MPI TRI-SEAL FIRE-FLEX 1150 Manual

FIRE-FLEX HIGH PERFORMANCE

FIRE-SAFE BUTTERFLY VALVE

OPERATING AND

MAINTENANCE

INSTRUCTIONS

2 1/2 - 24", 1150/2150 and

1151/2151 ANSI Class 150

Table of Contents:

Design Overview ................................................... 2

Installation Instructions ........................................ 2

Valve Operation..................................................... 2

Maintenance.......................................................... 3

Troubleshooting .................................................... 3

Dimensions........................................................... 4

Materials of Construction...................................... 5

Technical Data and Flow Characteristics ............... 7

The Tri-Seal Valve Fire-Flex Series Butterfly valves contain

improvements and refinements not found in any other high

performance butterfly valves. These features serve to insure

a long and trouble-free life as well as provide much simple

and less expensive maintenance when required.

A. DESIGN FEATURES

1. The Fire-Flex features an exclusive resilient and

metallic seating arrangement, under normal operating

temperatures, that assures bubble tight shutoff affected

by the pressure-activated resilient seat. In the event of

a fire, the 304 stainless steel metal seat provides sealing

conforming to API 607 4th edition requirements without

relying on springs, system pressure, or the complete

destruction of the resilient seat. The flexible graphite

packing and gaskets prevent external leakage, avoiding

the possibility of intensifying fire.

2. Body Design – The Fire-Flex valve employs a rugged

one-piece body design with an integrally cast travel stop

and installation guides for flange bolts. These guide holes

have sufficient clearance to allow flexibility for misalignment

of mating flanges.

3. Shaft Design – The Fire-Flex shaft is a double offset

style with one-piece construction design through 16”

size, two-piece construction 18” and larger.

4. Gland Design – The Fire-Flex packing gland is a flexible

graphite design. This design offers excellent sealing

characteristics at the temperature rating of the valve,

as well as the higher temperature that would be seen

in the event of a fire.

5. Disc Design – The Fire-Flex disc is of rugged construction

with a sealing edge that is a segment of a ball. Once the disc

is forced into the seat, a bubble-tight seal is affected. Any

change of position of the disc once it is forced into the seat

will not affect performance. The result being that (within the

width of the edge) an exact stop position is not critical.

B. INSTALLATION

1. The Fire-Flex Series valves are bi-directional, and as

such can be installed for flow in either direction. However,

a preferred flow is indicated.

2. When installing a butterfly valve always be sure that the

new flange gasket of the proper material for the intended

service media are used.

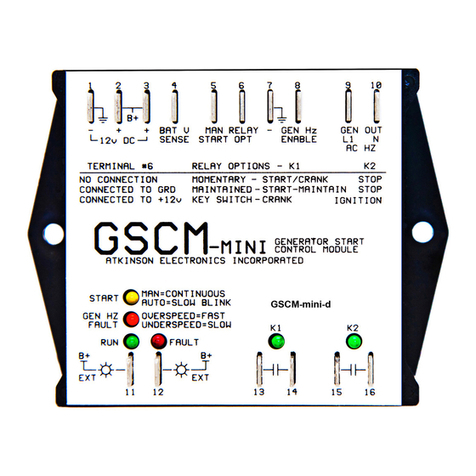

3. When installing flange bolts, always tighten bolts in a

sequential pattern, shown in Fig. 1. Bolts should be

tightened to the appropriate torque, as specified by SAE

for the bolting material used.

FIRE-FLEX HIGH PERFORMANCE BUTTERFLY VALVE

1

NOTE: After bolts have been tightened, it is good practice

to recheck flange bolt torques one-half to one hour after

initial tightening (particularly when stainless steel bolting

is used).

WARNING: As is the case with most valve types available

on the market today, (regardless of manufacturer), valve

stem seals may require periodic adjustment, therefore,

installations that do not allow access to the valve stem

should be avoided.

C. VALVE OPERATION

1. All Tri-Seal Valve Fire-Flex Butterfly Valves feature

¼ turn operation. Turning the valve handle 90 degrees

clockwise will fully close the valve, while 90 degree

counter-clockwise rotation will fully open the valve.

The valve handle also serves as a disc position indicator.

When the valve handle is parallel to the pipe the valve is

open, when perpendicular to the pipe the valve is closed.

To disengage the handle from the locking plate, simply

squeeze the bottom lever of the handle.

2. All Tri-Seal Valve Fire-Flex Butterfly valves are designed

to provide bubble tight performance when properly

selected in accordance with the valve’s pressure/temperature

rating, unless otherwise noted in the seat material

selection chart.

1

3

4

2

Figure 1: Flange bolt tightnening sequence

3. To provide the longest possible service life, a hand-

operated butterfly valve should be operated in either

its fully open or fully closed position. However, a

10 position locking plate is provided if an intermediate

operating position is desired.

4. The torques listed under “Break Away” at the end of this

instruction sheet are the normal expected breakaway

torques. These values represent the maximum force

required to begin to open the valve at specified differential

pressures. Typically, this breakaway torque is the maximum

torque requirement for the valve during a closed-to-open,

open-to-close cycle. Bear in mind that these have been

confirmed by laboratory testing of each valve size while

pressurized with water to its maximum pressure rating

(certain highly viscous or abrasive services could cause

an increase in torque requirements).

D. MAINTENANCE

During its normal service life, the only maintenance that

may be required by your Tri-Seal Valve Fire-Flex butterfly

valve should be periodic stem seal adjustment. If leakage

at the stem is noted, simply tighten the packing plate until

leakage subsides. DO NOT OVER TIGHTEN, AS PREMATURE

WEAR COULD RESULT.

It is impractical to predict frequency of stem adjustment,

as it is influenced by such factors as frequency of cycling

and service media.

IMPORTANT: As is the case with ANY valve on the market

today, it is important that stem leaks do not go unattended.

Lack of maintenance of stem leakage could cause a

premature need to replace stem seals.

NOTE: If operating temperature of system is substantially

higher or lower than 80° F, initial stem seal adjustment may

be required to prevent leakage.

E. DISASSEMBLY

WARNING: Most standard bi-directional High Performance

butterfly valves on the market today, regardless of

manufacturer, can trap fluid in the valve cavity when closed.

If your Tri-Seal Valve Fire-Flex butterfly valve has been used

to conduct a hazardous media, the following steps must be

taken prior to removal from line and disassembled:

1. Relieve line pressure.

2. Place valve in its half-open position and flush the line to

remove the hazardous material from the valve cavity.

The valve can now be removed from the line.

NOTE: Always advise maintenance personnel when they

are maintaining or rebuilding a valve that has been

conducting hazardous material. Proper protective clothing

and eye protection should always be utilized.

3. To disassemble entire valve:

a. Having assured that BOTH line and valve cavity pressures

have been relieved, remove the valve from the line.

b. Place the valve in a vice or other suitable retention tool

that will adequately support the valve while it is being

disassembled.

c. Remove valve handle, gear operator or actuator.

d. To access the seats (PTFE and metal back up) remove

outer seat retainer and inner seat retainer by the appropriate

method listed below, wafer style 2 ½ - 14 only. With the

valve rotated so the shaft side of disc is on the seat retainer

side (past full open), rotate the seat retainer such that the

notches are no longer in the 12 and 6 o’clock positions. Lift

outer seat retainer to remove from valve then lift out inner

seat retainer. Any Grafoil gasket material should be removed.

Lift the backup metal seat out of the body by prying it from

its outside edge or inside lock lip.

e. Remove hex head cap screws, lock washers and

positioning plate from top mounting flange.

f. Remove self-locking gland retainer hex nuts and

gland retainer.

g. Remove jam nuts, shaft retaining plate and outer gland ring.

h. Remove shaft retaining ring (2 ½ ” through 14” only)

stem packing and inner gland ring.

i. Remove hex head cap screws, lock washers, and cap on

the bottom of the valve.

j. Remove key (2 ½ ”- 8”) or pins (10”- 24”) from disc and

shaft assembly.

