TeeJet AEROS9040 User manual

USER GUIDE

AEROS9040

Software version 4.31

Table of Contents

START SIMPLE GUIDANCE 1

#1 POWER ON 1

#2 HOME SCREEN 1

System Setup .................................................................................................................................................................1

RealView Camera Full Screen Video View......................................................................................................................1

ISOBUS Universal Terminal View ....................................................................................................................................1

Simple or Advanced Mode.........................................................................................................................................1

#3 GO TO CONFIGURATION 2

1) Set Up the Local Cultural Settings.......................................................................................................................................................2

2) Set Up the GNSS.........................................................................................................................................................................................2

3) Set Up the Implement..............................................................................................................................................................................3

Implement Settings per Equipment Present...............................................................................................................3

Single Section Setup ......................................................................................................................................................3

Section(s) with ISOBUS Sprayer/Spreader Setup...........................................................................................................4

Additional Settings per Implement Type ....................................................................................................................4

Section Numbers .............................................................................................................................................................5

Straight ............................................................................................................................................................................5

Spreader – TeeJet............................................................................................................................................................6

Lateral Implement Offset Distance Adjustment ..........................................................................................................7

GNSS Offset Adjustment Calculation...............................................................................................................................7

Lateral Implement Offset Adjustment...............................................................................................................................8

4) Set Up the Mapping Location ...............................................................................................................................................................9

#4 START NEW JOB OR CONTINUE JOB 10

Simple Mode ................................................................................................................................................................................................. 10

Advanced Mode........................................................................................................................................................................................... 10

#5 SET UP GUIDANCE 11

1) Choose a Guidance Mode.................................................................................................................................................................... 11

2) Establish an AB guideline .................................................................................................................................................................... 12

3) Create an Application Boundary....................................................................................................................................................... 12

ADD RATE CONTROL 14

Guidance Screen Options......................................................................................................................................................................... 14

MAPPING OPTIONS 15

Duplicating and Transferring Maps ................................................................................................................................15

Coverage Map............................................................................................................................................................................................... 16

Polygons Map ............................................................................................................................................................................................... 16

Prescription Map.......................................................................................................................................................................................... 16

Application and Target Rate Maps ........................................................................................................................................................ 17

Target Rates...................................................................................................................................................................17

Color Range Selection ............................................................................................................................................17

iii

98-01504-ENUS R2

Aeros 9040 Field Computer

INFORMATION ON GUIDANCE MODES 18

Vehicle View................................................................................................................................................................................................... 18

Field View........................................................................................................................................................................................................ 18

RealView Guidance ..................................................................................................................................................................................... 19

GUIDANCE MODES 19

Straight AB Guidance................................................................................................................................................................................. 19

Curved AB Guidance .................................................................................................................................................................................. 19

Adaptive Curve AB Guidance.................................................................................................................................................................. 19

Circle Pivot Guidance ................................................................................................................................................................................. 20

Last Pass Guidance...................................................................................................................................................................................... 20

NextRow Guidance ..................................................................................................................................................................................... 20

No Guidance.................................................................................................................................................................................................. 20

SCREENS OPTIONS 21

GUIDANCE BAR 25

STATUS BAR 26

GUIDANCE FEATURES DETAILS 27

A+ Nudge Feature....................................................................................................................................................................................... 27

Azimuth Degree........................................................................................................................................................................................... 27

Return to Point.............................................................................................................................................................................................. 28

Next Guideline Feature.............................................................................................................................................................................. 29

REFRESH GNSS POSITION 29

BOOMPILOT 30

No Section Control Module ..................................................................................................................................................................... 30

ISOBUS Sprayer............................................................................................................................................................................................. 30

ISOBUS Spreader.......................................................................................................................................................................................... 31

With TeeJet Section Control Module And Switchbox or ISM....................................................................................................... 32

With TeeJet Section Control Module .................................................................................................................................................... 32

ADDITIONAL IMPLEMENT OPTIONS 33

TIP SELECTION 33

Preset .....................................................................................................................................................................33

Tip Sizes and Associated Colors....................................................................................................................................33

Current Tip..............................................................................................................................................................34

DROPLET SIZE MONITOR 34

Setup................................................................................................................................................................................................................ 34

Enable/Disable DSM ...............................................................................................................................................34

Tip Selection / Current Tip.......................................................................................................................................34

Input/Output Module Pressure Sensor.....................................................................................................................34

iv www.teejet.com

Aeros 9040 Field Computer

Operation ....................................................................................................................................................................................................... 35

Status Bar...............................................................................................................................................................35

Droplet Size Chart..........................................................................................................................................................35

Guidance Bar ..........................................................................................................................................................35

REVERSE SENSE 36

BOOMPILOT SECTION CONTROL 37

TIP FLOW MONITOR 38

ISOBUS SPRAYER OFFSETS 38

Self-propelled ............................................................................................................................................................................................... 39

Three Point Hitch ......................................................................................................................................................................................... 39

Trailed .............................................................................................................................................................................................................. 40

DATA MANAGEMENT 41

Job Data .......................................................................................................................................................................................................... 42

Copy Job Data ...............................................................................................................................................................42

Machine Settings......................................................................................................................................................................................... 43

Copy Machine Prole.....................................................................................................................................................43

SYSTEM CONFIGURATIONS 44

Safety Information

TeeJet Technologies is not responsible for damage or physical harm caused by failure to adhere to the following safety requirements.

As the operator of the vehicle, you are responsible for its safe operation.

The Aeros 9040 in combination with any assisted/auto steering device is not designed to replace the vehicle’s operator.

Do not leave a vehicle while the Aeros 9040 is engaged.

Be sure that the area around the vehicle is clear of people and obstacles before and during engagement.

The Aeros 9040 is designed to support and improve efciency while working in the eld. The driver has full responsibility for the quality and work

related results.

Disengage or remove any assisted/auto steering device before operating on public roads.

