Telma TL113005 User manual

17feb12jh

TL113005

INSTALLATION MANUAL

FOR

TELMA AC50-55

ON FORD E-350/450 CUTAWAY

WITH TELMA CONTROL MODULE

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 2 of 30__________________________________________________________________________17feb12jh

TABLE OF CONTENTS

1 Preparation of the Chassis

1.1 Driveline

1.2 Exhaust

2 Telma Installation

2.1 Installation Kit TIK10677

2.2 Install the Chassis Brackets

2.3 Install vent tube extension

2.4 Assemble the Telma Brackets and mounts

2.5 Install the Telma in the Chassis

2.6 Drive Shaft Modification and Installation

2.7 Axle Shim Installation

3 Control Components

3.1 Relay Box Installation

3.2 Light Bar Installation

3.3 Telma Control module and Foot Control Switch Installation

3.4 Foot Switch Adjustment

4 Wiring Harness Installation

4.1 Power Harness Installation

4.2 Control Harness Installation

4.3 Wiring Diagram

5 Recommended Tools

6 Post Install Checklist

Appendix

(1.1) E350 138” WB with 5.4L engine

(1.2) E350 138” WB with 6.0L/6.8L engine

(1.3) E350/450 158” WB with 5.4L engine

(1.3.1)E350/450 158” WB with 6.0L/6.8L engine

(1.4) E350/450 176” WB with 6.0L/6.8L engine (X1=24)

(1.4.1) E350/450 176” WB with 6.0L/6.8L engine (X1=22.5 / L1= original)

(1.4.2) E350/450 176” WB with 6.0L/6.8L engine (X1=10)

(1.4.3) E350/450 158 to 176” WB with 6.0L/6.8L engine (stretch in front of x-member)

(1.5) E350/450 186” WB with 6.0L/6.8L engine (stretched chassis)

(1.5.1) E350/450 158 to 186” WB with 6.0L/6.8L engine (stretch in front of x-member)

(1.6) E350/450 190” WB with 6.0L/6.8L engine (stretched chassis)

(1.6.1) E350/450 158 to 190” WB with 6.0L/6.8L engine (stretch in front of x-member)

(1.7) E350/450 208” WB with 6.0L/6.8L engine (stretched chassis)

(1.7.1) E350/450 158 to 208” WB with 6.0L/6.8L engine (stretch in front of x-member)

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 3 of 30__________________________________________________________________________17feb12jh

SECTION 1 PREPARATION OF THE CHASSIS

1.1 DRIVELINE

Remove the complete drive-line assembly from the transmission flange yoke to the rear axle flange yoke.

1.2 EXHAUST

There should be no exhaust modification necessary for any wheelbase other than 138. A shorter replacement muffler

is necessary for E350 138” wheelbase.