For key removal: grind off spot welds and punch out key.

For pin removal: All dowel pins have been drilled and tapped

to facilitate their extraction. The thread sizes are as follows:

10”-20” = ¼ - 20, 24” = 3/8-16.

k. Slide shaft from valve body, lift out disc and thrust

washers located at the top and bottom of shaft bore.

l. Care should be taken when replacing the bearings, as

they can be damaged while pressing them out.

F. REASSEMBLY

Having assured that all critical surfaces have been inspected,

cleaned and/or replaced, reassembly can begin.

1. If replacing shaft bearings, carefully press bearings into

the shaft bore of the valve body until bearings are flush with

shoulder inside bore.

FIRE-FLEX HIGH PERFORMANCE BUTTERFLY VALVE

2

2. While holding the thrust washers against the milled spot

faces on the O.D. of the disc, insert the disc into the valve and

align the disc shaft bore with the body bore.

NOTE: Be sure that the disc is orientated such that the “T” on

the keyed disc (8” and smaller) or the dowel pin holes (10” and

larger) are located toward the side opposite of the seat retainer

and near the packing side.

3. Insert the shaft through the shaft bore and disc, ensuring

proper alignment of the key way or pinholes to the same of

the disc.

4. Press the key or dowel pins in place and stake to secure.

NOTE: Key should be tack-welded to insure proper operation.

5. Making sure disc is rotated fully CCW, lay first Grafoil gasket

in seat counter bore, insert metal back up seat into body, making

sure back lock lip is in place. Lay second Grafoil on top of metal

seat. Place inner seat retainer into body. Lay third Grafoil gasket

on top of inner seat retainer. Insert the seat into the seat retainer

ensuring the flat back of the seat is flush with the top edge of

the retainer.

CAUTION: Care must be exercised to assure the seat is not

installed upside down. Install the seat retainer springs, with

seat retainer notches located at the 6 and 12 o’clock positions

insert the retaining springs as follows: insert the straight leg of

the retaining spring into the hole located at the bottom of the

groove on the OD of the retainer to the left of the notch that is

located at 12 o’clock, making sure that other end of the spring is

extending to the right. Then insert the remaining spring into the

hole located to the right of the notch located at 6 o’clock with the

opposite end extending to the left. NOTE: See enclosed drawing

for location of retaining springs.

6. With the valve still in the full CCW position and laying flat

on a safe working surface, place the seat retainer, seat and seat

retainer springs into the valve body, such that the seat retainer is

locked into place. Rotate disc to the fully closed position. On lug

valves the seat retainer screw should not be tightened until the

disc is in the closed position.

7. To secure the seat retainer to the valve body use the

following procedure:

WAFER (2 ½ ”-14”) ONLY – With one side of the seat retainer

pressed into the valve body, depress seat retainer seat retaining

spring and push the seat retainer down so that it is flush to .010

above the body. Rotate seat retainer until the notches are in the

6 and 12 o’clock positions locking the retaining springs in place.

LUG (and Wafer 16”-24”) – Install and tighten socket head cap

screws insuring the retainer is bottomed in body.

8. Install inner gland ring into shaft bore. Install flexible graphite

stem packing.

9. Install shaft-retaining ring into groove on shaft. Slide outer

gland ring onto the shaft and place nameplate and shaft retaining

plate onto gland retaining studs. Secure with jam nuts.

10. Install gland retainer plate and secure finger tight with

self-locking retainer nuts. Tighten as required when installed

into service.

11. Install end cap with Grafoil seal onto bottom of the valve and

secure with lock washer and hex head cap screws.

12. Place positioning plate onto mounting flange and secure

finger tight with lock washers and hex head cap screws. NOTE:

The overhang of the plate should be behind and to the right of

the seat retainer while looking at the retainer side of the valve.

13. With the valve in an approximate closed position, slide the

handle onto the shaft so that the bottom tang of the handle

engages the positioning plate. Secure handle to shaft by tight-

ening hex head cap screw on handle. Rotate the valve to its fully

closed position if the handle is not locked into the last notch of

the positing plate.

G. COMMON PROBLEMS encountered with high performance

butterfly valves (with associated corrective action options):

1. Shaft Leakage:

a. Tighten gland retainer nuts (careful not to over tighten –

just enough so leakage stops.)

b. Replace gland packing.

2. Leakage between Flange and Valve:

a. Tighten flange bolts.

b. Replace flange gasket.

3. Leakage through Valve Seat:

a. Clean seat and retainer groove. Replace seat.

b. Reposition seat on disc if evidence of minor damage is visible.

c. Replace disc and shaft assembly.

4. Excessive Torque:

a. Check alignment of valve actuator and adjust if side

loading is evident.

b. Replace bearings if slight galling has occurred on shaft.

c. Replace bearing and shaft if galling is excessive.

TRI-SEAL QUARTER-FLEX BUTTERFLY VALVE

3

TRI-SEAL QUARTER-FLEX BUTTERFLY VALVE

4

MATERIALS OF CONSTRUCTION - ANSI CLASS 150

Dimensions (inches) - ANSI Class 150

Wafer Style

Seat Detail

Stem Detail

Keyed Stem

10"-24" Cl. 150

8"-12" Cl. 300

Flatted Stem

2

1

/

2

"- 8" Cl. 150

3"- 6" Cl. 300

Lug Style

Seat Detail

20 10

27

13

12

13

14

3

2

1

12

4

9

6

8

8

7

6

14

22

21

20

24

22

21

19

18

17

16

19

18

17

16

5

A-

Dia.

C

B

G

Dia.

D

E

T

V-

Dia.

Thru

N

Flats

U

Y

V-

Dia.

Thru

U

R

Y

X

TX

P

S

S

J

1

-

Dia. Thru

W-

Qty.

K-

Dia.

J-

Dia.

(2) Thru Holes

See Stem Detail

See Seat Detail

K-

Dia.

H

˚

H

˚

L-

Dia.

L-

Dia.

F

D

1

E

F

A

1

-

Dia.

Lug Style Wafer Style

Size

Dimension (in.) - ANSI Class 150

A A1 B C D D1 E F G H J J1 K L N P R S T U V W X Y

2.5

4.69 6.75 1.06 1.88 3.00 3.00 4.75 1.00 2.19 45.00 .69

5

/

8

-11 5.50 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

3

5.19 7.25 1.06 1.88 3.25 3.31 5.13 1.00 2.81 45.00 .69

5

/

8

-11 6.00 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

4

6.50 8.88 1.06 2.13 3.94 4.94 6.25 1.00 3.88 22.50 .69

5

/

8

-11 7.50 .63 .50 — — 1.078 2.00 3.50 .406 8 1.00 1.75

5

7.56 10.00 1.25 2.25 4.56 5.44 7.06 1.00 4.75 22.50 .81

3

/

4

-10 9.00 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

6

8.63 11.00 1.25 2.25 5.00 5.88 7.63 1.00 5.75 22.50 .81

3

/

4

-10 9.50 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

8

10.81 13.50 1.44 2.50 6.19 7.00 9.63 1.75 7.63 22.50 .81

3

/

4

-10 11.75 1.13 .88 — — 1.828 2.56 4.00 .563 8 1.28 2.00

10

12.88 16.00 1.63 2.81 7.25 8.44 10.22 2.94 9.69 15.00 .94

7

/

8

-9 14.25 1.13 — .25 .984 2.25 3.25 4.75 .563 12 1.63 2.38

12

15.25 19.00 1.75 3.19 8.75 10.00 11.94 3.00 11.69 15.00 .94

7

/

8

-9 17.00 1.25 — .38 1.033 2.25 3.50 5.00 .688 12 1.75 2.50

14

16.75 21.00 1.88 3.63 9.88 10.88 13.19 3.00 12.81 15.00 1.06 1-8 18.75 1.38 — .38 1.156 2.25 4.75 5.63 .688 12 2.38 2.81

