relay switching, these relays de-

energize with consequent turning off of relevant LED.

DISPLAY MODE

Pressing the MODE key, the display modes can be set:

SCAN: the monitoring unit displays a sequence of all activated channels (each 2 seconds)

HIGH: the monitoring unit automatically displays the hottest channel

MAN: manual reading of the channels temperature using the up/down keys

MEMO: the monitoring unit displays the alarm log updated to the last reset. Select the channels through the ▲

▼ keys and press RESET to reset the values.

USE AND OPERATION OF THE MM453 UNIT

The MM453 control unit consists of a system from 1 to 6 Pt100-P1000-TCK interchangeable cards.

Each card has 4 channels: the top card identifies the channels 1-2-3-4, the second 5-6-7-8 channels, the third card 9-10-

11-12 channels, the fourth 13-14-15-16 channels, the fifth 17-18-19-20 channels, and sixth 21-22-23-24 channels.

NOTE: the use of cables not complying with the above might cause reading anomalies. It is always important to take

into account that any interference on the signal lines might cause anomalies on the Pt100 inputs (CH1-CH2-CH3-

CH4..........................CH24) or on the sensors themselves.

1MN0035 REV. 0

14 MM453 SERIES

CH 12 O N P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1 > A L 2 119°C

P R O G R AM M I N G M E N U

1→C h a n n e l s s e t t i n g

2 M M 4 5 3 S e t t i n g

3 F a c t o r y D e f a u l t

PROGRAMMING SEQUENCE

MM453

PROGRAMMING MENU

Introduction page to the programming parameters.

PROGRAMMING OF CHANNELS SETTING PAGE

Selecting Channels setting, the page allowing to set the programming parameters for each channel is shown.

FUNCTION DESCRIPTION DISPLAY PAGE

Press and hold the PRG / SET key for 7 seconds until the

PROGRAMMING MENU page is displayed.

Press the ▲▼ keys and place the cursor → on the function desired.

Press the ENT / RST key to confirm your choice.

STEP FUNCTION DESCRIPTION DISPLAY PAGE

1

The cursor → is positioned at the

first available channel.

Press the ▲ ▼ keys to select the page

programming of other channels.

Press the ► key to proceed to step 2.

2

Press the ▲ ▼ keys to enable (ON) or disable

(OFF) the channel.

Press the ► key to proceed to step 3.

3

Press the ▲ ▼ keys to enable (ON) or disable

(OFF) the Alarm AL0 threshold.

Press the ► key to proceed to step 4

(if AL0 ON) or to step 5 if (AL0 OFF).

4

Press the ▲ ▼ keys to set the Alarm AL0 threshold.

Press the ► key to proceed to step 5.

5

Press▲ ▼ keys to select the relay set (AL1-AL2 or

AUX1-AUX2) where 1 and 2 thresholds must be

connected.

Press ► key to proceed to step 6.

CH 1 2 ON P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1 > A L 2 119°C

CH 1 2 O N P T 1 0 0 S E T

A L 0 ON A L 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1 > A L 2 119°C

CH 1 2 O N P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1 > A L 2 119°C

CH 1 2 O N P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1 > A L 2 119°C

15

MM453 SERIES

6

Press the ▲ ▼ keys to set the Alarm AL1

(or AUX1) threshold.

Press the ► key to proceed to step 7.

7

Press ▲ ▼ keys to set the AL1 (or AUX1) relay

intervention logic when the set threshold is

reached.

Mode 1 (>): intervention for T°>threshold

Mode 2 (<): intervention for T°<threshold

Mode 3 (><): intervention for T°<threshold just ex-

ceeded

Mode 4 (><): same logic as mode 3, but with

storage in MEMO page only for the first

alarm occurred among AL1, AL2, AUX1, AUX2

Press ► key to proceed to step 8.

8

Press the ▲ ▼ keys to set the threshold alarm

AL2 (or AUX2).

Press F2 to return to the page PROGRAMMING

MENU

NOTES:

Press the ◄ key to return to the previous step.

