TELEDYNE API Everywhereyoulook 480H User manual

User Manual

Model 480H

OZONE MONITOR

©Teledyne API (TAPI)

9970 Carroll Canyon Road

San Diego, CA 92131-1106

Toll-Free:

+1 800-324-5190

Phone:

+1 858-657-9800

Fax:

+1 858-657-9816

Email:

api-sales@teledyne.com

Website:

http://www.teledyne-api.com

Copyright 2021 09421A DCN8343

Teledyne API 30 June 2021

E IS INTENTIONALLY LEFT BLANK

09421A DCN8343 Teledyne API Model 480H O3Monitor User Manual i

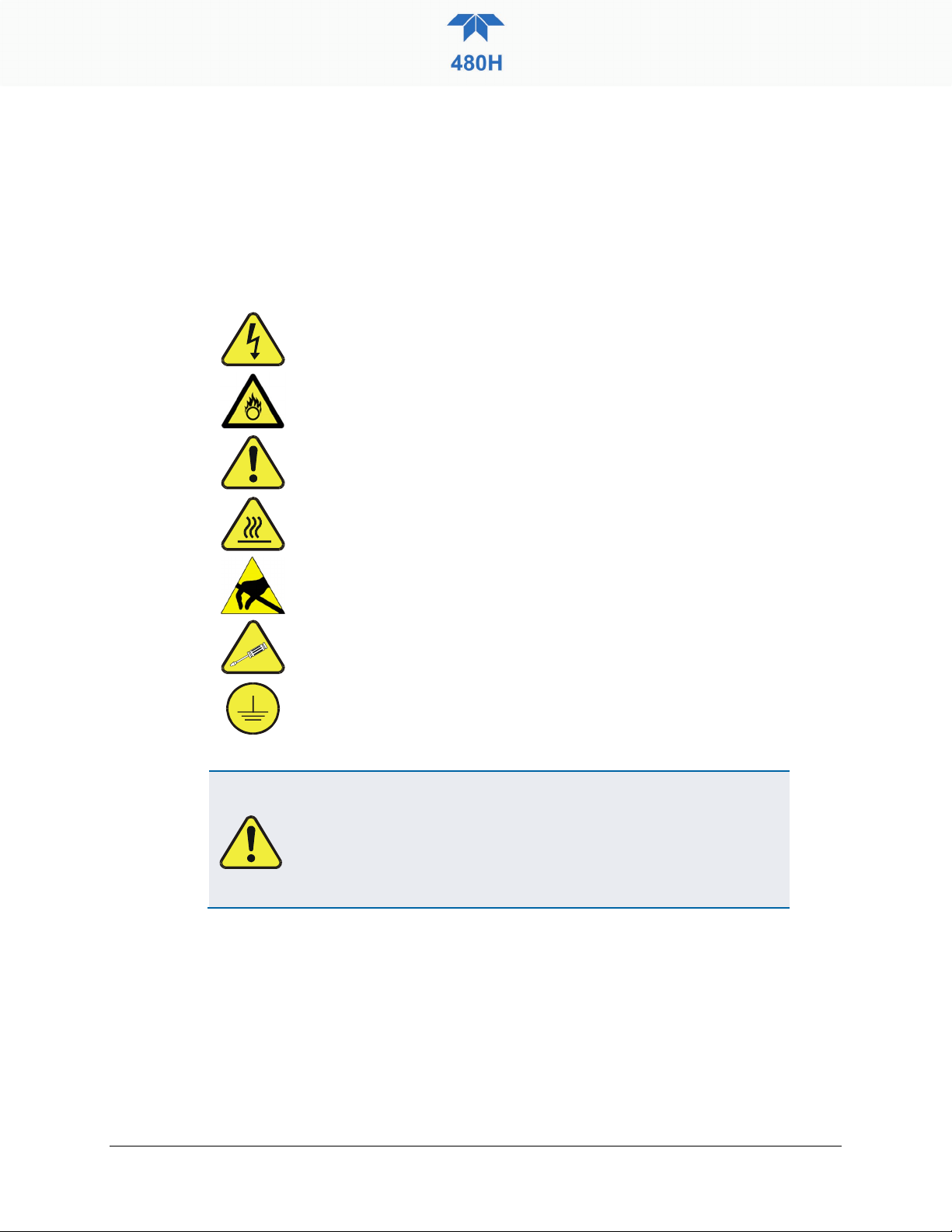

SAFETY MESSAGES

Important safety messages are provided throughout this manual for the purpose of

avoiding personal injury or instrument damage. Please read these messages

carefully. Each safety message is associated with a safety alert symbol and placed

throughout this manual and inside the instrument. The symbols with messages are

defined as follows:

WARNING: Electrical Shock Hazard

HAZARD: Strong oxidizer

GENERAL WARNING/CAUTION: Read the accompanying message

for specific information.

CAUTION: Hot Surface Warning

Do Not Touch: Touching some parts of the instrument without

protection or proper tools could result in damage to the part(s) and/or the

instrument.

Technician Symbol: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central

safety grounding point for the instrument.

CAUTION

This product should only be used for the purpose and in the manner

described in this manual. If you use this product in a manner other

than that for which it was intended, unpredictable behavior could

ensue with possible hazardous consequences.

