2

Teel Operating Instructions and Parts Manual 4RJ40, 4RJ41, 4RJ42, 4RJ43 and 4RJ44

Teel Professional Self-Priming

Centrifugal Pump

®

E

N

G

L

I

S

H

General Safety Information

(Continued)

Keep safety labels in good condition.

Replace missing or damaged safety

labels.

Make workshops childproof; use

padlocks and master switches; remove

starter keys.

ELECTRICAL SAFETY

Hazardous voltage.

Can shock, burn, or

cause death. Ground pump before

connecting to power supply. Disconnect

power before working on pump, motor,

or tank.

Wire motor for correct voltage. See

“Electrical” section of this manual,

motor nameplate, and diagram inside

motor junction box cover.

Ground motor before connecting

to power supply.

Meet United States National

Electrical Code, Canadian Electrical

Code, and local codes for all wiring.

Follow wiring instructions in this

manual and in motor junction box

when connecting motor to power lines.

GENERAL SAFETY Hazardous

pressure! Do not

run pump against closed discharge.

Release all pressure on system before

working on any component.

Do not touch an

operating motor.

Modern motors are designed to operate

at high temperatures. To avoid burns

when servicing pump, allow it to cool for

20 minutes after shut-down before

handling.

To avoid heat build-up, over-pressure

hazard and possible injury, do not use

in a domestic water system. Do not use

as a booster pump; pressurized suction

may cause pump body to explode.

Never run pump above recommended

pressure shown on the performance

chart.

Do not allow pump or any system

component to freeze. Freezing pump

will void warranty.

Pump should only be used to pump

liquids compatible with pump

component materials.

Periodically inspect pump and system

components.

Keep work area clean, uncluttered,

and properly lighted; properly store all

unused tools and equipment.

Keep visitors at a safe distance from

the work areas.

Make workshop childproof with

padlocks, master switches, and by

removing starter keys.

Know the pump application,

limitations, and potential hazards.

Installation Risk of fire and

explosion. Do not

use this pump to pump flammable or

explosive fluids such as gasoline, fuel oil,

kerosene, etc. Do not use in flammable

or explosive atmospheres. Pump should

only be used with liquids compatible

with pump component materials. Failure

to follow this warning can result in

personal injury and/or property damage.

Make certain that the power source

conforms to the requirements of your

equipment.

Provide adequate protection and

guarding around moving parts.

Disconnect power before servicing.

Release all pressure within the system

before servicing any component.

Drain all liquids from the system

before servicing.

Secure the discharge line before

starting the pump. An unsecured

discharge line will whip, possibly

causing personal injury and/or

property damage.

Check hoses for weak or worn

condition before each use, making

certain that all connections are secure.

Provide a means of pressure relief for

pumps whose discharge line can be

shut or obstructed.

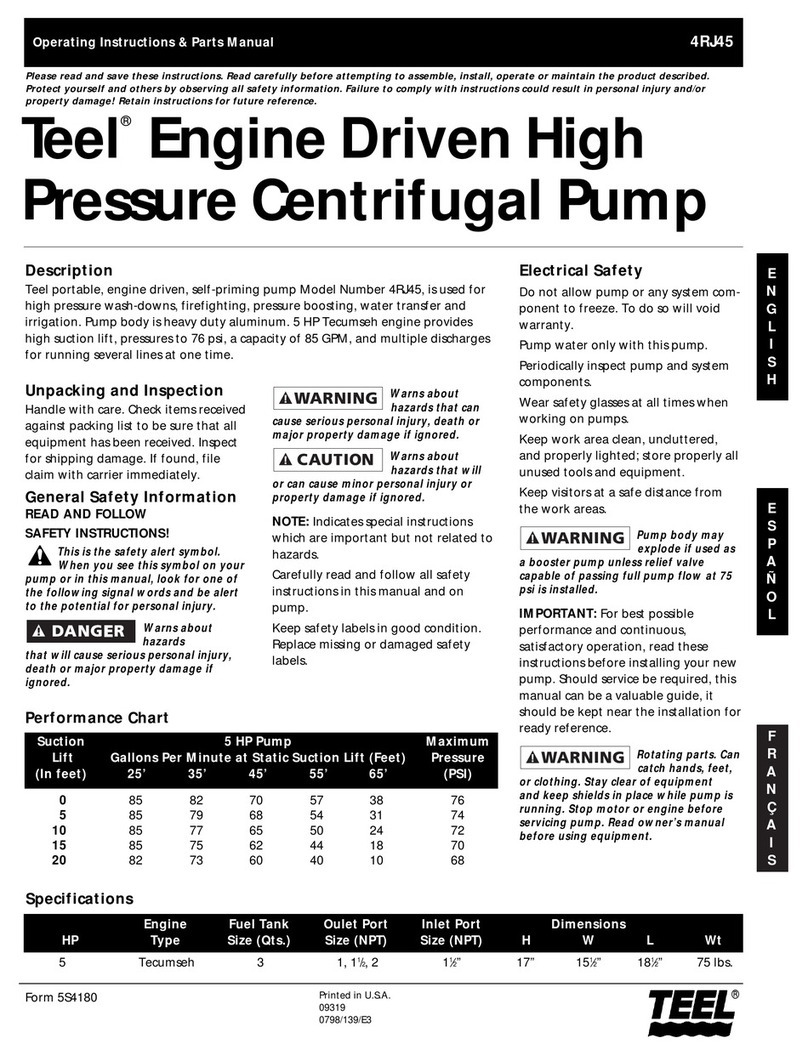

Performance Chart*

49 44 43 40 55 49 48 45 67 61 56 46 69 67 65 62 59 92 83 81 78 64

46 41 40 39 51 46 45 44 66 58 55 45 64 62 60 57 54 86 80 78 76 62

40 38 35 33 45 42 39 37 61 56 54 44 59 56 54 52 49 80 76 75 74 59

34 31 29 26 38 35 32 29 55 52 51 43 53 50 48 46 43 73 71 70 68 57

28 25 22 18 31 28 24 20 48 45 44 37 47 45 42 40 37 66 66 65 64 55

15 12 7 – 23 19 16 11 39 37 34 28 40 38 35 32 28 61 60 59 58 52

– – – – 17 13 8 – 33 27 20 11 34 30 27 23 19 55 54 53 52 50

– – – – – – – – 18 14 8 – 24 18 13 10 – 48 46 45 44 42

– – – – – – – – – – – – 14 7 – – – 40 38 37 36 34

Discharge Gallons Per Minute at Discharge Pressure (psi)

Pressure 4RJ44 4RJ41 4RJ42 4RJ43 4RJ40

5’ 10’ 15’ 20’ 5’ 10’ 15’ 20’ 5’ 10’ 15’ 20’ 5’ 10’ 15’ 20’ 25’ 5’ 10’ 15’ 20’ 25’

PSI

10

15

20

25

30

35

40

45

50

(*) Performance listed at 68° F (20° C), specific gravity 1.0.