TeeJet Technologies Matrix 908 User manual

98-01578 R2

USER GUIDE

Matrix 908 Field Computer

ii www.teejet.com

CONSOLE START JOBSETUP HELPMEASUREMENTS UT

Table of Contents

MEASUREMENTS TO HAVE ON HAND BEFORE YOU GET STARTED 1

SPRAYERS 2

Self-Propelled Front Mount Sprayer ........................................................................................................................................................2

Self-Propelled Rear Mount Sprayer..........................................................................................................................................................3

Tractor with Fixed Mount O-Centre Sprayer......................................................................................................................................4

Tractor with Fixed Mount Aft Mount Sprayer.......................................................................................................................................5

Tractor with Pivot Mount Sprayer.............................................................................................................................................................6

SPREADERS 7

Self-propelled Spreader ...............................................................................................................................................................................7

Tractor with Fixed Mount Spreader .........................................................................................................................................................8

Tractor with Pivot Mount Spreader..........................................................................................................................................................9

CONSOLE CONNECTIONS AND FEATURES 10

SYSTEM DIAGRAM 11

SETUP THE CONSOLE 12

NO.1 WELCOME SCREEN 12

NO.2 WALK THROUGH THE VEHICLE WIZARD 13

NO.3 ENTER AVAILABLE UNLOCKS 15

NO.4 ESTABLISH AN IMPLEMENT THROUGH THE DEVICE WIZARD 16

Device Manager ........................................................................................................................................................................................... 16

Create New Device...................................................................................................................................................................................... 16

Activate a Dierent Device....................................................................................................................................................................... 18

Edit a Device.................................................................................................................................................................................................. 18

Delete a Device............................................................................................................................................................................................. 18

NO.5 SET UP GUIDANCE SETTINGS 19

NO.6 SET UP MAPPING LOCATION 20

NO.7 SET UP THE GNSS 21

NO.8 SET UP ASSISTED/AUTO STEERING 22

NO.9 SELECT JOB MODE 23

Job Manager.................................................................................................................................................................................................. 24

Data Manager ............................................................................................................................................................................................... 25

Matrix 908 Field Computer

iii

98-01578-ENUS R2

CONSOLESTART JOB SETUPHELP MEASUREMENTSUT

START A JOB 26

Simple Job Mode......................................................................................................................................................................................... 26

Advanced Job Mode .................................................................................................................................................................................. 27

Guidance Screen Features........................................................................................................................................................................ 28

NO.1 CHOOSE A GUIDANCE MODE 29

NO.2 ESTABLISH AN AB GUIDELINE 31

Switch Guideline.......................................................................................................................................................................................... 31

Delete Last Guideline................................................................................................................................................................................. 32

Adjust Guideline .......................................................................................................................................................................................... 32

Assisted/Auto Steering Nudge ............................................................................................................................................................... 32

Dynamic Adaptive AB Guideline Action Bar Options.................................................................................................................... 33

NO.3 CREATE AN APPLICATION BOUNDARY 34

Delete Last Marked Boundary................................................................................................................................................................. 35

NO.4 UNDERSTAND MORE ABOUT THE GUIDANCE SCREEN 36

Map Options.................................................................................................................................................................................................. 36

Information & Status Bar........................................................................................................................................................................... 36

Mapping Layers............................................................................................................................................................................................ 38

Guidance Bar................................................................................................................................................................................................. 39

NO.5 APPLICATION MAPPING INSTRUCTIONS 40

Without Section Control Module........................................................................................................................................................... 40

ISOBUS Sprayer............................................................................................................................................................................................. 40

ISOBUS Spreader.......................................................................................................................................................................................... 41

TeeJet Section Control Module .............................................................................................................................................................. 41

ACCESS THE UNIVERSAL TERMINAL 42

HELP OPTIONS 43

About ............................................................................................................................................................................................................... 43

User Guide...................................................................................................................................................................................................... 43

Product Registration................................................................................................................................................................................... 43

Feature Unlock.............................................................................................................................................................................................. 43

Copyrights

© 2022 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced,

copied, photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without

prior written consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or

organizations.

Limitation of Liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR

IMPLIED. NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR

ANY LOSS OF BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED

OF SUCH DAMAGES ARISING FROM TEEJET TECHNOLOGIES SOFTWARE.

TeeJet®Technologies

98-01556-ENUS R0

IMPORTANT SAFETY INFORMATION

All safety related and operating instructions should be read before the system is operated. Safe operation of machinery is the operators

responsibility. Safety procedures must be posted close to the equipment and clearly visible to and legible by the operator. Safety

procedures should meet all company and local regulations, as well as MSDS-requirements. For assistance, contact a local dealer.

Safety Alert Symbol Definitions:

DANGER! This symbol is reserved for the most extreme situations where serious personal injury or death is

imminent.

WARNING! This symbol indicates a hazardous situation that could result in serious personal injury or death.

CAUTION! This symbol indicates a hazardous situation that could result in minor or moderate personal injury.

NOTE: This symbol addresses practices in which the operator should be aware.

GENERAL WARNINGS AND PRECAUTIONS

DANGER!

