Telegan Anton Sprint V2 User manual

User Manual

INS 29612

November 2011

Issue 6

Multi-function flue gas analyser

Tel: +44 (0) 870 428 0075

Fax: 870 428 0076

www.anton-group.com

+44 (0)

Anton Group

Tel: +44 (0) 870 428 0075

ANTON

V2.2 i1.05

Safety information:

• Read and understand all instructions in the operation

section of this manual before use.

• Do not substitute components as this may impair safety

and invalidate warranty.

• Observe all warnings and instructions marked on the

unit and within this manual.

• If this product is not working properly, read the trouble-

shooting guide or call Anton.

• Ensure qualified service personnel change sensors and

provide maintenance and calibration.

Additional information:

Sprint is designed to support the working practices defined

in British Standard BS7967 and the Design Standards

EN50379, BS7927 for flue gas analysers. It is highly

recommended that users are fully conversant with BS7967

when using a flue gas analyser for servicing or installing a

boiler system.

Sprint offers a timed let-by/tightness test in accordance

with the UK's Institute of Gas Engineers' procedure IGE/11/

UP/1B.

Performing CO measurements

When performing any CO measurements ensure the unit

is zeroed in clean air in accordance with British Standard

BS7967. A suitable location for sampling clean air will be

outside of the building where the boiler system is installed.

1. Repair of this equipment and gas sensor replacement

shall be carried out by the manufacturer or certified

service centre in accordance with the applicable code

of practice.

2. If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility of the

user to take suitable precautions that prevent it from

being adversely affected.

3. The equipment is designed for use in ambient tempera-

tures in the range -10°C to +50°C and should not be

used outside this range

4. Use only charger(s) supplied by Telegan/Anton.

5. Use only the appropriate Telegan/Anton supplied cables

for connection to the sockets on the instrument.

© Copyright Telegan Gas Monitoring 2011.

All rights are reserved. No part of the document may be photo-

copied, reproduced, or translated to another language without the

prior written consent of Telegan Gas Monitoring

Publication number: INS 29612

Fifth edition: September 2011

Summary of Screen Icons

þSelect, pick or action

éUp item or entry

êDown item or entry

çLeft field

èRight field

P=0

Zero pressure

u

Start

(Pressure & CO Room Safety tests)

Stop

(Pressure & CO Room Safety tests)

¢

tt

Restart

(Restart timer)

üYes, pass or done

ûNo or fail or cancel

Purge icon

Hold / pause readings

T2

T1

Select temp 1 (flow)

(Differential Temperature test)

T2

T1

Select temp 2 (return)

(Differential Temperature test)

<Save log

Print

Send XML report to Bluetooth®

(V3+V5 only)

Serial communications with PC in

progress – please wait

Delete

>

Darker contrast

>

Lighter contrast

–

–

Restore default contrast

–

+

Edit value

+

Increment value

–

Decrement value

Decrement through character list

(String edit)

Increment through character list

(String edit)

Logging busy

CO Alarm

ηSelect Net/Gross/NetHE Efficiency

Bluetooth® is a trademark owned by Bluetooth SIG, Inc.

