TEK 222 User manual

TCZL/’ SERVICE 070-7459-00

ILPi MANUAL Product Group 41

222

Digital Storage

Oscilloscope

Service

WARNING

THE FOLLOWING SERVICING INSTRUCTIONS ARE

FOR USE BY QUALIFIED PERSONNEL ONLY. TO

AVOID PERSONAL INJURY, DO NOT PERFORM ANY

SERVICING OTHER THAN THAT CONTAINED IN

OPERATING INSTRUCTIONS UNLESS YOU ARE

QUALIFIED TO DO SO. REFER TO OPERATORS

SAFETY SUMMARY AND SERVICE SAFETY

SUMMARY PRIOR TO PERFORMING ANY SERVICE.

First Printing mar 1990 Scan by John Barnes Tfektronix

COMMIT TED TO EXCELLENCE

Copyright© 1990 Tektronix, Inc. All rights reserved. Contents of this publi-

cation may not be reproduced in any form without the written permission of

Tektronix, Inc.

Products of Tektronix, Inc. and its subsidiaries

foreign patents issued and pending.

TEKTRONIX, TEK, SCOPE-MOBILE, and

are covered by U.S. and

are registered trademarks

of Tektronix, Inc.

Printed in U.S.A. Specification and price change privileges are reserved.

