Telegan Tempest 50 User manual

CONTENTS

Section

INTRODUCTION 1

INSTRUMENT FEATURES 2

Standard Features 2.1

Options & Upgrades 2.2

Accessories & Consumables 2.3

Default Settings 2.4

TEMPEST GRAND TOUR 3

Left: Physical Connections3.1

Centre: Control Panel 3.2

Right: Printer & Communications 3.3

QUICK START 4

Before Starting 4.1

Switching On 4.2

Operation Mode 4.3

Probe Position 4.4

Taking an Emissions Reading 4.5

Printing (if option available) 4.6

Switching Off 4.7

HARDWARE SET UP 5

Power Requirements 5.1

Battery Operation 5.1.1

Mains Adapter 5.1.2

12v DC Adapter 5.1.3

Sample Probe Attachment 5.2

Printer Roll Insertion 5.3

Filter Unit 5.4

Assembly 5.4.1

Filter Replacement 5.4.2

Water Removal 5.4.3

Exhaust Removal 5.5

OPERATION 6

Principal Keys 6.1

First Menu Page 6.2

Second Menu Page 6.3

SPECIFICATIONS 7

1. INTRODUCTION

Congratulations on buying your Tempest 50 combustion

performance analyser. The unit has been carefully designed and

includes the latest technology to give you an instrument that is easy

to use, reliable and accurate.

The Tempest 50 is part of a new family of instruments from

Telegan, a company with over 15 years of combustion

instrumentation experience. It measures the oxygen (O2) and

carbon monoxide (CO) content of tested flue gas and the flue,

ambient, inlet and nett temperatures. It calculates the carbon

dioxide (CO2) content of the flue gas as well as the nett or gross

percentage boiler efficiencies for a wide range of different fuels.

The Tempest 50 is rugged and has been designed for a tough life

with heating professionals. Its wipe-clean touch panel allows you

to achieve the results you need quickly and simply, without the risk

of moisture or dust damaging the contents. As you will see from

this manual, much of the instrument’s operation can be done with

just three buttons.

Several options are available with the TEMPEST 50. These can be

specified for delivery with the instrument or can be added later.

They include a built-in printer, pressure/draught measurement,

nitric oxide (NO) measurement and total nitrogen oxides (NOx)

calculation, display back-light and RS232 output for other devices.

If you would like to add any of these options please contact our

sales office (see back cover for details).

This manual will show you how to get the best out of your new

TEMPEST 50. Section 3 shows you the layout of the instrument.

Go straight to Section 4 to start using your TEMPEST 50. If you

have any questions please contact us. Thank you very much for

buying our product -we wish you many years of successful use.

2. INSTRUMENT FEATURES

2.1 Standard Features

TEMPEST 50 offers the following standard features and functions:

•flue, ambient, inlet and nett temperature measurement (oC or oF)

•% oxygen (O2) with calculated % carbon dioxide (CO2) for a range

of standard fuels i.e. natural gas, light oil, propane, heavy oil, coal

and coke

•carbon monoxide (CO) in parts per million (ppm)

•& combustion efficiency and excess air

•CO/CO2ratio

•real time clock

•advanced menu driven software

•tactile push button membrane keypad

•integral combined water-trap and particulate filter

•soft carrying case for instrument and probe

2.2 Options and Upgrades

•high level CO sensor (20 x concentration range)

•nitric oxide (NO) sensor and calculated total nitrogen oxides (NOx)

•pressure/draught measurement

•sample conditioning probe

•integral impact dot matrix printer

•backlit display

•additional fuels

2.3 Accessories and Consumables

The following accessories and consumables are available:

Part Number

Protective aluminium case CAS20014

Soot testing kit for measuring particulates OPT20038

Long probe (1 metre) PRB20062

High temperature probe PRB20061

12v Adapter CHG99002

Particulate filters (minimum 5) FIL20019

Coalescing filters (minimum 5) FIL20021

Printer rolls PAP20053

2.4 Default Settings

Feature Default

Setting Alternatives See Section

Standard

Temperature OCoFKey 6 in 6.2

Fuel Natural Gas (See 2.1) Key 2 in 6.2

Efficiency Basis Gross Nett Key 8 in 6.2

Time UK time Any Key 0 in 6.1

Date DD-MM-YY MM-DD-YY Key 0 in 6.1

Options

Pressure Units mbar Inches WG Key 2 in 6.3

Print-out Interval 1 minute 1,3,5,10,20 &

30 minutes Key 1 in 6.2

Timed Print-out Off On Key 1 in 6.2

Backlit Display Off On Key 4 in 6.1

3. TEMPEST GRAND TOUR

This chapter describes the layout of the TEMPEST 50 unit and gives a

brief introduction to the physical and electrical connections, the keypad

details and functions and the various output devices which include the

display, printer and indicator lights. The top panel is broadly divided into

three sections as follows:

Left: Physical Connections which include the various ports and

thermocouple sockets.