16

19.88 23.50 2.19 4.00 11.28 12.59 14.34 4.56 14.78 11.25 1.13 1-8 21.25 1.50 — .38 1.28 3.63 5.13 7.00 .688 16 2.56 3.50

18

21.00 25.00 2.47 4.50 13.38 13.38 16.44 4.81 16.75 11.25 1

1

/

8

-8 1

1

/

8

-8 22.75 1.75 — .50 1.47 4.00 5.50 8.00 .813 16 2.75 4.00

20

23.00 27.50 2.47 5.00 14.81 14.81 18.00 4.81 18.72 9 1

1

/

8

-8 1

1

/

8

-8 25.00 1.75 — .50 1.47 4.00 5.50 8.00 .813 20 2.75 4.00

24

27.75 32.00 3.03 6.06 16.63 16.63 20.25 4.44 22.63 9 1

1

/

8

-8 1

1

/

8

-8 29.50 2.75 — .75 2.38 4.00 9.00 11.00 .813 20 4.50 5.50

30

34 38.75 4.25 8.50 29.88 29.88 33.13 10.31 28 6.25 1

1

/

4

-8 1

1

/

4

-8 36.00 2.992 — .75 2.562 4.50 6.38 6.38

3

/

4

-10 28 3 3

36 39.25 47.25 4.19 8.38 27.38 27.38 37.00 11.00 34.0 5.63 1

1

/

2

-8

1

1

/

2

-8 4.75 3.999

—

1.0 3.437 4.50 6.50 9.50 1-8 32 3.25 4.75

Dimensions (inches) - ANSI Class 150

Wafer Style

Seat Detail

Stem Detail

Keyed Stem

10"-24" Cl. 150

8"-12" Cl. 300

Flatted Stem

2

1

/

2

"- 8" Cl. 150

3"- 6" Cl. 300

Lug Style

Seat Detail

20 10

27

13

12

13

14

3

2

1

12

4

9

6

8

8

7

6

14

22

21

20

24

22

21

19

18

17

16

19

18

17

16

5

A-

Dia.

C

B

G

Dia.

D

E

T

V-

Dia.

Thru

N

Flats

U

Y

V-

Dia.

Thru

U

R

Y

X

TX

P

SS

J

1

-

Dia. Thru

W-

Qty.

K-

Dia.

J-

Dia.

(2) Thru Holes

See Stem Detail

See Seat Detail

K-

Dia.

H

˚

H

˚

L-

Dia.

L-

Dia.

F

D

1

E

F

A

1

-

Dia.

Lug Style Wafer Style

Size

Dimension (in.) - ANSI Class 150

A A1 B C D D1 E F G H J J1 K L N P R S T U V W X Y

2.5

4.69 6.75 1.06 1.88 3.00 3.00 4.75 1.00 2.19 45.00 .69

5

/

8

-11 5.50 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

3

5.19 7.25 1.06 1.88 3.25 3.31 5.13 1.00 2.81 45.00 .69

5

/

8

-11 6.00 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

4

6.50 8.88 1.06 2.13 3.94 4.94 6.25 1.00 3.88 22.50 .69

5

/

8

-11 7.50 .63 .50 — — 1.078 2.00 3.50 .406 8 1.00 1.75

5

7.56 10.00 1.25 2.25 4.56 5.44 7.06 1.00 4.75 22.50 .81

3

/

4

-10 9.00 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

6

8.63 11.00 1.25 2.25 5.00 5.88 7.63 1.00 5.75 22.50 .81

3

/

4

-10 9.50 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

8

10.81 13.50 1.44 2.50 6.19 7.00 9.63 1.75 7.63 22.50 .81

3

/

4

-10 11.75 1.13 .88 — — 1.828 2.56 4.00 .563 8 1.28 2.00

10

12.88 16.00 1.63 2.81 7.25 8.44 10.22 2.94 9.69 15.00 .94

7

/

8

-9 14.25 1.13 — .25 .984 2.25 3.25 4.75 .563 12 1.63 2.38

12

15.25 19.00 1.75 3.19 8.75 10.00 11.94 3.00 11.69 15.00 .94

7

/

8

-9 17.00 1.25 — .38 1.033 2.25 3.50 5.00 .688 12 1.75 2.50

14

16.75 21.00 1.88 3.63 9.88 10.88 13.19 3.00 12.81 15.00 1.06 1-8 18.75 1.38 — .38 1.156 2.25 4.75 5.63 .688 12 2.38 2.81

16

19.88 23.50 2.19 4.00 11.28 12.59 14.34 4.56 14.78 11.25 1.13 1-8 21.25 1.50 — .38 1.28 3.63 5.13 7.00 .688 16 2.56 3.50

18

21.00 25.00 2.47 4.50 13.38 13.38 16.44 4.81 16.75 11.25 1

1

/

8

-8 1

1

/

8

-8 22.75 1.75 — .50 1.47 4.00 5.50 8.00 .813 16 2.75 4.00

20

23.00 27.50 2.47 5.00 14.81 14.81 18.00 4.81 18.72 9 1

1

/

8

-8 1

1

/

8

-8 25.00 1.75 — .50 1.47 4.00 5.50 8.00 .813 20 2.75 4.00

24

27.75 32.00 3.03 6.06 16.63 16.63 20.25 4.44 22.63 9 1

1

/

8

-8 1

1

/

8

-8 29.50 2.75 — .75 2.38 4.00 9.00 11.00 .813 20 4.50 5.50

30

34 38.75 4.25 8.50 29.88 29.88 33.13 10.31 28 6.25 1

1

/

4

-8 1

1

/

4

-8 36.00 2.992 — .75 2.562 4.50 6.38 6.38

3

/

4

-10 28 3 3

36 39.25 47.25 4.19 8.38 27.38 27.38 37.00 11.00 34.0 5.63 1

1

/

2

-8

1

1

/

2-

8 4.75 3.999

—

1.0 3.437 4.50 6.50 9.50 1-8 32 3.25 4.75

Dimensions (inches) - ANSI Class 150

Wafer Style

Seat Detail

Stem Detail

Keyed Stem

10"-24" Cl. 150

8"-12" Cl. 300

Flatted Stem

2

1

/

2

"- 8" Cl. 150

3"- 6" Cl. 300

Lug Style

Seat Detail

20 10

27

13

12

13

14

3

2

1

12

4

9

6

8

8

7

6

14

22

21

20

24

22

21

19

18

17

16

19

18

17

16

5

A-

Dia.

C

B

G

Dia.

D

E

T

V-

Dia.

Thru

N

Flats

U

Y

V-

Dia.

Thru

U

R

Y

X

TX

P

SS

J

1

-

Dia. Thru

W-

Qty.

K-

Dia.

J-

Dia.

(2) Thru Holes

See Stem Detail

See Seat Detail

K-

Dia.

H

˚

H

˚

L-

Dia.

L-

Dia.

F

D

1

E

F

A

1

-

Dia.

