telsiu altas START-S3XL User manual

START-S3XL

START-S3XL-R_180914_VXX06_GB www.ebtechnology.it www.nologo.info

Universal control unit for 1 sliding gate or up-and-over door.

Motor, 3levels of slow down. Inputs: start-timer- clock, photocell during closing,

limit switch during opening and closing, partial opening, stop.

Time acquisition “real-time”.

Radio receiver

-1-

-2-

-3-

-4-

-5-

-6-

-7-

-8-

-9-

-10-

-11-

-12-

-13-

-14-

-15-

-16-

-17-

-18-

-19-

230 Vac

230 Vac

Lamp

Lamp

MOT common

MOT close

MOT open

+ Antenna

Com 1 and - Antenna

Com 2 / - 12/24Vdc

+ 12 Vdc

STOP

FOTO

LSO

LSC

START

Pedestrian

24 Vac

+ 24 Vac/dc

-20-

-21-

Light-Fototest

Light-Fototest

-22-

-23-

Mechanical edge - NC

Mechanical edge - NC

*Connect this point to the terminal board no.

21 for the photo-test, otherwise connect it to

the terminal board no. 19

Photocells working

in closing

Lamp or courtesy light

230 Vac

If the input SAFETY-EDGE

is not used, make a link (22-23)

MOP

CL

COM

*

N.C.

C

N.C. N.C. N.A. N.A.

100%

ITALY

24 V OUT24 V

TX RX

START-S3XL Technical Manual

Foreword

need to familiarize yourself with and correctly operate

your unit. Read it very carefully when you purchase the

instrument and consult it whenever you have doubts

regarding use and before performing any maintenance

operations. Nologo has the right to modify the product

without previous notice.

Environmental protection

measures

Information regarding the environment for

customers within the European Union. Eu-

ropean Directive EC 2002/96 requires that

units bearing this symbol on the unit and/or

on the packaging be disposed of separately

from undifferentiated urban wastes.

The symbol indicates that the product must not be dis-

posed of with the normal household wastes. The owner

is responsible for disposing of this product and other

waste collection facilities indicated by the government

or local public agencies. Correct disposal and recycling

help prevent any potentially negative impact on the en-

vironment and human health. To receive more detailed

information regarding disposal of your unit, we recom-

mend that you contact the competent public agencies,

the waste collection.