NEVER use any combustible/explosive gas with this product!

ii Teledyne API Model 480H O3Monitor User Manual 09421A DCN8343

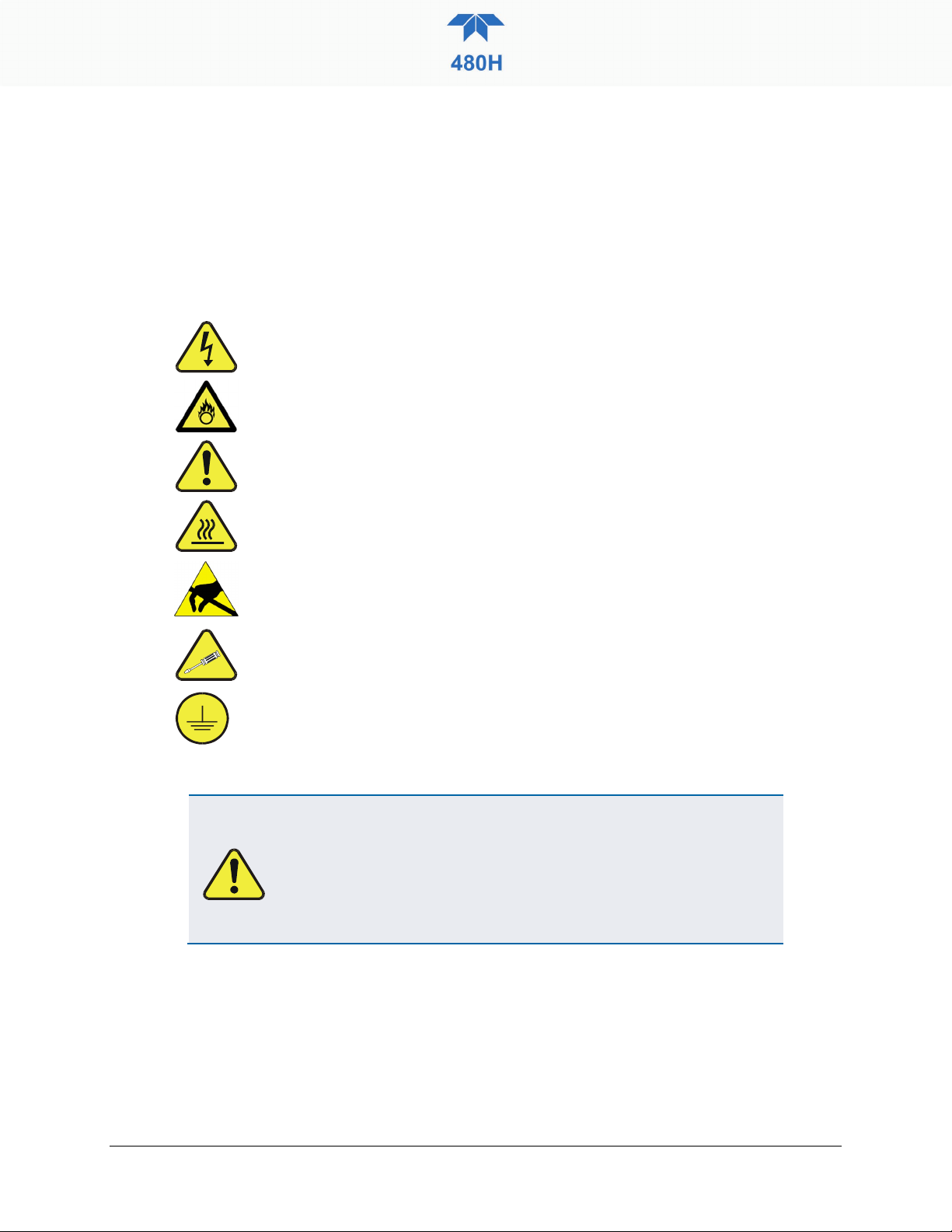

CONSIGNES DE SÉCURITÉ

Des consignes de sécurité importantes sont fournies tout au long du présent manuel

dans le but d’éviter des blessures corporelles ou d’endommager les instruments.

Veuillez lire attentivement ces consignes. Chaque consigne de sécurité est

représentée par un pictogramme d’alerte de sécurité; ces pictogrammes se

retrouvent dans ce manuel et à l’intérieur des instruments. Les symboles

correspondent aux consignes suivantes:

AVERTISSEMENT: Risque de choc électrique

DANGER: Oxydant puissant

AVERTISSEMENT GÉNÉRAL / MISE EN GARDE: Lire la consigne

complémentaire pour des renseignements spécifiques

MISE EN GARDE: Surface chaude

Ne pas toucher: Toucher à certaines parties de l’instrument sans protection

ou sans les outils appropriés pourrait entraîner des dommages aux pièces ou

à l’instrument.

Pictogramme « technicien »: Toutes les opérations portant ce symbole

doivent être effectuées uniquement par du personnel de maintenance

qualifié.

Mise à la terre: Ce symbole à l’intérieur de l’instrument détermine le point

central de la mise à la terre sécuritaire de l’instrument.

MISE EN GARDE

Cet produit doit être utilisé aux fins décrites et de la manière décrite

dans ce manuel. Si vous utilisez cet produit d’une autre manière que

celle pour laquelle il a été prévu, l’instrument pourrait se comporter de

façon imprévisible et entraîner des conséquences dangereuses.