Lug Style Wafer Style

Size

Dimension (in.) - ANSI Class 150

A A1 B C D D1 E F G H J J1 K L N P R S T U V W X Y

2.5

4.69 6.75 1.06 1.88 3.00 3.00 4.75 1.00 2.19 45.00 .69

5

/

8

-11 5.50 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

3

5.19 7.25 1.06 1.88 3.25 3.31 5.13 1.00 2.81 45.00 .69

5

/

8

-11 6.00 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

4

6.50 8.88 1.06 2.13 3.94 4.94 6.25 1.00 3.88 22.50 .69

5

/

8

-11 7.50 .63 .50 — — 1.078 2.00 3.50 .406 8 1.00 1.75

5

7.56 10.00 1.25 2.25 4.56 5.44 7.06 1.00 4.75 22.50 .81

3

/

4

-10 9.00 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

6

8.63 11.00 1.25 2.25 5.00 5.88 7.63 1.00 5.75 22.50 .81

3

/

4

-10 9.50 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

8

10.81 13.50 1.44 2.50 6.19 7.00 9.63 1.75 7.63 22.50 .81

3

/

4

-10 11.75 1.13 .88 — — 1.828 2.56 4.00 .563 8 1.28 2.00

10

12.88 16.00 1.63 2.81 7.25 8.44 10.22 2.94 9.69 15.00 .94

7

/

8

-9 14.25 1.13 — .25 .984 2.25 3.25 4.75 .563 12 1.63 2.38

12

15.25 19.00 1.75 3.19 8.75 10.00 11.94 3.00 11.69 15.00 .94

7

/

8

-9 17.00 1.25 — .38 1.033 2.25 3.50 5.00 .688 12 1.75 2.50

14

16.75 21.00 1.88 3.63 9.88 10.88 13.19 3.00 12.81 15.00 1.06 1-8 18.75 1.38 — .38 1.156 2.25 4.75 5.63 .688 12 2.38 2.81

16

19.88 23.50 2.19 4.00 11.28 12.59 14.34 4.56 14.78 11.25 1.13 1-8 21.25 1.50 — .38 1.28 3.63 5.13 7.00 .688 16 2.56 3.50

18

21.00 25.00 2.47 4.50 13.38 13.38 16.44 4.81 16.75 11.25 1

1

/

8

-8 1

1

/

8

-8 22.75 1.75 — .50 1.47 4.00 5.50 8.00 .813 16 2.75 4.00

20

23.00 27.50 2.47 5.00 14.81 14.81 18.00 4.81 18.72 9 1

1

/

8

-8 1

1

/

8

-8 25.00 1.75 — .50 1.47 4.00 5.50 8.00 .813 20 2.75 4.00

24

27.75 32.00 3.03 6.06 16.63 16.63 20.25 4.44 22.63 9 1

1

/

8

-8 1

1

/

8

-8 29.50 2.75 — .75 2.38 4.00 9.00 11.00 .813 20 4.50 5.50

30

34 38.75 4.25 8.50 29.88 29.88 33.13 10.31 28 6.25 1

1

/

4

-8 1

1

/

4

-8 36.00 2.992 — .75 2.562 4.50 6.38 6.38

3

/

4

-10 28 3 3

36 39.25 47.25 4.19 8.38 27.38 27.38 37.00 11.00 34.0 5.63 1

1

/

2

-8

1

1

/

2-

8 4.75 3.999

—

1.0 3.437 4.50 6.50 9.50 1-8 32 3.25 4.75

Dimensions (inches) - ANSI Class 150

Wafer Style

Seat Detail

Stem Detail

Keyed Stem

10"-24" Cl. 150

8"-12" Cl. 300

Flatted Stem

2

1

/

2

"- 8" Cl. 150

3"- 6" Cl. 300

Lug Style

Seat Detail

20 10

27

13

12

13

14

3

2

1

12

4

9

6

8

8

7

6

14

22

21

20

24

22

21

19

18

17

16

19

18

17

16

5

A-

Dia.

C

B

G

Dia.

D

E

T

V-

Dia.

Thru

N

Flats

U

Y

V-

Dia.

Thru

U

R

Y

X

TX

P

SS

J

1

-

Dia. Thru

W-

Qty.

K-

Dia.

J-

Dia.

(2) Thru Holes

See Stem Detail

See Seat Detail

K-

Dia.

H

˚

H

˚

L-

Dia.

L-

Dia.

F

D

1

E

F

A

1

-

Dia.

Lug Style Wafer Style

Size

Dimension (in.) - ANSI Class 150

A A1 B C D D1 E F G H J J1 K L N P R S T U V W X Y

2.5

4.69 6.75 1.06 1.88 3.00 3.00 4.75 1.00 2.19 45.00 .69

5

/

8

-11 5.50 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

3

5.19 7.25 1.06 1.88 3.25 3.31 5.13 1.00 2.81 45.00 .69

5

/

8

-11 6.00 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

4

6.50 8.88 1.06 2.13 3.94 4.94 6.25 1.00 3.88 22.50 .69

5

/

8

-11 7.50 .63 .50 — — 1.078 2.00 3.50 .406 8 1.00 1.75

5

7.56 10.00 1.25 2.25 4.56 5.44 7.06 1.00 4.75 22.50 .81

3

/

4

-10 9.00 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

6

8.63 11.00 1.25 2.25 5.00 5.88 7.63 1.00 5.75 22.50 .81

3

/

4

-10 9.50 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

8

10.81 13.50 1.44 2.50 6.19 7.00 9.63 1.75 7.63 22.50 .81

3

/

4

-10 11.75 1.13 .88 — — 1.828 2.56 4.00 .563 8 1.28 2.00

10

12.88 16.00 1.63 2.81 7.25 8.44 10.22 2.94 9.69 15.00 .94

7

/

8

-9 14.25 1.13 — .25 .984 2.25 3.25 4.75 .563 12 1.63 2.38

12

15.25 19.00 1.75 3.19 8.75 10.00 11.94 3.00 11.69 15.00 .94

7

/

8

-9 17.00 1.25 — .38 1.033 2.25 3.50 5.00 .688 12 1.75 2.50

14

16.75 21.00 1.88 3.63 9.88 10.88 13.19 3.00 12.81 15.00 1.06 1-8 18.75 1.38 — .38 1.156 2.25 4.75 5.63 .688 12 2.38 2.81

16

19.88 23.50 2.19 4.00 11.28 12.59 14.34 4.56 14.78 11.25 1.13 1-8 21.25 1.50 — .38 1.28 3.63 5.13 7.00 .688 16 2.56 3.50

18

21.00 25.00 2.47 4.50 13.38 13.38 16.44 4.81 16.75 11.25 1

1

/

8

-8 1

1

/

8

-8 22.75 1.75 — .50 1.47 4.00 5.50 8.00 .813 16 2.75 4.00

20

23.00 27.50 2.47 5.00 14.81 14.81 18.00 4.81 18.72 9 1

1

/

8

-8 1

1

/

8

-8 25.00 1.75 — .50 1.47 4.00 5.50 8.00 .813 20 2.75 4.00

24

27.75 32.00 3.03 6.06 16.63 16.63 20.25 4.44 22.63 9 1

1

/

8

-8 1

1

/

8

-8 29.50 2.75 — .75 2.38 4.00 9.00 11.00 .813 20 4.50 5.50

30

34 38.75 4.25 8.50 29.88 29.88 33.13 10.31 28 6.25 1

1

/

4

-8 1

1

/

4

-8 36.00 2.992 — .75 2.562 4.50 6.38 6.38

3

/

4

-10 28 3 3

36 39.25 47.25 4.19 8.38 27.38 27.38 37.00 11.00 34.0 5.63 1

1

/

2

-8

1

1

/

2-

8 4.75 3.999

—

1.0 3.437 4.50 6.50 9.50 1-8 32 3.25 4.75

Dimensions (inches) - ANSI Class 150

Wafer Style

Seat Detail

Stem Detail

Keyed Stem

10"-24" Cl. 150

8"-12" Cl. 300

Flatted Stem

2

1

/

2

"- 8" Cl. 150

3"- 6" Cl. 300

Lug Style

Seat Detail

20 10

27

13

12

13

14

3

2

1

12

4

9

6

8

8

7

6

14

22

21

20

24

22

21

19

18

17

16

19

18

17

16

5

A-

Dia.

C

B

G

Dia.

D

E

T

V-

Dia.

Thru

N

Flats

U

Y

V-

Dia.

Thru

U

R

Y

X

TX

P

SS

J

1

-

Dia. Thru

W-

Qty.

K-

Dia.

J-

Dia.

(2) Thru Holes

See Stem Detail

See Seat Detail

K-

Dia.

H˚

H˚

L-

Dia.

L-

Dia.

F

D

1

E

F

A

1

-

Dia.