Centre: Control Panel which includes the keypad layout, display and

indicators.

Right: Printer and Communications Ports which includes the printer,

charger input socket and the communications ports.

3.1 Left: Physical Connections

This section shows how to connect the sampling probe, thermocouples

and other accessories to the TEMPEST 50 unit. Please refer to Figure 1

for the following reference numbers.

Ref

No

Name

Description/Function

1Sample Port The port through which the sample gas to be analysed

must pass. The sample line from the probe should be

fitted to the spigot of the sampling port for emissions

measurement.

2Auxiliary Port Used with a sample conditioning probe, if chosen as an

option.

3Pressure Port The sample line from the probe should be fitted to the

spigot of the pressure port for pressure/draught

measurement, if chosen as an option.

4Stack

Thermocouple

Socket

Socket for the thermocouple plug attached to the

sampling probe. When connected the TEMPEST 50

will measure the temperature at the tip of the probe.

5. Intake

Thermocouple

Socket

Socket for a thermocouple plug that may be attached to

an auxiliary thermocouple placed in the intake gas

stream. If this is not fitted a spot measurement of the

temperature of the intake gas may be measured using

the standard sampling probe.

6. Vent Auxiliary vent for use with the sample

conditioning probe.

3.2 Centre: Control Panel

This section details the control panel area which is used to operate the

TEMPEST 50 unit. It incorporates a keypad, display and various

indicators (Refer to Figure 2 Centre : Control Panel).

Ref

No

Name

Description/Function

7Power On/Off Keys These two keys must be pressed

simultaneously to switch the unit on and off.

This prevents the unit from being turned off

accidentally during operation.

8Battery Recharge

Indicator An illuminated green LED next to the battery

symbol indicates that the internal battery is

being charged by an external power source.

9Power Indicator An illuminated red LED next to the on/off

symbol indicates that the unit is switched on

and receiving power from either the internal

battery or an external power source.

10 Display The area where all the information regarding

the current mode of operation of the

TEMPEST 50 is displayed.

11 Keypad Allows the operator to control the unit and

access the TEMPEST 50 functions using

simple keystrokes. The positions of the

principal keys are shown in Figure 2 and a

tabulated brief description of their functions is

given in Table 1 : Quick Key Reference

(centre page).

3.3 Right : Printer and Communications

This section describes the physical layout of the integral printer (if

fitted as an option), the charger input socket and the various

communications ports used to send emissions data to external

devices (Refer to Figure 3 Right : Printer and Communications

Ports).

No. Name Description/Function

12 Printer Cover Protects the printer unit from damage

while allowing easy access for

replacement and insertion of the

printer roll and ribbon

13 Paper Slot The printer paper roll should be fed

through the paper slot which also acts

as a sharp cutting edge to tear the

paper.

14 Printer Cover

Catch Click-tight catch that holds the printer

cover in place.

15 RS232 Port If chosen as an option, the RS232

communications port allows the

TEMPEST to send emissions data to a

suitable terminal or data logging

hardware.

16 Charger Socket Receiving socket for either the mains

charger or the 12V DC charger.

17 Parallel Port Performs no function for the

TEMPEST 50. An additional

communications port for higher

specification units.

4. QUICK START

This reference section will enable the user to operate the TEMPEST

50 quickly. However, it is advisable to consult the relevant sections

to familiarise yourself with the layout of the TEMPEST 50 (Section

3 -Tempest Grand Tour). For a more detailed explanation of the

set up conditions see Section 5 and for key operations see Section 6.

4.1 Before Starting

Check that the contents supplied (Section 2) are in good condition.

Always use the TEMPEST 50 in the upright position.

4.2 Switching ‘On’

Press the on and off keys together.

4.3 Operation Mode

When switched on the display will read:

----------------

***T

E

L

E

G

A

N

***

**T

E

M

PE

ST

50**

----------------

unless specially configured for you

The display will then countdown a stabilising or calibrating

sequence from 30 to 0 as the unit stabilises before returning to the

initial display as illustrated above.

Listen to check that the pump is running.

Check the current battery charge level by pressing key ‘O’

and reading the percentage battery charge remaining

(Battery (%)):

?If the level is below 40% then it is advisable to change the

battery

? If the level is below 10% then the low battery warning will

be displayed and the battery must be changed.

? The TEMPEST 50 can be used normally with the battery

charger connected.