Press the F2 key to return to the PROGRAMMING MENU.

Press the F1 key to exit the programming mode if you do not need to set other parameters.

The value of alarm threshold 1 cannot be higher than the threshold value of alarm 2.

CH 1 2 O N P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1 > A L 2 119°C

CH 1 2 O N P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1> A L 2 119°C

CH 1 2 O N P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1 > A L 2 119°C

PROGRAMMING MM453 PAGE SETTING

Selecting MM453 SETTING it appears the page that allow you to load the MM453 base operating settings.

M M 4 5 3 S E T T I N G

1→D i s p l a y C o n t r a s t

---------------------

---------------------

C O N T R AS T S E T T I N G

■■■■■■

0123456789

STEP FUNCTION DESCRIPTION DISPLAY PAGE

1

The cursor → is placed near the setting on which you

want to operate

Press ▲ ▼ keys to change the selection

Press ENTER key to confirm the choice.

NOTE: several optional selections may depend on the

unit model.

2

By selecting Display Contrast the page to

adjust the display contrast is shown.

Press ▲ ▼ keys to modify it.

NOTES:

Press the F2 key to return to the MM453 SETTING

Press the F1 key to exit the programming mode if you do not need to set other parameters.

16 MM453 SERIES

FACTORY DEFAULT SELECTION

Selecting FACTORY DEFAULT the factory settings of the control unit can be restored.

Attention, pressing (yes) all programmed data will be erased and replaced with the default ones.

F A C T O R Y D E F A U L T

R e s e t d a t a ?

→no

P r e s s E n t e r

STEP FUNCTION DESCRIPTION DISPLAY PAGE

1

Press the ▲ ▼ keys to select yes or no.

Press the ENTER key to confirm your choice.

Setting YES after selecting the default data, the control unit

resets and returns to the display on the screen

“Temperatures”.

NOTES:

Press the F2 key to return to the PROGRAMMING MENU.

Press the F1 key to exit the programming mode and return to display mode temperatures.

FACTORY DEFAULT SETTINGS ALARM AND CONFIGURATION

The selection of the factory default includes:

All channels enable “ON”.

SCAN mode setting.

For the storage of temperature alarms and configuration,

see example screen on the right.

CH 1 2 ON P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1 > A L 2 119°C

RELAYS LOGIC (AL/AUX).

CH 1 2 O N P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 1> A L 2 119°C

MM453 PROGRAMMING ALARMS

INDICATION OF OPTIONAL PROGRAM STEPS STATUS ALARM L1 L2

AL1= 90°C - AL2 = 119°C

SWITCHING OVER THE PRESET AL1 and AL2 VALUES 90°C 119°C

CH 1 2 O N P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 2> A L 2 119°C

SWITCHING BELOW THE PRESET AL1 VALUE 90 ° C 119 ° C

SWITCHING OVER THE PRESET AL2 VALUE

17

MM453 SERIES

CH 1 2 O N P T 1 0 0 S E T

A L 0 O N AL 0 C 6 0 ° C

R e l AL > A L 1 90°C

M o d e 3> A L 2 119°C

SWITCHING OVER THE PRESET AL2 VALUE 90 ° C 119 ° C

SWITCHING IF THE VALUE RETURNS BELOW AL1 SET VALUE 90 ° C 119 ° C

MODE 4: In mode 4, the alarm intervention logic is exactly the same as mode 3. The difference is in the all-time alarm

display page (MEMO page): when in mode 4 only the first intervention of one of the following alarms is stored and

displayed :

AL1 or AUX1 (temperature lower than the minimum threshold, with threshold already exceeded)

AL2 or AUX2 (temperature higher than the maximum threshold)

In this case, from the MODE page the first channel triggering the alarm signal can be unequivocally identified.

After the first alarm, the all-time alarm storage in MEMO page is inhibited, but not the interventions and the signal in

SCAN, MAN, HIGH pages. To reset the storage inhibition, press RESET key in MEMO page for all the channels that work

in mode 4.