SECTION 2 RETARDER INSTALLATION

2.1 INSTALLATION KIT TIK10677

P/N DESCRIPTION QTY

CN201155 AC50-55 / 12V (1410-1550) 1

TIB03123 LEFT SIDE RETARDER BRACKET (4.5 DEGREE) 1

TIB03124 RIGHT SIDE RETARDER BRACKET (4.5 DEGREE) 1

TIB03127 FORD E350-450 CHASSIS BRACKET 2

JZ100280 SIDE PLATE FASTENERS 1

JZ1007XX-30 TELMA SHOCK MOUNT SET (30 SHORE) 1

VF120340 ALL METAL LOCKNUT ½-20UNF G8 8

TIF03003 NUT 9/16 - 12 UNC G8 6

TIF03005 LOCKWASHER 9/16 G8 6

TIF04001 BOLT 9/16 - 12 UNC X 2 HEX HEAD G8 6

TID11050 HARNESS W/ JD331121 1

TIB01017 CONTROL / RELAY BOX BRACKET 2

TIG31063 TELMA CONTROL MODULE FORD CAN 1

TIB05002 FORD E350-450 PEDAL CLAMP 1

TIB05046 FORD E350-450 FOOT SWITCH BRACKET 1

TIB05047 FORD E350-450 PEDAL BRACKET 1

JC120102 FOOT SWITCH 1

TIG11010 TELMA LIGHT BAR DISPLAY 1

TIF05021 MUSIC WIRE / RETURN SPRING 1

TIF05000 LOCKWASHER 1/4 SPLIT 6

TIF05002 NUT 3/8 - 16 UNC G5 2

TIF05003 LOCKWASHER 3/8 G5 SPLIT 1

TIF05004 NUT 1/4 - 28 UNF G8 6

TIF05005 BOLT 1/4 - 28 UNF X ¾ HEX HEAD G8 6

TIF05010 LOCKWASHER 5/16 SPLIT 4

TIF05011 NUT 5/16 4

TIF05012 BOLT 5/16 - 18 UNC X 1-3/4 HEX HEAD G5 4

TIF05013 BOLT 1/2 - 13 UNC X 1-1/2 HEX HEAD G5 2

TIF05014 LOCKWASHER ½ MED SPLIT 2

TIF05019 ELEVATOR BOLT 3/8 - 16 UNC 2-1/2 1

TIF05034 FENDER WASHER ¼ X 1 1

JZ100110 DISCHARGE ASSEMBLY 1

Note: 1410 Flange yokes 2 x Telma part number TIF01080 / Spicer part number 3-2-429 must be ordered separately.

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 4 of 30__________________________________________________________________________17feb12jh

2.2 INSTALL THE CHASSIS BRACKETS

•Remove any bolts such as battery box and/or exhaust hanger mounts or other components that may interfere with

the chassis bracket mounting.

•Clamp the chassis bracket (TIB03127) against the frame rail at dimension X1 from the body mount hole and

dimension T1 from the outside top of the frame. If T1 is 4.5”, the chassis bracket will be against the inside bottom

lip of the frame rail.

•Drill three 9/16” holes in each frame rail using the chassis bracket as a template and secure with bolts (TIF03001),

nuts (TIF03003), and lock washers (TIF03005) included in the kit.

•Tighten the 9/16” bolts to 150 lb-ft (±10%).

•Drill through the chassis bracket any holes needed for battery box and/or exhaust hanger mounts and reinstall the

original bolts and components that were removed previously.

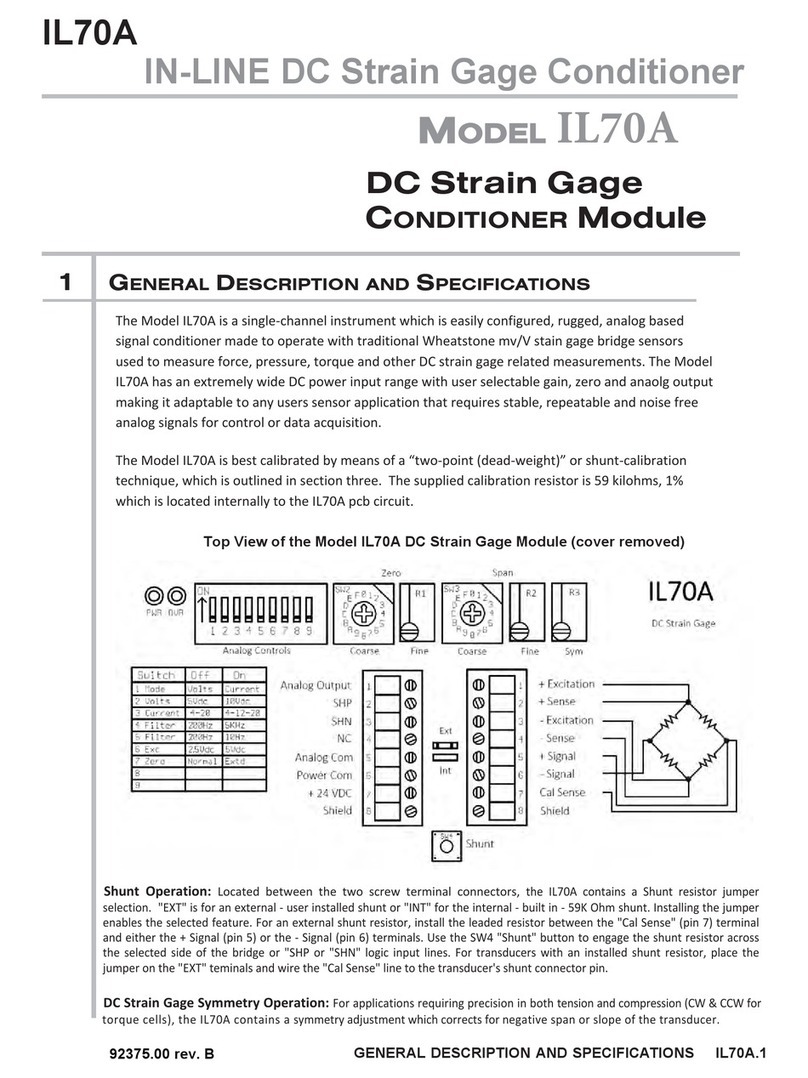

•Refer to the figure below for details.