and licensed to Crowcon Detection Instruments Ltd

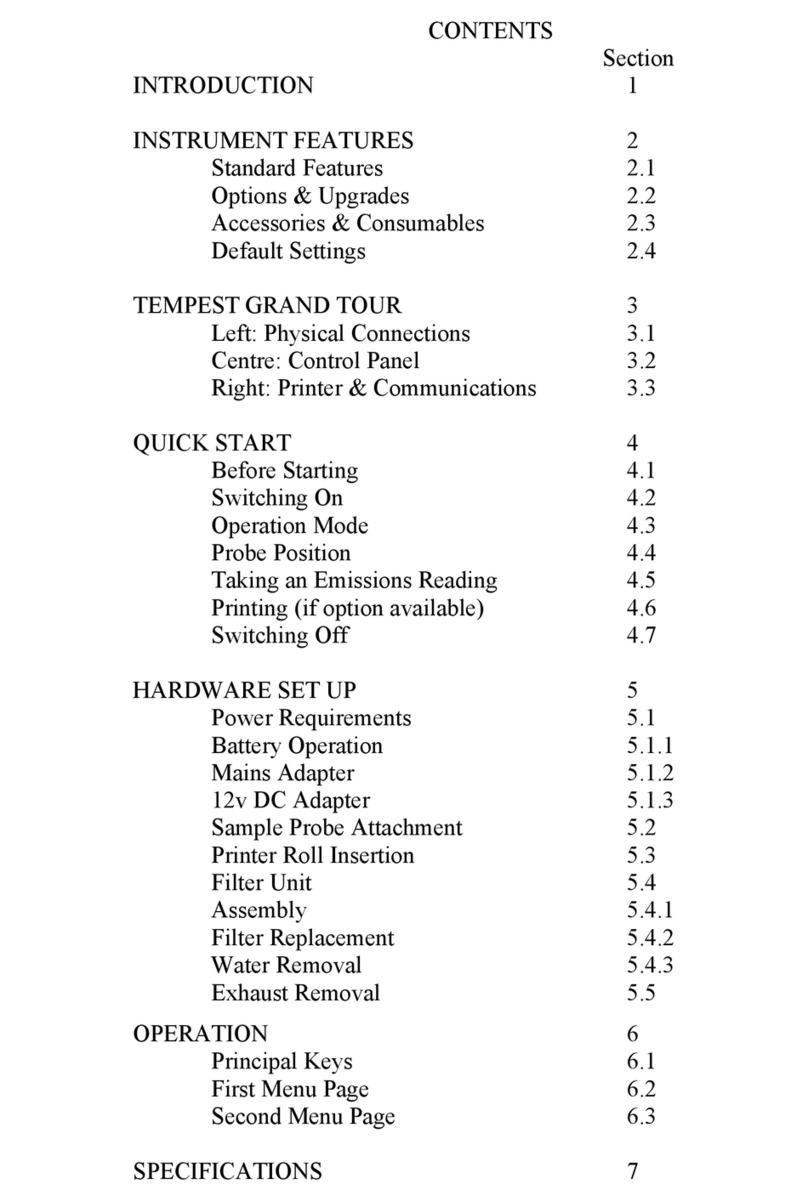

Contents

Sprint V2/V3/V4/V5Multi-function Flue Gas Analyser ............2

Unpacking..............................................................................................2

Overview................................................................................................3

Probe connections..................................................................................4

Quickstart Guide...................................................................5

I. Operation ........................................................................14

1.1 Menu and operator button overview ..............................................14

II. Setting Up .....................................................................16

2.1 Configuration Options ...................................................................16

III. Battery Charging............................................................19

Charging the batteries..........................................................................19

IV. Maintenance and calibration..........................................20

4.1 Unit................................................................................................20

4.2 Water trap......................................................................................20

V. Specification ...................................................................21

VI. Accessories and spare parts ...........................................23

Accessory list........................................................................................23

VII. Logging ........................................................................24

VIII. Printing and Data Transfer............................................25

IX. Troubleshooting guide ...................................................26

Appendix I: Carbon Monoxide Room Safety Tests ...............28

2

Unpacking Sprint V2/V3/V4/V5

Sprint V2/V3/V4/V5

Multi-function Flue Gas Analyser

Thank you for purchasing the Sprint V2/V3/V4/V5 Multi-function Flue Gas

Analyser. Sprint has redefined flue gas analysis and will give you years of unpar-

alleled service and reliability.

There are four versions covered in this manual as follows:

Sprint V2 Standard full function flue gas analyser

Sprint V3 V2 with Bluetooth

Sprint V4 V2 with NO sensor included

Sprint V5 V4 with Bluetooth

Please read the instructions carefully before use. Keep the manual for future

reference.

Unpacking

Important: ensure unit is fully charged.

Remove the Sprint unit from the packaging. The Sprint accessories will be

located in the carry case. Check the contents are complete, you should have:

• Carry case;

• Sprint unit;

• Mains battery charger power supply;

• Rubber boot;

• Flue probe, including water trap;

• A5 user guide;

• User manual on CD;

• Certificate of calibration;

• 2 x 1 m tubes for pressure (Natural gas).

Options to include:

• Gas leak probe;

• Additional thermocouple probes;

• In-car charger;

• Infra red printer.

Warning: Do not attempt to use any other charger power supply, with this

unit except the one(s) supplied. Failure to comply could invalidate the war-

ranty and may result in permanent damage to the unit.

3

Sprint V2/V3/V4/V5 Overview

Overview

ESC

Tel: +44 (0) 870 428 0075

Fax: 870 428 0076

www.anton-group.com

+44 (0)

Anton Group

Tel: +44 (0) 870 428 0075

ANTON

V2.2 i1.05

USB connector

Connect gas leak

probe here.