• Read and follow instructions. If instructions are unclear after reading the manual, please contact a local dealer.

• Keep children away from equipment.

• Do not operate machinery under the inuence of alcohol or any illegal substance.

• Some systems include a fan heater. Never cover the heater otherwise there will be a serious danger of re!

WARNING! ELECTRICAL / SHOCK HAZARDS

• Before working on any particular component, make sure that all power supplies have been switched off and cannot

be accidentally switched on.

• Disconnect power leads before using an arc welder on equipment or anything connected to the equipment.

• Systems including frequency drives have a risk of electric shock due to residual voltage. It is not permissible to open

the equipment neither to disconnect the system or any quick connection until 5 minutes after the power has been

removed.

• Only operate the system from the power source indicated in the manual. If you are not sure of the power source,

consult qualied service personnel.

• Do not use a high pressure cleaner to clean electrical components. This could damage electrical components and

subject the operator to risk of electrical shock.

• The electrical supply to the equipment must be properly routed and connected to the equipment. All connections

must meet the specied requirements.

TeeJet®Technologies

www.teejet.com

WARNING! PRESSURIZED HYDRAULIC SYSTEMS

• Always wear personal protective equipment (PPE) when performing work on hydraulic systems.

• Adhere to the machine manufacture’s approved maintenance instructions when working on the hydraulic system.

• Always turn equipment off when working on the hydraulic system. Take appropriate precautions when opening

systems that have been previously pressurized.

• Be aware that hydraulic oil may be extremely hot and under high pressure.

WARNING! CHEMICAL HANDLING

• Always wear PPE when handling any chemical substance.

• Always follow safety labels and instructions provided by the chemical manufacturer or supplier.

• The operator should have full information on the nature and the quantity of the material to be distributed.

• ADHERE TO FEDERAL, STATE AND LOCAL REGULATIONS REGARDING THE HANDLING, USE OR

DISPOSAL OF AGRICULTURAL CHEMICALS.

WARNING! PRESSURIZED SPRAY SYSTEM

• It is important to recognize proper safety precautions when using a pressurized spray system. Fluids under pressure

can penetrate skin and cause serious personal injury.

• The system pressure should never exceed the lowest rated component. Always know your system and all

component capabilities, maximum pressures and ow rates.

• Filters can only be opened when the manual valves in front of and behind the lter are in closed position. If any

appliance has to be taken out of the piping, manual valves in front of and behind this appliance have to be in closed

position. If they are reinstalled, make sure that this happens correctly, that this apparatus is well aligned, and that all

connections are tight.

• The plumbing supply to the equipment should meet all company and local regulations and must be properly routed

and connected to the equipment. All connections must meet the specied requirements.

• It is advised to drain and purge the liquid train when the equipment shall not be used for a longer period of time.

WARNING! AUTO STEERING SAFETY

• To prevent serious personal injury or death from being run over by the vehicle or automated motion of the steering

system, never leave the vehicles operator seat with the system engaged.

• To prevent serious personal injury or death from being run over by the vehicle or automated motion of the steering

system, verify the area around the vehicle is clear of people or obstacles before startup, calibration, tuning or

engaging the system.

• Make sure equipment is tightly secured to the proper components.

• Never drive on public roads with system engaged.

CAUTION! EQUIPMENT SAFETY, MAINTENANCE, AND SERVICE

• The equipment should be operated only by properly trained, qualied personnel. They must have proven their skills

in the operation of the equipment.

• Before using the equipment, the operator has to check if the equipment is in good condition and can be used safely.

If not, the equipment cannot be used.

• All necessary PPE must be readily available to the operator at all times.

• Routinely check the system and components for wear and damage. Replace or repair when necessary.

• Only qualied authorized experts are allowed to repair or maintain the installation. The maintenance and operating

instructions shall be rigidly observed and followed.

• A complete manual for the equipment must be available to the operator or maintenance technician at all times.

TeeJet®Technologies

98-01556-ENUS R0

CAUTION! HARNESS CABLE AND HOSE SAFETY

• Routinely check all harness cables and hoses for damage or wear. Replace or repair when necessary.

• Do not route harness cables and hoses with sharp bends.

• Do not strap harness cables and hoses to lines with high vibration or spikes in pressure.

• Do not strap harness cables and hoses to lines transporting hot uids.

• Protect harness cables and hoses from sharp objects, equipment debris, and material buildup.

• Allow sufcient length for harness cables and hoses to have free movement on sections that move during operation,

and be sure that harness cables or hoses do not hang below the equipment.

• Allow sufcient clearance for harness cables and hoses from implement and machine operational zones.

• When cleaning equipment, protect harness cables from high pressure wash.

NOTE: TOUCH SCREEN CARE

• Keep sharp objects away from the touch screen device. Touching the screen with a sharp object could result in

damage to the display.

• Do not use harsh chemicals to clean the console/display. The correct way to clean a console/display is to use a soft

damp cloth or anti-static wipe, similar to cleaning a monitor on a computer.

NOTE: RECOMMENDED REPLACEMENT PARTS

• The system has been designed with components that work together to provide the best system performance. When

the system requires replacement parts, only TeeJet recommended components should be used to maintain proper

system operation and safety.