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 5 of 30__________________________________________________________________________17feb12jh

2.3 INSTALL VENT TUBE EXTENSION

•At the time of installation the plastic vent tube extension kit should be attached to the grease chamber vent tube

according to the instructions supplied. Install the vent tube before the retarder bracket is installed to avoid the

possibility of crimping the nylon tube and restricting the outlet. The vent tube is located at the upper passenger

side corner of the Telma. Cut off the vent tube at the bottom of the Telma using a knife or cable cutter. Do not use

diagonal cutters which may crimp and restrict the outlet. Do not wrap the vent tube under the retarder.

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 6 of 30__________________________________________________________________________17feb12jh

2.4 ASSEMBLE THE TELMA BRACKETS AND MOUNTS

•Identify the driver’s side of the Telma from the passenger side. To do so, orient the arrow of the red plate on the

Telma towards the axle with the red plate on the driver’s side.

•Identify the Telma brackets. The longer bracket TIB03123 is for the driver’s side. The shorter passenger side

bracket is TIB03124.

•Use four M14 bolts flat washers and Trep washers provided with the set of fasteners (JZ100280) to fasten the

Telma bracket onto each side of the unit. Tighten bolts to 65 lb.-ft (±10%).

•Install the rubber mounts into the retarder brackets. Insert the male parts of the rubber mounts into the 1 5/8” holes

in the brackets from the bottom and the other half of the rubber mount on top. Place one 2 ¾” diameter 5/8” flat

washer on top of each mount.

•Refer to the figure below for details.

2.5 INSTALL THE TELMA IN THE CHASSIS

•Lift the Telma, equipped with its brackets and mounts, into place against the bottom of the chassis brackets.

•Install the M16x1.5x100mm (4”) bolts and spring washers down through the holes in the chassis brackets, mounts

and Telma brackets at each mount. Install a 2 ¾” diameter flat washer, a spring washer and M16 locknut at each

mount and tighten to 150 lb.-ft (±10%).

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 7 of 30__________________________________________________________________________17feb12jh

2.6 DRIVE SHAFT MODIFICATION and INSTALLATION

•A slip assembly is required on each side of the Telma. Slip position should be at center of slip travel when shaft is

installed

•Refer to FORD QVM guidelines and SPICER recommendations for proper drive shaft manufacture, balance,

straightness, and critical speed limits.

•Refer to the appendix for Telma guidelines

•Use u-joint SPICER part number SPL36-1X (1410)

•Refer to installation drawings in the appendix for shaft length guidelines

•Shaft lengths over 50” should use 4” tubing

•Always verify proper shaft lengths before modification

•Connect the Telma flange yoke of each drive shaft to the Telma coupling flange.

CN201155: Tighten the 1/2”-20UNF all metal lock nuts to 97-116 lb-ft.

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 8 of 30__________________________________________________________________________17feb12jh

2.7 AXLE SHIM INSTALLATION

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 9 of 30__________________________________________________________________________17feb12jh

SECTION 3 CONTROL SYSTEM COMPONENTS INSTALLATION

3.1 RELAY BOX MOUNTING

•Install the relay box on the inside driver side frame rail using an existing hole approximately 40” forward from the

center of the Telma and down 1 1/2“ from the top of the frame rail using the relay box mounting brackets TIB01017

x 2 and fasteners supplied in the kit.

•Tighten the four 5/16” bolts to 17 lb-ft (±10%) and the two ½” bolts to 75 lb-ft (±10%).

3.2 LIGHT BAR INSTALLATION

•The Light Bar should be mounted so that it is easily visible to the driver.

•Make a rectangular hole 7/8” wide x 1 ¾” tall in the lower dash to the right of the steering column or install the Light

Bar in an existing console receptacle.

•Install the mating connector onto the five wires (org/wht, blu/wht, yel,grn, brn/wht, blk) found in the relay box

control harness.

•Feed the harness through the hole and connect to the Light Bar

•Plug the light bar into the hole

LIGHT BAR

DISPLAY

PANEL OPENING

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 10 of 30__________________________________________________________________________17feb12jh

3.3 TELMA CONTROL MODULE & FOOT CONTROL SWITCH INSTALLATION

Bracket TIB05046 is used to mount the Telma Control Module and foot switch to the dash as shown.