222 Service

TABLE OF CONTENTS

Page

LIST OF ILLUSTRATIONS iii

LIST OF TABLES iii

OPERATORS SAFETY SUMMARY iv

SERVICING SAFETY SUMMARY iv

SECTION 1PERFORMANCE CHARACTERISTICS

INTRODUCTION 1-1

RECOMMENDED

PERFORMANCE CHECK

SCHEDULE 1-1

ELECTRICAL

SPECIFICATIONS 1-1

VERTICAL DEFLECTION

SYSTEM 1-1

TRIGGER SYSTEM 1-3

HORIZONTAL SYSTEM 1-3

X-Y OPERATION 1-4

RS-232 INTERFACE 1-4

EXTERNAL POWER

REQUIREMENTS 1-4

ENVIRONMENTAL

SPECIFICATIONS 1-5

MECHANICAL

SPECIFICATIONS 1-5

SECTION 2OPERATING INFORMATION

SAFETY 2-1

BATTERY-CHARGER

ADAPTER 2-1

EXTERNAL SUPPLY

VOLTAGE 2-1

BATTERY OPERATION 2-2

FIRST TIME BATTERY

OPERATION 2-2

START-UP 2-2

AUTO TIMEOUT 2-2

VIEWING ASIGNAL QUICKLY 2-2

TIPS ON BATTERY CARE 2-2

Page

ALTERNATE METHOD FOR

BATTERY CHARGING 2-3

BATTERY REPLACEMENT 2-3

SECTION 3BLOCK DIAGRAM OVERVIEW

INTRODUCTION 3-1

ACQUISITION SYSTEM 3-1

TIME BASE 3-4

PROCESSOR SYSTEM 3-4

DISPLAY SYSTEM 3-7

BATTERY CHARGER

REGULATOR 3-9

POWER SUPPLY 3-10

SECTION 4PERFORMANCE CHECK

PROCEDURE

INTRODUCTION 4-1

TEST EQUIPMENT

REQUIRED 4-1

PERFORMANCE

CONDITIONS 4-1

PERFORMANCE CHECK

INTERVAL 4-1

PREPARATION 4-1

INDEX TO PERFORMANCE

CHECK PROCEDURE 4-5

DISPLAY CHECKS 4-6

INITIAL CONTROL SETTINGS ... 4-6

PROCEDURE 4-6

VERTICAL 4-7

INITIAL CONTROL SETTINGS ... 4-7

PROCEDURE 4-7

HORIZONTAL 4-11

INITIAL CONTROL SETTINGS .. 4-11

PROCEDURE 4-11

TRIGGER 4-12

INITIAL CONTROL

SETTINGS 4-12

PROCEDURE 4-12

i

222 Service

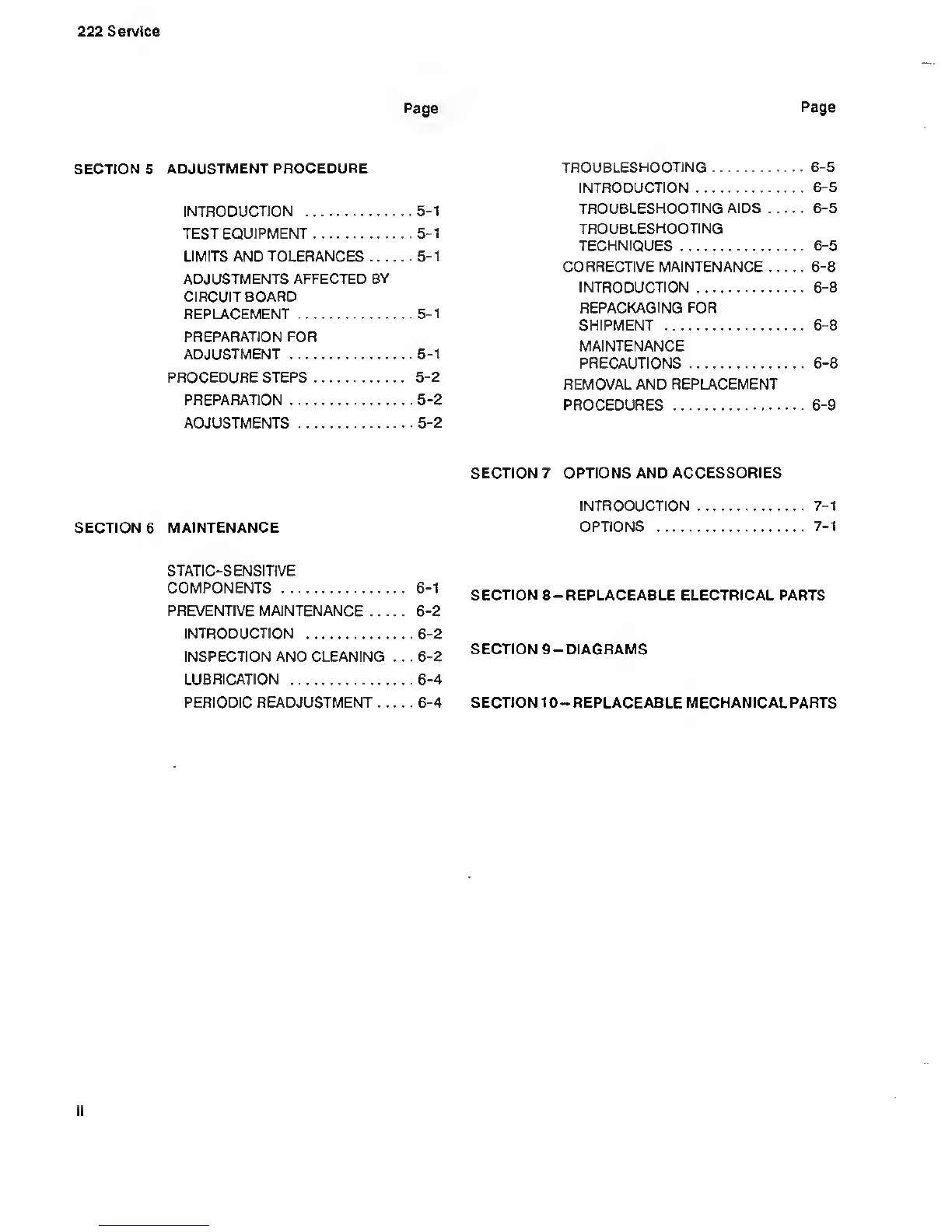

SECTION 5

SECTION 6

Page Page

ADJUSTMENT PROCEDURE

INTRODUCTION 5-1

TEST EQUIPMENT 5-1

LIMITS AND TOLERANCES 5-1

ADJUSTMENTS AFFECTED BY

CIRCUIT BOARD

REPLACEMENT 5-1

PREPARATION FOR

ADJUSTMENT 5-1

PROCEDURE STEPS 5-2

PREPARATION 5-2

ADJUSTMENTS 5-2

TROUBLESHOOTING 6-5

INTRODUCTION 6-5

TROUBLESHOOTING AIDS 6-5

TROUBLESHOOTING

TECHNIQUES 6-5

CORRECTIVE MAINTENANCE 6-8

INTRODUCTION 6-8

REPACKAGING FOR

SHIPMENT 6-8

MAINTENANCE

PRECAUTIONS 6-8

REMOVAL AND REPLACEMENT

PROCEDURES 6-9

SECTION 7OPTIONS AND ACCESSORIES

INTRODUCTION 7-1

MAINTENANCE OPTIONS 7-1

STATIC-SENSITIVE

COMPONENTS 6-1 SECTION 8-REPLACEABLE ELECTRICAL PARTS

PREVENTIVE MAINTENANCE 6-2

INTRODUCTION 6-2

INSPECTION AND CLEANING ... 6-2 SECTION 9-DIAGRAMS

LUBRICATION 6-4

PERIODIC READJUSTMENT 6-4 SECTION 10- REPLACEABLE MECHANICAL PARTS

II

222 Service

LIST OF ILLUSTRATIONS

Figure Page

1-1 Maximum normal-mode voltage versus frequency derating curve 1-2

1-

2Maximum common-mode voltage versus frequency derating curve 1-3

2-

1External Power Input 2-1

3-

1Simplified block diagram of the 222 DSO 3-2

3-2 Floating Acquisition System 3-3

3-3 Time Base block diagram 3-4

3-4 Processor System simplified block diagram 3-5

3-5 Display System 3-8

3-6 Battery Charger block diagram 3-9

3-

7Power Supply block diagram 3-10

4-

1RS-232 interconnection cable wiring between aPC XT® (or compatible)

and the 222 4-4

4-

2Trigger Jitter check 4-14

5-

1Locations at which horizontal and vertical gains are adjusted 5-3

5-2 Rear Panel adjustments 5-3

5-3 Top accessible adjustments 5-4

5-4 CHI and CH2 Input Compensation 5-5

5-

5Clock Delay adjustment 5-6

6-

1Circuit board locations 6-10

LIST OF TABLES

Table Page

4-1 Test Equipment Required 4-2

4-2 VOLTS/DIV Accuracy Settings 4-9

6-1 Relative Susceptibility to Static-Discharge Damage 6-1

6-2 External Inspection Checklist 6-2

6-3 Internal Inspection Checklist 6-3

6-4 Power Up Error Codes 6-5

6-5 Self Cal Error Codes 6-6

6-6 Index To Self Cal Procedures 6-7

6-7 Error Codes Occurring During Normal Operations 6-7

iii

222 Service

OPERATORS SAFETY SUMMARY

The safety information in this summaryis for operatingpersonnel. Warnings andcautions will also be foundthroughout

the manual where they apply.

Terms in this Manual Symbols as Marked on Equipment

CAUTION statements identify conditions or practices

that could result in damage to the equipment or other

property.

WARNING statements identify conditions or practices

that could result in personal injury or loss of life.

Terms as Marked on Equipment

CAUTION indicates apersonal injury hazard not

immediately accessible as one reads the markings, or a

hazard to property, including the equipment itself.

DANGER -High voltage.

ATTENTION -Refer to manual.

[51 DOUBLE INSULATED -No safety ground

required.

Safety Grounding

DANGER indicates apersonal injury hazard This instrument is double insulated and does not

immediately accessible as one reads the marking. use or require asafety-grounding conductor.

Symbols in this Manual

Indicates where applicable cautionary or

other information is to be found. For

maximum input voltage ratings, see

the Specifications.

Do Not Operate in an Explosive Atmosphere

To avoid explosion, do not operate this product in

an explosive atmosphere unless the product is

certified for such operation.

Do Not Remove Covers or Panels

Indicates that the instrument is double

insulated. Asafety earth ground is

not needed.

To avoid personal injury, do not remove the prod-

uct covers or panels. Do not operate the product

without the covers and panels properly installed.

SERVICING SAFETY SUMMARY

FOR QUALIFIED SERVICE PERSONNEL ONLY

Refer also to the preceding Operators Safety Summary

Do Not Service Alone Disconnect power and remove the battery before

removing protective panels, soldering, or replacing

Do not perform internal service or adjustment of this components,

product unless another person capable of rendering first

aid and resuscitation is present.

Use Care When Servicing With Power On

Dangerous voltages exist at several points in this

product. To avoid personal injury, do not touch exposed

connections or components while power is on.