Check that the fuel setting is correct. This is shown below the

Battery (%) status on the display. To select a different fuel press

the menu key once (refer to the Quick Key Reference) then select

option 2 and scroll through the list of standard fuels using the up

and down cursor keys (keys 1 and 5). Select the desired fuel when

displayed (refer to 2 in Section 6.2).

4.4 Probe Position

Select the sampling probe and fit the sample tubing to the sample

port of the TEMPEST 50 unit (1 in Fig 1) and the thermocouple

plug to the stack thermocouple socket (4 in Fig 1). Position the

probe in the flue to take the required sample.

4.5 Taking an Emissions Reading

Press key ‘8’ to obtain the emissions data i.e. the carbon monoxide

concentration plus the nitric oxide and calculated NOx(when fitted

as an option).

Press key ‘9’ to obtain the efficiency data, which includes the

carbon monoxide and oxygen concentrations, the excess air,

calculated carbon dioxide concentration, ratio and efficiency for the

selected fuel.

4.6 Printing (if option available)

To obtain a print-out press key ‘1’.

4.7 Switching ‘Off’

Remove the fitted probe and allow the pump to empty the

TEMPEST 50 of flue gas for about 60 seconds. Switch off by

pressing both ON / OFF buttons together as in 4.2. In transport

ensure that the filter bowl is empty of water (refer to 5.4.3).

5. HARDWARE SET-UP

5.1 Power Requirements

The TEMPEST 50 unit can be powered in three ways:

1. Internal rechargeable battery

2. Mains charger and connector

3. 12 V DC charger for use in a vehicle

5.1.1 Battery Operation -the TEMPEST 50 is designed for

battery operation enabling 4-6 hrs continuous use. Fully recharging

the cell takes less than 2 hrs. The approximate percentage battery

charge remaining can be identified by pressing the STATUS key

(Refer to 0 in 6.1) when the unit is switched on. During operation a

low battery warning will indicate when recharging is necessary.

The internal battery will recharge automatically when the unit is

connected to either the mains (Section 5.1.2) or a 12 V DC power

source (Section 5.1.3) and the green power indicator next to the

battery symbol (9 in Fig 2) will illuminate to indicate that the unit is

charging whether the unit is operating or not.

5.1.2 Mains Adapter -the TEMPEST 50 unit can be run

continuously from a mains socket using the standard mains charger

supplied. This adapter should be inserted into the charger socket (16

in Fig 3). To quick-charge (in 2 hours) the unit must be switched on,

otherwise the charging time will be greater than 5 hours.

5.1.3 12 V DC Adapter -the TEMPEST 50 unit can also be run

continuously or charged from a normal car battery via the cigarette

lighter socket using an optional 12 V DC adapter. The power

connector leading from the adapter should be inserted into the

charger socket (16 in Fig 3).

5.2 Sample Probe Attachment

The sample tubing should be connected to the sample port (1 in Fig

1) or pressure port (3 in Fig 1) depending on which measurement is

being performed (emissions or draught measurement, respectively).

The yellow thermocouple plug should be correctly inserted (thinner

pin marked + to the left) into the stack thermocouple socket (4 in

Figure 1) for stack temperature measurement.

The user must ensure that the sample tubing is not bent, blocked or kinked

in such a way that the gas cannot be drawn through the unit. When the

sample line is blocked the pump and motor unit will begin to labour

generating increased noise.

5.3 Printer Roll Insertion

The printer cover (12 in Fig 3) can be flicked up by unfastening the printer

cover catch (14 in Fig 3). The paper roll should be placed in the

compartment so that the free end is drawn from below the roll and feeds

towards the front of the unit. A short length of the paper roll (4-8cm)

should be unwound and fed through the printer mechanism by press Key 2

-Paper Feed until the paper is visible. The paper should be fed through

the paper slot (13 in Fig 3) in the printer cover and the cover should then

be shut. Excess paper should be torn off by pulling against the sharp edge

of the paper slot. The printer should now be fully operational.