Attach pedal clamp TIB05002 and pedal bracket TIB05047 to the brake pedal using the ¼” bolts, nuts and lock

washers supplied in the kit.

The return spring TIB05021 attaches using the 1/8” holes in the pedal bracket and foot switch bracket.

The special 3/8’ adjustment bolt, nuts and lock washers are assembled as shown.

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 11 of 30__________________________________________________________________________17feb12jh

3.4 FOOT SWITCH ADJUSTMENT

The plunger type foot switch should be carefully adjusted

to avoid switch damage and optimize retarder activation in

the free play of the pedal. With the return spring installed,

use a feeler gauge and adjust the switch stop (item 5) until

there is 1/8” gap. The switch plunger should be fully

compressed and the brake pedal should be in its highest

position.

ITEM DESCRIPTION

1 3/8” lock washer

2 Pedal bracket

3 foot switch JC120102

4 feeler gauge

5 3/8” diameter switch stop adjusting bolt

6 3/8” jam nuts

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 12 of 30__________________________________________________________________________17feb12jh

SECTION 4 WIRING HARNESS INSTALLATION

4.1 POWER HARNESS INSTALLATION

•From the relay box, route the Telma power connection and ground harness along the inside of the left frame rail

and up over the top along the middle of the Telma. Connect the 10G orange, blue, yellow, and brown wires to the

connecting block at the top right rear corner. Connect the 10G relay box ground cable and the 4G Telma main

ground cable to the insulated ground terminal at the Telma top left front corner. Coat the terminals with anti-

corrosion paint or body undercoat after the connections are made. Secure the harness to the center of the Telma

brackets with rubber coated cable clamps. The harness should be secured along the centerline of the Telma and

as far away as possible from either rotor to avoid heat damage to the harness. No cables should cross the heat

outlets in the periphery of the rotors. Continue across with the black 4G ground cable and connect to negative

terminal of the battery pack. Route the red power positive cable along the cross member in front of the Telma and

connect to the positive terminal of the battery pack. Secure the cable to the cross member with rubber coated

cable clamps.

POWER CONNECTIONS AT

TOP RIGHT REAR

GROUND CONNECTION AT

TOP LEFT FRONT

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 13 of 30__________________________________________________________________________17feb12jh

Control Module

Telma PN:

Date Code:

4.2 CONTROL HARNESS INSTALLATION

•Open the driver’s door and remove the plastic foot well insert and the rubber plug towards the rear in the bottom of

the body. From the relay box, feed the control cable along the inside of the frame rail, up through the hole in the

cab where the plug was removed. Continue feeding the harness from the foot well area behind the left kick panel

and up under the dash towards the steering column area. Make sure the harness does not interfere with the

parking brake mechanism and cannot be damaged when the parking brake is actuated.

•Find the Telma Control Module cab harness and insert the two plugs into the module.

•Plug the foot switch connector onto the foot switch so that the orange and blue wires are on terminal 1.

•Remove the OEM OBD2 diagnostics connector from its attachment points under the dash and plug the mating

OBD2 connector of the Telma harness into the OEM OBD2 connector. Secure together with a wire tie. Attach the

OBD2 connector of the Telma harness to the OEM attaching points where the OEM OBD2 diagnostics connector

was installed.

•Attach the mating connector to the four wires (org, blu, yel, brn) found in the relay box control harness and plug

into the cab harness receptacle labeled “to relay box”.

•After final installation of the wiring, connect the PC to configure the Telma Control Module (TRCM) and check

proper function. Unplug the gray connector from the module and reconnect in order to power cycle after a

configuration change has been made.

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 14 of 30__________________________________________________________________________17feb12jh

4.3 WIRING DIAGRAM

SECTION 5 RECOMMENDED TOOLS

•Transmission Jack

•Heavy duty drill motor

•Standard assortment of mechanics hand tools

•Vehicle hoist, pit, or floor jack with stands

•Electrical connector crimping pliers for use with non-insulated connectors

•Dana Anglemaster electronic angle meter

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 15 of 30__________________________________________________________________________17feb12jh

SECTION 6 POST INSTALL CHECKLIST

TL105064 TELMA INSTALLATION CHECKLIST CHASSIS # (last 8)

REVISED: 25aug11jh INSTALLATION REPORT Telma serial #

OBD2 AC50-55 INSPECTION DATE:

INSPECTION LOCATION:

INSPECTED BY:

Customer:

Body Manufacturer:

chassis Make / Model:

engine:

Wheelbase:

Telma installed by:

PHYSICAL

CHECKS The following checks should be made after the installation is completed. A copy of the completed inspection report should be kept in the vehicle file.