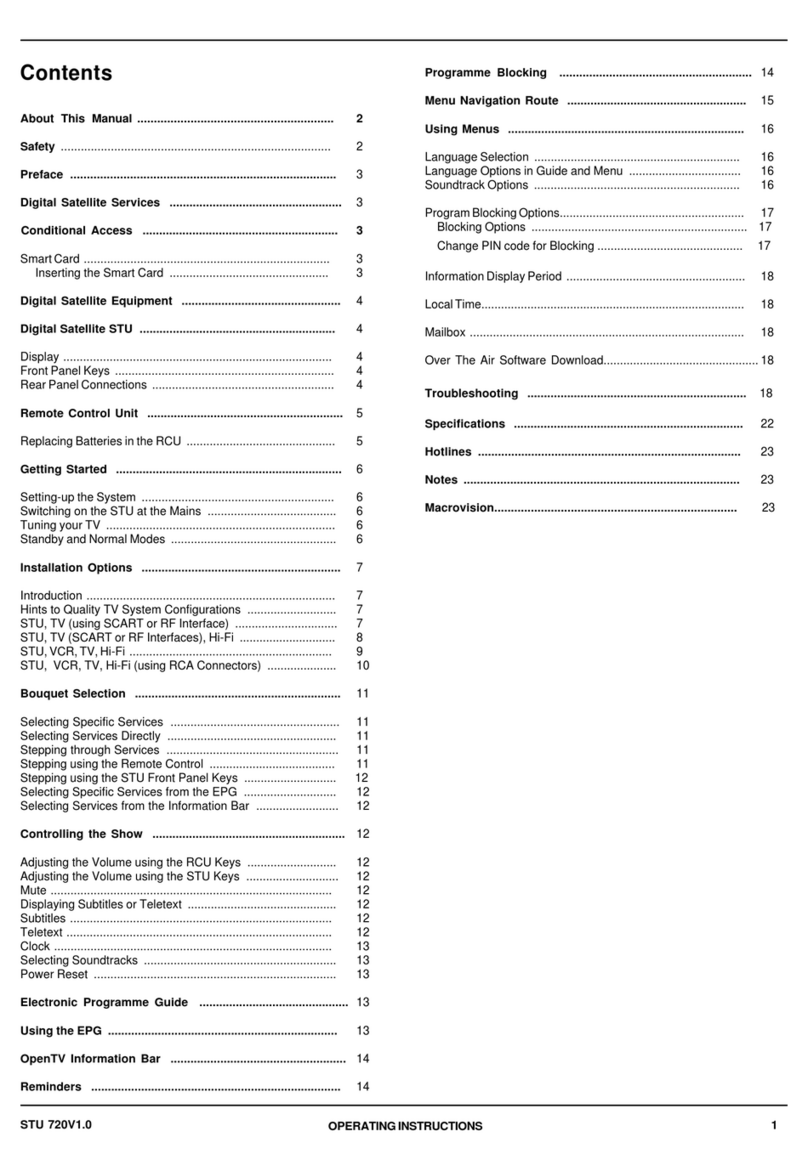

Index

Par. Description Pag.

1 Introduction 3

1.1 Product description

1.2 Field of application

1.3 Type of installation

1.4 Technical features

2 Installation 4

2.1 Diagram of the control unit and electrical connections

2.2 Description of the electrical connection 5

2.3 Connection of the FLASHING LIGHT 230 Vac 6

2.4 Connection of one 24V gate open and moving LIGHT

2.5 Connection of the COURTESY light

2.6 Power supply of the accessories

2.7 Connection of the STOP/ALT control devices 7

2.8 Connection of LIMIT SWITCHES LSO and LSC

2.9 Connection of the MAGNETIC LIMIT SWITCHES

2.10 Connection of the 24 Vac photocell 8

2.11 Connection of the 24 Vdc photocell

2.12 Connect the 3 wires photo-beam 9

2.13 Connection of the “START” and “PEDESTRIAN” commands

2.14 Checking connections

3 Operating logic for DIP 10

4 Management of Remote control

4.1 Activation of the radio receiver

4.2 DELETING the codes memory 16

4.3 Remote control LEARNING

5 Turning on and programming the unit 12

5.1 Learning “START” OPENING COMMAND times 13

5.2 Times learning with the “PEDESTRIAN” COMMAND 14

5.3 Regulating of the MOTOR FORCE

5.4 Increasing the PAUSE time 15

5.5 RESET of the CONSTRUCTION SETTING UP

6 Problems solution

7 Declaration of CE conformity 16

Symbols and warning

DANGEROUS

This is a warning and if it is not re-

spec it can provoque material dam-

age.

DEVICE UNDER TENSION

The installation should be done

only from professional installer.

READ CAREFULLY THE

OPERATING MANUAL

Read carefully this manul before in-

stallation and keep it for the future.

-2-

START-S3XL Technical Manual

declines any responsibility for damages due to inappropriate use of the product and due to any use other than the

use the product was designed for. The producer declines any responsibility for consequential damages except civil

liability for the products.

1.1 Safety precautions

1 Introduction

The START-S3XL electronic control unit is used to control the movement of entrances, swinging gateways, rolling

gates and automatic doors. It can be connected to a hydraulic or electromechanical actuator equipped with an

asynchronous, single-phase motor operating at a voltage of 230 Vac.

1.2 Field of application

1.3 Type of installation

These two simple diagrams show only one of the possible applications for this control unit. The risks inherent to

the “MACHINE” and the user’s requirements must be analyzed in depth in order to establish how many elements

need to be installed. All photocells have a system of synchronism that makes it possible to eliminate interference

between two pairs of photocells (for other details, see the instructions for the photocells). In the diagram, the pair of

photocells “Photo A” (considered in this control unit) has no effect during opening while it causes a total inversion

during closing. “Photo A2” is connected in series to “Photo A”.