END USER LICENSE AGREEMENT

• ALWAYS READ AND FOLLOW THE CHEMICAL LABEL’S DIRECTIONS. Droplet size classication is in

accordance with ISO 25358 at the date of publication. Classications are subject to change. The chemical being

sprayed, tank mixes, temperature, humidity, wind speed, vehicle speed, etc. can inuence the actual drop size.

Matrix 908 Field Computer

1

98-01578-ENUS R2

CONSOLESTART JOB SETUPHELP UT MEASUREMENTS

MEASUREMENTS TO HAVE ON HAND BEFORE YOU GET STARTED

The following pages are to assist in dening vehicle measurements in the Vehicle Wizard, device measurements in the Device Wizard,

and mapping location measurements in the Mapping Location options.

Illustrations are for general reference only. See tractor manufacture's documentation for precise measurement locations.

NOTE: Some of the listed settings may not be required for your vehicle or device. The Vehicle Wizard and Device Wizard will guide you

through each required settings based on your selections.

Sprayers

Self-Propelled Front Mount Sprayer ............................................................................................................................. page 2

Self-Propelled Rear Mount Sprayer ............................................................................................................................. page 3

Tractor with Fixed Mount Off-Center Sprayer ............................................................................................................... page 4

Self-Propelled Front Mount Sprayer ............................................................................................................................. page 2

Tractor with Pivot Mount Sprayer ................................................................................................................................. page 6

Spreaders

Self-propelled Spreader ............................................................................................................................................... page 7

Tractor with Fixed Mount Spreader .............................................................................................................................. page 8

Tractor with Pivot Mount Spreader ............................................................................................................................... page 9

NOTE: Some spreader features are limited until an Advanced Spreader unlock code is entered. See "No.3 Enter Available Unlocks" on

page 15 for unlock code instructions.

Measurement Best Practices

• Measure as if vehicle and device are in a straight-line and in the operating position.

• Device dimensions may shift when in operation. Measure implement when engaged with the

ground to achieve the best accuracy.

• Hold tape measure plumb or level in vertical or horizontal directions.

• Measure to the center of the antenna.

• Sections are numbered from left to right while facing in the machine's forward direction.

• Lateral left/right direction is determined while facing in the machine's forward direction.

Terminology Notes

• Vehicle Pivot Point – the center of the vehicle's non-steering axle

– Example: the center of the rear axle for a front steering vehicle

• Hitch Point / Hitch/Connection Point – the point where the implement connects to the

machine or the pivot point between implement and machine depending on Hitch Type

– Not all vehicles have hitch points. On these vehicles, the Hitch Point and the Vehicle Pivot

Point will be the same point and the value should be entered as 0 in / 0 cm.

• Guidance Width – the width between guidelines

– May be different than the Application Width or Working Width (total width of all sections).

Matrix 908 Field Computer

2www.teejet.com

CONSOLE START JOBSETUP HELPUTMEASUREMENTS

SPRAYERS

Self-Propelled Front Mount Sprayer

Table 1-1: Vehicle Wizard Measurements

Description Measurement/Option

Vehicle In-Line Direction to Hitch

Point

Forward of

Vehicle Pivot Point

Vehicle In-Line Distance from the

Vehicle Pivot Point to Hitch

Point

0 in / 0 cm

Vehicle Pivot Point

and Hitch Point are

the same point

Vehicle Lateral Direction to Hitch

Point

On Center

Antenna In-Line Direction and

Distance from Vehicle Pivot

Point to the Antenna

Antenna Lateral Direction1and

Distance from vehicle centerline to

the Antenna

Table 1-2: Guidance and Mapping Distances

Description Measurement

Guidance Width

Mapping Location In-Line Distance

from the Vehicle Pivot Point

to the Mapping Location

Mapping Location Lateral Distance

from the Vehicle Centerline

to the Mapping Location

1 When an Assisted/Automatic Steering Device is available, Antenna Lateral

Distance and Direction will be established under the Assisted/Automatic Steering

“Manage Vehicles” settings.

Table 1-3: Device Wizard Measurements

Description Measurement/Option

Hitch Type

Fixed Mount

Boom and Section Layout

Front Centered

Distance to Boom: In-Line Distance

Hitch/Connection Point to

Product Delivery Point

Table 1-4: Section Information

Description Option

Section Symmetry

Description Width Measurement

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Section 8

Section 9

Section 10

Total Application Width

Matrix 908 Field Computer

3

98-01578-ENUS R2

CONSOLESTART JOB SETUPHELP UT MEASUREMENTS

Self-Propelled Rear Mount Sprayer

Table 1-5: Vehicle Wizard Measurements

Description Measurement/Option

Vehicle In-Line Direction to Hitch

Point

Aft of Vehicle Pivot

Point

Vehicle In-Line Distance from the

Vehicle Pivot Point to Hitch

Point

0 in / 0 cm

Vehicle Pivot Point

and Hitch Point are

the same point

Vehicle Lateral Direction to Hitch

Point

:

On Center

Antenna In-Line Direction and

Distance from Vehicle Pivot Point

to the Antenna

Antenna Lateral Direction2and

Distance from vehicle centerline to

the Antenna

Table 1-6: Guidance and Mapping Distances

Description Measurement

Guidance Width

Mapping Location In-Line Distance

from the Vehicle Pivot Point

to the Mapping Location

Mapping Location Lateral Distance

from the Vehicle Centerline

to the Mapping Location

2 When an Assisted/Automatic Steering Device is available, Antenna Lateral

Distance and Direction will be established under the Assisted/Automatic Steering

“Manage Vehicles” settings.