Iv

Section 1—222 Service

PERFORMANCE CHARACTERISTICS

INTRODUCTION

Performance characteristics given in the Electrical

Specifications apply when the instrument has been self

calibrated within ±5°C of the ambient temperature, has

warmed up at least 20 minutes, and is operating in an

ambient temperature between -10°C and +55°C

(unless otherwise noted).

Environmental and Mechanical Specifications are listed

after the Electrical Specifications.

RECOMMENDED PERFORMANCE

CHECK SCHEDULE

To ensure accurate measurements, check the perform-

ance of this instrument every 2000 hours of operation

(once each year if used infrequently). If repairs are made,

affected circuits may need to be readjusted.

ELECTRICAL SPECIFICATIONS

VERTICAL DEFLECTION SYSTEM

Deflection Factor

5mV per division to 50 Vper division in a1-2-5

sequence.1

Vertical Resolution

VOLTS/DIV Variable Control

Increases the deflection factor by 2.5 to 1

.

Aberrations

+6%, -6%, 6% p-p or less. 1

Measured with a5-division reference signal from a

50-n source driving a50-n load at the probe tip.

Vertically center the top of the reference signal.

Useful Rise Time

Rise time is limited to 35 ns by the vertical amplifier

response.

Useful Bandwidth

SAMPLE SEC/DIV

Useful-storage bandwidth is limited to the

frequency where there are 10 samples per sine-

wave signal period at the maximum sampling rate.

This yields amaximum amplitude error of 5%.Maxi-

mum sampling rate is 10 MHz at 5ps per division.

8-bits, 25 levels per division. 10.24 divisions of

dynamic range.1

DC Accuracy

+15°C to +35°C ±3%.2

-15°C to +15°C ±4%.2

+35°C to +55°C ±4%.2

'Performance Requirement not checked in manual.

’When the eetf calibration haa been done within ±5°C of the

ambient temperature.

Accuracy at the useful-storage-bandwidth limit is

measured with respect to a6-division, 50-kHz sine

wave.

REPETITIVE

0.5 ps/div to 50 ps/div 10 MHz.

1ps/div 5MHz.1

2pS/div 2.5 MHz.1

Repetitive bandwidth is limited to 10 MHz by the

analog system.

1-1

Performance Characteristics -222 Service

PEAK DETECT (ENV and CONT ENV acquisition

modes at 20 jis per division and slower)

Sine-wave Amplitude Capture

(5% p-p maximum amplitude

uncertainty) 1MHz.

Pulse Width Amplitude Capture

(50% p-p maximum amplitude

uncertainty). 100 ns.

A/D Converter Linearity

Monotonic with no missing codes. 1

Input Current

2.5 nA or less (0.5 division or less trace shift when

switching between DC and GND input coupling with

the VOLTS/DIV switch at 5mV per division). 1

Input Rand C

Input Resistance 1Mfl ±10%.1

Input Capacitance 27pF±3pF.1

These R and Ccharacteristics include the probe.

Common-to-Ground

Capacitance Less than 150 pF. 1

Position Control Range

±12 divisions.

Maximum Rated Normal-Mode Input

Voltage (probe tip to probe common)

Input Linear Range

±20 divisions. 1

400 V(dc +peak ac) to 2MHz.1

See Figure 1-1 for voltage versus frequency

derating curve.

DC Balance

0.2 division or less trace shift when switching

between VOLTS/DIV switch settings when the

ambient temperature is within ±5°C of the tem-

perature at which the last self calibration was done. 1

INVERT Balance

0.4 division or less trace shift when switching

between INVERT and non-INVERT displays when

the ambient temperature is within ±5°C of the tem-

perature at which the last self calibration was done.1

Maximum Common-Mode Potential

(probe common to chassis)

400 V(dc +peak ac) to 1kHz. 1

See Figure 1-2 for voltage versus frequency

derating curve.

AMaximum Rated Potential Between

Channels

800 V(dc +peak ac). 1

^40°

O

uj «280

in

-r -c 200

160

°+120

=* CJ

S80

40

100

11Ii!!

mmmmamwmatmm PHImmm 5mamma iamm

bhh mm H.'Vi aam aaa

HiHHHHiHI HMHlHiHHHH^ 1

alm

ii1

Ki

111i1

kHz 1MHz 2MHz 10 MHz

FREQUENCY 7100-2J

Figure 1-1. Maximum normal-mode voltage versus frequency derating curve.

1-2

Performance Characteristics -222 Service

Figure 1-2. Maximum common-mode voltage versus frequency derating curve.

Common-Mode Rejection Ratio

DC-to-1 kHz 80 dB or more. 1

1kHz-to-100 kHz 60 dB or more. 1

Isolation: Channel Signal to Channel Signal

DC-to-10MHz 80 dB or more. 1

Isolation: Channel Common to Channel

Signal

DC-to-1 kHz 80 dB or more. 1

1kHz-to-100 kHz 60 dB or more.1

TRIGGER SYSTEM

Internal

Sensitivity 0.5 division to 20 MHz.

Level ±20 divisions. 1

External

Sensitivity 250 mV at 10MHz.

Level ±2.3 V.

Input Resistance 1Mn ±10%.1

Input Capacitance 18 pF ±5 pF. 1

'Performance Requirement not checked in manual.

Trigger Jitter

2ns/div to 50 ns/div (5 ns/div in XI 0MAG).

XI 1/50th division ±2 ns. 1

XI 0MAG 1/5th division ±2 ns.

HORIZONTAL SYSTEM

Range

50 ns per division to 20 sper division. 1

The XI 0MAG control extends the maximum sweep

speed to 5 ns per division.

Displayed Accuracy

XI ±2%.

XI 0MAG ±5%.1

Accuracy is over 10 divisions.

Sample Rate

-SL_ hz 1

NORMAL SEC/DIV

PEAKDET (ENV and

CONTENV) 10 MHz.1

REPETITIVE

50 ns/div to 1jis/drv 10MHz.1

2ns/div 5MHz.1

ACCURACY 0.01 %.'

Sample accuracy is based on the accuracy of the

20-MHz oscillator.

1-3

Performance Characteristics -222 Service

Record Length

512 data points; calibrated to 50 points per

division. 1

POSITION Control Range

Start of the first division and end of the tenth division

can be positioned past the center vertical graticule.