On the contrary, AL0 and FAULT don’t cause the alarm inhibition. Once it is inhibited, due to the switching of AL1, AL2,

AUX1, AUX2, data are not stored.

ATTENTION: if mode 4 is not reset on all the channels, the monitoring unit will not be able to identify the first

alarm occurred on AL1, AL2, AUX1, AUX2.

NOTE: the alarms are stored in the log after approximately 5 seconds after the triggering of the alarm.

If the monitoring unit is turned off before these 5 seconds, the alarm is not stored in the log.

ATTENTION:

We recommend you to check the programming before starting to use the control unit.

The default parameters set by TECSYSTEM might not suit your requirements.

Programming the device is the end user’s responsibility: the set alarm thresholds and the enabled

functions described in this manual must be checked (by a specialized technician) referring them to the

application and system characteristics on which the control unit is installed.

18 MM453 SERIES

The MM453 Modbus allows to transfer data on a RS485 network with ModBus RTU protocol.

OPERATING NOTES

For a correct working of Modbus it is necessary to load the RS485 network setup parameters: address, baud rate, parity

bit (please refer to Modbus parameter programming at page 20).

The serial communication of the temperature control monitoring unit is active only when the MM453 is in monitoring mode

and not in programming mode.

DATA TRANSMISSION ON MODBUS NETWORK

The Modbus output allows you to read all the data shown in the tables MAP: TEMPERATURE-STATE AND SETTING

CHANNELS and write those indicated in the tables MAP: AL0-AL1-AL2.

The module is always in slave mode.

RS485 ELECTRICAL CONNECTIONS

As far as the signal cable to be used in order to ensure the correct network operation is concerned, we recommend you

follow the provisions of the EIA RS485 standard which suggests using a 24AWG twisted pair.

The twisted pair that connects units in RS485 might need a 120 ohm end resistor on the last unit of the series.

Connect the twisted pair paying attention to polarities and lay the network avoiding to make sharp bends or ring windings

in order not to modify line impedance.

Connection RS485 terminal 61 (-) 62 (+). If necessary, the GND terminal (60) for grounding is also available.

Always position the RS485 twisted pair far from power cables.

DATA FRAME

The frame in asynchronous transmission consists of: 1 start bit, 8 data bits, 1 parity bit (even or odd, if the parity has been

set) and 1 stop bit. Admitted baud rates are: 2400, 4800, 9600 and 19200.

If not otherwise specified, the word length (DATA) is 16 bits.

DATA PACKET

A complete sequence of request/answer consists of the following:

Master request:

SLAVE ADDRESS - 1 byte

FUNCTION CODE - 1 byte

DATA - variable, it depends by function code

CRC - 2 bytes

Slave request:

SLAVE ADDRESS - 1 byte

FUNCTION CODE - 1 byte

DATA - variable, it depends by function code

CRC - 2 bytes

FUNCTION CODE

The MM453 ModBus module supports the following function codes:

3(10):- holding register reading

16(10):- register multiple writing

If MODBUS receives a message and a CRC error is detected, no answer is given.

CODE 3(10).

Request:

Slave address, code 3(10), Starting address HI, Starting address LO, Number of Point HI, Number of Point LO, Crc LO, Crc

HI.

Answer:

Slave address, code 3(10), Byte count, Data HI, Data LO……., Crc LO, Crc HI.

OPZIONE MODBUS

19

MM453 SERIES

CODE 16(10).

Request:

Slave address, code 16(10), Starting address HI, Starting address LO, Number of Point HI, Number of Point LO, Byte

count, Data HI, Data LO……., Crc LO, Crc HI.

Answer:

Slave address, code 16(10), Starting address HI, Starting address LO, Number of Register HI, Number of register LO, Crc

LO, Crc HI.

The writable registers are the ones containing the following data: AL0, AL1, AL2.