Also used for

communications to PC

Power jack

IR window

Printer output, senses ambient light to

control backlight.

Tip: to quickly activate backlight, cover this window

Note: V3 and V5 have Bluetooth®communications

Exhaust exit

Warning: do not

inhale exit gas exhaust

or block exit

Thermocouple

sockets

K-type connectors

Flue sample inlet

Display

Showing start-up

splash screen

Battery icon

Three bars show

complete charge

ON/OFF/ENTER key

Press and hold button for two

seconds to switch on and switch

off Sprint unit. Use this key to

finish edits, save changes and

view next page of multiple

paged screens.

Soft keys

Use these unmarked buttons

to make selections from the

menu, start and stop tests,

print and store results.

See section Operation for more

details

ESCAPE key

Use this button to quit

tests and step back

through menus.

Pressure inlets

(-) (+)

Purge icon

Rotating icon shows

pump is purging

4

Probe connections Sprint V2/V3/V4/V5

Probe connections

Flue gas analysis

Connect the flue probe to the flue sample inlet and the thermocouple to the

k-connector marked FLOW (Efficiency). To measure flue draught pressure con-

nect pressure tube to (-) Pressure inlet marked draught.

Differential pressure, working pressure, operating pressure and let-by

and tightness test

Connect tubing to pressure inlet(s).

Differential temperature test

Connect one or two thermocouple probes to the k-type connectors. When

using one probe, Sprint will display a soft key option to switch between T1 and

T2 snapshot measuring points.

Room CO safety test

Connect CO room safety test probe (optional), where suitable, to the flue sam-

ple inlet.

Gas escape test

Connect gas leak probe to the USB connector.

Note: The pump may operate at different speeds or switch off depending on the test

being performed. This will vary the pitch of the sound from the pump and does not

indicate the pump is performing incorrectly.

Accessories

Sprint is supplied with a rubber boot for protection of your Sprint unit. A mag-

net on the reverse of the rubber boot can be used to place the Sprint unit in

location on the boiler system for easy hands-free operation. Take care not to

place items which may be sensitive to strong magnetic fields near this magnet,

eg credit cards or magnetic storage devices like computer hard drives.

(-) PRESSURE

(+) PRESSURE

FLUE SAMPLE

INLETS

FLOW

(EFFICIENCY)

TEMPERATURE

RETURN

(DRAUGHT)

Tip: see label

underneath unit

for details of probe

connections

5

Sprint V2/V3/V4/V5 Quickstart guide

Quickstart Guide

Switch On

Important: please connect flue probe first before switching on your Sprint

unit, ensure the water trap is empty and is fitted in the right direction. Do

not insert probe in flue till after auto zero. Always start in clean air.

Press and hold the ON/OFF/ENTER key for two seconds. Sprint will emit a few ris-

ing beeps, performs a screen test and starts the pump to purge any residual gas

from the unit. Ensure the gas exhaust outlet is not blocked.

The welcoming splash screen is displayed for approxi-

mately 30 seconds and will automatically go to the Auto

zero screen. When Auto zero is complete the display will

change to the Test Menu. Warm-up should be extended

if sensor needs to recover from previous gas exposure.

Auto zero

When Sprint has completed warm-up the auto zero screen will be displayed.

Ensure you are in clean air before proceeding.

Tip: auto zero Sprint outside of the building or well away from the heating appliance to

avoid any potential gases in the vicinity affecting the auto zero process.

Ensure the sensor reading is stable, press the proceed ükey to begin auto zero.

After a successful auto zero Sprint will display the Test

Menu screen and switch off the pump.

Note: Sprint will switch off the pump when not performing

tests or purging.

Stable

14:44:27 08-Feb-2006

Purged in clean air

and stable?

CO

Auto zero

NO

Test Menu

Fuel Options

Units of Measurement

Anayser Settings

Stored Logs

14:44:27

Cal due

Main Menu

08-Feb-2006

17-Jan-2007

Tip: see soft key

icon list on the

inside front cover

of this manual

Tip: check sensor reading is

stable. Otherwise Sprint will

display 'Not stable' and arrow

will tilt up or down

Note: image is of V4/V5 Auto

zero screen with NO sensor

6

Quickstart guide Sprint V2/V3/V4/V5

Using the menu

From the Test Menu press the ESC key to display the Main Menu. Use the soft

keys to scroll, select and edit menu items (see icon list - inside front cover). Press

accept þto make change or the ESC key to cancel. Press the ESC key to return

to the Main Menu.