Lug Style Wafer Style

Size

Dimension (in.) - ANSI Class 150

A A1 B C D D1 E F G H J J1 K L N P R S T U V W X Y

2.5

4.69 6.75 1.06 1.88 3.00 3.00 4.75 1.00 2.19 45.00 .69

5

/

8

-11 5.50 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

3

5.19 7.25 1.06 1.88 3.25 3.31 5.13 1.00 2.81 45.00 .69

5

/

8

-11 6.00 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

4

6.50 8.88 1.06 2.13 3.94 4.94 6.25 1.00 3.88 22.50 .69

5

/

8

-11 7.50 .63 .50 — — 1.078 2.00 3.50 .406 8 1.00 1.75

5

7.56 10.00 1.25 2.25 4.56 5.44 7.06 1.00 4.75 22.50 .81

3

/

4

-10 9.00 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

6

8.63 11.00 1.25 2.25 5.00 5.88 7.63 1.00 5.75 22.50 .81

3

/

4

-10 9.50 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

8

10.81 13.50 1.44 2.50 6.19 7.00 9.63 1.75 7.63 22.50 .81

3

/

4

-10 11.75 1.13 .88 — — 1.828 2.56 4.00 .563 8 1.28 2.00

10

12.88 16.00 1.63 2.81 7.25 8.44 10.22 2.94 9.69 15.00 .94

7

/

8

-9 14.25 1.13 — .25 .984 2.25 3.25 4.75 .563 12 1.63 2.38

12

15.25 19.00 1.75 3.19 8.75 10.00 11.94 3.00 11.69 15.00 .94

7

/

8

-9 17.00 1.25 — .38 1.033 2.25 3.50 5.00 .688 12 1.75 2.50

14

16.75 21.00 1.88 3.63 9.88 10.88 13.19 3.00 12.81 15.00 1.06 1-8 18.75 1.38 — .38 1.156 2.25 4.75 5.63 .688 12 2.38 2.81

16

19.88 23.50 2.19 4.00 11.28 12.59 14.34 4.56 14.78 11.25 1.13 1-8 21.25 1.50 — .38 1.28 3.63 5.13 7.00 .688 16 2.56 3.50

18

21.00 25.00 2.47 4.50 13.38 13.38 16.44 4.81 16.75 11.25 1

1

/

8

-8 1

1

/

8

-8 22.75 1.75 — .50 1.47 4.00 5.50 8.00 .813 16 2.75 4.00

20

23.00 27.50 2.47 5.00 14.81 14.81 18.00 4.81 18.72 9 1

1

/

8

-8 1

1

/

8

-8 25.00 1.75 — .50 1.47 4.00 5.50 8.00 .813 20 2.75 4.00

24

27.75 32.00 3.03 6.06 16.63 16.63 20.25 4.44 22.63 9 1

1

/

8

-8 1

1

/

8

-8 29.50 2.75 — .75 2.38 4.00 9.00 11.00 .813 20 4.50 5.50

30

34 38.75 4.25 8.50 29.88 29.88 33.13 10.31 28 6.25 1

1

/

4

-8 1

1

/

4

-8 36.00 2.992 — .75 2.562 4.50 6.38 6.38

3

/

4

-10 28 3 3

36 39.25 47.25 4.19 8.38 27.38 27.38 37.00 11.00 34.0 5.63 1

1

/

2

-8

1

1

/

2

-

8 4.75 3.999

—

1.0 3.437 4.50 6.50 9.50 1-8 32 3.25 4.75

Dimensions (inches) - ANSI Class 150

Wafer Style

Seat Detail

Stem Detail

Keyed Stem

10"-24" Cl. 150

8"-12" Cl. 300

Flatted Stem

2

1

/

2

"- 8" Cl. 150

3"- 6" Cl. 300

Lug Style

Seat Detail

20 10

27

13

12

13

14

3

2

1

12

4

9

6

8

8

7

6

14

22

21

20

24

22

21

19

18

17

16

19

18

17

16

5

A-

Dia.

C

B

G

Dia.

D

E

T

V-

Dia.

Thru

N

Flats

U

Y

V-

Dia.

Thru

U

R

Y

X

TX

P

S

S

J

1

-

Dia. Thru

W-

Qty.

K-

Dia.

J-

Dia.

(2) Thru Holes

See Stem Detail

See Seat Detail

K-

Dia.

H

˚

H

˚

L-

Dia.

L-

Dia.

F

D

1

E

F

A

1

-

Dia.

Lug Style Wafer Style

Size

Dimension (in.) - ANSI Class 150

A A1 B C D D1 E F G H J J1 K L N P R S T U V W X Y

2.5

4.69 6.75 1.06 1.88 3.00 3.00 4.75 1.00 2.19 45.00 .69

5

/

8

-11 5.50 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

3

5.19 7.25 1.06 1.88 3.25 3.31 5.13 1.00 2.81 45.00 .69

5

/

8

-11 6.00 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

4

6.50 8.88 1.06 2.13 3.94 4.94 6.25 1.00 3.88 22.50 .69

5

/

8

-11 7.50 .63 .50 — — 1.078 2.00 3.50 .406 8 1.00 1.75

5

7.56 10.00 1.25 2.25 4.56 5.44 7.06 1.00 4.75 22.50 .81

3

/

4

-10 9.00 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

6

8.63 11.00 1.25 2.25 5.00 5.88 7.63 1.00 5.75 22.50 .81

3

/

4

-10 9.50 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

8

10.81 13.50 1.44 2.50 6.19 7.00 9.63 1.75 7.63 22.50 .81

3

/

4

-10 11.75 1.13 .88 — — 1.828 2.56 4.00 .563 8 1.28 2.00

10

12.88 16.00 1.63 2.81 7.25 8.44 10.22 2.94 9.69 15.00 .94

7

/

8

-9 14.25 1.13 — .25 .984 2.25 3.25 4.75 .563 12 1.63 2.38

12

15.25 19.00 1.75 3.19 8.75 10.00 11.94 3.00 11.69 15.00 .94

7

/

8

-9 17.00 1.25 — .38 1.033 2.25 3.50 5.00 .688 12 1.75 2.50

14

16.75 21.00 1.88 3.63 9.88 10.88 13.19 3.00 12.81 15.00 1.06 1-8 18.75 1.38 — .38 1.156 2.25 4.75 5.63 .688 12 2.38 2.81

16

19.88 23.50 2.19 4.00 11.28 12.59 14.34 4.56 14.78 11.25 1.13 1-8 21.25 1.50 — .38 1.28 3.63 5.13 7.00 .688 16 2.56 3.50

18

21.00 25.00 2.47 4.50 13.38 13.38 16.44 4.81 16.75 11.25 1

1

/

8

-8 1

1

/

8

-8 22.75 1.75 — .50 1.47 4.00 5.50 8.00 .813 16 2.75 4.00

20

23.00 27.50 2.47 5.00 14.81 14.81 18.00 4.81 18.72 9 1

1

/

8

-8 1

1

/

8

-8 25.00 1.75 — .50 1.47 4.00 5.50 8.00 .813 20 2.75 4.00

24

27.75 32.00 3.03 6.06 16.63 16.63 20.25 4.44 22.63 9 1

1

/

8

-8 1

1

/

8

-8 29.50 2.75 — .75 2.38 4.00 9.00 11.00 .813 20 4.50 5.50

30

34 38.75 4.25 8.50 29.88 29.88 33.13 10.31 28 6.25 1

1

/

4

-8 1

1

/

4

-8 36.00 2.992 — .75 2.562 4.50 6.38 6.38

3

/

4

-10 28 3 3

36 39.25 47.25 4.19 8.38 27.38 27.38 37.00 11.00 34.0 5.63 1

1

/

2

-8

1

1

/

2

-8 4.75 3.999

—

1.0 3.437 4.50 6.50 9.50 1-8 32 3.25 4.75

Dimensions (inches) - ANSI Class 150

Wafer Style

Seat Detail

Stem Detail

Keyed Stem

10"-24" Cl. 150

8"-12" Cl. 300

Flatted Stem

2

1

/

2

"- 8" Cl. 150

3"- 6" Cl. 300

Lug Style

Seat Detail

20

10

27

13

12

13

14

3

2

1

12

4

9

6

8

8

7

6

14

22

21

20

24

22

21

19

18

17

16

19

18

17

16

5

A-

Dia.

