Tempest Power Blower Direct-Drive Series User manual

OWNER’S MANUAL

Power BlowersTM

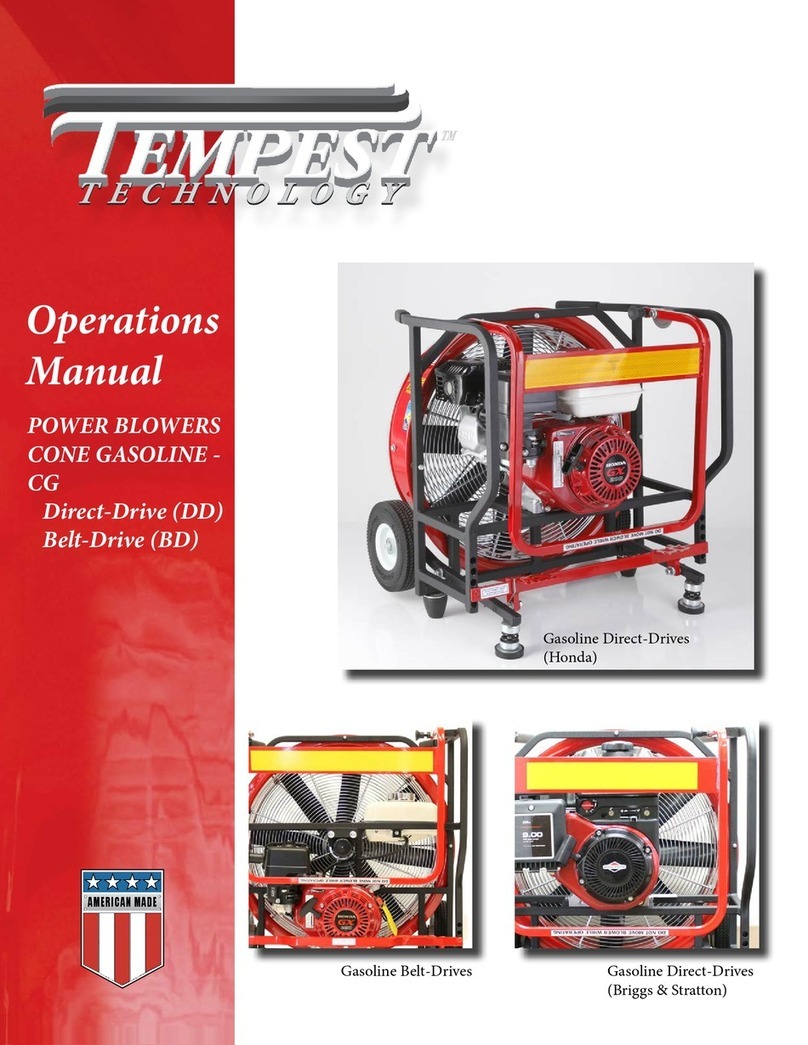

Cone Air Flow (CAF) - Gasoline Driven

Direct-Drive Series

(Incl. BASIC & ECO)

Belt-Drive Series

0216_01A

2

INTRODUCTION

ank you for choosing Tempest Technology Corporation for your

ventilation needs. With this manual we hope to help you operate

your Tempest product safely and to its full potential. Maintained

according to the specications set in this manual and the engine

manufacturer’s manual, it is not uncommon to receive many years

of use and operation out of your Tempest equipment.

is manual is produced solely for the use of purchasers and

operators of Tempest Technology Corporation equipment. Any

reproduction, retransmission, or other use of the contents of

this manual without written consent of Tempest Technology

Corporation is strictly prohibited.

It is the intent of this manual to provide the owner/operator of

Tempest Technology Corporation products with both general and

specic information regarding the safe and proper operation and

maintenance of the equipment described within.

CONTACT

If aer careful review, any questions arise concerning any portion

of this manual, please contact Tempest Technology Corporation

for assistance:

TEMPEST TECHNOLOGY CORP.

4708 N. BLYTHE AVENUE

FRESNO, CA 93722

Toll Free: 800.346.2143

t: 559.277.7577

f: 559.277.7579

respon[email protected]m

www.tempest.us.com

TABLE OF CONTENTS

ABOUT TEMPEST 2

SAFETY GUIDE 3

GENERAL INFORMATION 3

POWER BLOWERTM DATA 4

POWER BLOWERTM INFORMATION 6

OPERATING PROCEDURES 6

MAINTENANCE PROCEDURES 7

POWER BLOWERTM TROUBLESHOOTING 9

REPLACEMENT PARTS - Belt-Drive 10

REPLACEMENT PARTS - Direct-Drive 11

REPLACEMENT PARTS - Direct-Drive BASIC 12

REPLACEMENT PARTS - ECO Direct-Drive 13

WARRANTY BACK COVER

ABOUT TEMPEST

Tempest Technology Corporation is the leading manufacturer

of products and accessories for environmental management in

reghting and industrial applications.

Tempest began as a manufacturer of gasoline and electric powered

blowers for the re service. Fire departments use the Tempest

Power BlowerTM to provide “Positive Pressure Ventilation / Attack”

(PPV/PPA) to remove heat, gases and smoke from the interior of

a burning structure.

Tempest has expanded into other industries and found new

applications for its products. e Tempest Power BlowerTM and

PPV/PPA are used by industrial applications to control dust, fumes

and unhealthy gases like carbon monoxide, greatly improving

safety in conned spaces.

Tempest Technology Corporation has earned a reputation as a

leader and innovator in the air movement industry and continues

in that role today.