NE JAMAIS utiliser de gaz explosive ou combustible avec cet produit!

09421A DCN8343 Teledyne API Model 480H O3Monitor User Manual iii

WARRANTY

WARRANTY POLICY (02024J)

Teledyne API (TAPI), a business unit of Teledyne Instruments, Inc., provides that:

Prior to shipment, TAPI equipment is thoroughly inspected and tested. Should

equipment failure occur, TAPI assures its customers that prompt service and support

will be available. (For the instrument-specific warranty period, please refer to the

“Limited Warranty” section in the Terms and Conditions of Sale on our website at

the following link: http://www.teledyne-api.com/terms_and_conditions.asp).

COVERAGE

After the warranty period and throughout the equipment lifetime, TAPI stands ready

to provide on-site or in-plant service at reasonable rates similar to those of other

manufacturers in the industry. All maintenance and the first level of field

troubleshooting are to be performed by the customer.

NON-TAPI MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by TAPI is warranted and will be

repaired to the extent and according to the current terms and conditions of the

respective equipment manufacturer’s warranty.

Product Return

All units or components returned to Teledyne API should be properly packed for

handling and returned freight prepaid to the nearest designated Service Center. After

the repair, the equipment will be returned, freight prepaid.

The complete Terms and Conditions of Sale can be reviewed at

http://www.teledyne-api.com/terms_and_conditions.asp

CAUTION – Avoid Warranty Invalidation

Failure to comply with proper anti

-Electro-Static Discharge (ESD)

handling and packing instru

ctions and Retu

rn Merchandise

Authorization (RMA) procedures when returning parts for repair or

calibration may void your warranty. For anti

-ESD handling and

packi

ng instructions please refer to the manual, Fundamentals of

ESD, PN 04786, in its

“Packing Components for Return to Teledyne

API’s Customer Service”

section. The manual can be downloaded

from our website at

http://www.teledyne-api.com. RMA procedures

can also be found on our website

.

iv Teledyne API Model 480H O3Monitor User Manual 09421A DCN8343

This page intentionally left blank

09421A DCN8343 Teledyne API Model 480H O3Monitor User Manual v

TABLE OF CONTENTS

1. INTRODUCTION..........................................................................................................9

2. SPECIFICATIONS AND AGENCY APPROVALS ................................................11

2.1. MODEL 480H SPECIFICATIONS ..........................................................................................................11

2.2. APPROVALS .......................................................................................................................................12

2.2.1. Safety...........................................................................................................................................12

2.2.2. EMC ............................................................................................................................................12

2.2.3. Other Type Certifications............................................................................................................12

3. GETTING STARTED.................................................................................................13

3.1. UNPACKING .......................................................................................................................................14

3.2. MECHANICAL INSTALLATION ............................................................................................................14

3.3. AC POWER CONNECTION...................................................................................................................16

3.3.1. Wiring Requirements...................................................................................................................16

3.3.2. Wiring Instructions .....................................................................................................................17

3.4. ELECTRICAL I/O CONNECTIONS.........................................................................................................18

3.4.1. Analog Output.............................................................................................................................19

3.4.2. Status Outputs .............................................................................................................................21

3.4.3. Hi-Current Relay Outputs ...........................................................................................................22

3.4.4. Failsafe Operation Signal and Relay outputs .............................................................................22

3.4.5. Digital Communication Interfaces..............................................................................................23

3.5. PNEUMATIC CONNECTIONS................................................................................................................24

3.5.1. Installing Flow Control Assemblies ............................................................................................24

3.5.2. Ozone Inlet Connection...............................................................................................................24

3.5.3. Zero Gas Inlet Connection ..........................................................................................................25

3.5.4. Exhaust Connection ....................................................................................................................25

3.6. PNEUMATIC FLOW DIAGRAM.............................................................................................................25

4. CALIBRATION...........................................................................................................26

4.1. FACTORY CALIBRATION ....................................................................................................................26

4.2. ZERO,SPAN,AND FLOW CALIBRATIONS ............................................................................................26

5. OPERATION ...............................................................................................................27

5.1. FRONT PANEL OVERVIEW ..................................................................................................................27

5.1.1. Display ........................................................................................................................................27

5.1.2. Control Keys ...............................................................................................................................28

5.1.3. Indicator LEDs............................................................................................................................28

5.2. FRONT PANEL MENUS........................................................................................................................29

5.2.1. Editing Settings ...........................................................................................................................29

5.2.2. Sensor Menu................................................................................................................................30

5.2.3. Diag Menu ..................................................................................................................................30

5.2.4. Setup Menu..................................................................................................................................32

5.2.5. Status Screen...............................................................................................................................35

6. DIGITAL COMMUNICATIONS..............................................................................36

6.1. ETHERNET CONFIGURATION ..............................................................................................................36

6.2. SERIAL CONFIGURATION -RS-232 AND RS-485................................................................................37

6.3. MODBUS REGISTER MAPS...............................................................................................................39

6.3.1. MODBUS Commands Supported................................................................................................39

6.3.2. Notes on MODBUS registers ......................................................................................................39

6.3.3. Real-Time Concentration and Status Registers (Read Only) ......................................................40

6.3.4. Instrument Setup and Configuration Registers (Read / Write)....................................................40

vi Teledyne API Model 480H O3Monitor User Manual 09421A DCN8343

7. MAINTENANCE.........................................................................................................42