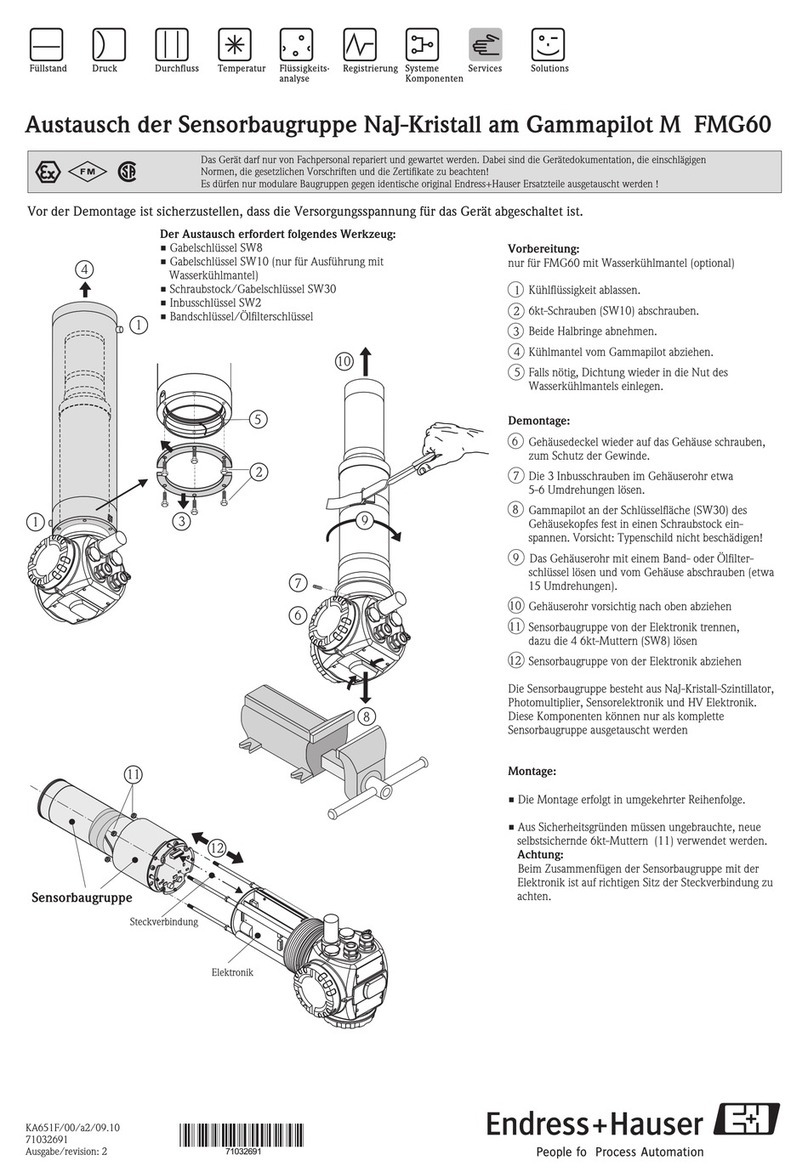

5.4 Filter Unit

The internal structure of the filter unit (Fig 4) consists of two separate

filter elements (e and f) that are attached at one end to the TEMPEST 50

unit (g) and separated at the bottom by the filter inner disc (d) which

allows water to pass through the assembly to the receiving filter bowl (b).

A gasket (c) is fitted to the filter inner disc to form a seal between the filter

inner disc and the filter bowl.

5.4.1 Assembly -to assemble the filter unit for the initial set up or to

replace damaged filter elements the TEMPEST 50 unit should be turned

upside down after ensuring that the filter bowl has been drained completed

(Section 5.4.3). The filter bowl (b) should be unscrewed clockwise and

removed from the unit. The coalescing and particulate filter elements (e &

f respectively) should be aligned and pushed down onto the TEMPEST 50

unit (g). The gasket (c) should be pushed onto the filter inner disc (d)

which should subsequently be pushed down onto the 2 filter elements (e &

f). Ensuring that the ‘O’ ring (h) is present in the base of the TEMPEST

50 (g) align the filter elements and fittings with the filter bowl (b) and

press against the ‘O’ ring and gasket / filter inner disc. Screw anti-

clockwise until the bowl locks into place and is held securely.

This action simultaneously exerts a compressive force upon the gasket,

pushing the filter inner disc upwards and producing a tight fit between

the filter elements, the inner disc and the filter bowl.

Before sampling can commence, ensure that the filter drain plug (a)

is inserted into the base of the filter bowl (b).

5.4.2 Filter Replacement -it is advisable to replace the filter

elements (e & f in Fig 4) when they appear dirty (see re-ordering

information on back page) to prevent filter inefficiency due to

blockage from particulate contamination or water saturation.

Following removal of the filter bowl (as described in 5.4.1) the filter

elements stick due to compression of the filter material and they can

be removed gently by pulling the filter inner disc (d) and gasket (c)

from the filter assembly. The filter elements should be discarded, if

damaged or irretrievably contaminated (see above), or reclaimed by

drying if water saturated. The filter unit should then be reassembled

as described previously (5.4.1).