POSITIVE PRESSURE

VENTILATION/ATTACK

3

SAFETY GUIDE

Failure to follow the operating, maintenance and lubrication

requirementssetforthin this manual andthe enginemanufacturer’s

owner’s manual may result in serious personal injury or death

and/or damage to equipment or property.

e following WARNING statements indicate potentially

hazardous conditions for operators and equipment. Make certain

that anyone who works on or around the blower has read and fully

understands the safety precautions listed.

1. Carefully read this owner’s manual before attempting to

operate, service or disassemble any part of your Tempest

Power BlowerTM.

2. DO NOT operate the unit when mentally or physically

fatigued or impaired.

3. Stay away from rotating parts; avoid wearing loose jackets,

shirts, and ties. Keep hands and feet away from moving parts.

4. Keep all unauthorized personnel at a safe distance from the

blower.

5. Keep all guards in place. DO NOT make repairs while the

unit is running. DO NOT operate if any guard or grille is not

in place.

6. Always wear eye protection. Loose debris can be picked up in

the air stream and own in the air.

7. Hearing protection is required. Engine and air noise may

exceed safe dB levels.

8. Gasoline is extremely ammable and is explosive under

certain conditions. To prevent re hazards, do not place

ammable objects close to the engine.

9. Do not overll the fuel tank. Aer refueling, make sure the

tank cap is closed properly and secured. If any fuel is spilled,

make sure the area is dry before starting the engine.

10. Never operate gasoline-powered blowers in an enclosed or

conned area. Exhaust contains poisonous carbon monoxide

gas; exposure may cause loss of consciousness and may lead

to death.

11. e muer becomes very hot during operation and remains

hot for some time aer stopping the engine. Be careful not

to touch the muer while it is hot. To avoid severe burns or

re hazards, let the engine cool before transporting or storing

the unit.

12. It is the sole responsibility of the owner/operator to develop

procedures for proper use of the Tempest Power BlowerTM in

accordance with generally accepted ventilation techniques as

well as the organization’s own operating procedures, before

placing the unit into service.

GENERAL INFORMATION

BLOWER IDENTIFICATION

Each Tempest Power BlowerTM has a part number as well as a serial

number. e part number identies the type of unit (size, drive,

etc.) while the serial number relates to information referencing the

date of manufacture. is information is useful should it become

necessary to contact the factory regarding your Power BlowerTM.

SERIAL NUMBER LOCATIONS

e serial number is typically located on the frame just right of the

engine mount (when viewed from behind).

Please write the Serial Number of your Tempest Power BlowerTM

in the spaces below. is will aid us in identifying which model

you have when assisting you.

Model (Part No.)

Date

Serial No.

WARRANTY

Warranty information on your unit can be found on the back page

of this manual. For further information, please contact Tempest

Technology Corp.

4

POWER BLOWERTM DATA

Positive Pressure Ventilation Fan, Cone Air Flow (CAF)

16” Models: Direct-Drive - HONDA® GX160 or Briggs & Stratton® 550

ECO Direct-Drive - HONDA® GX120

18” Models: Direct-Drive - HONDA® GX160 or Briggs & Stratton® 950

Direct-Drive BASIC - HONDA® GC160

Belt-Drive - HONDA® GX160

21” Models: Direct-Drive - HONDA® GX200 or Briggs & Stratton® 950

Direct-Drive BASIC - HONDA® GC160

ECO Direct-Drive - HONDA® GX200

Belt-Drive - HONDA® GX200

24” Models: Direct-Drive - HONDA® GX200 or Briggs & Stratton® 950

Belt-Drive - HONDA® GX200

27” Models: Belt-Drive - HONDA® GX270

TYPE: Single Cylinder, 4 Stroke, Gasoline

COOLING: Forced Air

LUBRICATION: Splash Type Oil Reservoir

STARTING: Recoil with Auto Rewind

AirFlex Fiberglass Reinforced Polyamide Blades

Keyed Sha and Set or Cap Screws

Turbo 2000 Tapered Aluminum w/ Durable Powder-Coat Finish

Locking, Self-Aligning and Permanently Lubricated

Rugged, Lightweight, Square-Steel Tubing with Powder-Coat Finish

Foot-Operated Tilt Mechanism

16” Models: Four Position Tilt, +10°, +5°, 0°, -5°

18”, 21”, 24”, 27” Models: Five Position Tilt, +15°, +10°, +5°, 0°, -5°

18”, 21” BASIC Models: ree Position Tilt, +15°, +10°, 0° (Hand-Operated)

Continuous Circular-Wound, External-Weld Steel Wire with 8 Tie Points for Additional Safety

Meets UL & European CE Safety Standards

Steel-Reinforced Rubber and Welded Steel Spring Feet

ECO Models - Steel-Reinforced Rubber (Only)

16” Models: 6” Non-Pneumatic w/ Steel Hubs

18“, 21”, 24“ and 27” Models: 8” Non-Pneumatic w/ Steel Hubs

16”, 21” ECO Models: 7” Non-Pneumatic w/ Steel Hubs

TYPE:

DRIVE:

GAS ENGINES:

BLADE:

BUSHING:

SHROUD:

BEARINGS (BELT-DRIVE):

FRAME:

TILT MECHANISM:

GRILLE:

VIBRATION DAMPENERS:

WHEELS:

(NON-BASIC)

5

POWER BLOWERTM DATA (CONTINUED)

DIRECT-DRIVE

SPECIFICATIONS:

DIRECT-DRIVE BASIC

SPECIFICATIONS:

ECO DIRECT-DRIVE

SPECIFICATIONS:

BELT-DRIVE

SPECIFICATIONS: Model No. Part No. Size HP CFM Dimensions (WxDxH) Weight

BD-18-H-4.8 910-1020 18” 4.8 15,023

23.25” x 21.00” x 25.25”

97 lbs.