Table 1-7: Device Wizard Measurements

Description Measurement/Option

Hitch Type

Fixed Mount

Boom and Section Layout

Aft Centered

Distance to Boom: In-Line Distance

Hitch/Connection Point to

Product Delivery Point

Table 1-8: Section Information

Description Option

Section Symmetry

Description Width Measurement

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Section 8

Section 9

Section 10

Total Application Width

Matrix 908 Field Computer

4www.teejet.com

CONSOLE START JOBSETUP HELPUTMEASUREMENTS

Tractor with Fixed Mount O-Center Sprayer

Table 1-9: Vehicle Wizard Measurements

Description Measurement/Option

Vehicle In-Line Direction to Hitch

Point

Aft of Vehicle Pivot

Point

Vehicle In-Line Distance from the

Vehicle Pivot Point to Hitch

Point

0 in / 0 cm

Vehicle Pivot Point

and Hitch Point are

the same point

Vehicle Lateral Direction to Hitch

Point

On Center

Antenna In-Line Direction and

Distance from Vehicle Pivot Point

to the Antenna

Antenna Lateral Direction3and

Distance from vehicle centerline to

the Antenna

Table 1-10: Guidance and Mapping Distances

Description Measurement

Guidance Width

Mapping Location In-Line Distance

from the Vehicle Pivot Point

to the Mapping Location

Mapping Location Lateral Distance

from the Vehicle Centerline

to the Mapping Location

3 When an Assisted/Automatic Steering Device is available, Antenna Lateral

Distance and Direction will be established under the Assisted/Automatic Steering

“Manage Vehicles” settings.

Table 1-11: Device Wizard Measurements

Description Measurement/Option

Hitch Type

Fixed Mount

Boom and Section Layout

Aft O-Centered

Boom Lateral Offset Direction

Boom Lateral Offset Distance from

the Centerline of the Vehicle to the

Center of the Boom

Distance to Boom: In-Line Distance

Hitch/Connection Point to

Product Delivery Point

Table 1-12: Section Information

Description Option

Section Symmetry

Description Width Measurement

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Section 8

Section 9

Total Application Width

Matrix 908 Field Computer

5

98-01578-ENUS R2

CONSOLESTART JOB SETUPHELP UT MEASUREMENTS

Tractor with Fixed Mount Aft Sprayer

Table 1-13: Vehicle Wizard Measurements

Description Measurement/Option

Vehicle In-Line Direction to Hitch

Point

Aft of Vehicle Pivot

Point

Vehicle In-Line Distance from the

Vehicle Pivot Point to Hitch

Point

0 in / 0 cm

Vehicle Pivot Point

and Hitch Point are

the same point

Vehicle Lateral Direction to Hitch

Point

On Center

Antenna In-Line Direction and

Distance from Vehicle Pivot Point

to the Antenna

Antenna Lateral Direction4and

Distance from vehicle centerline to

the Antenna

Table 1-14: Guidance and Mapping Distances

Description Measurement

Guidance Width

Mapping Location In-Line Distance

from the Vehicle Pivot Point

to the Mapping Location

Mapping Location Lateral Distance

from the Vehicle Centerline

to the Mapping Location

4 When an Assisted/Automatic Steering Device is available, Antenna Lateral

Distance and Direction will be established under the Assisted/Automatic Steering

“Manage Vehicles” settings.

Table 1-15: Device Wizard Measurements

Description Measurement/Option

Hitch Type

Fixed Mount

Boom and Section Layout

Aft Centered

Distance to Boom: In-Line Distance

Hitch/Connection Point to

Product Delivery Point

Table 1-16: Section Information

Description Option

Section Symmetry

Description Width Measurement

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Section 8

Section 9

Section 10

Total Application Width

Matrix 908 Field Computer

6www.teejet.com

CONSOLE START JOBSETUP HELPUTMEASUREMENTS

Tractor with Pivot Mount Sprayer

Table 1-17: Vehicle Wizard Measurements

Description Measurement/Option

Vehicle In-Line Direction to Hitch

Point

Aft of Vehicle Pivot

Point

Vehicle In-Line Distance from the

Vehicle Pivot Point to Hitch

Point

Vehicle Lateral Direction to Hitch

Point

On Center

Antenna In-Line Direction and

Distance from Vehicle Pivot Point

to the Antenna

Antenna Lateral Direction5and

Distance from vehicle centerline to

the Antenna

Table 1-18: Guidance and Mapping Distances

Description Measurement

Guidance Width

Mapping Location In-Line Distance

from the Vehicle Pivot Point

to the Mapping Location

Mapping Location Lateral Distance

from the Vehicle Centerline

to the Mapping Location

5 When an Assisted/Automatic Steering Device is available, Antenna Lateral

Distance and Direction will be established under the Assisted/Automatic Steering

“Manage Vehicles” settings.