Displayed Trace Length

10.24 divisions.1

X-Y OPERATION

Accuracy

Same as the Vertical system. 1

Useful Bandwidth

—-—Hz 1

SEC/DIV

Skew Between CH 1and CH 2

5ns. 1

RS-232 INTERFACE

Maximum Applied Voltage (any pin)

25 V(dc +peak ac).1

Baud Rates

300, 1200, 2400, 9600; 0.1 %accuracy based on

the microprocessor clock. 1

Signals

RD, TD, and SGND. SGND is connected internally to

EXTERNAL TRIG COM. DSR and CTS are always

high, and DTR and RTS are ignored. 1

Levels

Compatible with RS-232C.

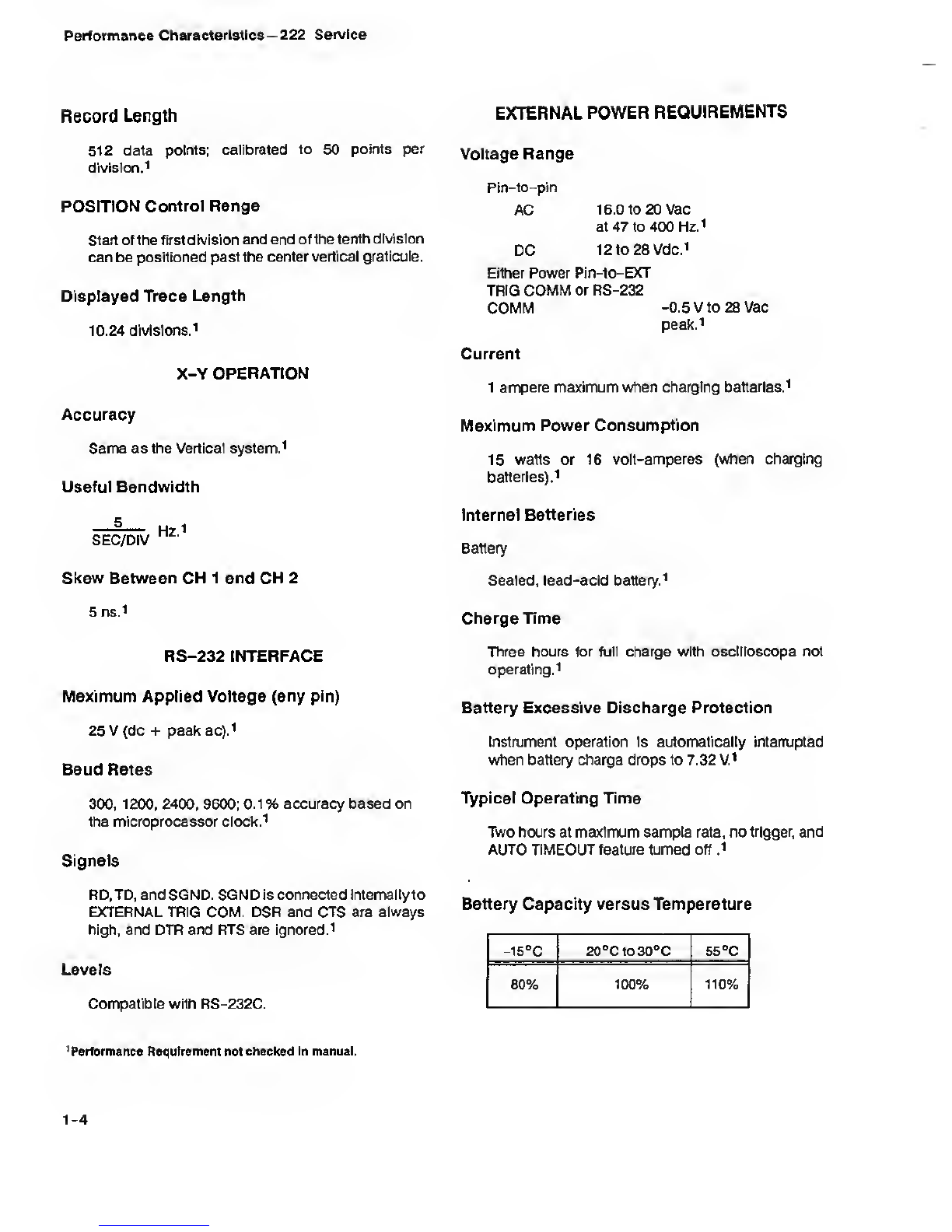

EXTERNAL POWER REQUIREMENTS

Voltage Range

Pin-to-pin

AC 16.0 to 20 Vac

at 47 to 400 Hz.1

DC 12 to 28 Vdc.1

Either Power Pin-to-EXT

TRIG COMM or RS-232

COMM -0.5 Vto 28 Vac

peak. 1

Current

1ampere maximum when charging batteries.1

Maximum Power Consumption

15 watts or 16 volt-amperes (when charging

batteries). 1

Internal Batteries

Battery

Sealed, lead-acid battery. 1

Charge Time

Three hours for full charge with oscilloscope not

operating. 1

Battery Excessive Discharge Protection

Instrument operation is automatically interrupted

when battery charge drops to 7.32 V. 1

Typical Operating Time

Two hours at maximum sample rate, no trigger, and

AUTO TIMEOUT feature turned off .’

Battery Capacity versus Temperature

-15°C 20°Cto30°C 55 °C

80% 100% 110%

'Performance Requirement not checked In manual.