BD-21-H-5.5 910-1040 21” 5.5 17,743

24.75” x 21.00” x 26.25”

101 lbs.

BD-24-H-5.5 910-1060 24” 5.5 18,130

28.25” x 21.75” x 30.00”

112 lbs.

BD-27-H-8.5 910-1080 27” 8.5 23,943

30.75” x 23.25” x 32.50”

154 lbs.

Model No. Part No. Size HP CFM Dimensions (WxDxH) Weight

DD-16-H-4.8 910-1100 16” 4.8 12,008 20.50” x 19.75” x 21.75” 79 lbs.

DD-18-H-4.8 910-1120 18” 4.8 14,773 22.75” x 21.00” x 24.25” 85 lbs.

DD-21-H-5.5 910-1140 21” 5.5 20,152 25.00” x 21.00” x 26.25” 90 lbs.

DD-24-H-5.5 910-1160 24” 5.5 19,606 28.00” x 21.00” x 30.00” 99 lbs.

DD-16-B-3.5 910-1101 16” 3.5 11,541 20.50” x 19.75” x 21.75” 73 lbs.

DD-18-B-5.5 910-1121 18” 5.5 14,341 23.50” x 21.00” x 25.00” 83 lbs.

DD-21-B-5.5 910-1141 21” 5.5 18,025 25.50” x 21.00” x 26.25” 87 lbs.

DD-24-B-5.5 910-1161 24” 5.5 19,232 28.00” x 21.00” x 30.00” 97 lbs.

Model No. Part No. Size HP CFM Dimensions (WxDxH) Weight

DD-18-H-4.6 910-1122 18” 4.6 14,126 22.00” x 18.50” x 24.00” 56 lbs.

DD-21-H-4.6 910-1142 21” 4.6 16,943 25.00” x 18.50” x 25.50” 59 lbs.

Model No. Part No. Size HP CFM Dimensions (WxDxH) Weight

EC-16-H-3.5 910-1103 16” 3.5 12,008 20.50” x 19.75” x 21.75” 67 lbs.

EC-21-H-5.5 910-1143 21” 5.5 20,152 25.00” x 20.50” x 26.25” 81 lbs.

6

POWER BLOWERTM INFORMATION

e Tempest Power BlowerTM is a high powered, portable

fan used for Positive Pressure Ventilation and Attack (PPV/

PPA), ventilation techniques that quickly and eciently replace

hazardous interior environments with clean, cool air.

PPV and PPA were pioneered in the reghting industry where

reghters use the Tempest Power BlowerTM to ventilate smoke,

heat, and harmful gases from buildings. is creates a safer

environment for them to work in and makes it easier for them to

nd victims and extinguish the re.

PPV and PPA rely on two principles, (1) an air pattern capable of

creating an eective door seal, and (2) pressure. To accomplish

Positive Pressure Ventilation or Attack, the blower is placed on

the outside of the structure. It is positioned so that the air pattern

created by the blower completely seals the entrance opening, or

at least 2/3 of it. When this seal is achieved, the air pressure is

increased equally at all points inside the structure. When an

exhaust opening is created, all of the interior air moves in one

mass towards it. e result is fast, ecient ventilation of the entire

structure.

NOTE: e Tempest Power BlowerTM is the most ecient

tool for PPV and PPA for two reasons. First, the exclusive

Tempest Turbo 2000 tapered shroud design creates a wide,

stable, conical air pattern. Second, the airex impeller used

on all Tempest blowers is designed to create high pressure.

ese two features working together make the Tempest

Power BlowerTM a highly eective and ecient ventilation

tool.

As with any new technique, Positive Pressure Ventilation requires

training and education in order to be implemented properly

and safely. Tempest oers access to a complete line of training

materials, which cover many applications for this powerful

ventilation technique. For more information visit www.tempest.

us.com, www.positivepressuretraining.com or contact us at

800.346.2143 or response@tempest.us.com.

OPERATING PROCEDURES

PRE-OPERATION

VISUAL INSPECTION

Aer receiving and unpacking your blower, be sure to carefully

inspect it for any damage that might have occurred during shipping.

Should you nd any damage: PLEASE NOTIFY TEMPEST

TECHNOLOGY CORP. IMMEDIATELY AT 800.346.2143 OR

RESPONSE@TEMPEST.US.COM.

ENGINE OIL

Be sure to use only high quality detergent oil. Detergent oils keep

the engine cleaner and retards the formation of gum and varnish

deposits.

RECOMMENDED OILS

HONDA® engines: SF or SG SAE 10W-30 oil.

BRIGGS & STRATTON® engines: SE, SF, SG SAE 30 oil.

ENGINE CAPACITY

B&S 550 0.63 US Quarts / 0.60 Liters

B&S 950 0.63 US Quarts / 0.60 Liters

HONDA® GC160 0.61 US Quarts / 0.58 Liters

HONDA® GX120 0.59 US Quarts / 0.56 Liters

HONDA® GX160 0.61 US Quarts / 0.58 Liters

HONDA® GX200 0.63 US Quarts / 0.60 Liters

HONDA® GX270 1.20 US Quarts / 1.10 Liters

FILLING THE CRANKCASE

Place blower on a level surface and make sure that the engine is

level. Remove the oil ll plug or dipstick. POUR OIL SLOWLY

into the crankcase. Replace oil ll plug or dipstick and tighten

securely. Refer to the engine manufacturer’s owner’s manual for

additional information regarding specic oil requirements.

CAUTION: DO NOT OVERFILL THE ENGINE. EXCESS

OIL VAPOR CAN BE EJECTED FROM THE ENGINE

BREATHER WHILE RUNNING.