Changing fuel, units and efficiency options

From the Main Menu select Fuel Options or Units of Measurement.

Fuel Options: select one of the following options: natural gas, LPG, heavy oil,

light oil, coal, wood, wood pellet dry, coke, Biomass and Bagasse.

NOx Factor (Sprint V4+V5 only): on selecting the Fuel press accept þSprint

will display the Fuel Constants. To edit the NOx Factor use the êscroll soft

key to select the NOx Factor. Press þand the NOx Factor screen will be

displayed. Use the soft keys – and + to adjust the NOx factor value, press þ

to accept the change or ESC to cancel.

Units of Measurement: select one of the following options:

Pressure units: mbar, Pa, hPa, kPa, PSI, inWG, mmWG, inHG or mmHG

Temperature scale: Centigrade or Fahrenheit

Efficiency: Net, Gross or NetHE*

*NetHE may be used for High Efficiency/Condensing boilers

NetHE not available on all fuel types

See section II. Setting up for more details.

Changing display and key pad settings

From the Main Menu select Analyser Settings and one of the following options:

Display contrast: use the soft keys to adjust the contrast level.

Auto off timeout: use the soft keys to adjust or disable the timeout period.

Back light: use the soft keys to select one of the following options: off, dim,

bright or controlled.

Key click: use the soft keys to enable or disable audible key click.

Report: Allows selection between 'Printer' and 'Bluetooth' for report output.

Changing date & time, report header and password

From the Main Menu select Analyser Settings>Supervisor settings: (if the

password has been set, enter the password now) select one of the following

options:

7

Sprint V2/V3/V4/V5 Quickstart guide

Set date & time: use the soft keys –and +to change units of date and time

and èto select hours, minutes, day, month and year. Press ESC to save.

Edit report header: use the soft keys éand êto select header text one or two

and

–

+

to edit text. Use the and keys to scroll through character lists

and character values. Press èto move on to the next letter in the header

text. Press ON/OFF/ENTER to delete all characters to the right. Press èto

move the cursor to the end of the text and þto accept change and return

to Edit report header screen. Press ESC to exit edit without saving changes.

Change password: press the soft key

–

+

to edit password. Use the and

keys to scroll through character lists and character values. Press èto move

on to the next letter in the password. Press èto move the cursor to the

end of the text and þto accept change and return to Password screen.

Press ENTER to store the change.

Print Cal Due: Enable or disable printing of calibration due on reports.

Flue CO Alarm: During flue gas analysis, a carbon monoxide alarm can be set

to activate at 300ppm of CO or disabled.

Retrieving stored logs

From the Main Menu select Stored logs and one of the following options:

Select a log: use the soft keys to scroll and select log.

Find a log by number: use the soft keys to scroll up and down the numbered

logs database.

Delete all logs: this option will delete all stored logs. Press accept þ'Are you

sure?' to clear logs or press ESC to cancel.

Switch off

Turn off unit in clean air and ensure any gas is purged from sensors. Press and

hold the ON/OFF/ENTER button for approximately two seconds. The power off

screen will be displayed and the pump will run to purge the sensors. The pump

will run for up to 30 or 40 seconds to purge unit if gas is present. Sprint will

normally switch off in 10 seconds. Press the ESC key to cancel the switch off

sequence.

Charging battery

Plug the supplied charger into the charger socket. The batteries will recharge

in six hours from flat. You may leave the unit on charge for longer periods, e.g.

overnight, without damaging the unit. A fully charged unit will give up to nine

hours of operation. A shorter charge time can be applied, such as 1/2 hour, to

allow a more limited length of operation.

8

Performing tests Sprint V2/V3/V4/V5

Performing tests

From the Main Menu select Test Menu. Refer to section III Operation for more

details.

1. Flue gas analysis

Before performing the flue gas analysis test, check the water trap is clean and

is upright (arrow should point in direction of gas flow). To begin test, select Flue

gas analysis from the Test Menu.

Sprint will switch on the pump

and begin making measurements.

Check the fuel type displayed on

the screen is correct. Use the soft

keys to log or print the results.