C

B

G

Dia.

D

E

T

V-

Dia.

Thru

N

Flats

U

Y

V-

Dia.

Thru

U

R

Y

X

TX

P

SS

J

1

-

Dia. Thru

W-

Qty.

K-

Dia.

J-

Dia.

(2) Thru Holes

See Stem Detail

See Seat Detail

K-

Dia.

H˚

H˚

L-

Dia.

L-

Dia.

F

D

1

E

F

A

1

-

Dia.

Lug Style Wafer Style

Size

Dimension (in.) - ANSI Class 150

A A1 B C D D1 E F G H J J1 K L N P R S T U V W X Y

2.5

4.69 6.75 1.06 1.88 3.00 3.00 4.75 1.00 2.19 45.00 .69

5

/

8

-11 5.50 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

3

5.19 7.25 1.06 1.88 3.25 3.31 5.13 1.00 2.81 45.00 .69

5

/

8

-11 6.00 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

4

6.50 8.88 1.06 2.13 3.94 4.94 6.25 1.00 3.88 22.50 .69

5

/

8

-11 7.50 .63 .50 — — 1.078 2.00 3.50 .406 8 1.00 1.75

5

7.56 10.00 1.25 2.25 4.56 5.44 7.06 1.00 4.75 22.50 .81

3

/

4

-10 9.00 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

6

8.63 11.00 1.25 2.25 5.00 5.88 7.63 1.00 5.75 22.50 .81

3

/

4

-10 9.50 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

8

10.81 13.50 1.44 2.50 6.19 7.00 9.63 1.75 7.63 22.50 .81

3

/

4

-10 11.75 1.13 .88 — — 1.828 2.56 4.00 .563 8 1.28 2.00

10

12.88 16.00 1.63 2.81 7.25 8.44 10.22 2.94 9.69 15.00 .94

7

/

8

-9 14.25 1.13 — .25 .984 2.25 3.25 4.75 .563 12 1.63 2.38

12

15.25 19.00 1.75 3.19 8.75 10.00 11.94 3.00 11.69 15.00 .94

7

/

8

-9 17.00 1.25 — .38 1.033 2.25 3.50 5.00 .688 12 1.75 2.50

14

16.75 21.00 1.88 3.63 9.88 10.88 13.19 3.00 12.81 15.00 1.06 1-8 18.75 1.38 — .38 1.156 2.25 4.75 5.63 .688 12 2.38 2.81

16

19.88 23.50 2.19 4.00 11.28 12.59 14.34 4.56 14.78 11.25 1.13 1-8 21.25 1.50 — .38 1.28 3.63 5.13 7.00 .688 16 2.56 3.50

18

21.00 25.00 2.47 4.50 13.38 13.38 16.44 4.81 16.75 11.25 1

1

/

8

-8 1

1

/

8

-8 22.75 1.75 — .50 1.47 4.00 5.50 8.00 .813 16 2.75 4.00

20

23.00 27.50 2.47 5.00 14.81 14.81 18.00 4.81 18.72 9 1

1

/

8

-8 1

1

/

8

-8 25.00 1.75 — .50 1.47 4.00 5.50 8.00 .813 20 2.75 4.00

24

27.75 32.00 3.03 6.06 16.63 16.63 20.25 4.44 22.63 9 1

1

/

8

-8 1

1

/

8

-8 29.50 2.75 — .75 2.38 4.00 9.00 11.00 .813 20 4.50 5.50

30

34 38.75 4.25 8.50 29.88 29.88 33.13 10.31 28 6.25 1

1

/

4

-8 1

1

/

4

-8 36.00 2.992 — .75 2.562 4.50 6.38 6.38

3

/

4

-10 28 3 3

36 39.25 47.25 4.19 8.38 27.38 27.38 37.00 11.00 34.0 5.63 1

1

/

2

-8

1

1

/

2

-

8 4.75 3.999

—

1.0 3.437 4.50 6.50 9.50 1-8 32 3.25 4.75

Dimensions (inches) - ANSI Class 150

Wafer Style

Seat Detail

Stem Detail

Keyed Stem

10"-24" Cl. 150

8"-12" Cl. 300

Flatted Stem

2

1

/

2

"- 8" Cl. 150

3"- 6" Cl. 300

Lug Style

Seat Detail

20

10

27

13

12

13

14

3

2

1

12

4

9

6

8

8

7

6

14

22

21

20

24

22

21

19

18

17

16

19

18

17

16

5

A-

Dia.

C

B

G

Dia.

D

E

T

V-

Dia.

Thru

N

Flats

U

Y

V-

Dia.

Thru

U

R

Y

X

TX

P

SS

J

1

-

Dia. Thru

W-

Qty.

K-

Dia.

J-

Dia.

(2) Thru Holes

See Stem Detail

See Seat Detail

K-

Dia.

H˚

H˚

L-

Dia.

L-

Dia.

F

D

1

E

F

A

1

-

Dia.

Lug Style Wafer Style

Size

Dimension (in.) - ANSI Class 150

A A1 B C D D1 E F G H J J1 K L N P R S T U V W X Y

2.5

4.69 6.75 1.06 1.88 3.00 3.00 4.75 1.00 2.19 45.00 .69

5

/

8

-11 5.50 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

3

5.19 7.25 1.06 1.88 3.25 3.31 5.13 1.00 2.81 45.00 .69

5

/

8

-11 6.00 .56 .38 — — 1.078 1.50 3.25 .344 4 .75 1.63

4

6.50 8.88 1.06 2.13 3.94 4.94 6.25 1.00 3.88 22.50 .69

5

/

8

-11 7.50 .63 .50 — — 1.078 2.00 3.50 .406 8 1.00 1.75

5

7.56 10.00 1.25 2.25 4.56 5.44 7.06 1.00 4.75 22.50 .81

3

/

4

-10 9.00 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

6

8.63 11.00 1.25 2.25 5.00 5.88 7.63 1.00 5.75 22.50 .81

3

/

4

-10 9.50 .88 .63 — — 1.078 2.00 3.50 .406 8 1.00 1.75

8

10.81 13.50 1.44 2.50 6.19 7.00 9.63 1.75 7.63 22.50 .81

3

/

4

-10 11.75 1.13 .88 — — 1.828 2.56 4.00 .563 8 1.28 2.00

10

12.88 16.00 1.63 2.81 7.25 8.44 10.22 2.94 9.69 15.00 .94

7

/

8

-9 14.25 1.13 — .25 .984 2.25 3.25 4.75 .563 12 1.63 2.38

12

15.25 19.00 1.75 3.19 8.75 10.00 11.94 3.00 11.69 15.00 .94

7

/

8

-9 17.00 1.25 — .38 1.033 2.25 3.50 5.00 .688 12 1.75 2.50

14

16.75 21.00 1.88 3.63 9.88 10.88 13.19 3.00 12.81 15.00 1.06 1-8 18.75 1.38 — .38 1.156 2.25 4.75 5.63 .688 12 2.38 2.81

16

19.88 23.50 2.19 4.00 11.28 12.59 14.34 4.56 14.78 11.25 1.13 1-8 21.25 1.50 — .38 1.28 3.63 5.13 7.00 .688 16 2.56 3.50