FUEL

Always use clean, fresh, lead-free gasoline with an (R+M)/2 octane

rating of 86 or higher. DO NOT USE leaded gasolines. Refer to the

engine manufacturer’s owner’s manual for acceptable substitute

gasolines.

CAUTION: PRECAUTIONS MUST BE FOLLOWED

WHENEVER REFUELING GASOLINE ENGINES. PLEASE

FOLLOW THE LISTED GUIDELINES.

• DO NOT FILL THE FUEL TANK INDOORS.

• DO NOT FILL THE FUEL TANK WHILE THE

ENGINE IS RUNNING OR HOT.

• DO NOT SMOKE DURING REFUELING.

• DO NOT FILL THE FUEL TANK COMPLETELY.

FILL THE TANK TO THE DESIGNATED LEVEL.

OVERFILLING WILL CLOG THE CHARCOAL

FILTER LOCATED IN THE FUEL CAP, INHIBITING

THE FLOW OF FUEL.

• WIPE ANY SPILLAGE FROM ENGINE AND

COMPONENTS BEFORE STARTING THE ENGINE.

7

FUEL CAPACITY

ENGINE CAPACITY

B&S 550 2.0 US Quarts / 1.9 Liters

B&S 950 3.3 US Quarts / 3.1 Liters

HONDA® GC160 1.9 US Quarts / 1.8 Liters

HONDA® GX120 2.1 US Quarts / 2.0 Liters

HONDA® GX160 3.3 US Quarts / 3.1 Liters

HONDA® GX200 3.3 US Quarts / 3.1 Liters

HONDA® GX270 5.6 US Quarts / 5.3 Liters

OPERATION

SET-UP, STARTING AND STOPPING

Assuming the previous Pre-Operation and safety instructions

have been followed, the blower is now ready to run. Please review

the engine manufacturer’s owner’s manual regarding starting and

stopping as well as the instructions in this section before actually

starting the blower.

CAUTION: DO NOT MOVE THE BLOWER WHILE

IT IS IN OPERATION. SEVERE PERSONAL INJURY IS

POSSIBLE AS WELL AS DAMAGE TO THE BLOWER.

ALWAYS SHUT-DOWN THE BLOWER PRIOR TO

MOVING.

SET-UP

Position the blower in the desired location, making sure it is

placed on a at, hard and debris free surface.

STARTING

1. Turn IGNITION SWITCH to the ON position

2. Flip FUEL SHUTOFF SWITCH to the ON position.

3. Close CHOKE lever.

4. Move THROTTLE to 1/2 open position.

5. Pull starter grip briskly, return slowly.

6. As engine warms, return CHOKE to OPEN position slowly.

7. Raise or lower THROTTLE for RPM needed.

STOPPING

1. To stop engine, slide throttle to the SLOW position and

shuto IGNITION SWITCH.

NOTE: e FUEL SHUTOFF SWITCH should be in the

OFF position during storage and transport.

MAINTENANCE PROCEDURES

Proper maintenance is necessary to ensure that your Power

BlowerTM operates as eciently and trouble-free as possible.

By following the instructions in this section you will be

providing the maintenance needed to achieve this goal. Detailed

engine maintenance instructions can be found in the engine

manufacturer’s owner’s manual.

CAUTION: THE ENGINE MAY START SIMPLY BY

ROTATING THE BLADES. ALWAYS REMOVE THE

SPARK PLUG WIRE PRIOR TO WORKING ON THE

BLADE SIDE OF THE MOTOR.

MAINTENANCE SCHEDULE

EVERY USE

• Check engine oil

• Check air cleaner

• Inspect blower for damage and x if any

• Tighten/replace any loose or missing parts

NEW BLOWER FIRST THREE HOURS

• Tension belt (Belt-Drive Only)

FIRST MONTH OR 20 HOURS

• Change engine oil

EVERY MONTH OR 20 HOURS

• Tension belt

• Inspect & clean engine housing

EVERY THREE 3 MONTHS OR 50 HOURS

• Clean air lter

EVERY SIX 6 MONTHS OR 100 HOURS

• Replace belt

• Change engine oil

• Inspect & clean spark plug

EVERY YEAR OR 300 HOURS

• Replace spark plug

IMPORTANT: Always operate the blower in an area free

of debris which may be pulled into the unit’s blades. If you

suspect the fan’s blade may have contacted a hard object,

thorough inspection of the blade assembly should be

conducted immediately to ensure safety. You may contact

Tempest Technology Corp. in order to nd out how to

properly inspect the blade assembly.

OIL CHANGE

Check the engine oil level before each use. e oil should be

changed aer the rst month or 20 operating hours and every

six (6) months or 100 hours thereaer. Oil changes should be

performed more frequently if the blower is being operated in dusty

or dirty conditions. Changing the oil is easier when the engine is

still warm (not hot) from a recent running.

8

OIL FILLER CAP

PROCEDURES

1. Position the blower so the engine oil drain plug is

the lowest point on the engine.

2. Place a two quart or larger container under the oil drain plug

for the oil to drain into.

3. Remove the oil drain plug and drain the used oil.

4. Install the oil drain plug and tighten securely.

5. Remove the oil ller cap and rell with the recommended oil

(refer to the Pre-Operation instructions in the Operations

section) and check the oil level.

AIR CLEANER

A dirty air cleaner will restrict airow to the carburetor. To prevent

carburetor malfunction, service the air cleaner regularly. More

frequent service may be necessary when the blower is operated in

extremely dusty conditions.