1

98-01504-ENUS R2

Aeros 9040 Field Computer

START SIMPLE GUIDANCE

#1 POWER ON

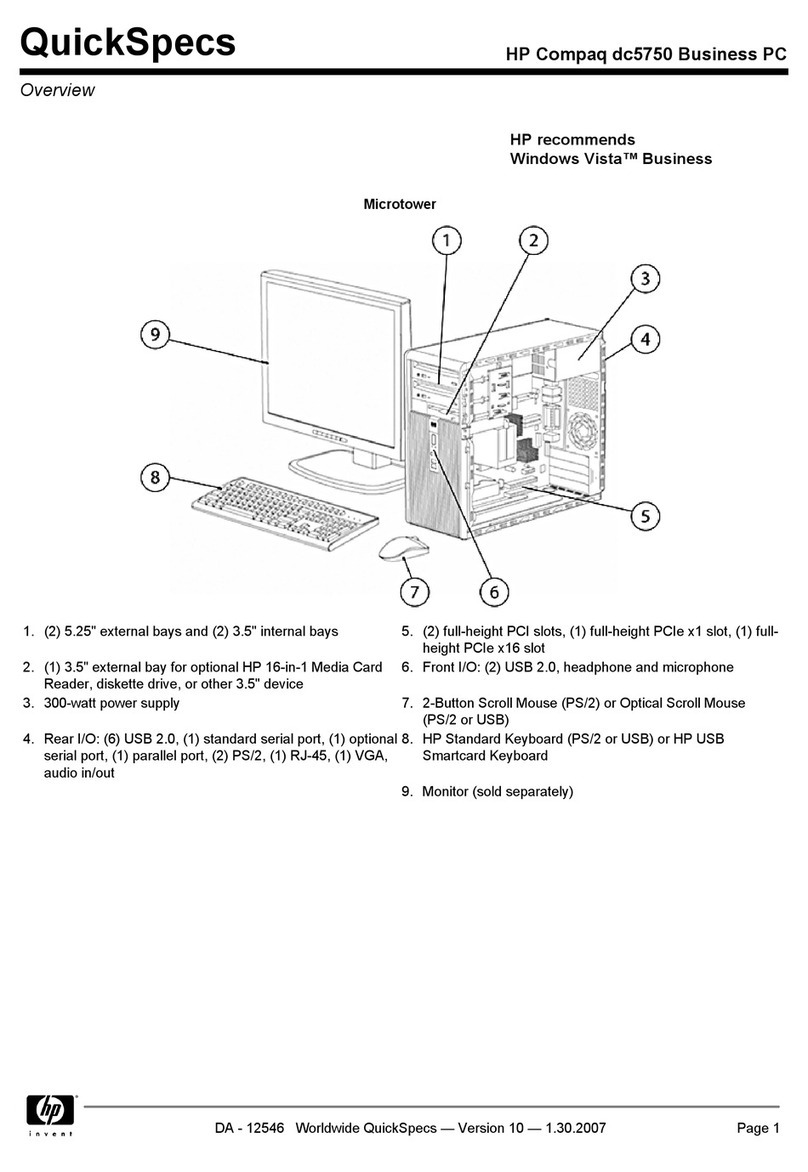

Integrated RAM Mount

(assembly required)

Speed Digital (LAN)

Connection

with Rubber Cover

Camera Connection

with Rubber Cover

Power Connection

Speakers

GNSS Antenna Connection

WiFi Antenna Connection

USB Ports with Rubber

Covers

USB Ports with Rubber Covers

Bright Touch Screen

Power Button

Favorites Button

Home Button

Recommended Antenna Installation

The GNSS antenna should be mounted as far forward as possible on

top of the cab on a metal surface of at least 4 in × 4 in / 10 cm × 10 cm.

Home Button

The Home button provides a shortcut to the Home screen.

Power On/Off Button

On – Press the POWER button to power on the console. Upon

power up, the Aeros will begin its start up sequence.

Off – Press and briey hold the POWER button until a conrmation

screen acknowledges shut down mode.

WARNING! Wait 10 seconds before restarting the console.

#2 HOME SCREEN

Once the power up sequence has completed, the Home screen will

appear with the options to start a new job or continue an existing job.

Home/Job Screen (or press Home Button)

Unit Setup

RealView Camera Full Screen Video View

ISOBUS Universal Terminal

System Setup

System Setup is used to congure the console, the machine and its

implements. Four side tabs access options for Machine/Implement

Conguration, Data Management, Console Settings, and Tools.

RealView Camera Full Screen Video View

View video feed(s) and setup cameras without GNSS available.

Options for RealView Guidance are not available on this screen.

ISOBUS Universal Terminal View

Access to an ISOBUS Electronic Control Unit (ECU) options and

operation. This provides crop sprayer or spreader control when

integrated into the implement of either capability.

Simple or Advanced Mode

To change between simple mode and advanced mode, see the

conguration chapter under Data –> Options.

►Simple Mode – only one job will be available at a time. Only

bounded area and coverage areas are displayed on the home

screen. Only the current job is available for saving in Reports.

Use with Fieldware Link is not available.

►Advanced Mode – more than one job will be available at any

time. Client, farm, eld and job names; bounded and coverage

areas; application time; and distance from selected job are

displayed on the home screen. All saved job proles can be

exported as a PDF, SHP or KML le to a USB drive using

Data -> Reports.

2www.teejet.com

Aeros 9040 Field Computer

#3 GO TO CONFIGURATION

From the Home screen, select the System Setup bottom button to congure the console, the machine and its implements. Four side tabs access

options for Machine/Implement Conguration, Data Management, Console Settings, and Tools.

Conguration side tab

Data Management side tab

Console Settings side tab

Tools side tab

System Setup bottom tab

Side Tabs

1) Set Up the Local Cultural Settings

Cultural is used to congure units, language, and time zone settings

for the Aeros console and any Electronic Control Units (ECUs) in the

system.

NOTE: The languages available in a particular ECU may vary.

1. Press SYSTEM SETUP bottom tab .

2. Press CONSOLE side tab .

3. Press Cultural .

4. Select from:

►Units – used to dene the system units

►Language – used to dene the system language

►Time Zone – used to establish the local time zone

2) Set Up the GNSS

GGNSS Receiver Conguration is used to congure GNSS Type,

GNSS Port, and PRN, and other GNSS parameters, and to view GNSS

status information.

1. Press SYSTEM SETUP bottom tab .

2. Press CONFIGURATION side tab .

3. Press GNSS Receiver Conguration .

4. Select from:

►GNSS Type – sets to accept GNSS source transmissions: GPS,

GLONASS, SBAS (with or without DGPS Required)

►GNSS Port – sets GNSS communication port to either Internal

or External

►GNSS Status Information – displays current GNSS status

information

►Program – only TeeJet support technicians should use this

feature

►PRN – selects the rst of two possible SBAS PRN’s to provide

SBAS correction data. Set to Automatic for automatic PRN

selection.

►Alternate PRN – when PRN is not automatic, allows possible

selection of a second SBAS PRN to provide correction data

►Show refresh GNSS position button – establishes if the refresh

GNSS position button is available on the guidance screens.

5. Press NEXT PAGE arrow to set up the selected specic GNSS

options.

6. Select:

►GPS – single point uncorrected position data based on GPS only

with a GGA QI of “1” is accepted.

NOTE: GPS is always selected.

►GPS+GLONASS – single point uncorrected position data based

on GPS and GLONASS with a GGA QI of “1” is accepted.

3

98-01504-ENUS R2

Aeros 9040 Field Computer

►GPS+SBAS – either single point uncorrected or SBAS corrected

position data are accepted - GGA QI of “1” or “2” (3, 4 or 5 are

also accepted).

►GPS+GLONASS+SBAS – either single point uncorrected or

SBAS corrected position data are accepted - GGA QI of “1” or

“2” (3, 4 or 5 are also accepted).

►GPS+GLONASS+SBAS+DGPS – only GGA data with a QI value

of “2” or higher is accepted (3, 4 or 5 are also accepted).

NOTE: All console based mapping, application and guidance

functions are ceased if the GGA QI value drops below “2” with

this setting checked.

7. Exit this screen to begin initializing the GNSS receiver. This takes

about a minute, and the console will not respond until complete.