18

21.00 25.00 2.47 4.50 13.38 13.38 16.44 4.81 16.75 11.25 1

1

/

8

-8 1

1

/

8

-8 22.75 1.75 — .50 1.47 4.00 5.50 8.00 .813 16 2.75 4.00

20

23.00 27.50 2.47 5.00 14.81 14.81 18.00 4.81 18.72 9 1

1

/

8

-8 1

1

/

8

-8 25.00 1.75 — .50 1.47 4.00 5.50 8.00 .813 20 2.75 4.00

24

27.75 32.00 3.03 6.06 16.63 16.63 20.25 4.44 22.63 9 1

1

/

8

-8 1

1

/

8

-8 29.50 2.75 — .75 2.38 4.00 9.00 11.00 .813 20 4.50 5.50

30

34 38.75 4.25 8.50 29.88 29.88 33.13 10.31 28 6.25 1

1

/

4

-8 1

1

/

4

-8 36.00 2.992 — .75 2.562 4.50 6.38 6.38

3

/

4

-10 28 3 3

36 39.25 47.25 4.19 8.38 27.38 27.38 37.00 11.00 34.0 5.63 1

1

/

2

-8

1

1

/

2

-

8 4.75 3.999

—

1.0 3.437 4.50 6.50 9.50 1-8 32 3.25 4.75

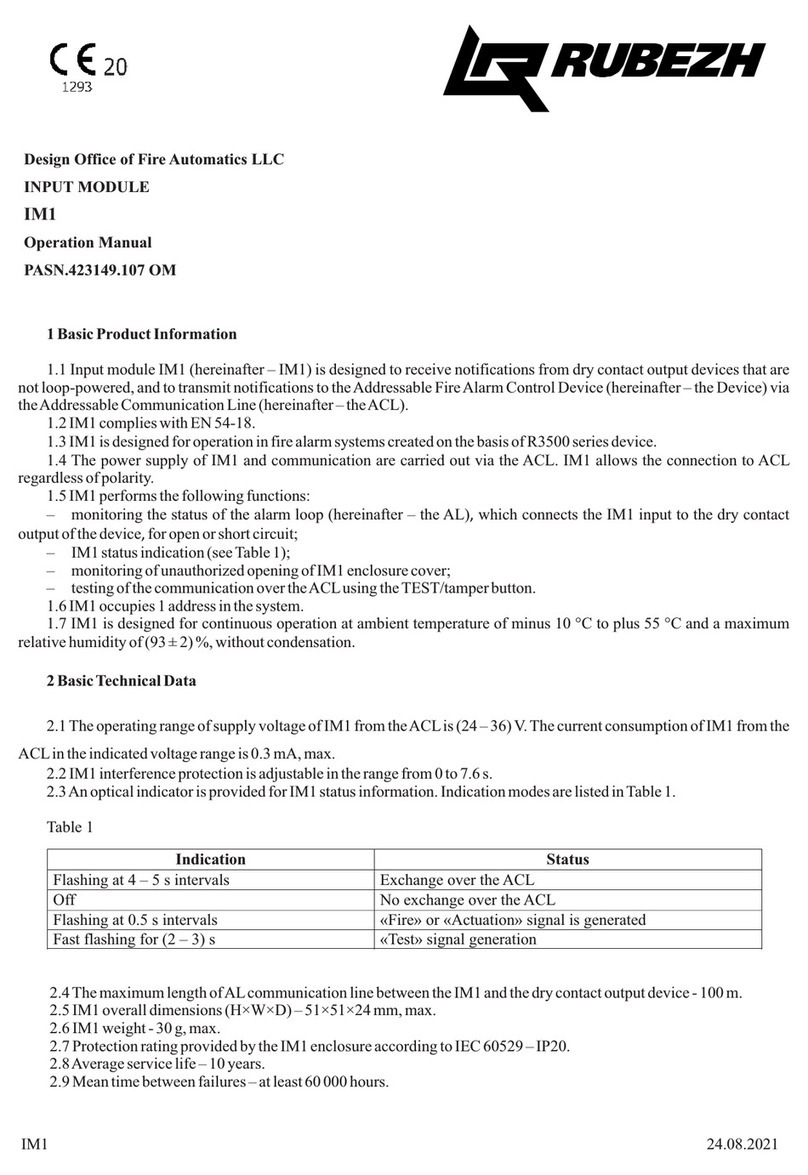

MATERIALS OF CONSTRUCTION

Materials Carbon Steel Stainless Steel

Part Name 1150 / 1151 / 1300 / 1301 2150 / 2151 / 2300 / 2301

1Outer Gland Ring 300 Series Stainless Steel

2Shaft Ret. Plate 300 Series Stainless Steel

3Shaft Ret. Ring 300 Series Stainless Steel

4Packing Flexible Graphite

5Inner Gland Ring 316 Stainless Steel

6Bearing Bronze or Microlube Coated Stainless Steel

7Thrust Washer 316 Stainless Steel

8Key/Pin Key 316 or 17-4 Stainless Steel / PIN 316 Stainless Steel

9Shaft/Disc Assembly 2 1/2” -10” (316 Stainless Steel Shaft / CF8M Disc) 12”- 36” (17.4 Shaft / CF8M Disc)

10 Body ASTM A216 Grade WCB ASTM A351 Grade CF8M

12 Seat Retainer ASTM A515 or 516 GR 70 ASTM A240 GR 316 SS

12A Inner Seat Retainer ASTM A515 or 516 GR 70 ASTM A240 GR 316 SS

13 Seat PTFE/RPTFE

13A Backup Seat 304 SS Plated w/Grafoil Gaskets

14 Retaining Spring Inconel X750

16 Stud 18-8 Stainless Steel

17 Self Locking Nut 18-8 Nyloc Stainless Steel

18 Gland Retainer 300 Series Stainless Steel

19 Jam Nut 18-8 Stainless Steel

20 End Cap 316 Stainless Steel

21 Hex Head Cap Screw 18-8 Stainless Steel

22 Split Lockwasher 18-8 Stainless Steel

23 Name Plate 300 Series Stainless Steel

24 Sockethead Cap Screw 18-8 Stainless Steel

27 End Cap Seal Grafoil

Note: Listed are standard materials of construction. Optional Materials may be substituted. Please consult the How to Order guide for various

trims. Teflon®& Viton®are registered trademarks of DuPont Dow Elastomers.

TRI-SEAL QUARTER-FLEX BUTTERFLY VALVE

5

TRI-SEAL QUARTER-FLEX BUTTERFLY VALVE

6

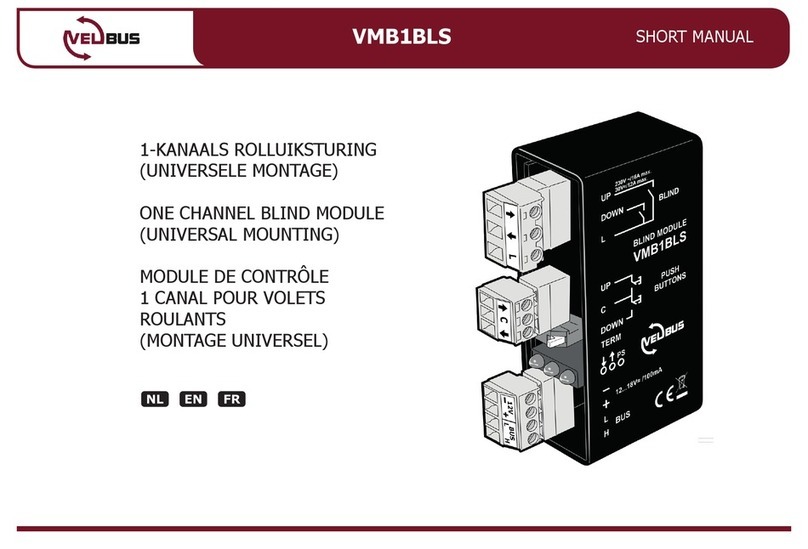

0

100

200

300

285

400

500

600

700

740

100

Temperature-˚F

ANSI Class 150 and 300

Differential Pressure-PSI

200 300 400 500

ANSI

Class 300

ANSI

Class 150

Saturated

Steam Curve

UHMWP

PTFE

RPTFE

PTFE

RPTFE

Valve

Size (in.)