Table 1-19: Device Wizard Measurements

Description Measurement/Option

Hitch Type

Pivot Mount

In-Line Distance from Hitch/

Connection to Trailer Axle

Boom and Section Layout

Aft Centered

Distance to Boom: In-Line Distance

Hitch/Connection Point to

Product Delivery Point

Table 1-20: Section Information

Description Option

Section Symmetry

Description Width Measurement

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Section 8

Section 9

Section 10

Total Application Width

Matrix 908 Field Computer

7

98-01578-ENUS R2

CONSOLESTART JOB SETUPHELP UT MEASUREMENTS

SPREADERS

Self-propelled Spreader

Table 1-21: Vehicle Wizard Measurements

Description Measurement/Option

Vehicle In-Line Direction to Hitch

Point

Aft of Vehicle Pivot

Point

Vehicle In-Line Distance from the

Vehicle Pivot Point to Hitch

Point

0 in / 0 cm

Vehicle Pivot Point

and Hitch Point are

the same point

Vehicle Lateral Direction to Hitch

Point

On Center

Antenna In-Line Direction and

Distance from Vehicle Pivot Point

to the Antenna

Antenna Lateral Direction6and

Distance from vehicle centerline to

the Antenna

Table 1-22: Guidance and Mapping Distances

Description Measurement

Guidance Width

Mapping Location In-Line Distance

from the Vehicle Pivot Point

to the Mapping Location

Mapping Location Lateral Distance

from the Vehicle Centerline

to the Mapping Location

6 When an Assisted/Automatic Steering Device is available, Antenna Lateral

Distance and Direction will be established under the Assisted/Automatic Steering

“Manage Vehicles” settings.

Table 1-23: Device Wizard Measurements

Description Measurement/Option

Hitch Type

Fixed Mount

In-Line Distance from Hitch/

Connection to Disc

In-Line Distance from Disc to

Leading Edge

Table 1-24: Section Information7

Description Option

Section Symmetry

Description

Measurement

Width Length In-Line

Offset

Section 1 0 in / 0 cm

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Section 8

Section 9

Section 10

Total Working Width

7 Some spreader features are limited until an Advanced Spreader unlock code is

entered.

Matrix 908 Field Computer

8www.teejet.com

CONSOLE START JOBSETUP HELPUTMEASUREMENTS

Tractor with Fixed Mount Spreader

Table 1-25: Vehicle Wizard Measurements

Description Measurement/Option

Vehicle In-Line Direction to Hitch

Point

Aft of Vehicle Pivot

Point

Vehicle In-Line Distance from the

Vehicle Pivot Point to Hitch

Point

0 in / 0 cm

Vehicle Pivot Point

and Hitch Point are

the same point

Vehicle Lateral Direction to Hitch

Point

On Center

Antenna In-Line Direction and

Distance from Vehicle Pivot Point

to the Antenna

Antenna Lateral Direction8and

Distance from vehicle centerline to

the Antenna

Table 1-26: Guidance and Mapping Distances

Description Measurement

Guidance Width

Mapping Location In-Line Distance

from the Vehicle Pivot Point

to the Mapping Location

Mapping Location Lateral Distance

from the Vehicle Centerline

to the Mapping Location

8 When an Assisted/Automatic Steering Device is available, Antenna Lateral

Distance and Direction will be established under the Assisted/Automatic Steering

“Manage Vehicles” settings.

Table 1-27: Device Wizard Measurements

Description Measurement/Option

Hitch Type

Fixed Mount

In-Line Distance from Hitch/

Connection to Disc

In-Line Distance from Disc to

Leading Edge

Table 1-28: Section Information9

Description Option

Section Symmetry

Description

Measurement

Width Length In-Line

Offset

Section 1 0 in / 0 cm

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Section 8

Section 9

Section 10

Total Working Width

9 Some spreader features are limited until an Advanced Spreader unlock code is

entered.

Matrix 908 Field Computer

9

98-01578-ENUS R2

CONSOLESTART JOB SETUPHELP UT MEASUREMENTS

Tractor with Pivot Mount Spreader

Table 1-29: Vehicle Wizard Measurements

Description Measurement/Option

Vehicle In-Line Direction to Hitch

Point

Aft of Vehicle Pivot

Point

Vehicle In-Line Distance from the

Vehicle Pivot Point to Hitch

Point

Vehicle Lateral Direction to Hitch

Point

On Center

Antenna In-Line Direction and

Distance from Vehicle Pivot Point

to the Antenna

Antenna Lateral Direction10 and

Distance from vehicle centerline to

the Antenna

Table 1-30: Guidance and Mapping Distances

Description Measurement

Guidance Width

Mapping Location In-Line Distance

from the Vehicle Pivot Point

to the Mapping Location

Mapping Location Lateral Distance

from the Vehicle Centerline

to the Mapping Location

10 When an Assisted/Automatic Steering Device is available, Antenna Lateral

Distance and Direction will be established under the Assisted/Automatic Steering

“Manage Vehicles” settings.