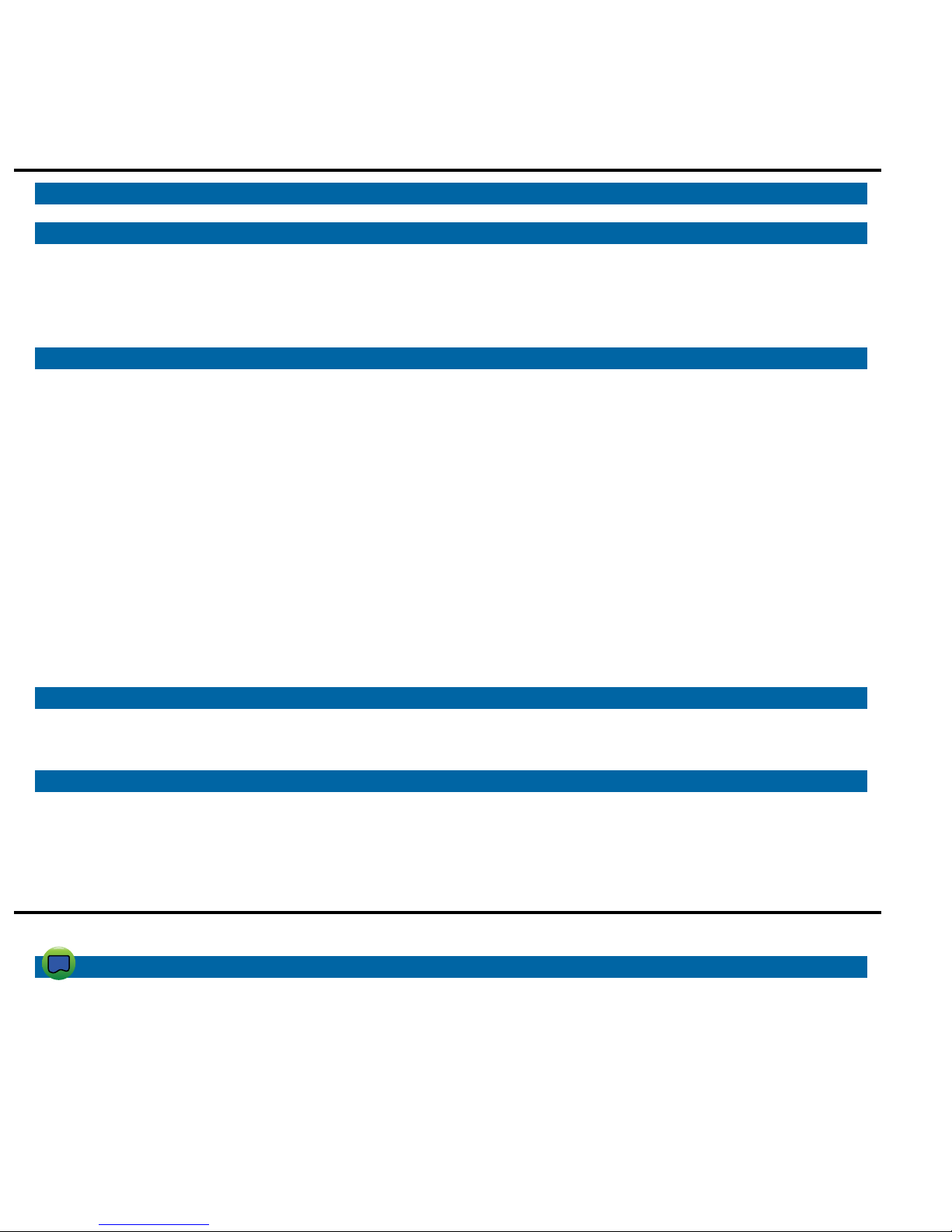

3) Set Up the Implement

Implement Setup is used to establish the various settings associated

with straight mode, spreader mode, or staggered mode. Available

settings will vary depending on the specic equipment present in the

system.

Implement Settings per Equipment Present

This section includes setup options for these implement congurations:

►Single Section

►Section(s) with ISOBUS Sprayer/Spreader Setup

Single Section Setup

Single Section Setup is used when a SmartCable, Section Driver

Module (SDM), or Switch Function Module (SFM) is not on the system

(that is, no section control is present). The entire boom or delivery area

is considered to be one section.

1. Press CONFIGURATION side tab .

2. Press Implement .

3. Select from:

►Machine Type [when available]– used to select the type of

machine that most closely represents your machine

►GNSS Antenna Height [when available]– used to measure the

height of the antenna from the ground

►Implement Type – used to select the layout of the sections for

the applied product location (see Implement Type section for

additional details)

►Working/ Application Width – used to enter the total width of the

implement. Range is 3.28 to 246.06 feet / 1.0 to 75.0 meters.

►Droplet Size Monitor [when available] – used to enable droplet

size monitoring for up to ve preselected sprayer tips

►Tip Selection [when available] – used to select the type of

sprayer tip (series and capacity) for determining droplet size

information

►Applied Alert – used to establish an alert to signal when exiting

or entering an applied area

►BoomPilot Start Mode – used to establish whether BoomPilot will

be controlled by speed or by the BoomPilot icon

4www.teejet.com

Aeros 9040 Field Computer

►BoomPilot Icon – used to activate the guidance screen icon for

manually controlling on-screen application painting

4. Press NEXT PAGE arrow to set up specic implement options.

See the Implement chapter for details.

Section(s) with ISOBUS Sprayer/Spreader Setup

Some Implement options are completed on the ISOBUS ECU. When

these options are also available in the Implement Setup section, they

will be grayed out or unavailable.