2½

3

4

5

6

8

10

12

14

16

18

20

24

30

36

Class 150

90

205

403

640

1075

2243

3885

5925

7307

10,050

13,075

18,050

26,863

Consult

Factory

Class 300

—

205

403

—

1075

1950

3100

4400

—

—

—

—

—

—

—

Cv Flow Coefficient

0

10

20

0

30

40

50

60

70

80

100

90

20

Percent of Disc Opening

Degree of Disc Opening

Percent of Maximum Cv

40 60 80 100

0 3015 45 60 75 90

Technical Charts and Data

Valve

Size (in.)

CV Flow Coefficient

Class 150 Class 300

2 ½ 90

3205 205

4403 403

5640

61075 1075

82243 1950

10 3885 3100

12 5925 4400

14 7307

16 10,050

18 13,075

20 18,050

24 26,863

30 Consult

Factory

36

Technical Charts and Data

Flow Characteristics CurveFlow Coefficients (Cv)Pressure Temperature Chart

NOTE: Maximum continuous operating temperature.

Consult factory for application above those shown.

NOTE: Flow coefficients (Cv) based

on ambient water temperature

0

100

200

300

285

400

500

600

700

740

100

Temperature-˚F

ANSI Class 150 and 300

Differential Pressure-PSI

200 300 400 500

ANSI

Class 300

ANSI

Class 150

Saturated

Steam Curve

UHMWP

PTFE

RPTFE

PTFE

RPTFE

Valve

Size (in.)

2½

3

4

5

6

8

10

12

14

16

18

20

24

30

36

Class 150

90

205

403

640

1075

2243

3885

5925

7307

10,050

13,075

18,050

26,863

Consult

Factory

Class 300

—

205

403

—

1075

1950

3100

4400

—

—

—

—

—

—

—

Cv Flow Coefficient

0

10

20

0

30

40

50

60

70

80

100

90

20

Percent of Disc Opening

Degree of Disc Opening

Percent of Maximum Cv

40 60 80 100

0 3015 45 60 75 90

Technical Charts and Data

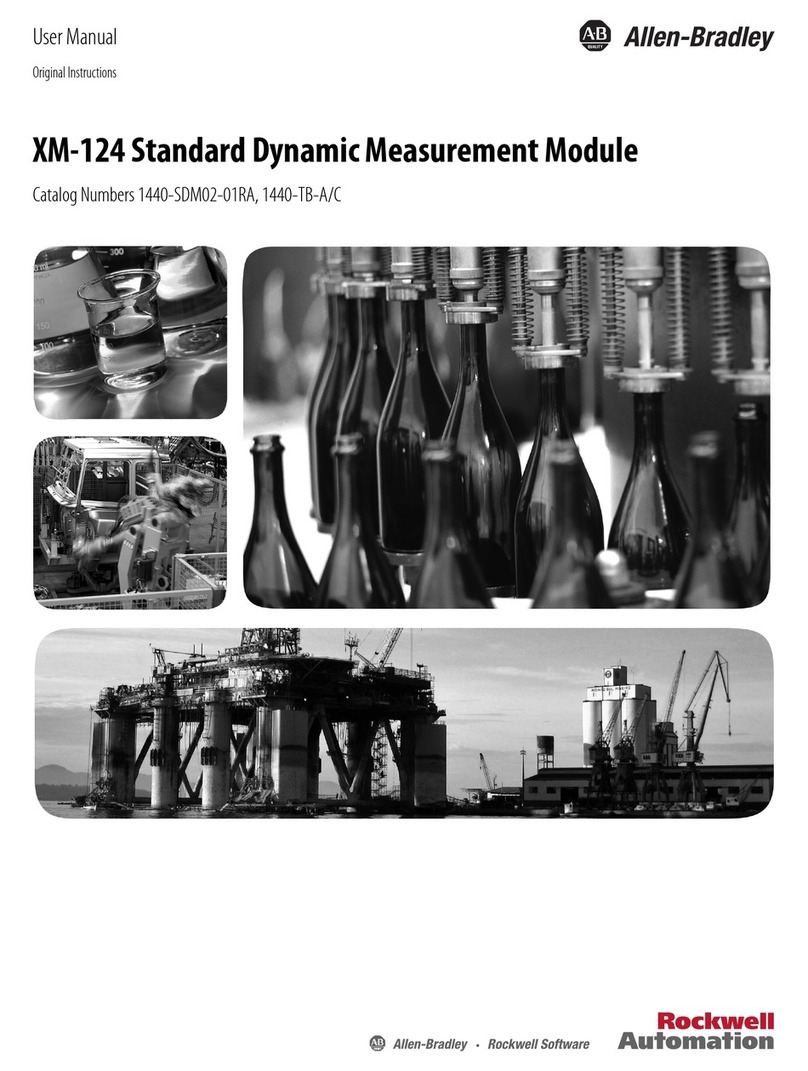

TECHNICAL DATA

Pressure Rating at 100°F

Class 150: 285 PSIG (A216 Gr. WCB)

275 PSIG (A351 Gr. CF8M)

Class 300: 740 PSIG (A216 Gr. WCB)

720 PSIG (A351 Gr. CF8M)

Minimum Operating Temperature

-35°F

Valve Operating and Rating Information

Maximum Temperature for Seats

and Seals at 0 PSIG

PTFE 425°F

Reinforce PTFE 450°F

UHMWPE 180°F

Steam Rating (Saturated)

PTFE 70 WSP

RPTFE 150 WSP

(On/off service only. For throttling

application, consult factory.)

TECHNICAL DATA

Torque - ANSI Class 150

Operating Torque

Torque - ANSI Class 300

Firesafe Operating Torque (in-lbs.)

PSIG 100 200 285 400 600 740

Size (in.) 150# 300# 150# 300# 150# 300# 300# 300# 300#

2 1/2 420 470 500

3500 500 610 610 720 720 750 775 8250

4900 900 1100 1100 1300 1300 1400 1500 1700

5

61600 1600 2400 2400 3000 3000 3200 3400 3500

82300 2900 3500

10 3700 4400 4600

12 7000 9100 9900

14 9000 12000 13000

16 14000 18000 24000

18 18000 29000 34000

20 22000 36000 44000

24 27000 48000 60000

30 29000 39000 49000

36 48000 69000 82000

NOTE: All torques based on clean service without safety factor

NOTE: Torques based on clean service only. Certain highly

viscous or abrasive services could increase these values.

NOTE: Torques based on clean service only. Certain highly

viscous or abrasive services could increase these values.

100,000

8

7

6

5

4

3

2

10,000 9

8

7

6

5

4

3

2

1,000 9

8

7

6

5

4

3

2

BREAKAWAY TORQUE (IN./LBS.)

100,000

8

7

6

5

4

3

2

10,000 9

8

7

6

5

4

3

2

1,000 9

8

7

6

5

4

3

2

BREAKAWAY TORQUE (IN./LBS.)

PRESSURE (BARS) PRESSURE (BARS)

DIFFERENTIALPRESSURE (PSIG) DIFFERENTIALPRESSURE (PSIG)

Note: Torques based on clean

service only. Certain highly

viscous or abrasive services

could increase these values.

Note: Torques based on clean

service only. Certain highly

viscous or abrasive services

could increase these values.

10 20 10 20 30 40 50

0 100 200 300 0 100 200 300 400 500 600 720

24”

20“

18”

16“

14”

12”

12”

10”

8”

6”

4”

3”

10”

8”

6”

5“

4”

3”

2 1/2”

VALVE

SIZE

MPI – MCWANE PLANT & INDUSTRIAL

Kennedy Valve | Tyler Union | McWane Ductile | Waterman | Tri-Seal Valve

MPIK-4008-1 11/2021

This manual suits for next models

7

Other MPI Control Unit manuals