Application on sliding automation Application on swinging automation

FOTO A

FOTO A

FOTO A2

We recommend to install a STOP switch which stops immediatelly the gate. The switch has a normally close contact

which opens the contact when it is working. See Par. 2.7

Dimensions 87 x 126 x 40 mm

Weight 0.46 Kg

MAX power of single motor 1

750

4

HP

W

A

MAX power of signal light 230 Vac 40 W

MAX absorption with clean contact 2 A

MAX absorption 24 Vac/dc 300 mA

MAX absorption 12 Vdc 50 mA

1.4 Technical features

-3-

START-S3XL Technical Manual

1 2 control unit power supply 230Vac

3 7

8 19 power supply voltage to accessories and to

service and safety inputs

20 21 “clean” contacts for light or photocell TEST

22 23 stop coast input + inversion for 1.5 sec

JUMPER

AC/DC

output power supply selection 24Vac

or 24Vdc on terminals 18 and 19

JUMPER

J-R activation or deactivation of the radio receiver

DIP 1-10 function of the control unit

DIP 11-12 deceleration rate or deceleration excluded

selection

Button Pmanages wireless codes, regulates force,

increases pause time

2.1 Diagram of the control unit and electrical connections

2 Installation

Connection of the VOLTAGE line

230 Volt Single-phase alternate current.

The control unit power supply line must

always be protected with a magnetother-

mal switch or a pair of 5A fuses.

A differential switch is recommended but

not indispensable if one is already installed

on the plant.

Connection of the MOTOR

Pay particular attention not to invert

the OPEN and CLOSE poles.

When in doubt as to the correct connection, if

possible, manually position the automation at the

midpoint of its stroke. Be ready to stop the system

using the STOP control!

To be sure that the opening is really “opening”, try

to block the photocells: if the gate begins to close,

the connection is incorrect and the motor OPEN

and CLOSE wires must be inverted.

-4-

START-S3XL Technical Manual

-5-

2.2 Description of the electrical connection

230 Vac 1 Electrical power supply 230 Vac 50 Hz

230 Vac 2 Electrical power supply 230 Vac 50 Hz

Lamp 3

the lamp 100W.

4

MOT common 5 Output for connection of COMMON motor pole

MOT close 6 Output for connection of CLOSING motor pole

MOT open 7 Output for connection of OPENING motor pole

Antenna 8 Input for antenna signal (end of antenna hot wire)

Common 1 9Common for all inputs:

services, safety devices, coaxial antenna braid

Com2 / -12Vdc 10 Output -12/24 Vdc (See Phar. 2.6), Common 2

+ 12Vdc 11 Output +12 Vdc maximumcurrent 50mA (positive)

Stop12 STOP input

Foto 13 Input for photocell

(PHOTO safety trips only when closing)

Lso 14 Input for opening limit switch

Lsc 15 Input for closing limit switch

Start 16 Input for stepped START

Pedestrian 17 Input for stepped control of partial PEDESTRIAN opening

(same setting as START)

24Vac 18 Output 24Vac (See Phar. 2.6)

+24Vdc / 24Vac 19 Output + 24Vdc, 24Vac (See Phar. 2.6)

C. Light 20 “clean” contacts for light or photocell TEST

C. Light 21

Alt 22 NC stop coast + inversion for 1.5 seconds

Alt 23

START-S3XL Technical Manual

-6-

2.3 Connection of the FLASHING LIGHT 230 Vac

Flashing light complete

with intermittence circuit board

Flashing light complete without intermittence circuit board

DIP 4 - ON

ON

2

143 5

If you plan to use the photocells test,

or a 24V light, this connection cannot be used.

!

2.4 Connection of one 24V gate open and moving LIGHT

DIP 10

ON Fix Light

ON

CTS

2

143 6

587 10

91211

If you plan to use the photocells test, or a

24V light, this connection cannot be used.

!

2.5 Connection of the COURTESY light

LIGHT

230 Vac

DIP 4 - OFF

ON

CTS

2

143 6

587 10

91211

17 18 19 20 21

3 4 5 3 4 5 20 21

3 4 5

2.6 Power supply of the ACCESSORIES

Terminal board 10 (-) / 11 (+)

Voltage: 12 Vdc

Maximum current: 50 mA

Put JUMPER

JAC/DC as shown

in the picture

Terminal board 10 (-) / 19 (+)

Voltage: 24 Vdc

Maximum current: 300 mA

8 9 10 11 12 13 14 15 16 17 18 19

Terminal board 18 / 19

Voltage: 24 Vac

Maximum current: 300 mA

Put JUMPER

JAC/DC as shown

in the picture

+

-

-+

!!

AC DC

AC DC

START-S3XL Technical Manual

-7-

8 9 10 11 12 13

2.7 Connection of the STOP/ALT control devices

Connection of the STOP control

Push-button: stops and temporarily prevents all

control unit function until it is pressed again.

Switch: keeps the automation blocked until it is

reset.

Connection of the ALT control

Stops the automation and activates an inversion of

direction for approximately 1.5 seconds.