Batteries The battery pack must consist of 2 batteries connected in parallel equivalent to diesel OEM capacity.

Telma Batt "-"

and "+" cables The Telma battery cables (4AWG) must be connected to the terminal of the battery pack or to a remote mounted post connected directly to the post

of the battery pack with at least a 4AWG cable. Protect the connection with anti-corrosion paint or body undercoating.

The relay box should be mounted in a vertical position.

The relay box should be away from heat sources and moving components to prevent damage.

The relay box placement should allow easy removal of the cover for inspection.

All harnesses should exit from the bottom of the relay box and be secured with a drip loop.

Telma The power connecting block should be at the top right rear corner of the Telma.

The Telma ground terminal should be at the top left front corner of the Telma.

Heat sensitive chassis components should be no closer than 4 inches from the Telma rotors.

All connections should be protected with anti-corrosion paint or coating.

Vent tube or vent valve should be installed before brackets are installed on the Telma

Control Module The Telma Control Module (TRCM) should be located on the Telma bracket under the driver side dash. Connect to the PC to configure and check

operation before release. Unplug the gray connector from the module and reconnect in order to power cycle after a configuration change has been

made. Refer to TL105087 and TL105088 for product details.

Foot Switch When the brake pedal is in the highest position, the Telma foot switch should be adjusted so that there is a 1/8" gap between the fully compressed

foot switch plunger and the pedal bracket.

There should be a return spring installed between the foot switch bracket and the pedal bracket in order to maintain the brake pedal in the highest

position when released.

The Telma foot switch should be oriented so that the wiring connector points up and away from the driver's foot.

Indicator Lights The Telma Light Bar Display should be mounted where it is easily visible to the driver.

General Wiring The control harness and battery connection cables should be secured with cable clamps and routed along the inside of the frame rail wherever

possible.

All harnesses should be positioned at least 6 inches from exhaust system components or protected with high temperature insulation and heat

shields.

Avoid sharp edges that could cause damage.

At least 3 inches clearance should be maintained from moving or rotating components.

Install grommets in holes through sheet metal.

Control Harness The Telma control harness should be routed along the inside of the driver side frame rail from the relay box toward the front of the chassis.

It should enter the cab through an existing hole under the driver side stepwell and be routed behind the left kick panel and up under the dash toward

the steering column area. Make sure the harness does not interfere with the parking brake mechanism and cannot be damaged when the parking

brake is applied.

Power Harness Harnesses connected to the retarder should be positioned along the center of the retarder frame as far away as possible from either retarder rotor and

secured to the retarder bracket with rubber-coated metal cable clamps.

Drive Shafts Drive shafts must be equipped with universal joints of the same type as supplied by the OEM.

The front drive shaft must be equipped with a slip yoke.

When the shaft is installed, the 3" slip should be extended approximately 1 1/2".

The rear drive shaft must be equipped with the same type of slip yoke as supplied by the OEM and installed toward the front at the rear of the

retarder.

When the shaft is installed, the slip should be extended approximately 1 1/2".

Front and rear Telma yokes should be in the same plane.

Drive shaft lengths and angles should conform to the installation drawing. An electronic anglemeter with 0.1 degree accuracy must be used. Contact

Telma for recommendations.

all angle measurements are with chassis reference of 0 degrees (zero meter on frame)

Check and record measurements and compare to the installation drawing used.

Place a copy of this checklist and the install drawing used in the vehicle file

A

NGLE LENGTH

TRANSMISSION ANGLE

(FRONT SHAFT INSTALLED LENGTH AND ANGLE) L1

(REAR OR SECOND SHAFT INSTALLED LENGTH AND ANGLE) L2

( REAR SHAFT IN A THREE SHAFT SYSTEM INSTALLED LENGTH AND ANGLE) L3

TELMA ANGLE

(outside top of frame to lower chassis bracket hole) T1

(body mount to lower chassis bracket hole) X1

AXLE ANGLE

Mor-Ryde Suspension (yes/no)

axle shims installed (yes/no)

The four dash lights illuminate progressively when the brake pedal is applied and vehicle is moving.