CAUTION: DO NOT RUN THE ENGINE WITH THE

AIR CLEANER REMOVED. RAPID ENGINE WEAR WILL

RESULT FROM CONTAMINANTS, SUCH AS DUST AND

DIRT BEING DRAWN THROUGH THE CARBURETOR

AND INTO THE ENGINE.

CLEANING AIR FILTER ELEMENTS

Foam Element:

1. Wash the element in a solution of household detergent and

warm water, then rinse thoroughly. Allow the element to dry

completely.

2. Soak the element in clean engine oil, and squeeze out the

excess oil.

NOTE: the engine will smoke during initial start-up if too

much oil is le in the foam element.

Paper Element:

1. To remove excess dirt, tap the element lightly several times

on a hard surface or blow compressed air through the lter

from the inside out.

2. Do not try to brush the dirt o. Brushing will force dirt into

the lter bers.

3. Replace the element if it becomes excessively dirty. You can

order/purchase paper elements through Tempest or your

local hardware home improvement store.

COOLING SYSTEM

Frequently remove dirt and debris from the cooling ns, air intake

screen, levers and linkage. is will ensure adequate cooling and

correct engine speed. Refer to the engine manufacturer’s owner’s

manual for additional cooling system information.

SPARK PLUG

A correctly ring spark plug is essential for the blower to operate

properly. Check the engine spark plug every six (6) months or

every 100 hours by following the listed procedures.

1. Clean the area around the spark plug.

2. Remove and inspect the spark plug.

3. Replace the spark plug if the electrodes are pitted, burned,

or the porcelain is cracked. Check the electrode gap with

a wire feeler gauge and set to the engine manufacturer’s

specications.

4. Make sure the spark plug washer is in good condition, and

start threading the spark plug by hand to prevent cross

threading.

5. Aer the spark plug is seated, tighten with a spark plug

wrench to compress the washer.

CARBURETOR

All carburetors comply with US federal & state regulations and are

preset by the engine manufacturer. Engine performance may dier

at various altitudes and climates. If you feel that the carburetor on

your blower needs adjusting contact Tempest or your local engine

dealer.

EMISSION CONTROL SYSTEM

US State regulations require that all manufacturers of gas powered

engines furnish written instructions describing the operation and

maintenance of the emission control systems. ese instructions

vary depending on engine type. Please refer to your engine

manufacturer owner’s manual for specic information and

instructions.

BELT ADJUSTMENT

e blower’s drive belt has been adjusted at the factory prior

to delivery. However, the belt should be inspected and checked

aer the initial three (3) hours of operation as it may require

retightening due to belt stretch. It should be inspected aer every

20 hours of operating time. Operating the blower with a loose

belt will cause excessive wear and reduce performance. Follow the

procedures listed to properly adjust the drive belt.

1. Remove the eight bolts holding the front grille in place and

remove the grille. (Figure 1.1)

2. Remove the blade assemble (detailed instructions on how to

remove the blade assembly are available from Tempest).

3. Loosen the four front engine mount bolts. (Figure 3.1)

4. Use a lever to space or push the engine downward to tighten

the belt. (Figure 3.2) e belt(s) should be snug and have

very little play. DO NOT OVERTIGHTEN THE BELT.

5. Tighten the front engine mount bolts.

6. Reinstall the front grille and test the blower.

BELT REPLACEMENT

e belt on your belt-drive blower should be replaced a minimum

9

of every six (6) months or aer 100 operating hours. e belt

should also be replaced if visual inspection reveals any cracks or

fractures. To remove the belt:

1. Remove the eight bolts holding the front grille in place and

remove the grille. (Figure 1.1)

2. Remove the blade assemble (detailed instructions on how to

remove the blade assembly are available from Tempest).

3. Loosen the four front engine mount bolts. (Figure 3.1)

4. Pry the engine up to loosen and remove the belt. (Figure 3.3)

5. Use a lever to pry or push the engine downward to tighten

the new belt. e belt should be snug and have very little

play. DO NOT OVERTIGHTEN THE BELT.

6. Tighten the front engine mount bolts.

7. Reinstall the front grille and test the blower.

POWER BLOWERTM TROUBLESHOOTING

Various factors can contribute to or be the sole cause of problems

for gas Power BlowersTM.is section will identify some of these

problems and provide solutions to correct them.

BLOWER FAILS TO START

• Check for fuel in the tank; make sure the fuel shut o valve

is open.

• Check the fuel line to determine if the carburetor is getting

fuel.

• Check to see if the fuel tank has been overlled. Too much

fuel in the tank, or tilting the unit too far can clog the charcoal

lter located in the fuel cap, inhibiting fuel ow.

• Check the oil level, HONDA® engines are quipped with

automatic oil alert systems. e engine will not start if oil is

low.

• Check the spark plug for a spark:

1. Remove the spark plug wire, clean any dirt from around

the spark plug base and remove the plug.

2. Install the spark plug into the plug cap.

3. Ground the plug to the engine and pull the starter to see

if a spark jumps the gap. DO NOT HOLD THE SPARK

PLUG IN YOUR HANDS; hold the spark plug cap or

wire.

4. If a spark is present, replace the spark plug and wire

then try starting the engine.

• If the blower still does not start, contact Tempest or your local

engine dealer.

POOR BLOWER PERFORMANCE

• Check the air lter for cleanliness, clean if dirty.

• If the blower is a Belt-Drive, make sure the belt is tight.

• If the blower is a Direct-Drive, make sure the blade is tight.

• If the fuel is more then two months old, replace the fuel with

fresh fuel.

• If blower is still not performing as normal, contact Tempest at

800.346.2143 or response@tempest.us.com.

BLOWER MOVEMENT OR “WALKING”

• Adjust the rubber footpads on the back of the blower by

turning them either in or out.