7.1. MAINTENANCE SCHEDULE.................................................................................................................42

7.2. INSTRUMENT LAYOUT .......................................................................................................................43

7.3. PARTICULATE FILTER REPLACEMENT ................................................................................................44

7.4. AUTO-ZERO VALVE REPLACEMENT ..................................................................................................45

7.5. UV LED REPLACEMENT....................................................................................................................46

7.6. SENSOR MODULE REPLACEMENT ......................................................................................................47

7.7. DISPLAY ASSEMBLY REPLACEMENT..................................................................................................48

7.8. CLEANING EXTERIOR SURFACES OF THE 480H ..................................................................................49

8. TROUBLESHOOTING ..............................................................................................50

8.1.REFERENCE DRAWINGS .....................................................................................................................50

8.2. TROUBLESHOOTING USING FRONT PANEL STATUS LED AND STATUS OUTPUTS...............................50

8.2.1. Sensor OK ...................................................................................................................................52

8.2.2. Invalid Reading...........................................................................................................................52

8.2.3. Check Lamp.................................................................................................................................52

8.2.4. Pneumatic Error .........................................................................................................................52

8.2.5. Technical Assistance ...................................................................................................................53

9. PRINCIPLES OF OPERATION................................................................................54

09421A DCN8343 Teledyne API Model 480H O3Monitor User Manual vii

FIGURES

Figure 3-1. Model 480H Display and Control Panel .....................................................................................13

Figure 3-2. 480H Dimensions........................................................................................................................16

Figure 3-3. AC Power Connection to Monitor ..............................................................................................17

Figure 3-4. Interior Location of I/O Connectors............................................................................................19

Figure 3-5. Mainboard – Analog Output Configuration................................................................................21

Figure 3-6. Pneumatic Connections...............................................................................................................24

Figure 3-7. Pneumatic Diagram.....................................................................................................................25

Figure 5-1. Front Panel Display and Controls ........................................................................................27

Figure 5-2. Front Panel Selection and Control Buttons.........................................................................28

Figure 6-1. RS-232 Signal Configurations ....................................................................................................38

Figure 7-1. Instrument Layout.......................................................................................................................43

Figure 7-2. Particulate Filter (PN 02832) Replacement ................................................................................44

Figure 7-3. O3 Sensor Module Board............................................................................................................46

Figure 7-4. UV LED Access..........................................................................................................................46

Figure 7-5. Sensor Module Removal.............................................................................................................47

Figure 7-6. Display Assembly Removal........................................................................................................49

Figure 8-1. Display and Control Panel ..........................................................................................................50

Figure 8-2. Status Outputs .............................................................................................................................51

viii Teledyne API Model 480H O3Monitor User Manual 09421A DCN8343

TABLES

Table 3-1. Status Output Definitions .............................................................................................................22

Table 5-2. Sensor Menu Parameters ..............................................................................................................30

Table 5-3. Analog Step Test Values ..............................................................................................................30

Table 5-4. VARS List ....................................................................................................................................32

Table 5-5. Alarm Configuration Settings ......................................................................................................34

Table 6-1. RS-232/RS-485 Port Setup...........................................................................................................37

Table 7-1. Maintenance Schedule..................................................................................................................42

Table 8-1. Status LED/Output Definitions ....................................................................................................51

09421A DCN8343 Teledyne API Model 480H O3Monitor User Manual 9

1. INTRODUCTION

Teledyne API’s Model 480H Ozone Monitor measures high concentration ozone

monitor that measures process ozone concentrations and is specifically optimized

for applications in water treatment and in the medical, food, and beverage

industries. This microprocessor-controlled instrument provides fast response times

with minimal zero drift for accurate and stable readings, and it has built-in tests and

diagnostics to allow maximum uptime.

We at Teledyne API will be pleased to provide you with any support required so

that you may utilize our equipment to the fullest extent. Our full time technical

support department is always available to answer your questions.

Teledyne API, Technical Support,

9970 Carroll Canyon Road

San Diego, California 92131-1106 USA

Toll-free: +1 800-324-5190

Phone:

+1 858-657-9800

Fax: +1 858-657-9816

Email:

api-techsupport@teledyne.com

Website: http://www.teledyne-api.com

10 Teledyne API Model 480H O3Monitor User Manual 09421A DCN8343

This page intentionally left blank

09421A DCN8343 Teledyne API Model 480H O3Monitor User Manual 11

2. SPECIFICATIONS AND AGENCY APPROVALS

2.1. MODEL 480H SPECIFICATIONS

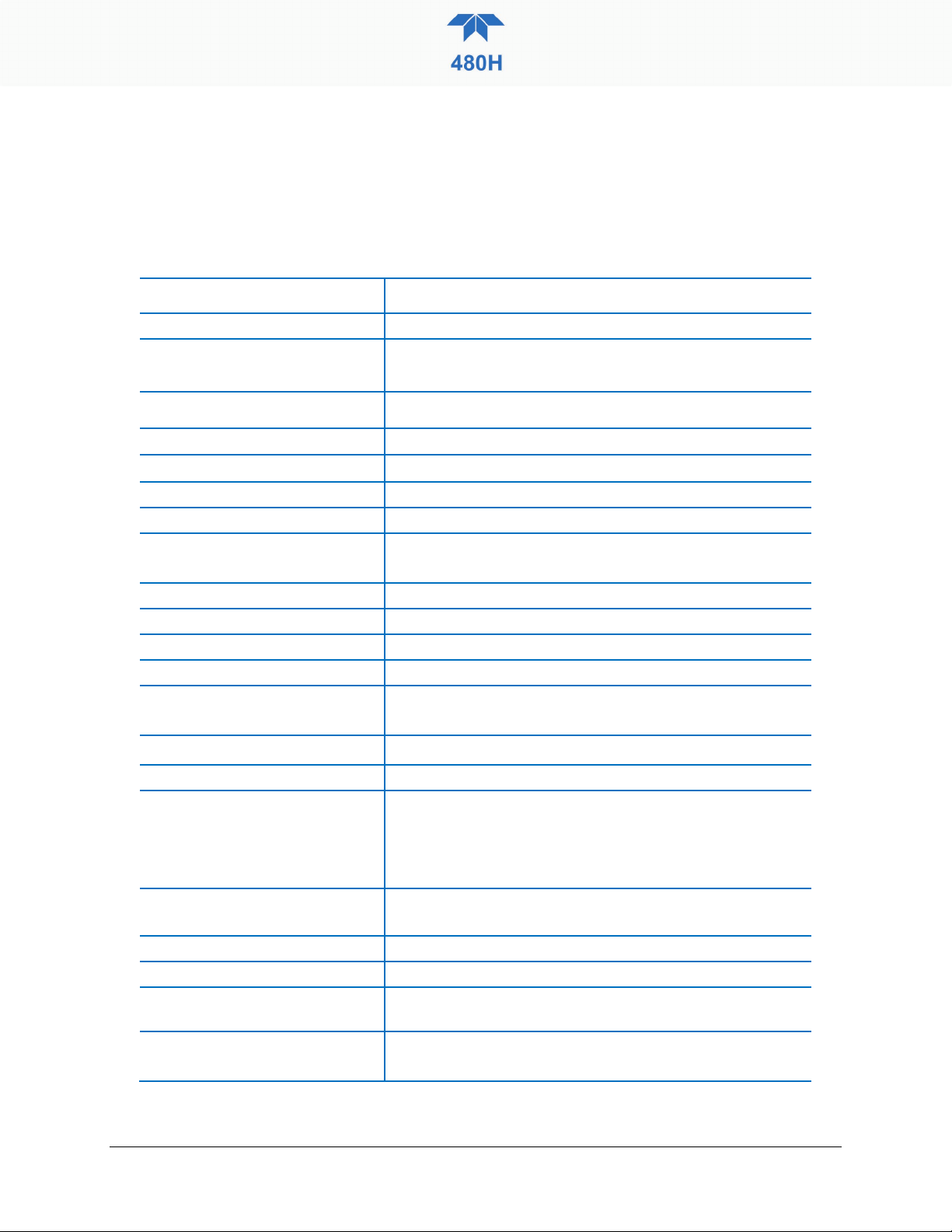

PARAMETER SPECIFICATION

M

easuring Principle UV absorption (Beer Lambert Law)

Ranges

0-5 WT% to 0-25 WT%

0-100 g/Nm3 to 0-400 g/Nm3

Measurement U

nits WT%, g/Nm3

Accuracy

±1% of Full Scale

Precision/Repeatabil

ity ±0.5% of Full Scale

Display Resolution

0.01 WT%, 0.1 g/Nm3

Response Time (

95%) <30 seconds to 95%

Com

pensation Pressure, Temperature

(NTP = 273.15K, 760 mmHg)

Gas Inlet Pressure Range

3.0-30.0 psig

Sample Flow Rate

0.2-2.0 LPM

Humidity Range

10-90% RH, non-condensing

Temper

ature Range 5-45o C

Dime

nsions (H x W x D)

NEMA 4X – 17.35” x 15.96” x 6.80”

(440.7 mm x 405.4 mm x 172.7 mm)

Weight

NEMA 4X – 17.6 lbs (8 kg)

Power

100-240 V~, 47-63 Hz, 74 W

E

nvironmental

Installation Category II

Pollution Degree 2

For Indoor/Outdoor Use

Maximum Operating Altitude 2000 meters

De

gree of Protection

(NEMA en

closure) IP65 (NEMA 4X)

Anal

og Output 0 – 5 V or 4-20 mA isolated output

Status Outputs

Sensor OK, Invalid Reading, Check Lamp, Pneumatic Error

High Current Relay Outputs

SPDT (Form C) Dry Contact, 250VAC, 5A

(System OK, Global HI alarm, Global HI-HI alarm)

Communication Int

erface Ethernet

RS-232/RS-485

12 Teledyne API Model 480H O3Monitor User Manual 09421A DCN8343

2.2. APPROVALS

This section presents Safety and Electromagnetic Compatibility (EMC) compliance

approvals for the Model 480H monitor.

2.2.1. SAFETY

IEC/EN 61010-1:2010 (3rd Edition), Safety requirements for electrical equipment

for measurement, control, and laboratory use.