Telma turns off when the brake pedal is released and vehicle is moving.

Telma turns off when the vehicle comes to a stop and the brakes are still applied

Telma does not activate if the accelerator is pressed

Telma does not activate if the cruise control is engaged

The four dash lights do not illuminate if the brakes are not applied

No vibrations noticed during road test up to speed limit

Road Test

INSPECTION COMMENTS

Relay Box

OPERATIONAL CHECKS

Installation

drawing

Post install

Check

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 16 of 30__________________________________________________________________________17feb12jh

APPENDIX

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 17 of 30__________________________________________________________________________17feb12jh

VEHICLE TECHNICAL DATA

CHASSIS MAKE / MODEL FORD E350 SPEED SWITCH JC251100

WHEELBASE 138.0" TIRE SIZE 225/75R-16

ENGINE MAKE / MODEL FORD 5.4L GVW / GCW 11500 lbs

TRANSMISSION MAKE / MODEL FORD 5R110 AXLE RATIO 4.10

AXLE MAKE / MODEL DANA 70 DRIVE LINE SERIES 1410 SPL36

DRIVE TYPE 4 X 2 Use OEM U-JOINT SPL36-1X

RETARDER MODEL

A

C50-55 FLANGE YOKE 3-2-429

RETARDER PART NUMBER CN201155 SUSPENSION Spring / Mor-Ryde

TELMA attests that this drawing corresponds to industry standards concerning driveline angularities and critical speeds

This drawing is valid for the application specified only. Always check all angles and dimensions for your installation.

Consult TELMA technical department if your application varies in any way Dc loaded: 9

Dv unloaded:10

TRANSMISSION= 4.1° CHASSIS BRACKET= 0.0° L2 UNLOADED WITH BODY (±1.0°) =6.3°

A

XLE UNLOADED= 4.5°

L1= 5.2° RETARDER= 4.5° L2 LOADED (±1.0°) =3.9°

A

XLE LOADED= 4.5°

AB1 C1 R1 T1 X1 L1 L2

3 3/4 6 5/16 7 5/16 12 1/16 4 1/2 -6 SHAFT LENGTH 28 9/16 24 15/16

S1 S2 S4 SR SHAFT MINIMUM TUBE DIAMETER 2.50 2.50

18 1/4 23 3/4 23 1/2 23 1/4 SHAFT MINIMUM TUBE THICKNESS 0.083 0.083

NOTE 1: Drive shaft lengths are measured from center of U-joint and are installed lengths. angle tolerance=±0.2°

NOTE 2:

A

ll drive shafts must be dynamically balanced after modification. dimension tolerance=±1/16"

NOTE 3: Always verify proper shaft lengths before modification

NOTE 4: When not specified, the front & the rear drive shafts, on each retarder side, must have at least the same slip as the original drive shaft

NOTE 5: When not specified, the flange yoke on each retarder side must have the maximum working angle capacity available in the driveline series concerned.

NOTE 6: Install chassis bracket against inside bottom lip of frame rail

NOTE 7: After installation is completed, measure drive shaft angles and compare to the angles on the installation drawing.

Contact TELMA Customer Support Engineering if the angles measured do not conform to the drawing

NOTE 8: USE BRACKETS TIB03123, TIB03124, TIB03127

NOTE 9: Check axle angle after body is installed and if necessary adjust to 4.5° with frame reference of 0°

NOTE 10: maximum allowed vehicle speed 89mph

NOTE 11: original muffler must be replaced with shorter one

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 18 of 30__________________________________________________________________________17feb12jh

VEHICLE TECHNICAL DATA

CHASSIS MAKE / MODEL FORD E350 SPEED SWITCH JC251100

WHEELBASE 138.0" TIRE SIZE 225/75R-16

ENGINE MAKE / MODEL FORD 6.8L / 6.0L GVW / GCW 11500 lbs

TRANSMISSION MAKE / MODEL FORD 5R110 AXLE RATIO 4.10

AXLE MAKE / MODEL DANA 70 DRIVE LINE SERIES 1410 SPL36

DRIVE TYPE 4 X 2 Use OEM U-JOINT SPL36-1X

RETARDER MODEL

A

C50-55 FLANGE YOKE 3-2-429

RETARDER PART NUMBER CN201155 SUSPENSION Spring / Mor-Ryde

TELMA attests that this drawing corresponds to industry standards concerning driveline angularities and critical speeds

This drawing is valid for the application specified only. Always check all angles and dimensions for your installation.