1. Press CONFIGURATION side tab .

2. Press Implement .

3. Select from:

►Machine Type [when available] – used to select the type of

machine that most closely represents your machine

►GNSS Antenna Height [when available] – used to measure the

height of the antenna from the ground

►Implement Type – used to select the layout of the sections for

the applied product location

►Application Width [Straight Implement Type completed on

ISOBUS ECU] – used to display the total width of the implement

as entered on the ISOBUS sprayer

►Working Width [Spreader Implement Type completed on the

ISOBUS ECU] – used to display the total width of the implement

as entered on the ISOBUS spreader

►Droplet Size Monitor [available only with Pressure Sensor

Interface Kit] – used to enable droplet size monitoring for up to

ve sprayer tips

►Tip Selection [Straight Implement Type completed on the

ISOBUS ECU] – used to display the type of sprayer tip as

entered on the ISOBUS sprayer

►Applied Alert – [only available without a switchbox] used to

establish an alert to signal when exiting or entering an applied

area

►BoomPilot Start Mode – used to control BoomPilot automatically

by speed, or manually by BoomPilot icon

►BoomPilot Icon – used to activate icon for manually controlling

BoomPilot

4. Press NEXT PAGE arrow to set up specic implement options.

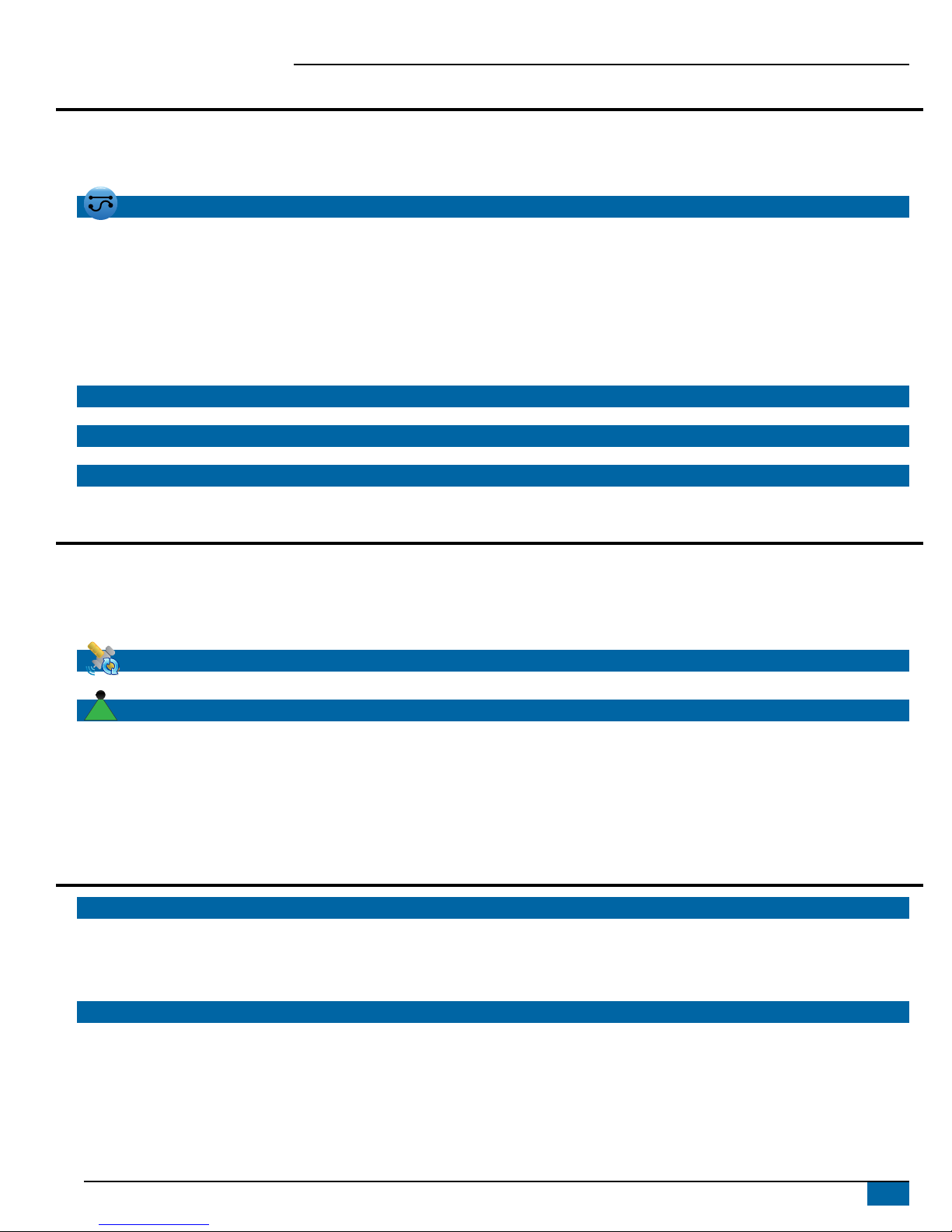

Additional Settings per Implement Type

Implement Type selects the type of application pattern that most closely

represents your system.

● In Straight Mode – the boom sections have no length and are on

a line a xed distance from the antenna

● In Spreader Mode – a virtual line is created in line with the delivery

disks from which the application section or sections can vary in

length and can be at different distances from the line (availability

depends on the specic equipment in the system)

● In Staggered Mode – a virtual line is created in line with

Section 1 from which the application section or sections have no

length and can be at different distances from the line (availability

depends on the specic equipment in the system)

Figure 1: Implement Type – Straight

54321

5

98-01504-ENUS R2

Aeros 9040 Field Computer

Figure 2: Implement Type – Spreader

5

6

7

43

2

1

Figure 3: Implement Type – Staggered

5

432

1

Section Numbers

Sections are numbered from left to right while facing in the machine’s

forward direction.

Straight

The boom sections have no length and are on a line a xed distance

from the antenna.

1. Select Straight implement type on Implement screen.

2. Press Implement Type NEXT PAGE arrow .

3. Select from:

►Connection Point In-line Offset Direction [ISOBUS only] –

establishes if reference point is located in front of (forward)

or behind (backward) the GNSS antenna while facing in the

machine’s forward direction

►Connection Point In-line Offset Distance [ISOBUS only]–

measured in parallel to the centerline of the machine, denes the

in-line distance from the GNSS antenna to reference point

►Connection Point Lateral Offset Direction [ISOBUS

only]– denes the lateral direction, either left or right, from the

centerline of the machine to the center of reference point

while facing in the machine’s forward direction

►Connection Point Lateral Offset Distance [ISOBUS only]–

denes the lateral distance from the centerline of the machine to

the center of reference point

►Implement In-line Offset Direction – displays if the implement

is located in front of (forward) or behind (backward) the GNSS

antenna while facing in the machine’s forward direction

►Implement In-line Offset Distance – measured in parallel to

the centerline of the machine, displays the in-line distance from

the GNSS antenna to the implement

►Implement Lateral Offset Direction – displays the lateral

direction, either left or right, from the centerline of the machine

to the center of the implement while facing in the machine’s

forward direction

►Implement Lateral Offset Distance – displays the lateral

distance from the centerline of the machine to the center of the

implement

►Overlap – used to dene the amount of overlap allowed when

using automatic boom section control

►Delay On Time – used to set the time when the section will

switch on when entering an area that has not been applied

NOTE: If the application turns on too soon when entering an

unapplied area, decrease the Delay On Time. If the application

turns on too late, increase the Delay On Time.

►Delay Off Time – used to set the time when the section will

switch off when entering an area that has been applied

NOTE: If the application turns off too soon when entering an

unapplied area, decrease the Delay Off Time. If the application

turns off too late, increase the Delay Off Time.

*Available with SmartCable, Section Driver Module (SDM) or Switch

Function Module (SFM) or ISOBUS)

6www.teejet.com

Aeros 9040 Field Computer

Figure 4: Implement Offset Directions and Distances

Figure 5: Connection Point Offset Directions and Distances

– Center of the GNSS antenna

– Reference point

– Implement In-line Offset Direction/Distance

– Implement Lateral Offset Direction/Distance

– Connection Point In-line Offset Direction/Distance

– Connection Point Lateral Offset Direction/Distance

Spreader – TeeJet

A virtual line is created in line with the delivery disks from which the

application section or sections can vary in length and can be at different

distances from the line (availability depends on the specic equipment

in the system).

1. Select Spreader implement type on Implement screen.

2. Press Implement Type NEXT PAGE arrow .

3. Select from:

►Setup type – used to select TeeJet spreader type

►Antenna to Disks In-line Offset Distance – measured in

parallel to the centerline of the machine, denes the in-line

distance from the GNSS antenna to the disks, or dispersal

mechanism

►Implement Lateral Offset Direction – denes the lateral

direction, either left or right, from the centerline of the machine

to the center of the implement while facing in the machine’s

forward direction

►Implement Lateral Offset Distance – denes the lateral

distance from the centerline of the machine to the center of the

implement

►Overlap – used to dene the amount of overlap allowed when

using automatic boom section control

►Delay On Time – used to set the time when the section will

switch on when entering an area that has not been applied

NOTE: If the application turns on too soon when entering an

unapplied area, decrease the Delay On Time. If the application

turns on too late, increase the Delay On Time.

►Delay Off Time – used to set the time when the section will

switch off when entering an area that has been applied

NOTE: If the application turns off too soon when entering an

unapplied area, decrease the Delay Off Time. If the application

turns off too late, increase the Delay Off Time.

►Spread Offset Distance – used to set the distance between

the disks or dispersal mechanism and where product initially hits

the ground on Section 1.

►Section Offsets – used to set the offset distance from

section 1 (the Spread offset line) to the leading edge of each

section. Section 1 is always 0. All other sections can be different

distances.

►Section Lengths – used to set the length of application in

each section. Each section can be a different length.

NOTE: Sections are numbered from left to right while facing in

the machine’s forward direction.

*Available with SmartCable, Section Driver Module (SDM), or Switch

Function Module (SFM) or ISOBUS)

7

98-01504-ENUS R2

Aeros 9040 Field Computer

Figure 6: Distances and Length Figure 7: Lateral Offset Direction and Distance

– Center of the GNSS antenna

– Antenna to Disks In-line Offset Distance

– Implement Lateral Offset Direction/Distance

– Spread offset distance

– Section offsets

– Section lengths

Lateral Implement Offset Distance Adjustment

Lateral implement offset distance is used to enter the distance from

the center line of the machine to the center of the implement. When

on-screen mapping shows no overlap or gap, yet eld application

produces an overlap or gap consistently to only one side in the direction

of travel, an adjustment to the lateral implement offset distance should

be calculated and made to the implement offset distance value.

If using a self-propelled sprayer or spreader, use the GNSS Offset

Adjustment Calculation to calculate the implement offset distance

adjustment.

If using a pull behind or trailed implement, use the Implement Offset

Adjustment Calculation to calculate the implement offset distance

adjustment.