Therefore the possible starting address are: 49-72 for AL0 thresholds, 73-96 for AL1 thresholds, 97-120 for AL2

thresholds. Number of Point LO parameter can be loaded from 1 to 24 (max).

If a writing request is sent to an address different from the above mentioned ones, MODBUS will answer with a 02 error

code (wrong data address).

If a writing request for a number higher than 24 registers is sent (Number of point LO), MODBUS won’t be able to accept

the request and it won’t give any answer. Therefore the query will go in “timeout”.

NOTES FOR REMOTE PROGRAMMING

Also in the remote programming phase via ModBus you must take into consideration that AL1 thresholds must be lower

than AL2 thresholds.

In case you try to set these thresholds incorrectly, the control unit will not proceed with the programming and

storage of data, therefore in subsequent readings will read the data from the previous schedule.

ERROR PROGRAMMING message will be displayed for 2 seconds.

After having sent a request for writing the control unit will take a time of about 1 to store the data in eeprom, during the

storage. To confirm the display will show REMOTE PROGRAMMING message.

ERROR CODES (exception code).

In case of a wrong request, MM453 will answer with modified codes and codified errors according to the following:

1: - Unsupported function code

2: - Wrong data address

3: - Wrong data (for instance length)

POLLING FREQUENCY

We recommend polling frequencies equal to or greater than 1 second are adopted.

More frequent polling can overload the system without any benefit whatsoever.

CRC CALCULATION

The protocol includes 2 CRC-16 bytes in each transmission. The characteristic polynomial (11000000000000101B) is

used for the calculation and the result is “hung” at the end of the packet. The polynomial is used in reverse order

with the most significant bit suppressed because useless for the purpose of the calculation.

PARAMETER DESCRIPTION

A - 16-bit registers

AL –A low part

AH –A high part

i,j, - COUNTERS

(+) - EXCLUSIVE OR

Di - Datum of the «i»th of the packet

N - number of bytes in the packet excluded 2 of the CRC

G - Polynomial : 1010-0000-0000-0001

shr - shift to the right

ALGORITHM

0xFFFF -> A

0 -> i

0 -> j

Di (+) AL -> AL

j +1 -> j

shr A

if carry then G (+) A -> A

if NOT j=8 then go to 5

i +1 -> i

if NOT i = N then go to 3

11) A -> in CRC (the result is in order L,H)

20 MM453 SERIES

MODBUS PARAMETER PROGRAMMING (only for MODBUS version)

Introduction page to the monitoring unit programming parameters

Selecting MM453 SETTING, the page allowing to load the operational settings for the base unit MM453 is displayed.

MODBUS TEMPERATURE MAPPING

STEP FUNCTION DESCRIPTION PAGE DISPLAY

1

Position cursor →on Modbus setting.

Press ▲ ▼ keys to change the selection.

Press ENTER key to confirm the choice.

2

Selecting Modbus Setting the page allowing to load

the Modbus parameter setting is displayed.

Press ◄ ► keys to select the parameter to modify

(ADR= address, Bdr= Baud rate, PAR= parity bit).

Press ▲ ▼ keys to modify it.

NOTES:

Press F2 key to return to MM453 SETTING page.

Press F1 key to leave the programming if you don’t need to load other parameters.

M O D B U S S E T T I N G

A D R → 0 1

B d r 9600

P A R N O N E

FUNCTION DESCRIPTION PAGE DISPLAY

Keep pressed PRG/SET key for 7 seconds until

PROGRAMMING MENU page appears.

Press ▲ ▼ keys and move the cursor → o n MM453 Setting

function.

Press ENT/RST key to confirm the choice.