Press the ON/OFF/ENTER button to

display the three screens available:

Screen 1: CO, CO2, CO/CO2

ratio and pressure.

Screen 2: O2, excess air,

temperature and efficiency.

Extra screen for V4&V5:

O2, CO, NO, NOX

Final screen combines elements from previous screens.

To perform a pressure zero, use the soft key marked

P=0

To end test press the ESC key.

Warning: During testing, ensure the combined filter and water trap is not blocked or

full. Failure to do so may result in an error message.

ESC

14:44:27 08-Feb-2006

Flue Gas

15

Natural gas

CO

ppm

CO2

%

Ratio

mBar

4.8

0.003

0.00

P=0

1

Pressure

Tip: Press the

ON/OFF/ENTER

button to cycle

through the

screens.

Tip: The screen

number is

displayed here.

Tip: If # symbol

is displayed

- flue probe is

not in flue or

not connected.

Screen 1 Screen 2 Screen 3 Screen 4

9

Sprint V2/V3/V4/V5 Performing tests

Note: for personal safety a carbon monoxide alarm will activate at 300ppm CO. This

will deactivate when CO levels drop below 150ppm. This is to protect the user from

potential hazardous exhaust gas levels.

2. Let-by and Tightness test

Let-by test

Before carrying out the test, the pressure must be zeroed with the tube con-

nected to the instrument but not the pressure source. Note: in these tests 'Diff

press' is the difference between start and finish pressures.

1. Select Pressure Menu from the Test Menu. From the Press Menu screen

options select Let-by / Tightness.

2. Connect tube to positive pressure inlet but not pressure source.

3. Zero pressure, use the soft key marked

P=0

.

4. Connect tube to pressure source to begin pressure test.

5. Press the soft key

u

to start test. Sprint displays the duration time on

the screen.

6. To stop test press the soft key .

7. Press the soft key üto pass test and proceed to Stabilisation test.

You may fail the test by pressing the key ûto indicate test has failed

(you can print the results).

Stabilisation Test

1. Press the soft key

u

to start test. Sprint displays the duration time on

the screen.

2. To stop test press the soft key .

3. Press the soft key üto proceed to Tightness test.

You may repeat the test by pressing the key û(you can print the

results).

14:44:27 08-Feb-2006

Let-by

Finish P2

mBar

Diff press

0.0

P=0

Start P1

mBar 0.0

Duration 00:00

mBar 0.0

14:44:27 08-Feb-2006

Let-by

Finish P2

mBar

Diff press

0.0

Start P1

mBar

0.0

Duration

00:25

mBar

0.0

14:44:27 08-Feb-2006

Let-by

Finish P2

mBar

Diff press

0.0

Start P1

mBar

0.0

Duration

00:54

mBar

0.0

Passed?

Screen 1 Screen 2 Screen 3

10

Performing tests Sprint V2/V3/V4/V5

Tightness Test

1. Press the soft key

u

to start test. Sprint displays the duration time on

the screen.

2. To stop test press the soft key .

3. Press the soft key üto pass test.

You may fail the test by pressing the key ûto indicate test has failed.

At the end of the tightness test you can log or print the results. Press the ESC

key to return to Press Menu.

Press ESC again to return to Test Menu.

3. Pressure, Differential Pressure, Working Pressure and

Operating Pressure tests

Before carrying out the test the pressure must be zeroed with the tubes con-

nected to the instrument but not the pressure source. A thermocouple may be

connected to provide temperature readings in these tests.

1. Select Pressure Menu from the Test Menu. From the Press Menu screen

options select Pressure, Diff Pressure. Working pressure or Operating

Pressure.

Screen 1 Screen 2 Screen 3 Screen 4

14:44:27 08-Feb-2006

Stabilisation

Finish P4

mBar

Diff press

0.0

P=0

Start P3

mBar 0.0

Duration 00:00

mBar 0.0

14:44:27 08-Feb-2006

Stabilisation

Finish P4

mBar

Diff press

0.0

Start P3

mBar

0.0

Duration

00:25

mBar

0.0

14:44:27 08-Feb-2006

Stabilisation

Finish P4

mBar

Diff press

0.0

Start P3

mBar

0.0

Duration

00:54

mBar

0.0

Stabilised?

Screen 1 Screen 2 Screen 3

11

Sprint V2/V3/V4/V5 Performing tests

2. Connect tube(s) to pressure inlet(s).

3. Zero pressure, use the soft key marked

P=0

.

