General Safety Information

(Continued)

Install a good grounding bond

between disconnect box, control

box, and piping system. Tape cable

closely to discharge pipe at intervals

of ten feet or less.

13.NEVER leave control box, fused

disconnect switch, or pressure

control switch covers open (either

partially or completely) when not

being worked on by a competent

electrician or repairman.

14.Always use caution when operating

electrical controls in damp areas. If

possible, avoid all contact with

electrical equipment during thunder

storms or extreme damp conditions.

15.Install all electrical equipment in

protected area to prevent

mechanical damage which could

produce serious electrical shock

and/or equipment failure.

16.Pump is designed to pump water

only. Fire or explosion

hazard! Do not

pump flammable liquids such as gasoline,

fuel oil, kerosene, etc., with this pump.

Pump water only with this pump.

17.DO NOT handle pump with wet

hands or when standing in water as

fatal electrical shock could occur.

Disconnect main power supply

before handling pump for any

reason.

Preinstallation Risk of electrical

shock. Connect

motor ground wire to grounded metal

raceway system or power system ground.

Bond (ground) pump and all metal

components to building ground system in

accordance with National Electrical Code

(NEC) requirements.

Most submersible pump problems are

electrical. To reduce problems, have all

electrical hook-up work or service work

done by a qualified electrician or

serviceman only.

To save added expense and extra trips,

complete as many as possible of the

following procedures before going to

the installation site.

1. Examine pump for damage. Make

sure check valve works properly. For

3-wire units, motor and control box

horsepower and voltage must match

exactly.

NOTE: All units are supplied with extra

label for above ground pump

identification. Place label in

conspicuous location (on control box,

etc.) for future reference.

2. Check electrical supply for correct

fusing, wire size, transformer size,

and adequate grounding.

3. Follow wiring directions in the

control box and make momentary

tests to see that motor runs. If test is

satisfactory, proceed to Step 4 (cable

splice).

4. First check cable size against

Submersible Wire Size Charts

(below). Use extreme care; this is a

very important step. If required

length falls between two wire sizes,

use the larger wire size (smaller

number) of the two.

IMPORTANT: Use of wire sizes smaller

than those specified in charts will cause

low starting voltage, may cause early

pump failure and will void warranty.

Larger wire sizes may be used for better

economy of operation. Be sure voltage

at pressure switch or fuse box is

between the following limits:

• 115 Volts Rated – Between 105

and 125 Volts

• 230 Volts Rated – Between 210

and 250 Volts

5. Use butt connectors and plastic

sleeves included in the splice kit to

make underwater cable splices.

IMPORTANT: Do not handle motor or

pump by power cable or motor leads!

Damage to cable will result!

IMPORTANT: Follow instructions

carefully to make a watertight splice! A

leak in the splice can result in:

a. Damage to motor winding.

b. Electrolytic deterioration of the

joint, resulting in an open circuit.