P R O G R A M M I N G M E N U

1 C h a n n e l s s e t t i n g

2 → M M 4 5 3 S e t t i n g

3 F a c t o r y D e f a u l t

M M 4 5 3 S E T T I N G

1 D i s p l a y C o n t r a s t

2 → M o d b u s s e t t i n g

3 F a c t o r y d e f a u l t

ADR_HI ADR_LO DATA_HI DATA_LO PRIMARY TABLES

0 1 TEMP_HI_CH1 TEMP_LO_CH1 HOLDING REGISTER

0 2 TEMP_HI_CH2 TEMP_LO_CH2 HOLDING REGISTER

0 3 TEMP_HI_CH3 TEMP_LO_CH3 HOLDING REGISTER

0 4 TEMP_HI_CH4 TEMP_LO_CH4 HOLDING REGISTER

0 5 TEMP_HI_CH5 TEMP_LO_CH5 HOLDING REGISTER

0 6 TEMP_HI_CH6 TEMP_LO_CH6 HOLDING REGISTER

0 7 TEMP_HI_CH7 TEMP_LO_CH7 HOLDING REGISTER

0 8 TEMP_HI_CH8 TEMP_LO_CH8 HOLDING REGISTER

0 9 TEMP_HI_CH9 TEMP_LO_CH9 HOLDING REGISTER

0 10 TEMP_HI_CH10 TEMP_LO_CH10 HOLDING REGISTER

0 11 TEMP_HI_CH11 TEMP_LO_CH11 HOLDING REGISTER

0 12 TEMP_HI_CH12 TEMP_LO_CH12 HOLDING REGISTER

0 13 TEMP_HI_CH13 TEMP_LO_CH13 HOLDING REGISTER

0 14 TEMP_HI_CH14 TEMP_LO_CH14 HOLDING REGISTER

0 15 TEMP_HI_CH15 TEMP_LO_CH15 HOLDING REGISTER

0 16 TEMP_HI_CH16 TEMP_LO_CH16 HOLDING REGISTER

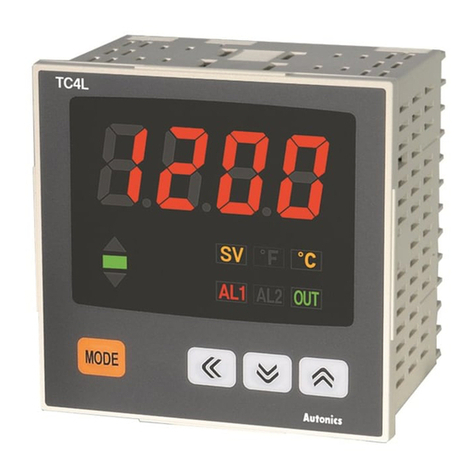

Table of contents

Other TECSYSTEM Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

United Electric Controls

United Electric Controls 800 Installation and maintenance instructions

Trane

Trane ZUSTATALS510 instruction manual

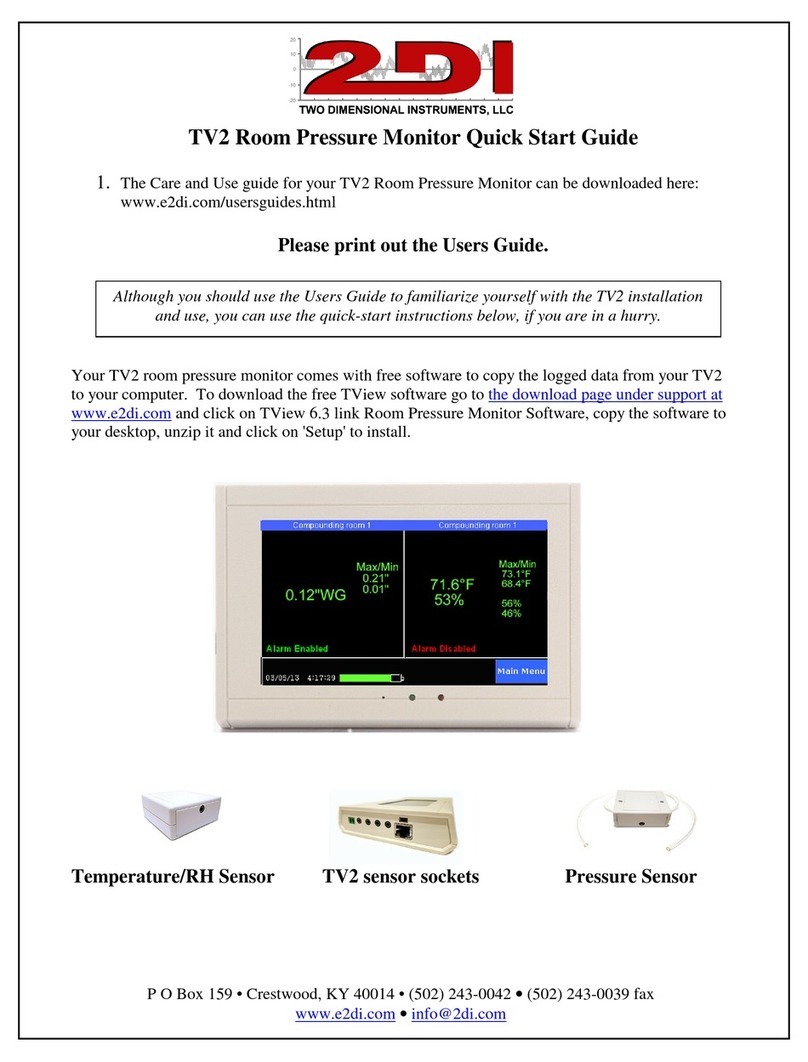