5.4.3 Water Removal -the water level in the transparent filter bowl

(b) can be observed during operation from the side of the unit and

the filter bowl should be drained of water at any convenient time,

such as before sampling, or before the water level reaches the base of

the filter inner disc (d) and gasket (c). When draining the filter bowl

the sampling pump of the TEMPEST 50 unit should be switched off

(refer to Section 6.3, 6 -Pump (On / Off)) and no emissions data (8

in Section 6.1) should be collected during this short period of time.

The filter bowl drain plug (a) should be removed from the filter bowl

(b) and water allowed to drain away completely. It should be noted

that removing the filter bowl drain plug will allow the ambient

atmosphere to dilute the sample gas stream in the unit and no

emissions data should be collected until this residual air has been

thoroughly flushed through the sampling system. After reactivating

the pump (see 6.3, 6 Pump (On / Off)) allow 60 seconds to

thoroughly flush the sampling system.

5.5 Exhaust Removal

If the instrument is to be used in a confined space, the exhaust gases

that exist the TEMPEST 50 unit following analysis can be vented away

from the user. Attach a suitable connector or flexible tube with the

required minimum internal diameter (15mm) to the exhaust spigot

located on the base of the unit. Care must be taken to ensure that this

vent is not blocked in any way that would prevent the transport of

exhaust gas along the tubing.

6. OPERATION

The TEMPEST 50 unit is operated using the membrane keypad located

on the top of the unit (11 in Fig 2) and a brief description of the

specific key functions is given in Table 1 (Quick Key Reference). A

comprehensive guide to the operation of the unit using the Principal

Key Operations (Section 6.1) and menu operations (Sections 6.2 &

6.3) follows:

6.1 Principal Keys

ON / OFF

The TEMPEST 50 unit can be switched on / off by simultaneously

pressing the two keys shown above.

A red light (9 in Figure 2) will indicate that the unit is on and a

characteristic beep will be heard before the start up screen is

displayed:

----------------

***T

E

L

E

G

A

N

***

**T

E

M

PE

ST

50**

----------------

(Note: This may be configured slightly differently in some cases.)

A green light (8 in Fig 2) will indicate that the unit is connected to a

charger unit. The characteristic noise of the pump will be heard unless

the charger unit is connected, the oxygen concentration is > 20% and

either the flue probe is not connected or the stack temperature is <

50oC=112oF. The unit will immediately begin a stabilising routine and

the following numeric countdown will be displayed, where [X] = 30 to

1:

----------------

ST

A

B

IL

ISIN

G

[X

]

----------------

The start up screen is displayed once again (see above) indicating

that the unit is now ready to perform emissions monitoring

functions.

1 Print (Optional)

Pressing the print function key will print the emissions data in the

following format (see below).

All temperature (Key 7 -Temperature) emissions (Key 8 -

Emissions) and efficiency (Key 9 -Efficiency) data will be printed.

If the probe is not attached correctly (Section 5.2) or the stack and

intake thermocouples are not connected then the temperature data

will not be printed.

If the optional pressure or nitric oxide (NO) sensors are not fitted

then the respective data will be absent from the print-out and

display.

----------------

***T

E

L

E

G

A

N

***

**T

E

M

PE

ST

50**

D

A

T

E

09-19-02

T

IM

E

15:11:06

N

A

T

U

R

A

L

G

A

S

A

M

B

IE

N

T

C

23

ST

A

C

K

C

187

N

E

T

T

C

162

IN

T

A

K

E

C

25

O

2%

....16.3

C

O

ppm

.....35

C

O

2%

.....3.5

X

A

IR

%

95

R

A

T

IO

E

FF%

(N

)85.5

Prs.m

B

ar975

N

O

ppm

.....15

N

O

xppm

.....18

----------------

While printing the following message will be displayed:

----------------

---PR

IN

T

IN

G

---

O

N

----------------

If at any time the user wishes to stop the printout the hold button

(Key 5 -Hold) should be depressed.

2 Paper Feed (Optional)

Pressing the paper feed function key will advance the paper roll by

one line of print and the following message will be displayed:

----------------

PA

PE

R

FE

E

D

----------------

3 Data Output (Optional)

Pressing the data output function key will send emissions data

through the RS232 socket so that the data may be accessed using a

suitable terminal. If this key is pressed the following message will

be displayed:

----------------

D

A

T

A

O

U

T

PU

T

----------------

Table of contents

Other Telegan Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Tankvision Gauge Link NXA20 operating instructions

THORLABS

THORLABS PM200 quick reference

Sylvac

Sylvac S_Dial WORK ANALOG Smart instructions

Variable

Variable Spectro 1 Getting started

ATI Technologies

ATI Technologies 2i Operation and maintenance manual

Teac

Teac TU-GR-G Instructions for use