1-4

Performance Characteristics -222 Service

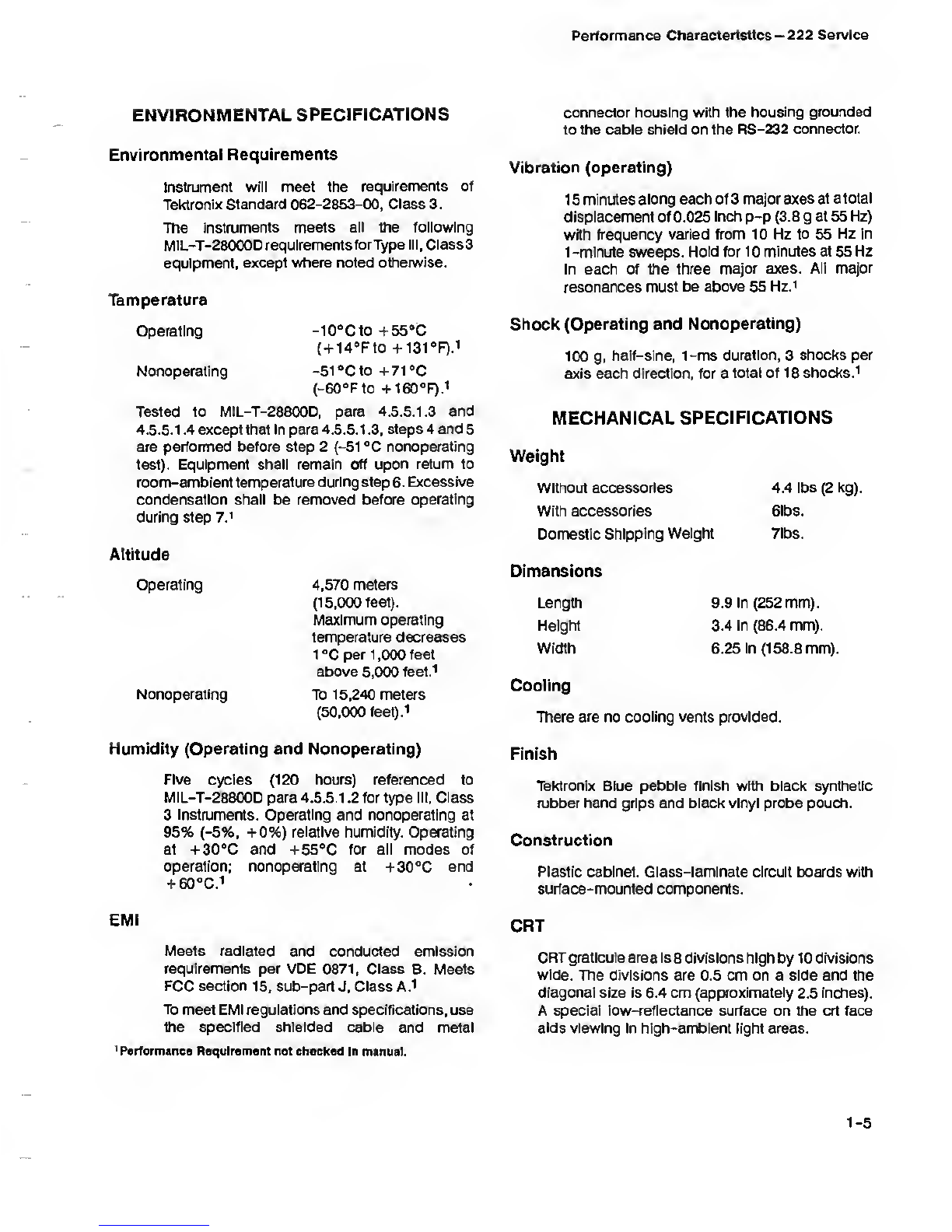

ENVIRONMENTAL SPECIFICATIONS connector housing with the housing grounded

to the cable shield on the RS-232 connector.

Environmental Requirements

Instrument will meet the requirements of

Tektronix Standard 062-2853-00, Class 3.

The instruments meets all the following

MIL-T-28000D requirements for Type III, Class 3

equipment, except where noted otherwise.

Temperature

Operating -10°Cto +55°C

(+ 14°F to +131°F).1

Nonoperating -51 °C to +71 °C

(-60°F to +160°F).1

Tested to MIL-T-28800D, para 4.5.5.1.3 and

4.5.5. 1.4 except that in para 4.5.5. 1.3, steps 4and 5

are performed before step 2(-51 °C nonoperating

test). Equipment shall remain off upon return to

room-ambienttemperature during step 6. Excessive

condensation shall be removed before operating

during step 7.

Altitude

Operating

Nonoperating

4,570 meters

(15,000 feet).

Maximum operating

temperature decreases

1°C per 1,000 feet

above 5,000 feet. 1

To 15,240 meters

(50,000 feet). 1

Vibration (operating)

15minutes along each of 3major axes at atotal

displacement of 0.025 inch p-p (3.8 gat 55 Hz)

with frequency varied from 10 Hz to 55 Hz in

1-minute sweeps. Hold for 10 minutes at 55 Hz

in each of the three major axes. All major

resonances must be above 55 Hz. 1

Shock (Operating and Nonoperating)

100 g, half-sine, 1-ms duration, 3shocks per

axis each direction, for atotal of 18 shocks. 1

MECHANICAL SPECIFICATIONS

Weight

Without accessories 4.4 lbs (2 kg).

With accessories 6lbs.

Domestic Shipping Weight 7lbs.

Dimensions

Length 9.9 in (252 mm).

Height 3.4 in (86.4 mm).

Width 6.25 in (158.8 mm).

Cooling

There are no cooling vents provided.

Humidity (Operating and Nonoperating)

Five cycles (120 hours) referenced to

MIL-T-28800D para 4.5.5.1 .2 for type III, Class

3instruments. Operating and nonoperating at

95% (-5%, +0%) relative humidity. Operating

at +30°C and +55°C for all modes of

operation; nonoperating at +30°C and

+60°C. 1

Finish

Tektronix Blue pebble finish with black synthetic

rubber hand grips and black vinyl probe pouch.

Construction

Plastic cabinet. Glass-laminate circuit boards with

surface-mounted components.

EMI

Meets radiated and conducted emission

requirements per VDE 0871 ,Class B. Meets

FCC section 15, sub-part J, Class A. 1

To meet EMI regulations and specifications, use

the specified shielded cable and metal

'’Performance Requirement not checked In manual.

CRT

CRT graticule area is 8divisions high by 10divisions

wide. The divisions are 0.5 cm on aside and the

diagonal size is 6.4 cm (approximately 2.5 inches).

Aspecial low-reflectance surface on the crt face

aids viewing in high-ambient light areas.

1-5

Scan by John Barnes

Section 2-222 Service

OPERATING INFORMATION

SAFETY

Refer to the Operator’s Safety Summary at the front of

this manual for safety information about the use of this

instrument. Before connecting the instrument to apower

source, read this section and the Safety Summary.