Connection of the safety devices requires the use of any push-button or N.C. (normally closed) contact.

When there are several safety devices, they are connected in series.

NOLOGO

If the STOP input is

NOT used put the

DIP 5 on ON.

If the input

SAFETY-EDGE

is not used,

make a link (22-23)

!

2.8 Connection of LIMIT SWITCHES LSO and LSC

switches, however, on this control unit they can also

be used individually. Therefore, it is possible to use

just the “Open limit switch” or just the “Close limit

switch”.

The limit switch contacts must be N.C.

(normally closed) contacts.

If the LSO or LSC inputs

aren’t in use, follow the

instructions you fi nd

in chapter n. 3

!

2.9 Connection of the MAGNETIC LIMIT SWITCHES

JUMPER AC/DC

Power Supply

magnetic limit

switches

+ 24 Vdc

Bring JUMPER

AC/DC as shown

in the picture.

22 23

8 9 10 11 12 13 14 15 16 17 18 19

8 9 10 11 12 13 14 15 16 17 18 19

OPEN

N.C.

CLOSE

N.C.

LIMIT

SWITCHES

OPEN

N.C.

CLOSE

N.C.

LIMIT

SWITCHES

START-S3XL Technical Manual

-8-

The photocell receiver con-

tact must be:

- clean

(insulated from power sup-

ply voltages)

- type N.C.

(Normally closed)

If more than one pair of pho-

tocells is used, they must be

connected in series.

The photocell TEST ensures that the automation only functions when the pho-

tocells are functioning properly. In fact, the control unit performs the test before

lights on for 5 seconds and the automation does not start.

The control unit automatically activates the test only after the START com-

mand times have been learnt. If you wish to return to the LIGHT function

on terminals 20 and 21, the photocells must be connected without the test

and then you must repeat the times learning operation with the START com-

mand.

The TEST function is compatible with lower devices (for example TRANSCEI-

VER) so the gate can have a delay when opening. The TEST can be done also

from some devices in the INPUT COSTA (safety edge) and STOP.

After the TEST connections, memorize the working time for the START control

during this time the control unit check the devices which should are connected to

the TEST.

2.10 Connection of the 24 Vac photocell

RX TX

NC Contact

TX

20 21

Without TEST With TEST

2.11 Connection of the 24 Vdc photocell

8 9 10 11 12 13 14 15 16 17 18 19

24 Vac

RX

NC Contact

8 9 10 11 12 13 14 15 16 17 18 19

24 Vac

RX TX

NC Contact

TX

20 21

Without TEST With TEST

8 9 10 11 12 13 14 15 16 17 18 19

24 Vdc

8 9 10 11 12 13 14 15 16 17 18 19

+

-

RX

NC Contact

24 Vdc +

-

AC DC

Put

JUMPER

JAC/DC

as shown in

the picture

Put

JUMPER

JAC/DC

as shown in

the picture

AC DC

If the STOP input is NOT

used put the DIP 6 on ON.

!

START-S3XL Technical Manual

-9-

2.13 Connection of the “START” and “PEDESTRIAN” commands

The PEDESTRIAN opening command can be connected to any push-

button or N.O. (normally open) contact. If several devices are used,

they must be connected.

Using terminals 9 and 16 it is possible connect a TIMER to program

gate opening. The timer contact must be an NO (normally open) con-

tact and must remain closed for as long as the gate remains open.

If an opening command is connected to terminal 16, it must be con-

nected in parallel.

The START opening command can be connected to

any push-button or N.O. (normally open) contact.

2.12 Connect the 3 WIRES PHOTO-BEAM

POWER SUPPLY

TX PHOTOCELL

POWER SUPPLY

RX PHOTOCELL +

-

+

-

Photocell receiver.

N.C. contact terminals

-+

Bring JUMPER AC/DC

as shown in the picture

Voltage: 24 Vdc

Maximum current: 300 mA

that the internal microprocessor is on and awaiting a command. When the control unit is powered, the warning

lights, set on the inputs, are ON when the contacts on the inputs are closed toward the common:

Normally the red lights on inputs STOP - PHOTO - LSO - LSC - STOP - ALT are ON

Normally the green lights on the control inputs START - PEDESTRIAN are OFF

STOP PHOTO LSO LSC START PED ALT

Safety edge

2.14 Checking connections

8 9 10 11 12 13 14 15 16 17 18 19

8 9 10 11 12 13 14 15 16 17 18 19

Table of contents