• Adjust the side that is walking. is will help to evenly

distribute the weight of the blower to all four points of the

frame.

• Most blowers will walk if not running at full speed, make sure

the blower is running at full speed.

• Make sure the blower is sitting at and not on small rocks or

other objects.

• If blower is still walking, contact Tempest at 800.346.2143 or

respon[email protected]m.

Figure 1.1 Figure 3.1

Figure 3.3

Figure 3.2

10

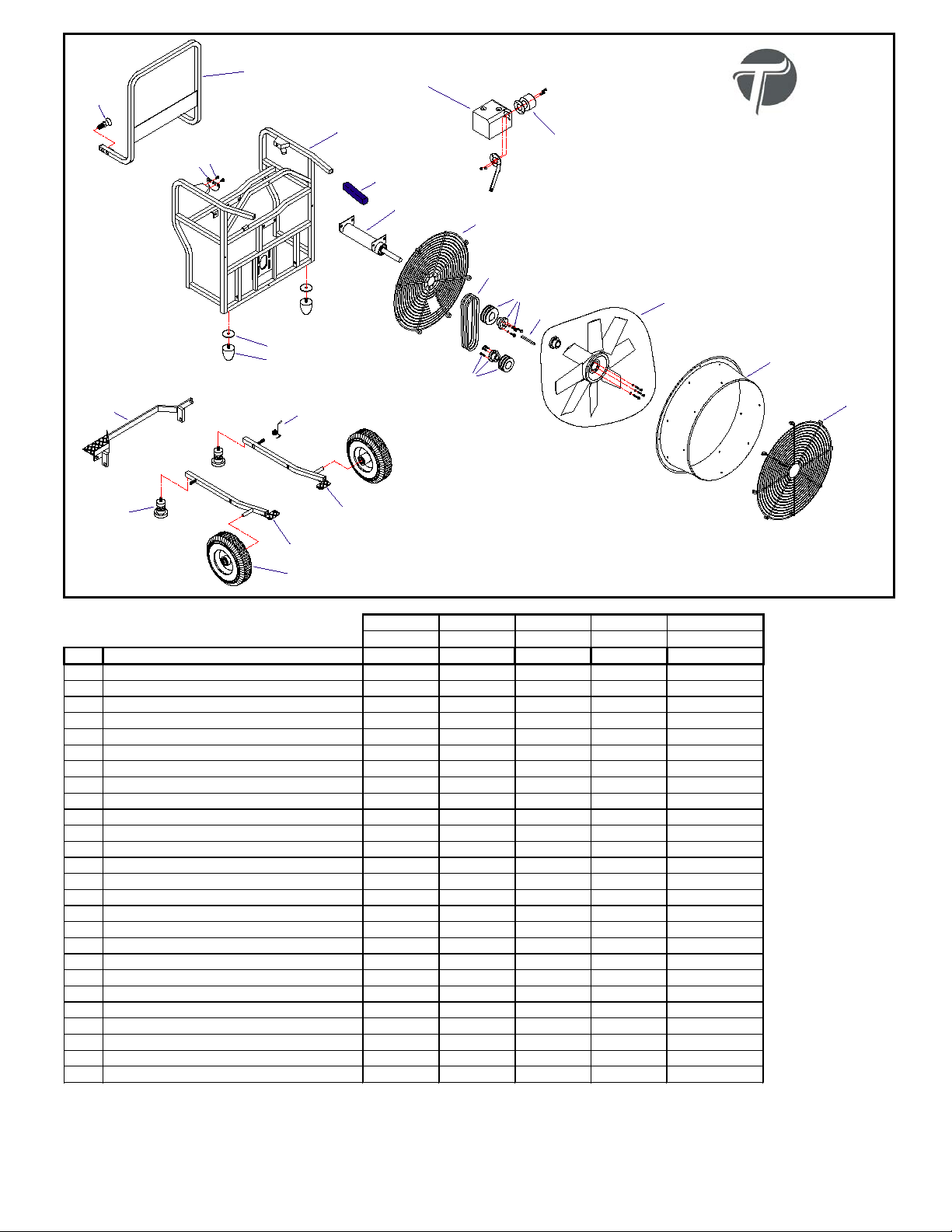

BD-18-H-4.8 BD-21-H-5.5 BD-24-H-5.5 BD-27-H-8.5 BD-27-H-8.5 NY

910-1020 910-1040 910-1060 910-1080 910-1085

Item # Description Part No. Part No. Part No. Part No. Part No.