Consult TELMA technical department if your application varies in any way Dc loaded: 9

Dv unloaded:10

TRANSMISSION= 4.1° CHASSIS BRACKET= 0.0° L2 UNLOADED WITH BODY (±1.0°) =6.3°

A

XLE UNLOADED= 4.5°

L1= 5.2° RETARDER= 4.5° L2 LOADED (±1.0°) =3.9°

A

XLE LOADED= 4.5°

AB1 C1 R1 T1 X1 L1 L2

4 6 5/16 7 5/16 12 1/16 4 1/2 -6 SHAFT LENGTH 25 9/16 24 15/16

S1 S2 S4 SR SHAFT MINIMUM TUBE DIAMETER 2.50 2.50

18 1/4 23 3/4 23 1/2 23 1/4 SHAFT MINIMUM TUBE THICKNESS 0.083 0.083

NOTE 1: Drive shaft lengths are measured from center of U-joint and are installed lengths. angle tolerance=±0.2°

NOTE 2:

A

ll drive shafts must be dynamically balanced after modification. dimension tolerance=±1/16"

NOTE 3: Always verify proper shaft lengths before modification

NOTE 4: When not specified, the front & the rear drive shafts, on each retarder side, must have at least the same slip as the original drive shaft

NOTE 5: When not specified, the flange yoke on each retarder side must have the maximum working angle capacity available in the driveline series concerned.

NOTE 6: Install chassis bracket against inside bottom lip of frame rail

NOTE 7: After installation is completed, measure drive shaft angles and compare to the angles on the installation drawing.

Contact TELMA Customer Support Engineering if the angles measured do not conform to the drawing

NOTE 8: USE BRACKETS TIB03123, TIB03124, TIB03127

NOTE 9: Check axle angle after body is installed and if necessary adjust to 4.5° with frame reference of 0°

NOTE 10: maximum allowed vehicle speed 89mph

NOTE 11: original muffler must be replaced with shorter one

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 19 of 30__________________________________________________________________________17feb12jh

V

EHI

C

LE TE

C

HNI

C

AL DAT

A

CHASSIS MAKE / MODEL FORD E350/E450 SPEED SWITCH JC251100

WHEELBASE 158.0" TIRE SIZE 225/75R-16

ENGINE MAKE / MODEL FORD 5.4L GVW / GCW 14500 lbs

TRANSMISSION MAKE / MODEL FORD 5R110 AXLE RATIO 4.56

AXLE MAKE / MODEL DANA 70HD DRIVE LINE SERIES SPL36

DRIVE TYPE 4 X 2 Use OEM U-JOINT SPL36-1X

RETARDER MODEL AC50-55 FLANGE YOKE 3-2-429

RETARDER PART NUMBER CN201154 SUSPENSION Spring / Mor-Ryde

TELMA attests that this drawing corresponds to industry standards concerning driveline angularities and critical speeds

This drawing is valid for the application specified only. Always check all angles and dimensions for your installation.

Consult TELMA technical department if your application varies in any way Dc loaded:

10

Dv unloaded:

10 3/4

L2 UNLOADED WITH BODY (±1.0°) = 5.0°

TRANSMISSION= 4.1° CHASSIS BRACKET= 0.0° L2 LOADED (±1.0°) = 3.9° AXLE UNLOADED= 4.5°

L1= 4.5° RETARDER= 4.5° AXLE LOADED= 4.5°

A

B1 C1 R1 T1

X

1L1L2

3 1/4 6 9/16 7 8/16 12 1/16 4 3/4 3

SHAFT LENGTH (±0.25")

42 1/4 36 11/16

S1 S2 S4 SR

SHAFT MINIMUM TUBE DIAMETER

3.00 3.00

18 1/4 23 3/4 23 1/2 23 1/4

SHAFT MINIMUM TUBE THICKNESS

0.083 0.083

NOTE

1

:

D

r

i

ve s

h

a

f

t

l

engt

h

s are measure

d

f

rom center o

f

U

-

j

o

i

nt an

d

are

i

nsta

ll

e

d

l

engt

h

s.