NOTE: While using assisted/auto steering, if on-screen mapping

shows overlaps and gaps, adjustments may need to be made

to the assisted/auto steering settings.

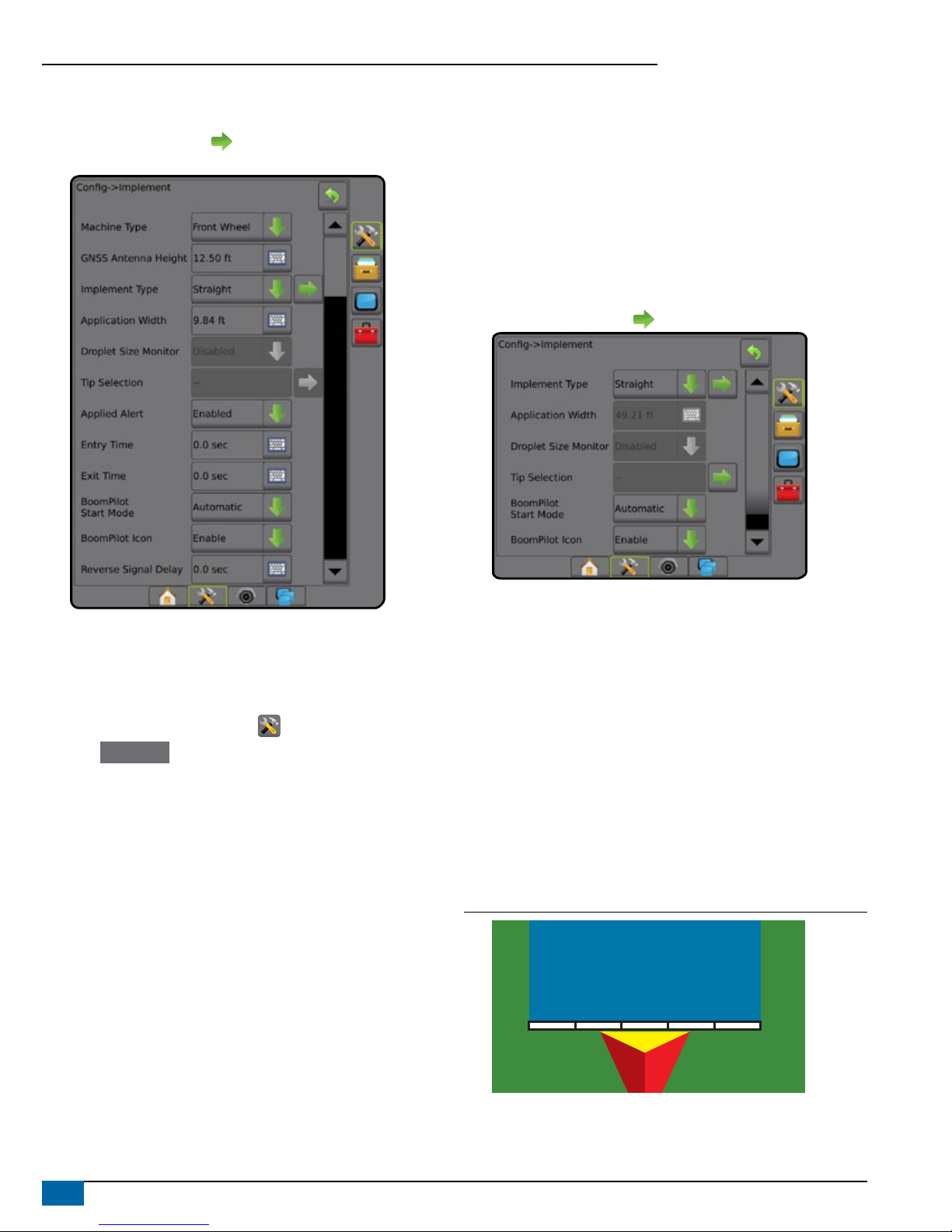

GNSS Offset Adjustment Calculation

To calculate a GNSS offset adjustment using the same guideline:

1. Create a straight AB line.

2. With assisted/auto steering engaged, drive pass at least 30

meters, and place ags at the draw bar or next to the machine.

3. Turn around and engage assisted/auto steering on pass on

the same AB guideline. Place ags at the draw bar or next to the

machine, or stop while on the AB guideline next to the ags you

placed on pass .

4. Measure the difference between the ags of pass and pass .

5. Divide the measured distance in half. This difference will be the

offset adjustment.

6. Increase or decrease the offset distance as needed dependent

on where the eld application overlap occurs and the current

implement offset direction setting.

Field Application Overlap

Current Offset Settings

Offset Direction = Left Offset Direction = Right

Offset Direction = Right

Offset Distance = 0 ft/m

To the right of pass Increase distance offset value Decrease distance offset value Increase distance offset value

To the left of pass Decrease distance offset value Increase distance offset value Change to implement offset direction to

