Information included herein is controlled by the Export Administration Regulations (EAR) and requires an export license, license exception or

other approval from the appropriate U.S. Government agency before being exported from the United States or provided to any foreign person.

Diversion contrary to U.S. law is prohibited.

ACCQPrep Pump Assembly

Replacement and HP150 to

HP125 Pump Assembly

Conversion Instructions

Instruction Sheet #69-5233-940

Revision A, Jan 2, 2020

Overview

The ACCQPrep replacement pump assembly contains

a pump sled assembled for a HP150 instrument, parts

to convert the pump assembly to be used on a HP125

instrument, and parts to convert the old Valco pump

bulkhead brackets and fittings to Swagelok on older

HP125 instruments. If the replacement pump assembly

is being installed on an HP150 configured ACCQPrep,

then no conversion work needs to be completed before

installing the replacement pump assembly.

Table 1: Parts List

Item Quantity

Replacement Pump Assembly 1

Swagelok Bulkhead Assembly 1

The table below lists additional items that are required

for the pump assembly conversion:

Table 2: Required Tools

Safety

The use of Personal Protective Equipment (PPE) is highly

encouraged due to potential contact with residual solvents.

Time Required:

Typical time required to perform the pump greasing is

approximately 1.5 hour.

Note

If the Swagelock Bulkhead Assembly (60-5237-141) will

be installed with the replacement pump, then use these

instructions to complete the work and ignore the

installation instructions (69-5233-941) that come with

the Swagelok Bulkhead Assembly.

Removing Solvent & Powering Down

the Instrument

1. Remove all solvent supply lines from the solvent

containers.

2. Remove the lower front cover of the instrument to

expose the front of the current pump assembly

3. Select Tools > Manual Control from the upper tabs

of the main screen of the instrument.

4. Set the Flow Path to “Prep HPLC column”. Set the

Flow Rate, ml/min to 50.

5. If the instrument does not include a Solvent Select Valve,

then proceed to Step 6, else Set Solvent A to one of the

plumbed solvent lines and Solvent B to another of the

plumbed solvent lines (ex: A1 - Methanol, B1-Water, etc.).

6. Press the Pump Solvent A button. Allow the pumps to

run until there is no longer solvent flowing to the bottom

of the A pumps. Press the Stop button. Press the Pump

Solvent B button and repeat this process for the B pumps.

7. Shutdown the instrument by toggling the red power

switch on the front of the instrument.

8. Wait 30 seconds after the touchscreen turns off and

then disconnect power to the instrument either by

disconnecting the power cable at the back of the

instrument or at the wall outlet.

Removal of the Current Pump Assembly

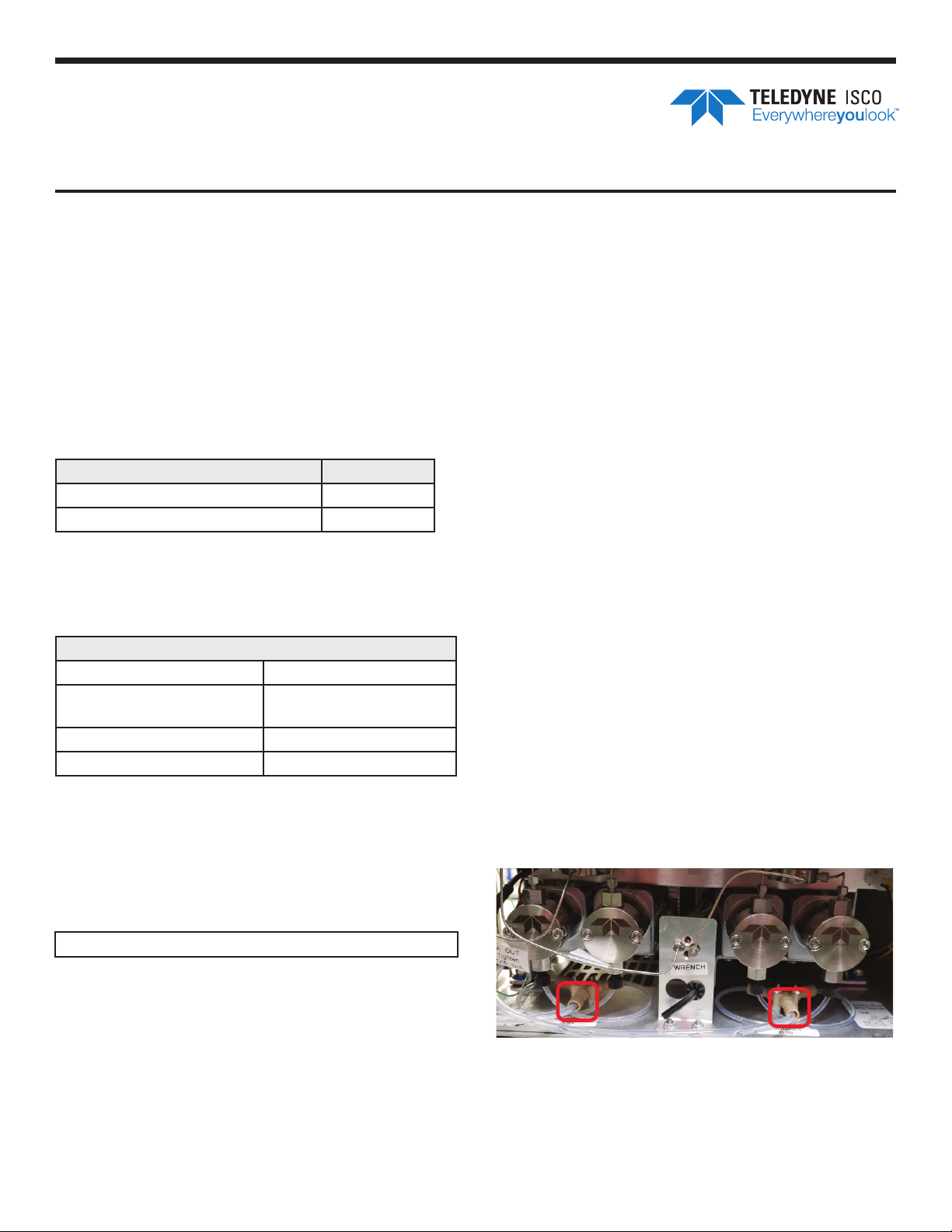

1. With your fingers, disconnect the input tube at

Y-connector below each set of pumps (Figure 1). If the

fittings are too tight to be disconnected by hand, then

gently use a pliers to loosen the fitting enough to finish

disconnecting it by hand.

Figure 1: Y-Fitting inlet tubing

Item

#2 Phillips Screwdriver

1/8” Small Flathead

Screwdriver

5/16” Open End Wrench

1/4” Open End Wrench

Side Cutter

5/16” Nut Driver or

Rachet (optional)

Pliers

1/4” Rachet (optional)