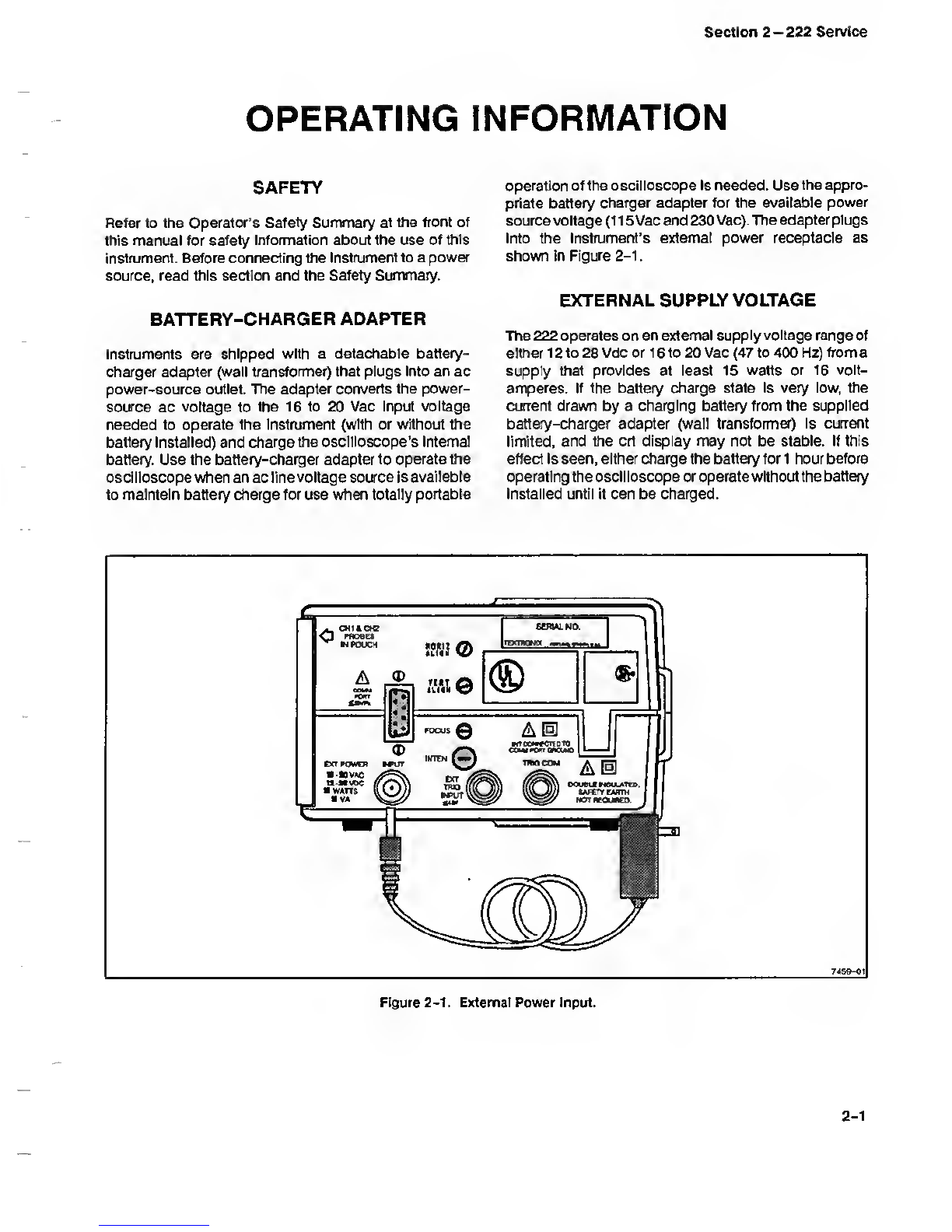

BATTERY-CHARGER ADAPTER

Instruments are shipped with adetachable battery-

charger adapter (wall transformer) that plugs into an ac

power-source outlet. The adapter converts the power-

source ac voltage to the 16 to 20 Vac input voltage

needed to operate the instrument (with or without the

battery installed) and charge the oscilloscope's internal

battery. Use the battery-charger adapter to operate the

oscilloscope when an ac line voltage source is available

to maintain battery charge for use when totally portable

operation of the oscilloscope is needed. Use the appro-

priate battery charger adapter for the available power

source voltage (1 15Vac and 230Vac). The adapter plugs

into the instrument’s external power receptacle as

shown in Figure 2-1.

EXTERNAL SUPPLY VOLTAGE

The 222 operates on an external supply voltage range of

either 12to 28 Vdc or 16to 20 Vac (47 to 400 Hz) from a

supply that provides at least 15 watts or 16 volt-

amperes. If the battery charge state is very low, the

current drawn by acharging battery from the supplied

battery-charger adapter (wall transformer) is current

limited, and the crt display may not be stable. If this

effect is seen, either charge the battery for 1hour before

operating the oscilloscope or operate without the battery

installed until it can be charged.

Figure 2-1. External Power Input.

2-1

Operating Information -222 Service

BATTERY OPERATION

The internal battery of the instalment is asealed lead-

acid type with four cells. The sealed cells are recharge-

able using the battery-charger adapter supplied with the

instrument. Operating time is at least two hours with a

fully charged battery. When the charge level reaches a

point where only ashort amount of operating time

remains, alow-battery indicator (fc=J )is displayed in

the upper right comer of the readout. The oscilloscope

turns off automatically when the battery voltage drops

below +7.32 V.

If the charge level of the battery is less than about 20%,

the instrument will not come on without the external

power provided by the battery-charger adapter. Typical

worst-case operating time for an instrument with fully

charged batteries is two hours at normal room tem-

perature with the AUTO TIMEOUT feature turned off.

One or two charged batteries may be carried in optional

pouches that attach to the carrying case for extended

use away from an ac power source. See Section 6for the

battery removal and replacement instructions.

An external power-on indicator ( ) appears in the

upper right comer of the readout when external power is

on. The battery is charging anytime external power is

being supplied and will charge while the instrument is

operating. However, the battery charges faster when the

instrument is not operating. Completely recharge the

battery as soon as possible after each discharge cycle.

Refer to "Tips on Battery Care” in this section for informa-

tion on how to extend the operating lifetime of the battery.

J^uwvwvw

iCAUTION ?

ivwwwvJ

When storing the Instrument for periods longer

than two months, fully charge the batteries; then

remove the batteries and store them in acool

place. Storing partially discharged batteries for

an extended time or in high temperatures can

deplete the remaining charge, leading to a

deep-discharge condition. Refer to Tips on

Battery Care" in this section for information on

restoring adeep-discharged battery.