left and increase distance offset value

Figure 8: GNSS Offset Distance

8www.teejet.com

Aeros 9040 Field Computer

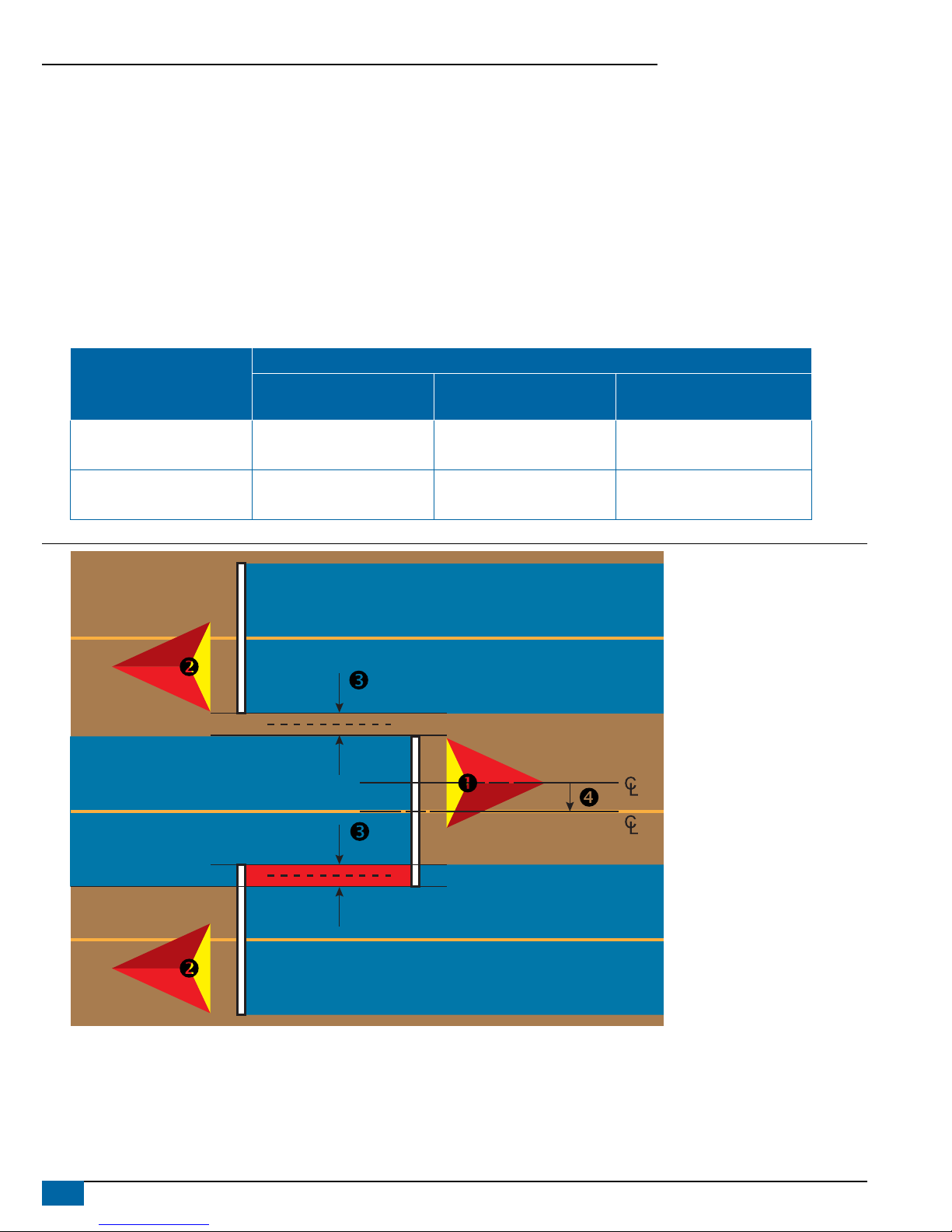

Lateral Implement Offset Adjustment

To calculate an implement offset adjustment using adjacent guidelines:

1. Create a straight AB line.

2. With assisted/auto steering engaged, drive pass as if you were operating the implement, and place ags at the outside edges of the

implement.

3. Turn around and engage assisted/auto steering on pass on the adjacent AB guideline. Place additional ags at the outside edges of the

implement or stop while on the AB guideline next to the ags you placed on pass .

4. Measure the difference between the ags of pass and pass .

5. Divide the measured distance in half. This difference will be the offset adjustment.

6. Increase or decrease the offset distance as needed dependent on where the eld application overlap occurs and the current implement

offset direction setting.

Field Application

Current Offset Settings

Offset Direction = Left Offset Direction = Right

Offset Direction = Right

Offset Distance = 0 m

Overlap on the right of pass or

Gap on the left of pass Increase distance offset value Decrease distance offset value Increase distance offset value

Overlap on the left of pass or

Gap on the right of pass Decrease distance offset value Increase distance offset value Change to implement offset direction to

left and increase distance offset value

Figure 9: Lateral Implement Offset Distance and Direction

9

98-01504-ENUS R2

Aeros 9040 Field Computer

4) Set Up the Mapping Location

Mapping location establishes the location from which boundary and

polygon mapping will take place.

1. Press CONFIGURATION side tab .

2. Press Mapping and Guidance .

3. Select from:

►Mapping Location – establishes the layout of the location from

which the boundary or polygon will be mapped.

● Default Location – While creating an exterior boundary or

polygon, the line will be to the exterior of the outermost active

section. While creating an interior boundary, the line will be

to the interior of the innermost active section. If no sections

are active, the boundary will be marked to the end of the

outermost section.

● User Entry – in-line and lateral offset from the GNSS antenna

directions and distances can be specied by the user. Up

to ve (5) user entries can be created. See “User Entered

Mapping Location” for details.

►Guidance Width – used to set the distance between guidelines

►Guidance Sensitivity – sets the distance around the guideline that

is perceived as zero error.

4. Select user entry location from the Mapping Locations drop-down

options.

5. Press MAPPING LOCATION NEXT PAGE arrow to set up the

selected specic mapping location options.

6. Select:

►Location Name – used to enter the name of the mapping location

for the current user entry selected

►Mapping Location In-line Offset Direction – used to select

whether the mapping location is located in front of or behind the

GNSS antenna as the vehicle moves in a forward direction

►Mapping Location In-line Offset Distance – used to dene the in-

line distance from the GNSS antenna to the mapping location

►Mapping Location Lateral Offset Direction – used to select

the lateral direction from the centerline of the machine to the

mapping location while facing in the machine’s forward direction

►Mapping Location Lateral Offset Distance – used to dene

the lateral distance from the centerline of the machine to the

mapping location

7. Press RETURN arrow to return to the Mapping and Guidance

screen or CONFIGURATION side tab to return to the main

Conguration screen.

Figure 10: User Entered Mapping Location

Default Location

User Entry 1

User Entry 2

User Entry 3

User Entry 4

User Entry 5

10 www.teejet.com

Aeros 9040 Field Computer

#4 START NEW JOB OR CONTINUE JOB

Once the power up sequence has completed, the Home screen will appear with the option to start a new job or continue an existing job. The

console must have GNSS before starting or continuing a job. Setup for the specic machine and its components must be

completed before starting a job. Once a job is active, some setup options can no longer be changed. To change between simple and

advanced mode, go to Data-> Options-> Job Mode in the System Setup.

Simple Mode

In simple mode, only one job will be available at a time.

New Job

1. On the Home screen , press New Job .

Continue Job

1. On the Home screen , press Continue .

If the current job is in a UTM zone other than the current or adjacent

UTM zone Continue will be disabled.

Close Job

1. On the Home screen , press Close Job .

To create a report of the job when closing a job, Insert a USB drive into

the USB port of the console before pressing “Close Job”.

Advanced Mode

In advanced mode, more than one job will be available at any time.

Client information, farm information, eld information, and prescription

maps can only be inputted using Fieldware Link. A job name can only

be edited using Fieldware Link.

A user can duplicate jobs for reuse of guidelines, boundaries, applied

data, prescription map and/or polygons using Fieldware Link or

Data -> Job Data -> Manage in the console.

New Job

1. On the Home screen , press New Job .

2. Press:

►Yes – to automatically generate a name

►No – to enter a name using the on screen keyboard

Client, farm, and eld information are inputted using Fieldware Link.

Start Job

The Aeros 9040 is programmed with a eld nder tool to assist the user

in nding the job closest to the vehicle’s location. With GNSS acquired,

the job pick list will be updated every ten seconds. During this update,

the list of jobs is sorted by distance and the closest two jobs are

displayed on the top of the list. The remaining jobs are listed beneath

these.

1. On the Home screen , press DOWN arrow to access the list

of jobs saved in the console.

2. Select the job name to be started/continued.

3. Press Start Job .

Close Job

1. On the Home screen , press Close Job .

To create a report of the job when closing a job, Insert a USB drive into

the USB port of the console before pressing Close Job .

11

98-01504-ENUS R2

Aeros 9040 Field Computer

#5 SET UP GUIDANCE

1) Choose a Guidance Mode

Three guidance screens assist in keeping you informed.

VehicleView guidance creates a

computer-generated image of the vehicle

position displayed in the application area.

FieldView guidance creates a computer-

generated image of vehicle position and

application area from an aerial perspective.

RealView guidance allows live video

input to be displayed instead of a computer-

generated image.

6.1

mph

7.62

ac 0.0

55

(psi)

6.1

mph

7.62

ac Mark A 6.1

mph

7.62

ac 0.0

To choose a guidance mode:

2. Press NAVIGATION AND GUIDANCE OPTIONS tab to display

navigation options.

3. Press GUIDANCE MODE icon .

4. Select from:

►No Guidance

►Straight AB Guidance

►Curved AB Guidance

►Circle Pivot Guidance

►Last Pass Guidance*

►NextRow Guidance*

►Adaptive Curve Guidance

*Guidance options may not be available depending on assisted/

automatic steering system installed.

Figure 11: Choose a Guidance Mode

0.0

mph

0.00

ac Mark A

0.0

mph

0.00

ac Mark A

12 www.teejet.com

Aeros 9040 Field Computer

2) Establish an AB guideline

1. Drive to the desired location of Point A .

2. Press NAVIGATION AND GUIDANCE OPTIONS tab to display

navigation options.

3. Press MARK A icon .

4. Drive to the desired location of Point B .

5. Press MARK B icon to establish the AB line.

6. “Would you like to name this guideline?”