Table 1-31: Device Wizard Measurements

Description Measurement/Option

Hitch Type

Pivot Mount

In-Line Distance from Hitch/

Connection to Trailer Axle

In-Line Distance from Hitch/

Connection to Disc

In-Line Distance from Disc to

Leading Edge

Table 1-32: Section Information11

Description Option

Section Symmetry

Description

Measurement

Width Length In-Line

Offset

Section 1 0 in / 0 cm

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Section 8

Section 9

Section 10

Total Working Width

11 Some spreader features are limited until an Advanced Spreader unlock code is

entered.

Matrix 908 Field Computer

10 www.teejet.com

START JOBSETUP HELPMEASUREMENTS UTCONSOLE

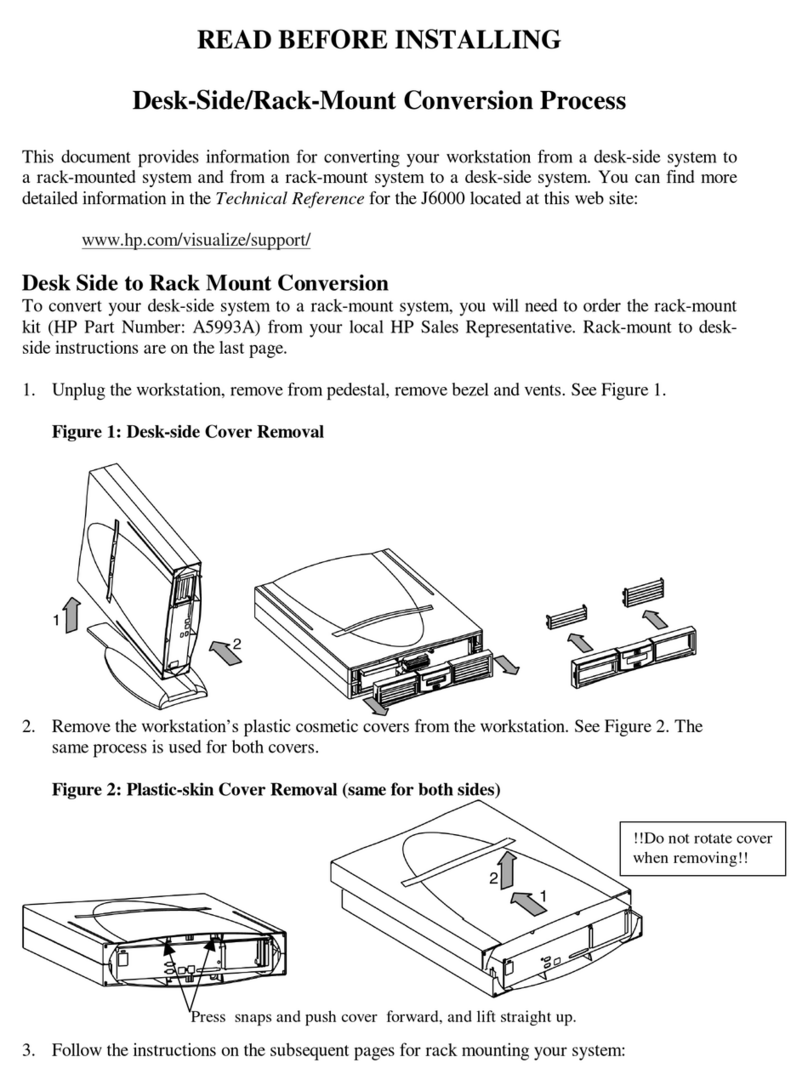

CONSOLE CONNECTIONS AND FEATURES

*Connection Activity is dependent on software version.

Power On/Off Button

Before powering on the console, attach all devices to the harness.

XOn – press the POWER button

XOff – press and briey hold the POWER button

WARNING! Wait 30 seconds before restarting the console.

Serial Number

Take note of your serial number. It is required for product registration.

Product Registration

Integrated RAM Mount (assembly required)