FIRST TIME BATTERY OPERATION

The battery supplied with the oscilloscope is charged at

the factory and shipped unplugged to preserve its shelf

life. However, the state of battery charge at the time you

receive It will be unknown. It is recommended that you

charge the battery for three hours before operating the

oscilloscope the first time.

START-UP

Press the EXbutton to enable the display and acquisi-

tion system. Pressing the Di button asecond time

turns off the oscilloscope operation but does not discon-

nect the battery or external power source.

AUTO TIMEOUT

There is an AUTO TIMEOUT feature that extends the

oscilloscope operating time on battery operation. With a

two-minute period of no front panel control activity, the

oscilloscope turns off. The acquisitionand display can

be turned back on by pressing the EX button. The

AUTO TIMEOUT feature does not turn off the oscillo-

scope when external power is applied. The feature may

also be disabled from turning off the oscilloscope when

operating on battery power alone. See Section 4of the

Operators Manual for operating instructions.

VIEWING ASIGNAL QUICKLY

Connect one or both of the probe tips to the signals to be

viewed.

Press E3.This gives you aquick setup of the front-

panel controls to view the signals applied to the probe

tip(s). Achannel that does not have asignal connected

is turned off (except CH 1will not be turned off if neither

channel has asignal applied). If signals are applied to

both channels, each will be autoranged vertically (set-

ting the VOLTS/DIV and vertical position for each), but

the signal applied to channel 1will determine the SEC/

DIV and Trigger LEVEL settings. If only channel 2has a

signal applied, that signal is used to determine the SEC

/

DIV setting and Trigger LEVEL.

NOTE

AUTO SETUP does not set the SEC/DIV setting

into the ROLL region (0. 1s/div andslower). The

practical low frequency for using the AUTO

SETUP feature is about 20 Hz.

2-2

Operating Information -222 Service

TIPS ON BATTERY CARE

The battery in your instrument is asealed lead-acid type

battery with four ceils. These tips will help extend the

battery life.

1. Completely recharge the battery after each dis-

charge cycle. Continued partial recharges shorten

the battery life. The battery is on charge any time

external power is used to operate the instrument.

However, the battery recharges faster when the

instrument is not operating.

2. Avoid situations that can lead to deep discharge of

the battery.

If the instrument starts and remains on only briefly

before shutting off, the battery charge state is low.

The instrument will not start on battery if the voltage

drops below 7.32 V. The battery must be recharged

as soon as possible when it is in this state. Do not

store the battery (or instrument with the battery

installed) in adischarged state. Extended storage or

storage in high temperatures will deplete the

remaining charge, leading to deep discharge. When

deep discharge occurs, the battery accepts charge

very slowly, and, in some cases, may not recharge.

3. If adeep-discharge condition occurs, it may be

possible to recover the battery with the following

procedure.

Leave the battery on charge for 24 hours. If it still

does not accept a charge, remove it from the instru-

ment and attempt to charge it using a20 Vpower

supply that is current limited to 100 milliamperes.

When attempting to recover the battery using an

external power supply, check the battery frequently

for the current-limit state. If the battery recovers from

the deep-discharge state, it will pull the power sup-

ply into current limit. When this happens, reinstall it

in the instrument and charge it normally. Do not

leave the battery on the external power supply for

long periods of time without checking it. If the battery

does not recover, dispose of it safely.

4. When storing the instrument for an extended period

of time, fully charge the battery and remove it from

the instrument. Store the fully charged battery in a

cool place. For short periods of storage, the battery

may remain installed. During "sleep” mode, the cur-

rent drawn from the battery is less than 1mA. With

the battery installed, the data stored in nonvolatile

memory will remain stored and be available when

the oscilloscope is turned on again.

5.

The instrument will operate from the battery-charger

adapter or other suitable ac or dc power source with

the battery removed from the instrument.

ALTERNATE METHOD FOR BATTERY

CHARGING

Batteries may be charged outside the instrument using

the External Battery Charger accessory (see section 7for

part number) or auser provided dc power supply. The

lead-acid cells of the battery require aconstant charging

voltage as provided by the External Battery Charger

accessory. An alternate charger must supply 9.8 Vdc at

20°C with the supply current limited to 1ampere. For

best results over awide temperature range, the charging

voltage should be thermally compensated for -10 mV

per degree C. For example, at 50°C ,the charging volt-

age should be:

9.80 V+[(50 -20) X-10 mV] =9.50 V.

BATTERY REPLACEMENT

If you frequently operate the oscilloscope using the

battery only, you may wish to obtain one or two extra

batteries and carry them in afully-charged condition to

the servicing site. When the charge level onthe battery in

the oscilloscope reaches the shut-off level, one of the

spare batteries may be used to provide more operating

time.

The battery is in acompartment behind the probe pouch.

To remove and replace it, follow this procedure:

1.Open the probe pouch and take the probes out of it.

This allows the battery compartment cover freedom

to move away from the oscilloscope.

2. Place the oscilloscope on its right side and slide the

battery compartment cover toward the rear to dis-

engage the locking tabs. The hole for the probe

leads makes aconvenient place to apply the

needed force with your finger.

3. Lift the battery compartment cover up and slide It far

enough downthe probe leads to lay the cover down.

4. Disconnect the 3-wire battery connector.

NOTE

Ifyou reconnectpowerto the battery connector

from the charged battery in less than 30 sec-

onds, the savedwaveforms andfront-panel set-

ups will not be lost.

2-3

Operating information -222 Service

5. Lift the battery pack out of the battery compartment.

6. Place the charged replacement battery into the

battery compartment with the battery leads on the

bottom side facing toward the rear.

7. Reconnect the battery plug.

8. Slide the battery compartment cover back up the

probe leads and place the cover locking tabs into

the matching slots in the battery compartment. Make

sure the locking tab are all the way into the slots on

both the top and bottom of the cover. If the tabs don't

seat easily seat the top tabs first then press on the

bottom of the cover to seat the bottom tabs.

9.

Push forward on the rear of the battery compartment

cover to engage the locking tabs.

10.

Remember to recharge the low battery at the first

opportunity. This prevents it from going into adeep-

discharge state.