Press:

►Yes – to enter a name and save the guideline in the console

►No – to automatically generate a name and save the guideline in

the console

The console will begin providing navigation information.

NOTE: The MARK B Icon is not available for selection (grayed out)

until the minimum distance is travelled (9.84 feet / 3.0 meters in

Straight or Curved guidance, 164.04 feet / 50.0 meters in Circle

Pivot guidance).

NOTE: It is not necessary to drive the entire circumference of the

center pivot in order to initiate Circle Pivot Guidance.

Use CANCEL MARK icon to cancel the Mark A command and

revert to the previous guideline (when established).

Figure 12: Mark A Point

1:12 pm

7.2

mph

Mark A

Figure 13: Mark B Point

1:14 pm

7.2

mph

Mark B

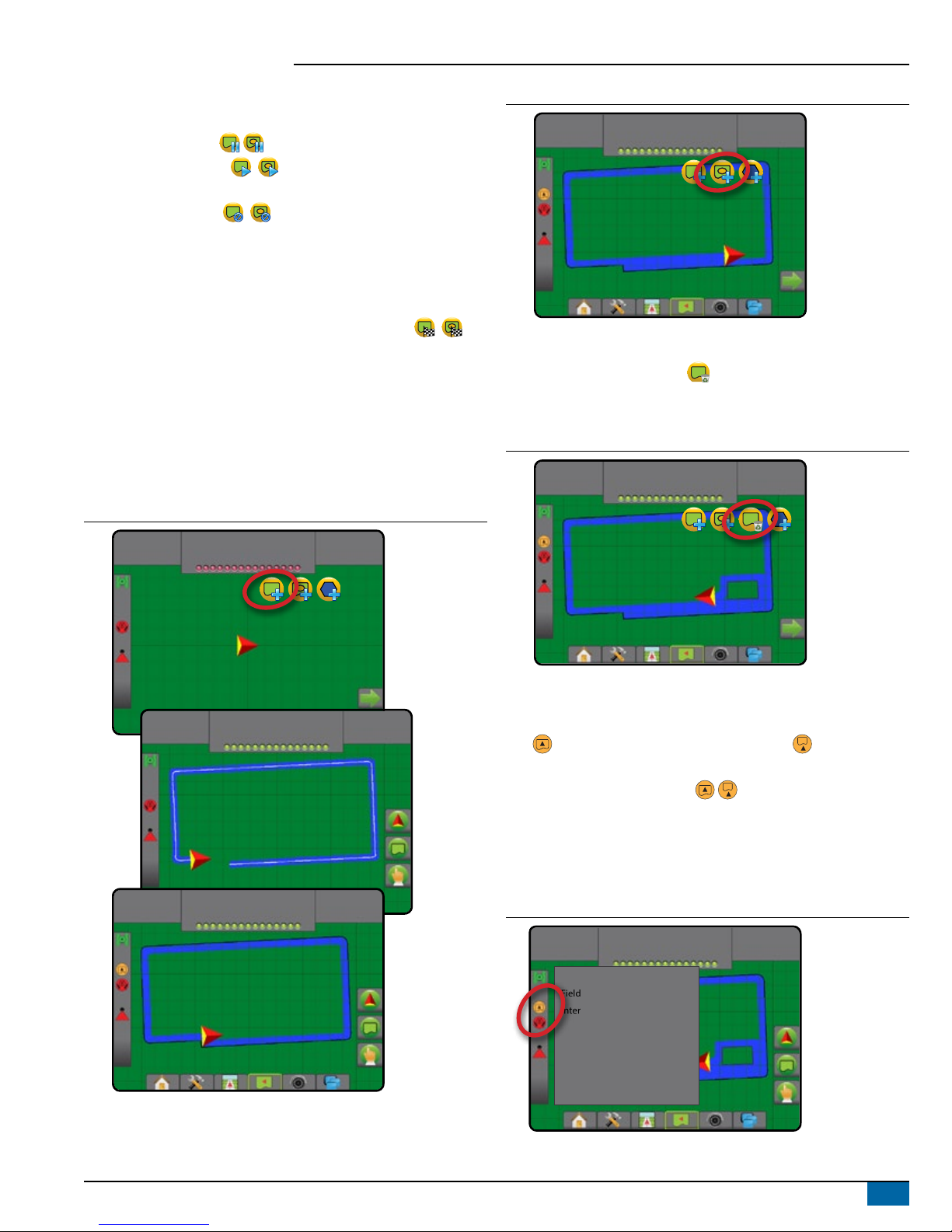

3) Create an Application Boundary

Available on any guidance screen, the Boundaries and polygons tab

displays exterior boundary, interior boundary and polygon options.

Application boundaries establish the work areas where product is or is

not applied while using ASC or BoomPilot.

• Exterior Boundary – establishes a work area where

application will be applied while using ASC or BoomPilot.

• Interior Boundary – establishes a work area where application

will NOT be applied while using ASC or BoomPilot.

Boundaries can be established in all guidance modes. Up to 100 total

exterior boundary and/or interior boundaries can be stored within a

single job. Application is not required to map a boundary.

Using Data -> Job Data -> Manage or with Fieldware Link, a user can

duplicate and edit jobs for reuse of boundaries for different applications

over the same eld.

Application is not required to map a boundary or polygon.

If mapping a boundary or polygon with one or more sections folded

in and turned off, it is necessary to maintain this section conguration

for the duration of the boundary or polygon pass. Any changes made

to the number of sections turned on, and therefore the width of the

machine after the boundary or polygon mapping process has started,

will result in the application mapping the boundary or polygon at the

outer edge of all the programmed sections – not necessarily those

turned on at any given time during the boundary or polygon pass.

When mapping a boundary or polygon with some sections turned off,

it is necessary to turn BoomPilot to Manual mode and turn ON the

master and section switches for all sections that will be used during

the boundary or polygon pass. Once the boundary or polygon pass

is complete the sections switches can be turned OFF, master switch

remains ON, BoomPilot can be returned to Automatic mode and

automatic section control can then be used.

NOTE: If a boundary is mapped with some sections folded

as described above, it may be necessary to use the

A+ NUDGE icon on the guideline over to the correct

position for subsequent passes in the field.

Establishing an Exterior or Interior Boundary

To establish an exterior or interior boundary:

1. Drive to a desired location at the perimeter of the application

area and orientate the vehicle in association to the established

mapping location.

2. Press BOUNDARY AND POLYGON OPTIONS tab to display

boundary and polygon options.

3. Press MARK BOUNDARY icon .

4. Verify that the Mapping location is correct.

◄If the Mapping location is not correct, press Cancel then go to

Configuration-> Mapping and guidance-> Mapping location.

13

98-01504-ENUS R2

Aeros 9040 Field Computer

5. Travel the perimeter of the application area.

While traveling, use as needed:

►Pause Boundary – pauses the mark boundary process.

►Resume Boundary – resumes the mark boundary

process.

►Cancel Boundary – cancels mark boundary process.

6. Finish the boundary:

►Automatic close – travel to within one swath width of the starting

point. The boundary will close automatically (the white guideline

will turn black).

►Manual close – press the FINISH BOUNDARY icon

to close the boundary with a straight line between the current

location and the starting point.

NOTE: If the minimum distance is not travelled (five times the

swath width), an error message will pop-up.

7. Press:

►Save – to save the boundary

►Delete – to delete the boundary

Figure 14: Exterior Boundary

0.00

ac

0.0

mph

2.32

ac

7.2

mph

3.68

ac

7.2

mph

Figure 15: Add Interior Boundary

4.55

ac

7.2

mph

Delete Last Marked Boundary

Use DELETE BOUNDARY icon to delete the last marked boundary

(interior or exterior) from the current job. Press again to remove

additional boundaries in order from last to rst created.