Speaker

Camera Connection*

WiFi Antenna Connection*

Harness Connection

Serial Number

Ethernet Connection*

Power Button

GNSS Antenna Connection

USB Port

Matrix 908 Field Computer

11

98-01578-ENUS R2

START JOB SETUPHELP MEASUREMENTSUT CONSOLE

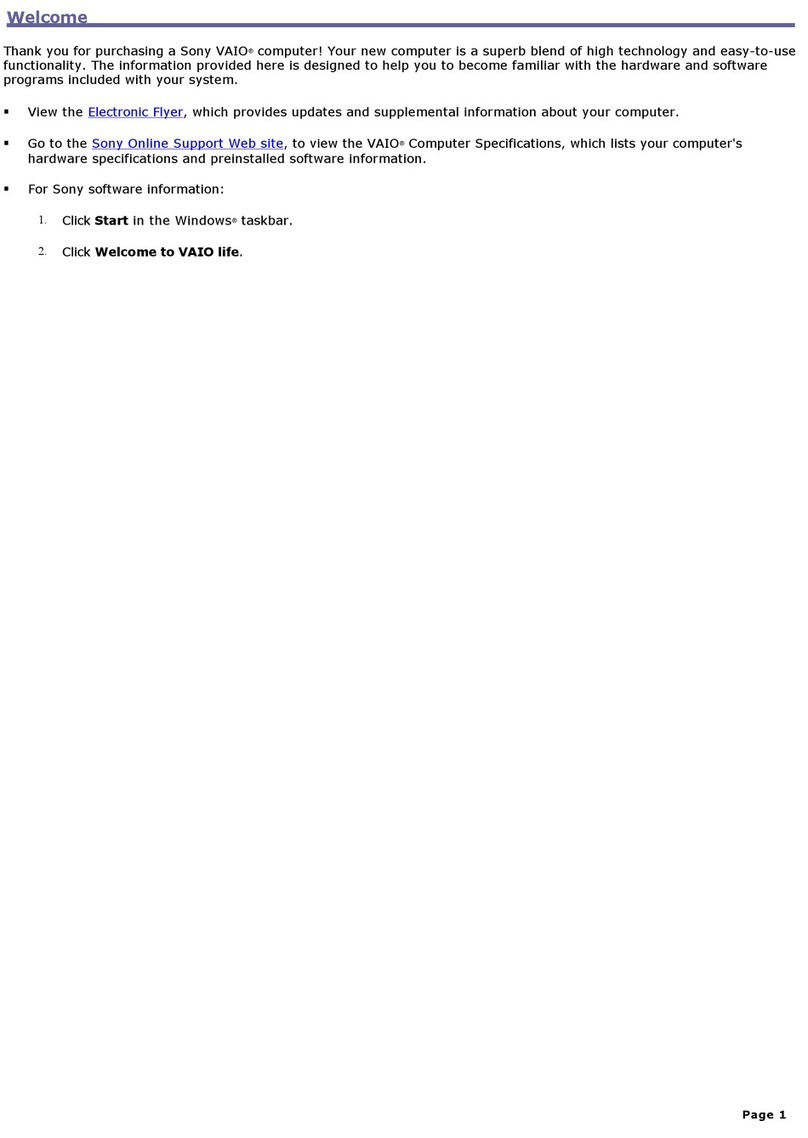

SYSTEM DIAGRAM

The following is to be used for general reference. Specic congurations will vary depending on available devices. Contact TeeJet

Customer Service or your local dealer for information on your specic conguration.

NOTE: Connectivity to different devices may be released with future software releases. Always refer to software release notes for

software/system connectivity at www.teejet.com/support/software.aspx.

Matrix 908 Console

RXA-52 Antenna

CAN "T" to 6 Socket

Deutsch DTM Terminator

OR

Ethernet Interface

UniPilot Pro

to Assisted/Auto Steering

Steering Control Module

(SCM Pro)

to BoomPilot Section Control

Section Driver Module (SDM)

Switch Function Module (SFM)

Matrix 908 Harness

to power

Battery Cable

Power Cable

to ISOBUS ECU

IC18 Sprayer, IC35 Sprayer, IC38 Spreader,

IC45 Sprayer, DynaJet IC7140

Matrix 908 Field Computer

12 www.teejet.com

CONSOLE START JOBSETUP HELPMEASUREMENTS UTSETUP

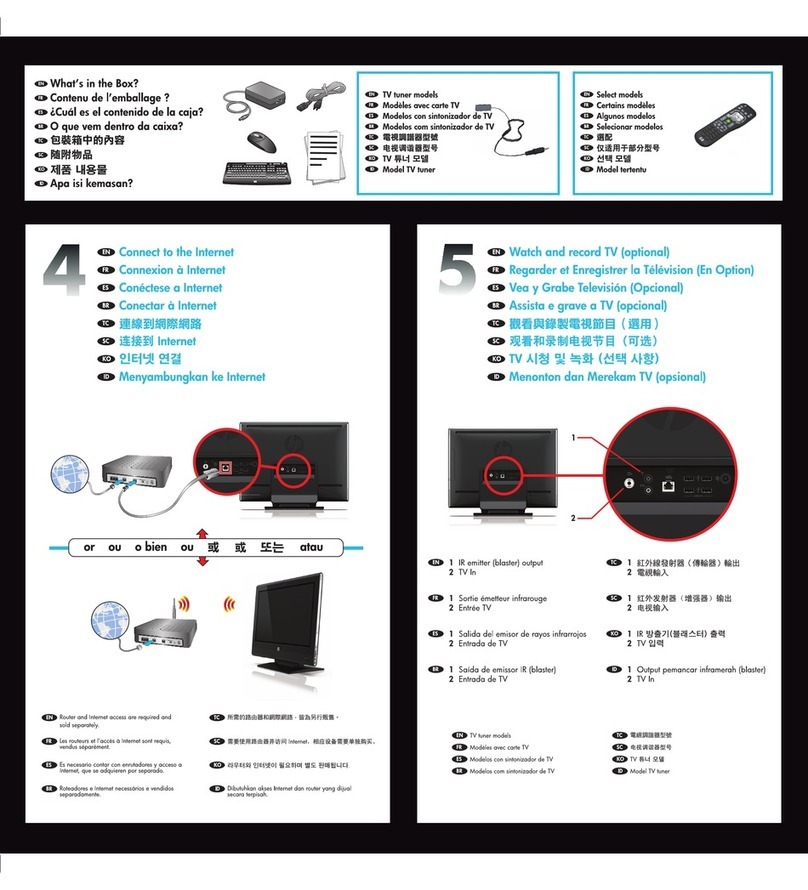

NO.1 WELCOME SCREEN

SETUP THE CONSOLE

Before powering on the console, verify that all devices are attached to the harness.