4. Connect tube(s) to pressure source(s) to

begin pressure test.

5. There is an option to time this test, Sprint

displays the duration time on the screen.

Press the soft key

u

to start test and timer.

6. To stop timed test press the soft key .

7. To restart test press the soft key

tt

.

To re-zero the unit, press

P=0

.

Press the ESC key to return to the Press Menu

screen. To perform the other pressure tests repeat

steps 2 to 7 above.

Press ESC to return to the Test Menu.

4. Differential temperature test

Sprint can perform a differential temperature test with one or two thermocou-

ple probes. To begin test, select Diff Temperature from the Test Menu. Check

the units displayed are the correct temperature scale. If no probes are con-

nected Sprint will display ####.

Two probe test

Connect both probes to the k-type connectors. See label on back of unit for

FLOW and RETURN. Place probes in position. The screen will display the tem-

perature of probe 1 and probe 2, and the differential temperature.

Use the soft keys to log or print the results.

To end test press the ESC key.

Single probe test

When only a single probe is available, Sprint will display

an additional icon on the screen to represent the first and

second reading.

1. Place probe in position to make measurement T1.

2. Press the soft key icon

T2

T1

to take a snapshot

reading of T1. (Do not remove probe until this

snapshot is taken.)

3. Move the probe into position to take second reading

T2. The screen will display the icon

T2

T1

to show

temperature reading T2 is being taken.

14:44:27 08-Feb-2006

Pressure

Pressure

mBar

Duration

0.0

00:00

P=0

Tip:

optional

timer

Tip: plug in the

Thermocouple

probe to view

temperature on

screen.

14:44:27 08-Feb-2006

Ret T2

C

Diff temp

####

Flow T1

C####

C####

Temperature

T2

T1

T2

T1

Tip: this icon

will appear when

only one probe is

avaialble.

12

Performing tests Sprint V2/V3/V4/V5

The screen will display the snapshot temperature, the live probe

temperature, and the differential temperature.

Use the soft keys to log or print the results.

To end test press the ESC key.

5. Room CO safety test

Ensure the unit has been zeroed in clean air during switch on before

performing this test.

Note: For further details on performing Room CO Safety Tests, see Appendix I.

1. Select CO Room safety from the Test Menu. Sprint will display the

Appliance Menu. Select the appliance from the list.

The appliance will be displayed on the screen during the room CO

safety test.

2. Connect probe if required to the Sprint unit and place at the

recommended height. Refer to British Standard BS7967 if necessary.

3. The pump will switch on in readiness for test. NB. The sound of the

pump operating does not indicate the test has begun. Press the

u

soft key

to start test. During the test the screen will display the CO reading, peak

CO reading, duration of test and maximum allowed CO for the test.

The test will run for the required duration by appliance according to BS7967.

Sprint will emit an alarm if 30ppm (or 90ppm) threshold is exceeded. Sprint

is programmed with pass/fail criteria for this test. Refer to British Standard

BS7967 for further details on performing room CO safety tests.

When the minimum test period for an appliance has been reached (as defined

by BS 7967:2005 ) the ON/OFF/ENTER key can then be used to cycle through

the CO Room Safety screens. The test can be completed by pressing the soft

key to finish. Use the soft keys to log or print the results.

12:57:24 23-Feb-2009

CO Room

4

Water heater (flueless)

CO

ppm

Peak CO

ppm

Allowed

of test

5

10

07.12

1

Duration

12:57:24 23-Feb-2009

CO Room

Time(Min)

2

12:57:24 23-Feb-2009

CO Room

3

ppm

1

2

5

4

4

of test

07.12

Duration

1

2

3

4

5

Time(Min)

4

4

####

####

####

of test

07.12

Duration

6

7

8

9

10

CO(ppm) CO(ppm)

13

Sprint V2/V3/V4/V5 Performing tests

To stop test at any time, press the ESC key. Use the soft keys üor ûto select

'Quit test?'.

When printing Room CO safety test results Sprint will also provide data show-

ing for how long the recommended level of CO was exceeded. This is expressed

as hh:mm > allowed.

6. Gas escape test

Note: Battery power will be used at a higher rate under this test.

Select Gas escape from the Test Menu. Connect the Gas leak probe to the USB

connector, the light will illuminate on the probe. Sprint will display a warning if

the probe is not connected.