Figure 16: Delete Last Marked Boundary

7.03

ac

7.2

mph

Boundary on Status Bar

In reference to your current location, the IN EXTERIOR BOUNDARY

icon or OUT OF EXTERIOR BOUNDARY icon

is displayed on the Status Bar once a boundary is established.

1. Press BOUNDED AREA icon .

◄Working Area – total are of all exterior boundaries

◄Field Area – total area of all exterior boundries minus the area of

all interior boundaries

◄Internal Area – total area of all interior boundaries

Figure 17: Boundary on Status Bar

7.03

ac

7.2

mph

Working area: 61.22 ac

Field area: 64.45 ac

Internal area: 3.23 ac

14 www.teejet.com

Aeros 9040 Field Computer

ADD RATE CONTROL

NOTE: TeeJet Dual Control Module (DCM) is no longer supported and

will not be referenced in this manual.

ISOBUS universal terminal (UT) gives access to an ISOBUS electronic

control unit (ECU) options and operation. This provides crop sprayer or

spreader control when integrated into the implement of either capability.

NOTE: For detailed setup instructions, refer to the specific ISOBUS

user manual for the connected ECU.

1. Press UNIVERSAL TERMINAL bottom tab .

20.00

gal/ac

66.00

ac

Mark A

Soft Keys Area

Active ISOBUS ECUs Available on System

Activity Window

Ready for Operation

Upon starting up the system, an ISOBUS product may take a few

minutes to load all required information or object pools.

Before starting a job, check to be sure the ISOBUS ECU is ready.

• Home Screen is available

• Tack Control (TC) is active – Active Trip Count Number should

show “TC”

20.00

gal/ac

66.00

ac

Mark A

Guidance Screen Options

When a ISOBUS Electronic Control Unit (ECU) sprayer or spreader

control is integrated into the implement, rate control options and

mapping options are available on the Vehicle View and Field View

guidance screens.

Application Control Options Tab

Current Pressure

Mapping Options Tab

10.0

mph

55

(psi)

27.00

ac Mark A

Guidance Bar

Current Pressure

Displays the current pressure to the tip.

Guidance Bar

In addition to the standard Guidance bar options, the following

selectable information will become available with an ISOBUS ECU:

►Actual Application Rate – displays the current application rate

►Target Application Rate – displays the target application rate

►Volume/Product Applied – displays the volume or weight of

product applied

►Tank/Bin Amount Remaining – displays the volume or weight of

product remaining in the tank/bin

10.0

mph

55

(psi)

27.00

ac Mark A

System Pressure

Actual

Application Rate

Droplet Size

Target

Application Rate

Volume/Product

Applied

Tank/Bin Amount

Remaining

15

98-01504-ENUS R2

Aeros 9040 Field Computer

Mapping

GNSS-based product application mapping is available in Vehicle

View or Field View. Mapping can record areas covered by the

implement (Coverage) or how much product has been applied and

where (Application) and can direct single- and variable-rate product

application (Preset Target Rate and Prescription, respectively).

NOTE: For more information, see “Application Mapping”.

1. Press VEHICLE VIEW GUIDANCE bottom tab . or FIELD

VIEW GUIDANCE bottom tab .

2. Press MAPPING OPTIONS tab to display mapping options.

3. Select one or more:

►Coverage Map

►Polygons

►Prescription Map

►Application Map

►Target Rate Map

NOTE: Application Map and Target Rate Map cannot be selected

simultaneously.

10.0

mph

27.00

ac Mark A

27.00

ac

10.0

mph

Mark A

Application Control

Target Rate Percentage Increase/Decrease icons increase/decrease

the application target rate per the established percentage set in

the Machine Operation setup screen under Application Rate Step.

Automatic regulation mode will automatically adjust the application rate

based on the current speed in reference to the target rate.

NOTE: The Target Rate Percentage Increase/Decrease icons do the

same adjustment as the Boost/Step Percentage Increase/

Decrease Keys from the ISOBUS UT.

1. Press VEHICLE VIEW GUIDANCE bottom tab .

2. Press APPLICATION OPTIONS tab .

3. Select from:

►Target Rate Percentage Increase – establishes the required

boost percentage step increase

►Target Rate Percentage Decrease – establishes the required

boost percentage step decrease

►Percentage Boost and Reset – shows current boost

percentage step and when pressed, zeros the boost percentage

step

10.0

mph

55

(psi)

27.00

ac Mark A

MAPPING OPTIONS

On vehicle view or eld view guidance screens, in any guidance mode,

the mapping options tab displays options to display polygon maps,

coverage maps and application maps.

Polygon and coverage mapping are available when a polygon has

been established.

GNSS-based product application mapping is available when a rate

controller is on the system. Rate control mapping can record areas

covered by the implement (Coverage) or how much product has

been applied and where (Application), and can direct single- and

variable-rate product application (Preset Target rate and Prescription,

respectively).

NOTE: Before using mapping, set or verify product mapping options

under Configuration->Product.

Duplicating and Transferring Maps

Maps are stored in the job data. Using Data->Job Data, job data

containing maps can be duplicated or transferred to Fieldware Link so

the maps can be opened, viewed, edited, and printed, and transferred

back to the console. See “Data management->Job data->

Transfer” and “Data Management-> Job Data-> Manage” in the System

Setup chapter for details.

Using Data->Reports, reports in multiple formats can be generated

that contain data and any maps from the job.

16 www.teejet.com

Aeros 9040 Field Computer

To access application mapping:

1. Press VEHICLE VIEW GUIDANCE bottom tab or

FIELD VIEW GUIDANCE bottom tab .

2. Press MAPPING OPTIONS tab to display mapping options.

3. Select one or more:

►Coverage map – shows areas covered by the implement,

regardless of whether product was applied

►Polygons – shows all mapped polygons

►Prescription map – pre-loaded map that provides information

to the rate controller for use in applying product

►Application map – shows how much product has been

applied and where, using color to indicate level in proportion to

preset or automatically set maximum and minimum levels

►Target Rate map – shows the application rate that the rate

controller attempted to achieve at each location

NOTE: Application Map and Target Rate map cannot be selected

simultaneously.

Figure 18: Coverage, Polygon and Target Rate Maps

10.0

mph

27.00

ac Mark A

27.00

ac

10.0

mph

Mark A

Coverage Map

Coverage map showing areas covered by the implement.

ISOBUS requires product to be applied.

• Coverage area – illustrates applied area and overlap:

◄Blue – one application

◄Red – two or more applications

27.00

ac

10.0

mph

Mark A

Polygons Map

Polygon map shows all mapped polygons.

• Guidelines

◄Blue – polygon boundary line

27.00

ac

10.0

mph

Mark A

Prescription Map

Prescription map is a pre-loaded map that provides information to

the rate controller for use in applying product. Prescription maps

contain geo-referenced product rate information. The Aeros 9040 can

import job data containing Prescription maps for use with variable-rate

application (VRA) using compatible rate controllers.

• Zone Lines:

◄Black when approaching the application zone.

◄White when within the application zone.

◄ Other zones having the same rate will also be shown in white.

• Coverage Area – illustrates different prescription rate zones:

◄ User selected – zone colors are selected when establishing the

prescription map.

With Fieldware Link (v5.01 or later), users can import VRA jobs created

in Fieldware Link, as well as export job data from the console, edit the

included maps to create Target rate or Prescription maps, and transfer

back to the console for job use.

NOTE: Advanced Job Mode is required for variable rate applications.

See Options (Job mode) in the System Setup chapter.

27.00

ac

10.0

mph

Mark A

Table of contents