2.2.2. EMC

IEC/EN 61326-1:2010, Class A Emissions/Industrial Immunity

FCC 47 CFR Part 15B, Class A Emissions

2.2.3. OTHER TYPE CERTIFICATIONS

For additional certifications, please contact Technical Support:

Toll-free: +1 800-324-5190

Phone: +1 858-657-9800

Fax: +1 858-657-9816

Email: api-techsupport@teledyne.com

09421A DCN8343 Teledyne API Model 480H O3Monitor User Manual 13

3. GETTING STARTED

WARNING – RISK OF DEATH OR SERIOUS INJURY!

To reduce the risk of death or serious injury from a

chemical/combustion explosion hazard due to flammable

gases/vapors/liquids, never allow contaminants to enter monitor

during installation or use. The combination of ozone and the catalytic

ozone destruct media in the monitor can produce strong oxidation

reactions. Never allow organic contaminants, including but not limited

to peroxides and chlorates, into monitor.

Figure 3-1. Model 480H Display and Control Panel

14 Teledyne API Model 480H O3Monitor User Manual 09421A DCN8343

3.1. UNPACKING

Upon receiving the 480H please verify that there is no apparent shipping damage.

(If damage has occurred please advise shipper first, then Teledyne API).

Check your packing slip for options that may be included, depending on your order,

e.g., disposable sample inlet filters.