Sprint will display 'sensor stabilising' for approximately 30 seconds.

When the sensor is stable the unit will ask 'in clean air?' before zeroing.

Press üto zero the unit. Sprint will display a bar graph on the screen as gas

levels are monitored.

Place the probe in the area of inspection for several seconds before moving it

to other locations.

Sprint will emit continuous clicks like a Geiger counter. If higher gas levels are

detected the bar graph will increase in readings and the sounder will increase

in pitch.

Press ESC to quit the test.

As with many types of instrumentation the gas leak probe may be damaged

by impact. If the probe is dropped or suffers significant impact in another way

check its operation by first plugging it into the Sprint V and confirming that it

is recognised by the analyser. If this is successful select the gas leak mode and

briefly apply a sample of gas, for example from an unlit cooker ring. This will

allow the user to verify whether the sensor is working correctly or not. If the

gas is not detected contact Telegan or your local distributor to arrange for the

probe to be serviced.

It is recommended good practice that the above check is carried out periodically

even if the user is not aware of the probe being exposed to impact.

14

Operation Sprint V2/V3/V4/V5

I. Operation

Before using the Sprint flue gas analyser on any heating appliance installation,

ensure you are familiar with the working practices defined in the BS7967 which

details how to perform certain tests and safety issues to consider.

Auto zero setting

Allow the Sprint unit to auto zero during switch on in clean air before per-

forming any of the following tests: flue gas analysis and room CO safety test.

Ensure all tubes and probes are connected before switch on and zero outside

in clean air.

Pump

Sprint runs the internal pump during purge at switch on and switch off, and

during and after some tests. A rotating purge icon will appear on the screen

when purging. The speed and therefore the sound emitted by the pump, may

vary depending on the test being conducted. To save on the battery life, Sprint

will turn off the pump when it is not required.

When the pump is running ensure the exit gas exhaust is not blocked and do

not breath in the exhaust gases.

1.1 Menu and operator button overview

Sprint provides a large graphic LCD with blue backlight. Navigation and func-

tions are provided by three soft key buttons which change according to what

you are doing.

ESC

Use the soft keys to

navigate menus,

select, start and end

tests, change options

and select actions.

such as print, log

or zero

Use the escape key

to exit menus, exit

tests and step back

through screens

ON/OFF/ENTER switch.

Use this key to finish

edits, save changes

and view next page of

multiple paged screens.

15

Sprint V2/V3/V4/V5 Operation

After your Sprint unit has been switched on and performed an auto zero the

display will show the Test Menu screen ready for use. To display the Main Menu

press the ESC key.

To enter a menu item, use the soft keys below the éand êscreen icons to

scroll the menu list and press the soft key underneath the þscreen icon to

select. Some menus have their own submenu.

Press the ESC key to exit a menu, press ESC twice to return to the Main Menu

from a submenu.

The soft keys control the function displayed above them on the screen. These

will change depending on the test or menu, or if the ESC key is pressed.

The menu structure is shown below:

How to display unit serial number, identity and software

version

Press the ESC key from the Main Menu

Fuels

Test Menu

Main menu

Flue Gas

Analysis

Gas Escape

Detection

CO Room

Safety

Diff

Temperature

Pressure

Menu

Let-by / Tightness

Pressure

Diff Pressure

Appliance

Settings

Display Contrast Back light

Pressure

Units

Temperature

Logs

Select a log Find a log by number Delete all logs

Press ESC to go

to Main menu

Key clickAuto off

timeout

Supervisor

settings

Efficiency

Set date

& time

Edit report

header

Change

password

Reports

(V3+V5 only)

NOx Factor

(V4+V5 only)

Fuel Constant

(V4+V5 only)

Print

Cal Due

Flue CO

alarm

16

Setting up Sprint V2/V3/V4/V5

II. Setting Up

2.1 Configuration Options

Fuel Options:

Sprint displays the current fuel option on the screen. To change the fuel option

press the ESC key to enter the Main Menu and select Fuel Options. Use the soft

keys to scroll and select the desired fuel using ü. The new fuel option will be

displayed on the test screens.

Fuel options available are: natural gas, LPG, heavy oil, light oil, coal, wood,

wood pellet dry, coke, Biomass and Bagasse.

Note: NetHE only available for fuels natural gas, LPG, light oil and heavy oil.

From software versions i2.00, fuel types can be changed using Sprint PC Lite.