11/4 X 1/2 FLAT SOC C/S ZINC 100-079 100-079 100-079 100-079 100-079

2WASHER 3/8 X 2 FENDER HVY Z 120-037 120-037 120-037 120-037 120-037

3*

UPPER PULLEY KIT

160-030 600-072 600-065 600-066 600-066

4*

LOWER PULLEY KIT

160-030 600-371 600-371 600-372 600-372

5

DRIVE BELTS

180-014 180-003 180-001 180-002 180-002

6HANDLE BRACKET 220-069 220-069 220-069 220-069 220-069

7GRIP BASIC BLOWER HANDLE 220-248 220-248 220-247 220-247 220-247

8WHEEL FLAT FREE 240-012G 240-012G 240-012G 240-012G 240-008

9SPRING TORSION LHW RIGHT 300-018 300-018 300-018 300-018 300-018

NI SPRING TORSION RHW LEFT (BD 27 ONLY) NA NA NA 300-019 300-019

11 SPRING PLUNGER W/HANDLE 300-170 300-170 300-170 300-170 300-170

NI HONDA ENGINE 350-004 350-016 350-016 350-006 350-006

13 FOOT TAPERED 580-006 580-006 580-006 580-006 580-006

14 SPRING ASSEMBLY 600-001 600-001 600-001 600-001 600-001

15 KEYSTOCK SQ STEEL (CUT 3") 600-396 600-396 600-396 600-395 600-395

16* HANDLE RED 600-678K 600-679K 600-680K 600-682K 600-682K

17* WIN STEP RED 600-685K 600-688K 600-690K 600-691K 600-691K

18* BEARING HOUSING ASSEMBLY DARK GREY 610-1620K 610-1620K 610-1620K 610-1680K 610-1680K

19* LEG ASSEMBLY LEFT DARK GREY 610-1020K 610-1020K 610-1020K 610-1080K 610-1085K

20* LEG ASSEMBLY RIGHT DARY GREY 610-1021K 610-1021K 610-1021K 610-1081K 610-1086K

21* FRAME DARK GREY 610-1321K 610-1341K 610-1361K 610-1381K 610-1381K

22 FRONT GRILLE DARK GREY 610-1420K 610-1440K 610-1460K 610-1480K 610-1480K

23 REAR GRILLE DARK GREY 610-1421 610-1441 610-1461 610-1481 610-1481

24* SHROUD, RED 705-105 705-110 705-115 705-120 705-121

25* EXHAUST EXTENSION KIT FOR HONDA 725-047 725-039 725-039 725-093 725-093

26* BLADE ASSEMBLY 705-261 705-263 705-270 705-275 705-275

* denotes item includes necessary hardware for installation

NI Not Illustrated

This document contains proprietary information and intellectual property that cannot be reproduced or altered, in whole or in part, without the written consent of Tempest Technology Corp.

Copyright 2016 - All Rights Reserved

Information and Material Subject to Change Without Notice

Drawn By Bill Allen Rev. 0116_01A

Replacement Parts

Belt Drive Gas

Power Blowers™

For Technical Support;

1-800-346-2143

Please specify part number and

serial number of blower when

ordering parts.

Honda engine muffler exhaust guard

1

2

3

4

5

6

7

8

9

11

13

14

15

18

19

20

21

16

17 22

23

24

25

26

11

Honda® DD-16-H-4.8 DD-18-H-4.8 DD-21-H-5.5 DD-24-H-5.5

910-1100 910-1120 910-1140 910-1160

Briggs & Stratton® DD-16-B-3.5 DD-18-B-5.5 DD-21-B-5.5 DD-24-B-5.5

910-1101 910-1121 910-1141 910-1161

Item # Description Part No. Part No. Part No. Part No.

11/4 X 1/2 FLAT SOC C/S ZINC 100-079 100-079 100-079 100-079

2WASHER 3/8 X 2 FENDER HVY Z 120-037 120-037 120-037 120-037

3* SHAFT 1" EXTENSION 4140 H.T. 170-004K 170-004K 170-004K 170-004K

4HANDLE BRACKET 220-069 220-069 220-069 220-069

5GRIP BASIC BLOWER HANDLE 220-248 220-248 220-248 220-247

6WHEEL FLAT FREE 240-008 240-012G 240-012G 240-012G

7SPRING TORSION 300-019 300-018 300-018 300-018

8SPRING PLUNGER W/HANDLE 300-170 300-170 300-170 300-170

NI HONDA ENGINE 350-004 350-004 350-016 350-016

NI BRIGGS ENGINE 350-031 350-024 350-024 350-024

11 FOOT TAPERED 580-006 580-006 580-006 580-006

12 SPRING ASSEMBLY 600-001 600-001 600-001 600-001

13* HANDLE RED 600-677K 600-678K 600-679K 600-680K

14* WIN STEP RED 600-683K 600-684K 600-687K 600-689K

15* LEG ASSEMBLY LEFT DARK GREY 610-1001K 610-1020K 610-1020K 610-1020K

16* LEG ASSEMBLY RIGHT DARK DREY 610-1002K 610-1021K 610-1021K 610-1021K

17* FRAME DARK GREY 610-1300K 610-1320K 610-1340K 610-1360K

18 FRONT GRILLE DARK GREY 610-1400K 610-1420K 610-1440K 610-1460K

19 REAR GRILLE DARK GREY 610-1401 610-1421 610-1441 610-1461

20* SHROUD, RED 705-100 705-105 705-110 705-115

21* BLADE ASSEMBLY 705-272 705-283 705-262 705-271

22* EXHAUST EXTENSION KIT FOR HONDA 725-047 725-047 725-039 725-039

22* EXHAUST EXTENSION KIT FOR BRIGGS 725-103 725-103 725-103 725-104

* denotes item includes necessary hardware for installation

NI Not Illustrated

This document contains proprietary information and intellectual property that cannot be reproduced or altered, in whole or in part, without the written consent of Tempest Technology Corp.

Copyright 2016 - All Rights Reserved

Information and Material Subject to Change Without Notice

Drawn By Bill Allen Rev. 0116_01A

13

8

Replacement Parts

Direct Drive Gas

Power Blowers

™

For Technical Support;

1-800-346-2143

Please specify part number and

serial number of blower when

ordering parts.

Engine muffler exhaust guard

17

1

4

5

3

22

19

2

11

14

12

7

6

16

15

21

20

18

12

DD-18-H-4.6 BASIC DD-21-H-4.6 BASIC

910-1122 910-1142

Item # Description Part No. Part No.