4

Teel Operating Instructions and Parts Manual

Teel Deep Well Submersible Pumps

®

E

N

G

L

I

S

H

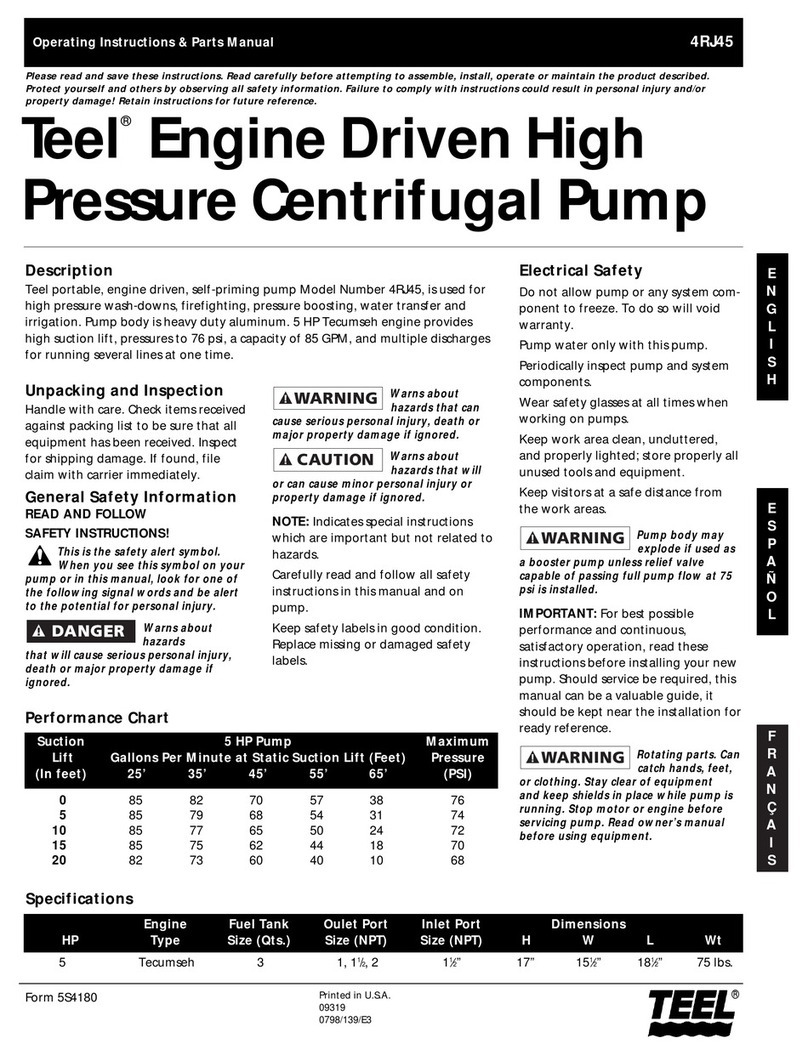

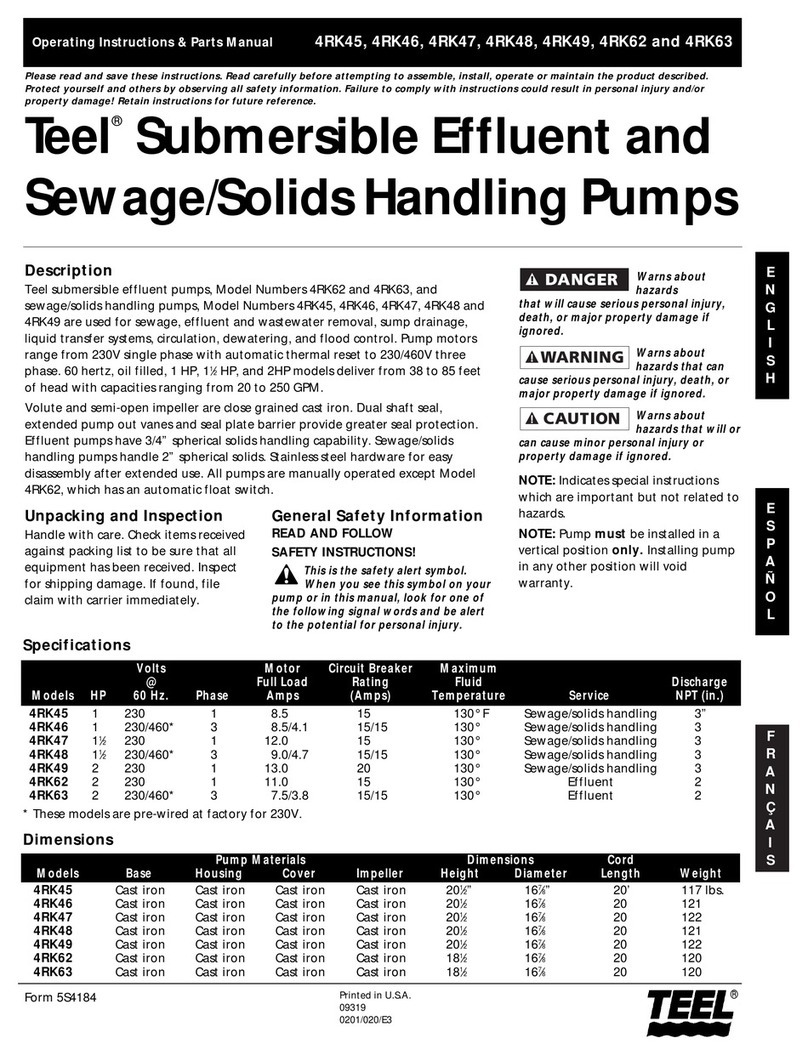

Wire Size Chart

1/3 115 130 210 340 540 840 1300

1/3 230 550 880 1390 2190 3400 5250

1/2 115 100 160 250 390 620 960

1/2 230 400 650 1020 1610 2510 3880

3/4 230 300 480 760 1200 1870 2890

1230 250 480 630 990 1540 2380

11⁄2230 190 310 480 770 1200 1870

Single Phase Submersible Pump Wire Size Chart

Pump to Power Source AWG Wire Size – Maximum Distance in Feet

HP Volts #14 #12 #10 #8 #6 #4

4P847A thru 4P851A, 4P852 thru 4P865, 4RH01 thru 4RH06,

4RG76 thru 4RG84, 4RG94 thru 4RG97 and 4RG99