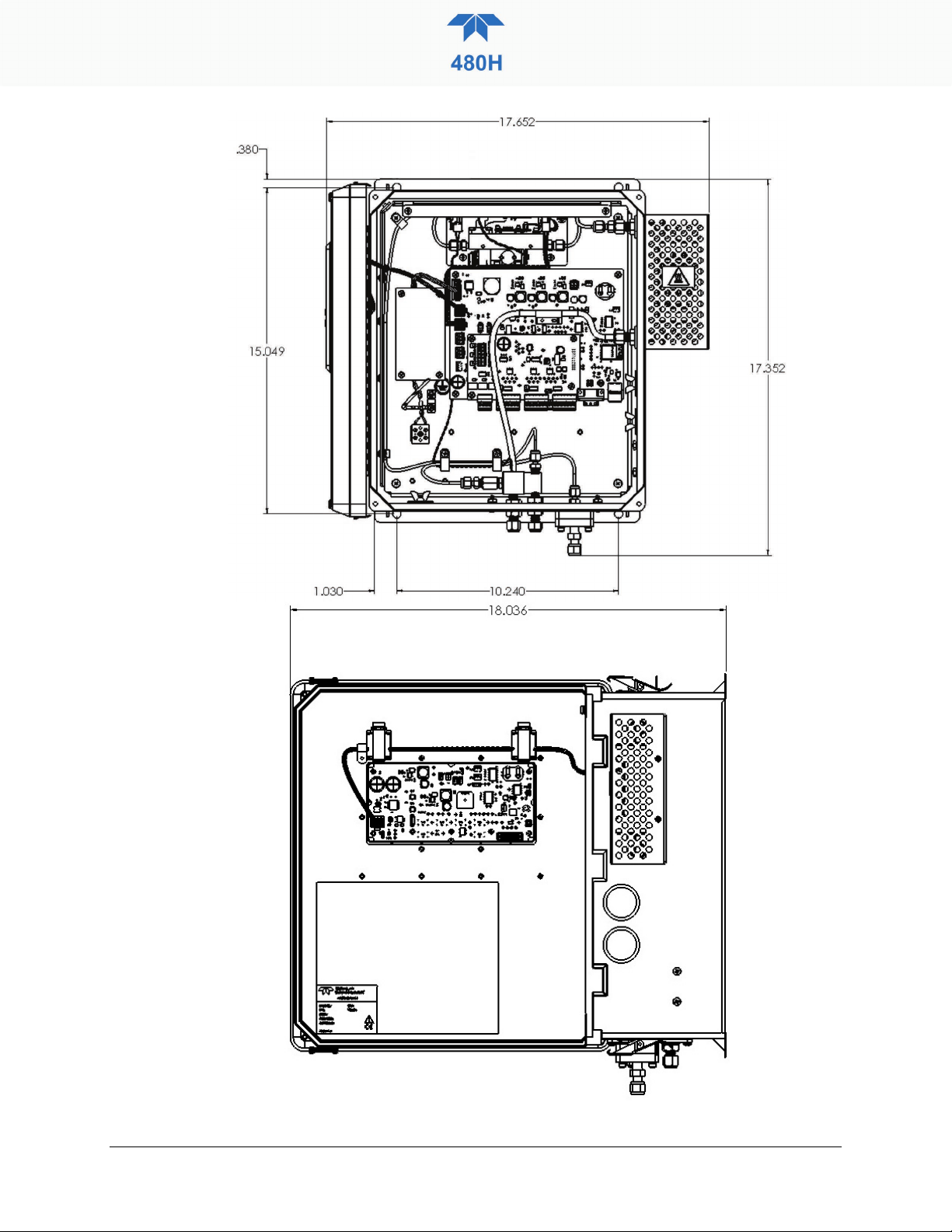

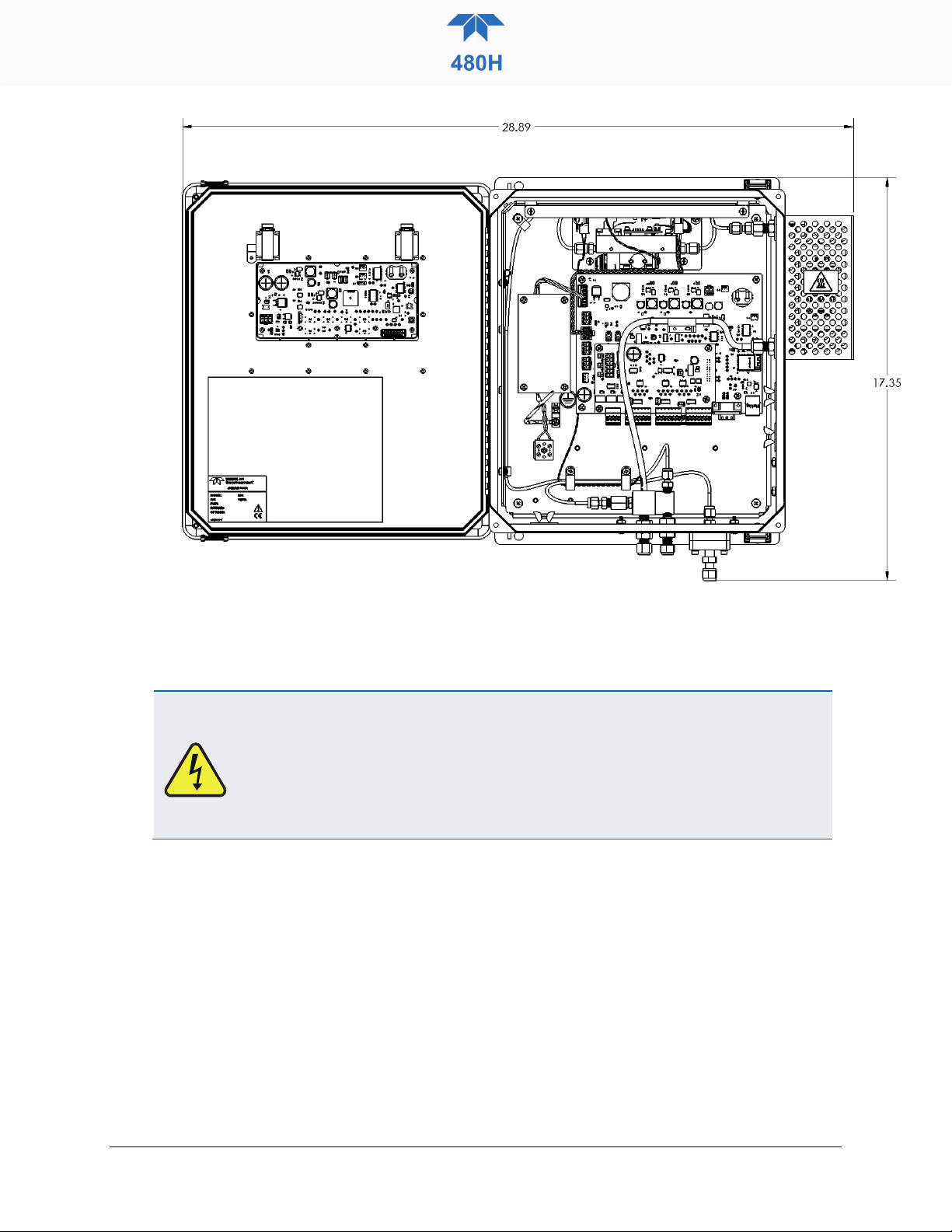

3.2. MECHANICAL INSTALLATION

When installing the monitor be sure to leave sufficient clearance on sides, top, and

bottom for adequate ventilation and for access to make/adjust all connections. The

monitor must be mounted securely with four (4) bolts or anchors to a vertical

structure or wall capable of supporting 80 lbs. The mounting bolts or anchors must

be capable of supporting 20 lbs each. If using wall anchors, they must be suitable

for the type of wall construction and installed per the manufacturer’s specifications.

•The illustrations in Figure 3-2 show the mounting dimensions and the

locations of the four mounting holes, which are 0.32” (8.128 mm)

diameter

•All four mounting holes should be used to secure the monitor.

•If using bolts, ensure they are stainless steel, 5/16” (8 mm) diameter,

capable of supporting 20 lbs each.

09421A DCN8343 Teledyne API Model 480H O3Monitor User Manual 15

16 Teledyne API Model 480H O3Monitor User Manual 09421A DCN8343

Figure 3-2. 480H Dimensions

3.3. AC POWER CONNECTION

WARNING – Electrical Shock Hazard

Disconnect power to the AC mains before making or removing any electrical

connections to the monitor.

A proper earth ground connection must be made to the receptacle labeled

“Earth Ground” on the 3-pin AC connector. Failure to do so may result in a

shock hazard and malfunction of the monitor.

3.3.1. WIRING REQUIREMENTS

Use appropriate wiring rated for this type of equipment, ensuring that it meets local

and national safety and building requirements.