TWO DIMENSIONAL INSTRUMENTS

TWO DIMENSIONAL INSTRUMENTS TV2 quick start guide

Munters

Munters Smart A Manual for use and maintenance

ILX Lightwave

ILX Lightwave LDT-5500B Series user guide

Elko

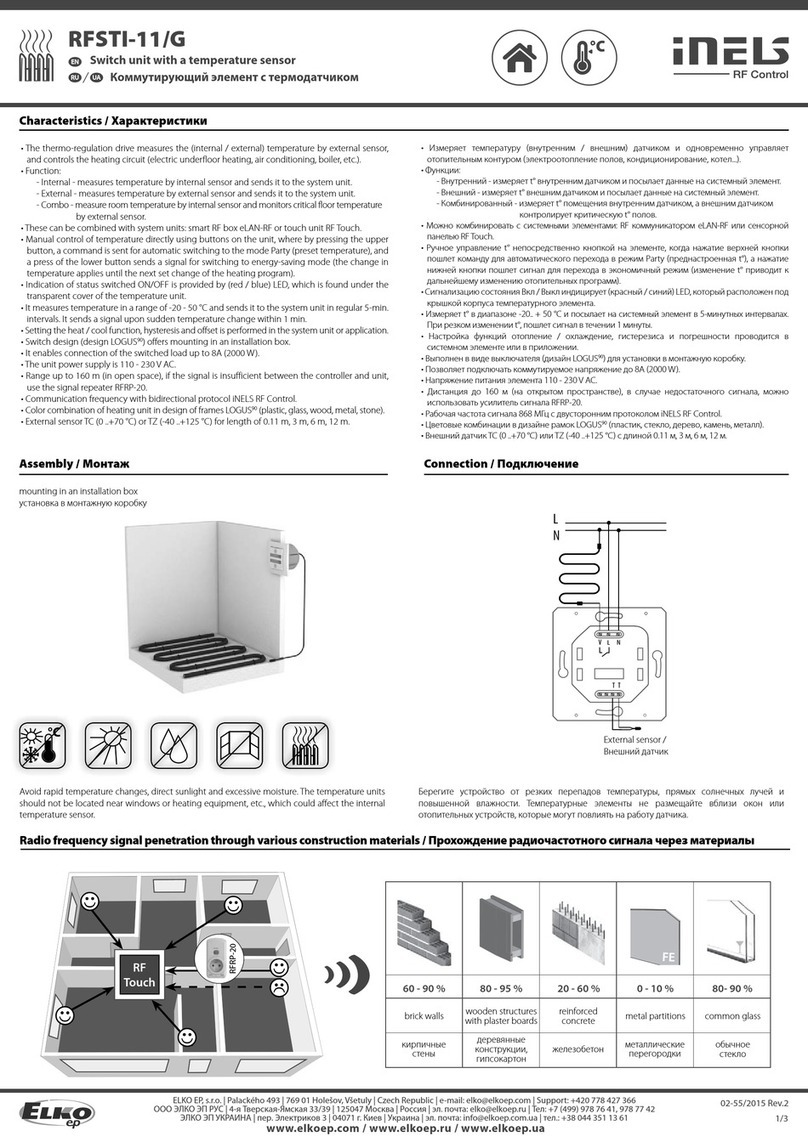

Elko iNels RFSTI-11/G Assembly instructions

AERMEC

AERMEC CXS 1207 H TECHNICAL AND INSTALLATION

Bosch

Bosch CRC200 Installation instructions for contractors

Vaisala

Vaisala HUMICAP HMM212 user guide

Ropex

Ropex CIRUS UPT-6012 operating instructions

Elektronikbau- und Vertriebs

Elektronikbau- und Vertriebs Ceta 100 operating manual

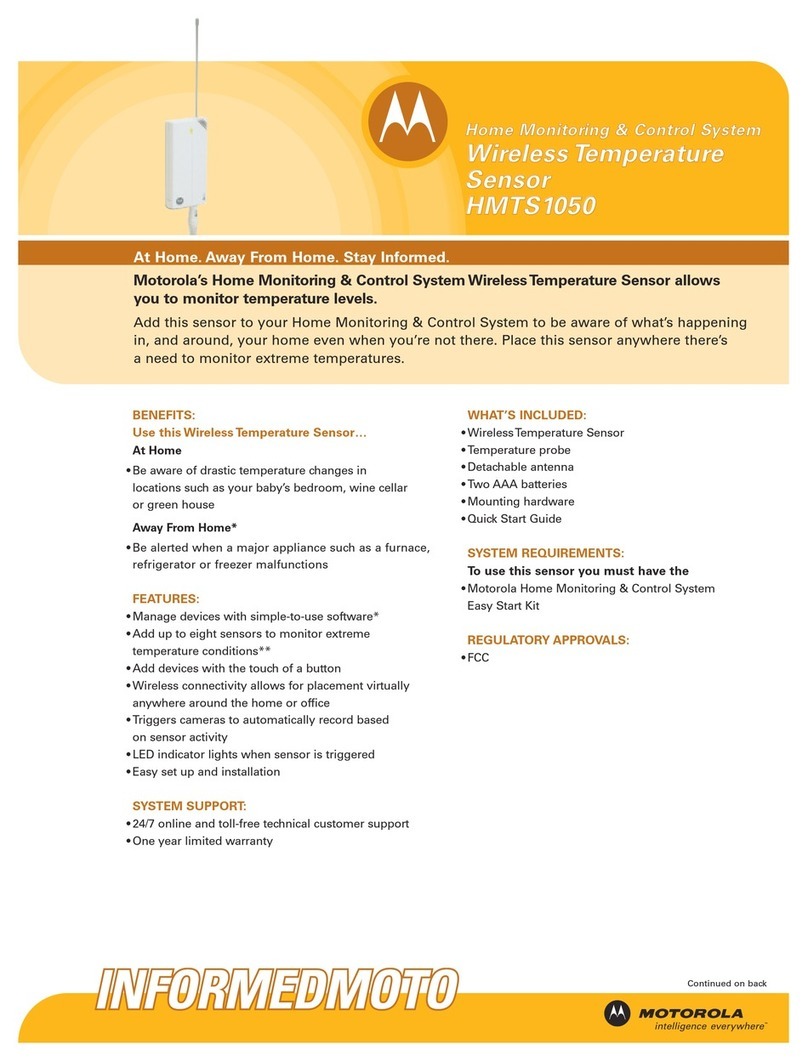

Motorola

Motorola HMTS1050 Specifications