NOTE

2

:

All

d

r

i

ve s

h

a

f

ts must

b

e

d

ynam

i

ca

ll

y

b

a

l

ance

d

a

f

ter mo

difi

cat

i

on.

general dimension tolerance (except shaft lengths)= ±1/16"

NOTE

3

:

Al

ways ver

if

y proper s

h

a

ft

l

eng

th

s

b

e

f

ore mo

difi

ca

ti

on

general angle tolerance (except L2) = ±0.2°

NOTE

4

:

When not specified, the front & the rear drive shafts, on each retarder side, must have at least the same slip as the original drive shaft

NOTE

5

:

When not specified, the flange yoke on each retarder side must have the maximum working angle capacity available in the driveline series concerned.

NOTE

6

:

Install chassis bracket a

g

ainst inside bottom li

p

of frame rail

NOTE

7:

After installation is completed, measure drive shaft angles and compare to the angles on the installation drawing.

Contact TELMA Customer Support Engineering if the angles measured do not conform to the drawing

NOTE 8:

USE

BRACKETS

TIB03123

,

TIB03124

,

TIB03127

NOTE 9:

Check axle an

g

le after bod

y

is installed and if necessar

y

ad

j

ust to 4.5° with frame reference of 0°

NOTE 10: maximum allowed vehicle s

p

eed 80m

p

h

TL113005

Ford E-350/450 Cutaway Installation Manual with Telma Control Module (TRCM)

Page 20 of 30__________________________________________________________________________17feb12jh

VEHICLE TECHNICAL DATA

CHASSIS MAKE / MODEL FORD E350/E450 SPEED SWITCH JC251100

WHEELBASE 158.0" TIRE SIZE 225/75R-16

ENGINE MAKE / MODEL FORD 6.8L / 6.0L GVW / GCW 14500 lbs

TRANSMISSION MAKE / MODEL FORD 5R110 AXLE RATIO 4.56

AXLE MAKE / MODEL DANA 70HD DRIVE LINE SERIES SPL36

DRIVE TYPE 4 X 2 Use OEM U-JOINT SPL36-1X

RETARDER MODEL

A

C50-55 FLANGE YOKE 3-2-429

RETARDER PART NUMBER CN201154 SUSPENSION Spring / Mor-Ryde

TELMA attests that this drawing corresponds to industry standards concerning driveline angularities and critical speeds

This drawing is valid for the application specified only. Always check all angles and dimensions for your installation.

Consult TELMA technical department if your application varies in any way Dc loaded: 10

Dv unloaded:10 3/4

L2 UNLOADED WITH BODY (±1.0°) =5.4°

TRANSMISSION= 4.1° CHASSIS BRACKET= 0.0° L2 LOADED (±1.0°) =4.2°

A

XLE UNLOADED= 4.5°

L1= 4.5° RETARDER= 4.5°

A

XLE LOADED= 4.5°

AB1 C1 R1 T1 X1 L1 L2

3 1/4 6 5/16 7 5/16 12 1/16 4 1/2 6SHAFT LENGTH (±0.25") 39 1/4 36 11/16

S1 S2 S4 SR SHAFT MINIMUM TUBE DIAMETER 3.00 3.00

18 1/4 23 3/4 23 1/2 23 1/4 SHAFT MINIMUM TUBE THICKNESS 0.083 0.083

NOTE 1: Drive shaft lengths are measured from center of U-joint and are installed lengths.

NOTE 2:

A

ll drive shafts must be dynamically balanced after modification. general dimension tolerance (except shaft lengths)= ±1/16"

NOTE 3: Always verify proper shaft lengths before modification general angle tolerance (except L2) = ±0.2°

NOTE 4: When not specified, the front & the rear drive shafts, on each retarder side, must have at least the same slip as the original drive shaft

NOTE 5: When not specified, the flange yoke on each retarder side must have the maximum working angle capacity available in the driveline series concerned.

NOTE 6: Install chassis bracket against inside bottom lip of frame rail

NOTE 7: After installation is completed, measure drive shaft angles and compare to the angles on the installation drawing.

Contact TELMA Customer Support Engineering if the angles measured do not conform to the drawing

NOTE 8: USE BRACKETS TIB03123, TIB03124, TIB03127

NOTE 9: Check axle angle after body is installed and if necessary adjust to 4.5° with frame reference of 0°

NOTE 10: maximum allowed vehicle speed 80mph

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

piezosystemjena

piezosystemjena d-Drive pro instruction manual

WAGO

WAGO 750-624/040-00 Series manual

Viessmann

Viessmann VITOTRONIC 300 Installation and service instructions

Hitachi

Hitachi H Series instruction manual

Congatec

Congatec COM Express conga-TCA5 user guide

Nice

Nice mindy A60 Instructions and warnings