Units of measurement:

To change the units of pressure, temperature or efficiency press the ESC key to

enter the Main Menu and select Units of Measurement. Use the soft keys to

select the submenu and units for Pressure, Temperature or Efficiency.

Temperature units are: degrees Celsius (ºC) or degrees Fahrenheit (ºF).

Pressure units are: mBar, Pa, hPa, kPa, PSI, inWG, mmWG, inHG and mmHG.

Efficiency units are: Net, Gross or NetHE.

Note: the formulae and constants used for Gross and Net efficiency calculations

are those specified in BS845 (UK-specific) or EN50379 (Europe). In general it

is Net efficiency which is normally quoted. For modern condensing boilers the

Net efficiency calculated may exceed 100%. Sprint V provides a condensing

efficiency calculation via the efficiency option NetHE. The result of this calcula-

tion takes into account the recovered latent heat.

Analyser settings:

The Analyser settings menu allows you to alter the settings for the display, auto

off timeout, back light, key pad and Supervisor settings. To change any of these

settings press the ESC key to enter the Main Menu and select Analyser Settings.

Use the soft keys to select the submenus.

Display contrast

On the display contrast screen a bar graph is displayed showing the level of

contrast. Use the soft keys < and > to reduce or increase the level of contrast.

Press the þkey to accept the change or ESC to cancel.

17

Sprint V2/V3/V4/V5 Setting up

Auto off timeout

On the auto off timeout screen the number of minutes at which the unit will

automatically switch off is shown. Use the soft keys – and + to reduce or increase

the number of minutes. Press the þkey to accept the change or ESC to cancel.

To disable Auto off timeout press – key until 'disabled' is displayed.

Back light

The back light can be set to four options: off, dim, bright or controlled. Use the

soft keys to scroll and select the option desired. Press the þkey to accept the

change or ESC to cancel.

Back light options are:

Off: switches the backlight off

Dim: lowers the light intensity

Bright: increases the light intensity

Controlled: Sprint monitors the ambient light level and adjusts the light

intensity accordingly.

Reports (V3 + V5 only)

Allows selection of Printer (IR comms) or Bluetooth®. Use the soft keys to toggle

between these and the þkey to accept.

Key click

The Key click settings allows you to enable or disable the key pad from making

audible 'clicks' when pressed. Use the soft keys to select 'enabled' or 'disabled'

from the submenu. Press the þkey to accept the change or ESC to cancel.

NOx Factor (Sprint V4 + V5 only)

The NOx Factor can be viewed and edited from the Fuels Menu. To view the

NOx Factor and other fuel constants, select the Fuel Menu from the Main Menu.

Select the Fuel and press accept þSprint will display the Fuel Constants.

To edit the NOx Factor use the êscroll soft key to select the NOx Factor. Press þ

and the NOx Factor screen will be displayed. Use the soft keys – and + to adjust

the NOx factor value, press þto accept the change or ESC to cancel.

Supervisor settings

Set date &time

On the Time & Date screen the current time and date are shown. Use the soft

keys – and + to alter the values of hours, minutes, day, month and year. Use the

èkey to select each unit. Press the ESC key to accept the change.

Edit report header

Use the soft keys éand êto select the report header text line one or two.

Press

–

+

key to edit text. The screen displays the character lists and highlights

18

Setting up Sprint V2/V3/V4/V5

the current list in use. Use the and keys to scroll through character values

in each list and èto move on to the next letter in the header text. The char-

acter lists are shown below.

Press ON/OFF/ENTER to delete characters to the right. Press èto move the cur-

sor to the end of the text and þto accept change and return to Edit report

header screen.

Print Calibration Due

Enable or disable printing of calibration due on reports.

CO Alarm

During flue gas analysis, a carbon monoxide alarm can be set to activate at

300ppm of CO or disabled.

Change password

Press the soft key

–

+

to edit password. Use the and keys to edit or create

a password as described above in Edit report header. Press þto accept change

and return to Password screen. Press ON/OFF/ENTER to store the change.

When a password has been created, Sprint will display the Supervisor pass-

word screen on entering Supervisor settings.

! .. / !"# $% & ' ( ) * + , - _ / A .. Z Uppercase alphabet

0 .. 9 0123456789 a .. z Lowercase alphabet

: .. @ : ; < = > ? @ Space

This manual suits for next models

3

Table of contents

Other Telegan Measuring Instrument manuals