NOTE: To access the Cultural Settings after initial startup:

Once the power up sequence has completed, the

Welcome screen will appear.

Select a different language ,

switch console units and

change the local time zone .

NOTE: When changing languages, reboot the console

as suggested. Upon restart, the console will

return to the Welcome Screen.

Press the NEXT button to advance to the

Vehicle Wizard.

Matrix 908 Field Computer

13

98-01578-ENUS R2

CONSOLESTART JOB SETUPHELP MEASUREMENTSUT SETUP

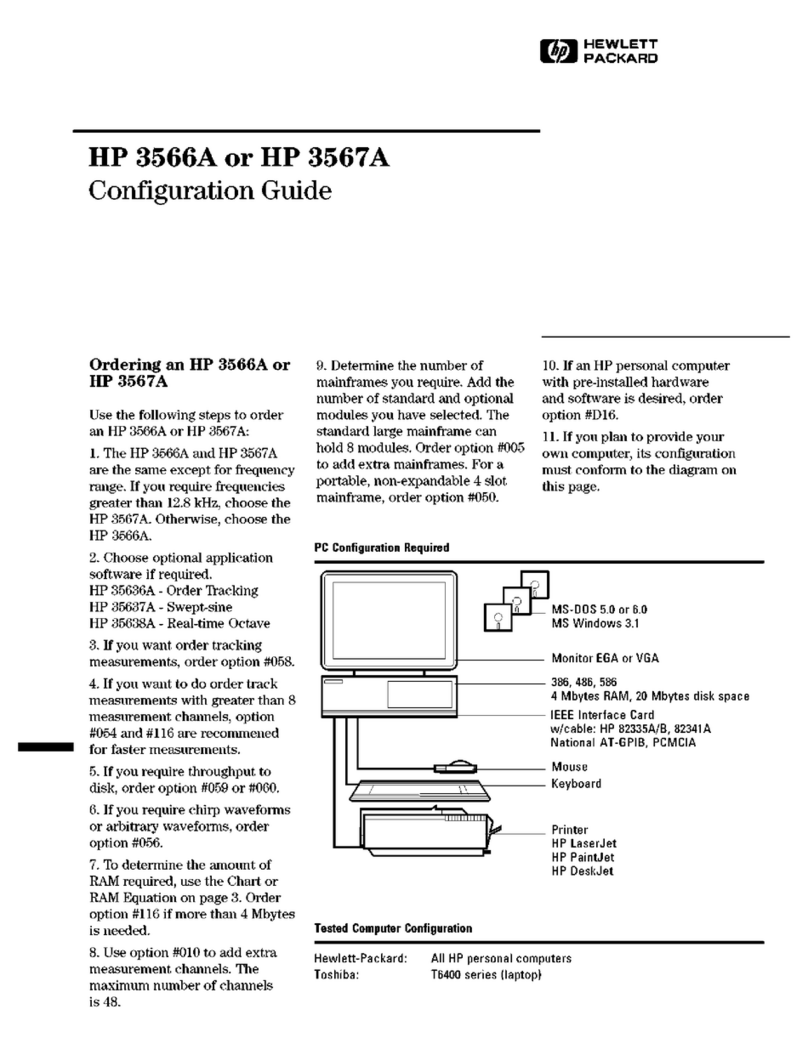

NO.2 WALK THROUGH THE VEHICLE WIZARD

Establishing an accurate vehicle is required for

mapping or guidance.

Follow the prompts on the Vehicle Wizard,

making adjustments to the vehicle settings as

needed.

To navigate through the wizard options:

Next Wizard Option – use to select the

highlighted option or value and go to

the next wizard option

Previous Wizard Option – use to revisit

the previous wizard option

To complete the vehicle setup:

Finish – shown when the end of

the wizard options has been reached;

use to save and close the wizard

Select "Yes" to activate the current settings.

Matrix 908 Field Computer

14 www.teejet.com

CONSOLE START JOBSETUP HELPMEASUREMENTS UTSETUP

To navigate in the Vehicle Manager:

Close Settings – use to exit the Settings

options and return to the Guidance screen

Edit Vehicle – use to enter the Vehicle

Wizard

Back One Menu – use to go to the Vehicle

& Device Manager menu

To Main Menu – use to go to the Main

Settings menu

To navigate in the Vehicle Wizard:

Exit Wizard – use to exit the wizard without

saving any changes

Next Wizard Option – use to select the

highlighted option or value and go to the

next wizard option

Previous Wizard Option – use to revisit the

previous wizard option

Save & Close – use to save all current

selections and close the wizard

Finish – shown when the end of the wizard

options has been reached; use to save and

close the wizard

Select "Yes" to activate the current settings.

To Access the Vehicle Manager After Initial Startup

Table of contents