2-4

Section 3-222 Service

BLOCK DIAGRAM OVERVIEW

INTRODUCTION

The 222 Digital Storage Oscilloscope comprises five

major functional blocks (see Figure 3-1). These are: the

Floating Acquisition System, the Time Base, the Proc-

essor System, the Display System, and the Power

Supplies. The operation of each of these functional

blocks is described. Abrief overview follows.

The signal is applied to the Floating Acquisition System

(so named because of the electrical isolation of the

inputs from the remainder of the functional blocks). There

it is amplified, offset (for position and calibration), and

limited (to the dynamic range of the A/D converter). The

signal is then digitized and stored in Acquisition

Memory.

An internal trigger signal is also derived from the input

signal. That signal starts events in the Time Base that

cause the acquisition of the input signal to be com-

pleted. (Acquisition is the digitization of the input signal

and storing of the digital values.)

The Processor System transfers the digital waveform

information from the Acquisition Memory to the Display

Memory. That data can then be displayed or stored in the

Save Memory for later recall and viewing. The Processor

System scans the Front-Panel and Top-Panel switches

to determine when the user presses abutton. It also con-

trols the Time Base, the Acquisition System, and the

Power Supplies. An RS-232C compatible serial port pro-

vides the Processor System with an interface to external

communication devices. Waveform data may be sent or

received over the interface, and the control settings of

the 222 may be changed or queried.

In the Display System the digital waveform data is con-

verted back to analog signals. These analog signals are

amplified and applied to the crt deflection plate to pro-

vide avisual display of the signal's waveshape.

Either the internal battery or the external wall transformer

provides the supply voltage for the power supplies. A

battery charger circuit supplies charging current to the

battery whenever external power is applied to the

instrument. The external power may be used to run the

instrument with or without the battery installed. Separate

supplies provide power for the crt, the Floating Acqui-

sition System, and the remaining digital circuitry of the

instrument.

ACQUISITION SYSTEM

The Acquisition System contains two complete, isolated

vertical channels, each with its own attenuator, amplifier,

trigger circuit, A/D converter, peak detector, acquisition

memory, and isolated power supply (see Figure 3-2).

The channel grounds are isolated from each other and

instrument ground. Data and clock signals are passed

through pulse transformers and opto-couplers to main-

tain the isolation.

The attenuator, amplifier, and trigger circuit for each

channel are formed by ahybrid circuit on asingle

ceramic carrier. Passive attenuators provide XI, XI 0,

XI 00, and XI 000 attenuator of the input signal. The gain

amplifier has a high Input impedance and alow output

impedance. Ahigh-speed trigger pulse is derived from

the input signal by the trigger circuit portion of the hybrid

component. Output signals from the amplifier are in the

range of 0to 2.5 Vto be applied to the A/D converter.

Output voltage samples from the amplifier are converted

into 8-bit digital words. Conversions occur at asample

rate of 10 MHz that does not change with the SEC/DIV

setting. To provide lower sampling rates of the input sig-

nal, the data words are stored in the acquisition memory

at asave clock rate that varies with the SEC/DIV setting.

The Acquisition Memory is aFIFO (first in, first out)

memory system. The length of the data pipeline is 512

data bytes (of 8bits each). In the normal sample mode,

each data byte produced by the A/D Converter is stored

into the pipeline at the sample clock rate (10 MHz). At

Time Base settings above 5jis/div, the save clock rate

(which changes with the SEC/DIV setting) is used to

store converted samples into the pipeline. With PEAK

DETECT enabled, two data bytes are stored into the

pipeline for each save clock. The data bytes are loaded

into ashift register at the output of the FIFO and the bits of

the data byte are shifted out serially through an isolation

pulse transfer to be placed into the display memory for

eventual display.

3-1

Block Diagram Overview-222 Service

+6AVcc

-6 Vee 100 V

CHI

TROW

ISOLATED

CH2

+5.3 V

ISOLATED

3-2

Block Diagram Overview- 222 Service

SERIAL

DATA from

BUS CHI

HYBRID

U123C.D

VSDATA

and

VSCLK U122C.D

II

cSAMPLE

AND *

SAVE P>

U122A.B

125 T1

CHANNEL 2

3-3

DiUbiv uiayiam wvcivicn —

TIME BASE

All acquisition clock signals are derived from afree-

running 20 MHz master oscillator. The Sample Clock

Generator contains counters and multiplexers to pro-

duce the various clocking signals to the A/D Converter,

the Acquisition Memory, and the data counters that keep

track of the number of samples taken for awaveform

record (see Figure 3-3).

The Pre-Fill Counter counts to determine when the

pretrigger waveform data has been acquired. Then the

trigger circuit is enabled to accept atrigger event. When

the trigger occurs, the remaining data points needed to

fill the waveform record are acquired. The Record

counter determines when those data points have been

acquired and then halts the acquisition system. Acom-

plete waveform record is then held in the Acquisition

Memory. An interrupt is also generated to the Processor

to Inform that device that the acquisition is completed.

The output of the Clock Delay circuit is used during

Repetitive Store Mode. The time difference between the

trigger event and the rising edge of the sample clock is

measured so that repetitive samples taken on different

triggers may be correctly placed in the waveform record.

The resolution of the Clock Delay timer is 0.5 ns.

When external trigger signals are connected to the

instrument, the External Trigger Comparator is used to

produce the actual trigger event from the applied

signals. For operation on internal trigger signals, the

Schmitt trigger circuit is used to allow the signal to return

to zero with producing afalse trigger signal.

PROCESSOR SYSTEM

The Processor System contains amicrocontroller, a

memory, chip-select logic, and the RS-232 interface

(see Figure 3-4). It receives inputs from the Front Panel

or RS-232 interface and controls the Acquisition

System. Time Base, and Display System through its

synchronous serial interface. The Processor System is

clocked by an 8MHz oscillator that is not frequency

related to the Time Base clocks (not derived from the

20 MHz Time Base oscillator).

3-4

Popular Storage manuals by other brands

LaCie

LaCie Rugged Triple USB 3.0 Quick install guide

Vestil

Vestil CYL-V Series Assembly & Maintenance Manual

Digital Electronics

Digital Electronics PL3000 Series installation guide

Arrow Storage Products

Arrow Storage Products EG108AN Owner's manual & assembly guide

SimpleTech

SimpleTech SimpleDrivePortable HSD1000 quick start guide

OWC

OWC Mercury Elite Pro Dual Assembly manual & user guide