Ensure that overcurrent protection is used (a 5 A circuit breaker is

recommended), and that it fulfills the following requirements:

•be located as near to the instrument as possible

•quickly and easily accessible

•clearly labeled as the disconnecting device for this instrument

09421A DCN8343 Teledyne API Model 480H O3Monitor User Manual 17

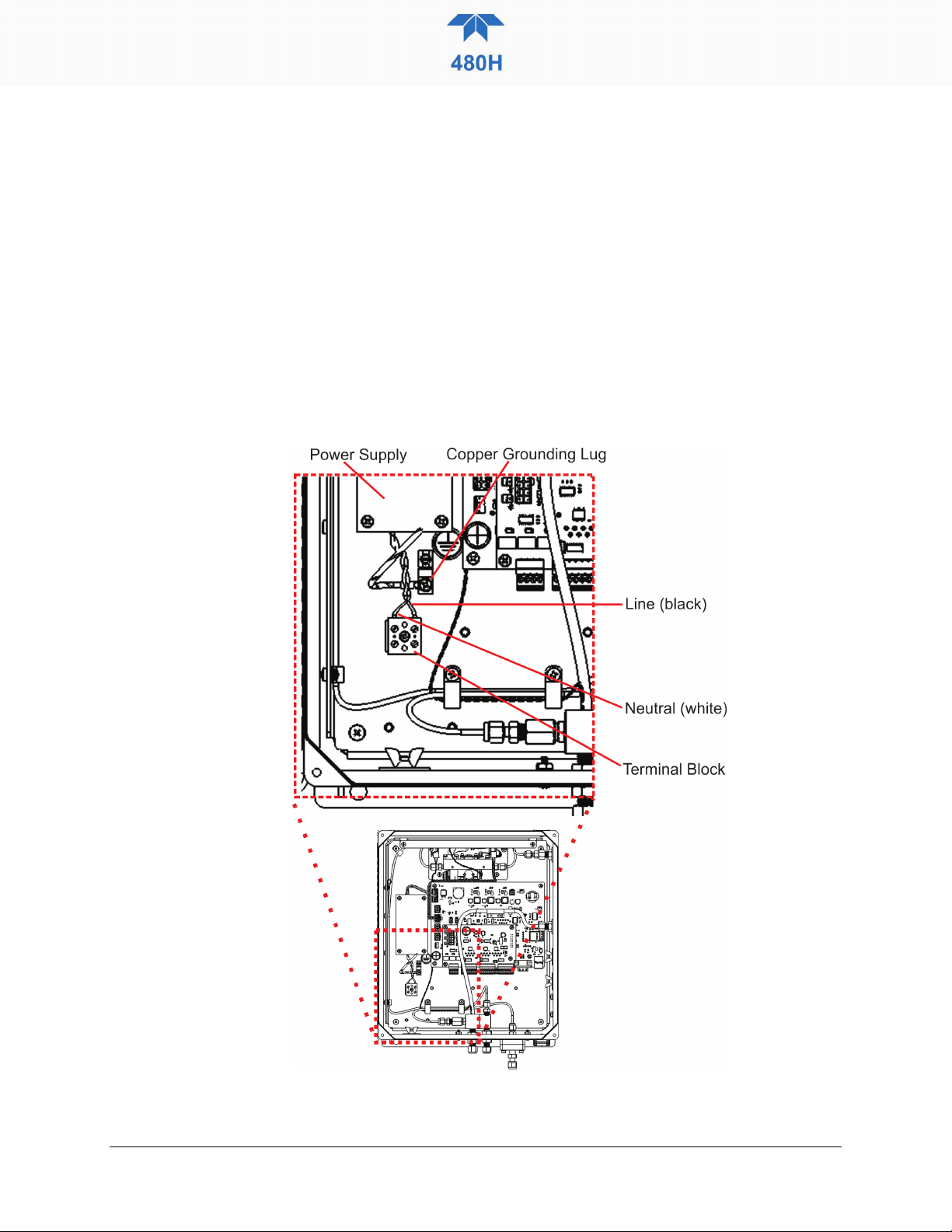

3.3.2. WIRING INSTRUCTIONS

1. Install a ½” conduit fitting for routing the electrical wiring into the monitor

through the hole provided in the bottom face of the NEMA enclosure; an

appropriate sealed conduit connector should be used.

2. Hard-wire the electrical connection to the terminal block and grounding lug on

the chassis. AC power connection to the monitor should be made with 12-14

AWG stranded copper wire, connected to the monitor as follows:

•Earth Ground (green):Connect the earth ground wire to the copper grounding lug

•Line (Black):Connect the Line wire to the terminal block directly across

from the black wire that leads to the power supply

•Neutral (White):Connect the Neutral wire to the terminal block directly

across from the white wire that leads to the power supply.

Figure 3-3. AC Power Connection to Monitor

18 Teledyne API Model 480H O3Monitor User Manual 09421A DCN8343

1. Connect the power cord to an appropriate power outlet or hardwired connection (see

the serial number tag for correct voltage and frequency).

WARNING

Verify that the instrument specification for proper line

voltage and frequency is followed. Observe local electrical

codes when connecting power to the monitor.

2. Turn on the 480L by applying power to the monitor. The front panel display will light

and display a Teledyne splash screen. The home screen will display the ozone

concentration and flow after the monitor begins taking stable readings.

3.4. ELECTRICAL I/O CONNECTIONS

The I/O connectors are located internally in the instrument. See Figure 3-4 for their

locations. Connection to these terminals is usually made via a conduit connection to

the enclosure. There are two conduit penetrations on the enclosure, and an

additional penetration can be added to one of the walls of the enclosure if needed.

Table of contents

Other TELEDYNE API Monitor manuals