1BOLT #10 X 1/2 OVAL PHIL Z 100-062 100-062

2WASHER 3/8 X 2 FENDER HVY Z 120-037 120-037

3MUFFLER DEFLECTOR BD/DD 21H6.5 190-037 190-037

NI HONDA ENGINE 350-030 350-030

5FOOT TAPERED 580-006 580-006

6SPRING & FOOT ASSY, COMPLETE 600-001 600-001

7BASIC TILT CAM ASSEMBLY 600-345K 600-345K

8* LEG KIT LEFT/RIGHT DARK GREY 610-1027K 610-1027K

9* FRAME DARK GREY 610-1304K 610-1344K

10 FRONT GRILLE DARK GREY 610-1420K 610-1440K

11 REAR GRILLE DARK GREY 610-1411 610-1441

12* SHROUD, RED 705-105 705-110

13* BLADE ASSEMBLY 705-286 705-282

Handle/Wheel Kit

610-1921

Item # Description Part No.

14 WHEEL 715-OF 7X1.50 OFFSET 240-001

15 HANDLE RECEIEVER ASSY 18 & 21 BASIC 610-1659

16 PULL UP HANDLE FOR BASIC 600-286K

17 BASIC WHEEL MOUNT LEFT 610-1657

18 BASIC WHEEL MOUNT RIGHT 610-1658

* denotes item includes necessary hardware for installation

NI Not Illustrated

This document contains proprietary information and intellectual property that cannot be reproduced or altered, in whole or in part, without the written consent of Tempest Technology Corp.

Copyright 2016 - All Rights Reserved

Information and Material Subject to Change Without Notice

10

15

1

6

12

Drawn By Bill Allen Rev. 0116_01A

16

2

7

13

Replacement Parts

Direct Drive Basic Gas

Power Blowers

™

For Technical Support;

1-800-346-2143

Please specify part number and

serial number of blower when

ordering parts.

17

3

8

14 18

11

5

9

13

EC-16-H-3.5 EC-21-H-5.5

910-1103 910-1143

Item # Description Part No. Part No.

1* SHAFT 1" EXTENSION 4140 H.T. 170-004K 170-004K

2WHEEL FLAT FREE 240-001 240-001

3SPRING TORSION 300-019 300-018

4SPRING PLUNGER W/HANDLE 300-170 300-170

NI HONDA ENGINE 350-025 350-016

6FOOT TAPERED 580-011 580-011

7* HANDLE RED 600-287K 600-427K

8* WIN STEP RED 600-288K 600-428K

9* LEG ASSEMBLY LEFT DARK GREY 610-1003K 610-1020K

10* LEG ASSEMBLY RIGHT DARK DREY 610-1004K 610-1021K

11* FRAME DARK GREY 610-1304K 610-1344K

12 FRONT GRILLE DARK GREY 610-1400K 610-1440K

13 REAR GRILLE DARK GREY 610-1401 610-1441

14* SHROUD, RED 705-100 705-110

15* BLADE ASSEMBLY 705-272 705-262

* denotes item includes necessary hardware for installation

NI Not Illustrated

This document contains proprietary information and intellectual property that cannot be reproduced or altered, in whole or in part, without the written consent of Tempest Technology Corp.

Copyright 2016 - All Rights Reserved

Information and Material Subject to Change Without Notice

9

12

10

13

Drawn By Bill Allen Rev. 0116_01A

2

6

7

6

14

1

3

8

11

15

4

Replacement Parts

ECO Direct Drive Gas

Power Blowers

™

For Technical Support;

1-800-346-2143

Please specify part number and

serial number of blower when

ordering parts.

Except as otherwise set forth below, any claim by Customer with reference to the Goods sold shall be

deemed waived by the Customer unless submitted in writing to Tempest within the earlier of (i) ve

(5) business days following the date Customer discovered, or by reasonable inspection should have

discovered, any claimed breach of the foregoing warranty, or (ii) thirty (30) calendar days following the

date of shipment. Any cause of action for breach of the foregoing warranty shall be brought within one

(1) year from the date the alleged breach was discovered or should have been discovered, whichever

occurs rst.

Limited Power Blower Warranty

Tempest warrants to the original purchaser that all Tempest gasoline and electric powered blowers

(except the engine or motor and drive) will be free from original defects in workmanship and material,

under normal-use conditions, and Tempest will replace any defective power blower part (except the

engine or motor and drive) if returned during the applicable warranty period, for the time frame

indicated below:

Firefighting Industry:

Five (5) years from date of shipment

Industrial/Rental Industry:

One (1) year from date of shipment

Blower Engine / Motor & Drive Warranty

e engines manufactured by Honda® and Briggs & Stratton® are covered by a separate manufacturer’s

warranty for a period of two (2) years. Electric motors manufactured by Magnetek, Marathon, Baldor,

Franklin Electric and Multi-Fan are covered by a separate manufacturer’s warranty for a period of one

(1) year.

Note: Unauthorized repair or modication of the factory assembly or parts voids the warranty.

All information provided in this operations manual is subject to change without notice. Please refer to

our website for the most recent sales terms and conditions.

WARRANTY INFORMATION

Tempest Technology Corporation

4708 N. Blythe Avenue, Fresno, CA 93722

t: 559.277.7577 • f: 559.277.7579 • response@tempest.us.com

www.tempest.us.com

This manual suits for next models

19

Table of contents

Other Tempest Blower manuals

Tempest

Tempest BB-16 User manual

Tempest

Tempest POWER BLOWER User manual

Tempest

Tempest Direct-Drive User manual

Tempest

Tempest BD-21-H-6.5 User manual

Tempest

Tempest SP Power Blower User manual

Tempest

Tempest LAMINAR ELECTRIC - LE User manual

Tempest

Tempest VS1-18-BLDC User manual

Tempest

Tempest VSG User manual

Tempest

Tempest VSM Series User manual

Popular Blower manuals by other brands

Nilfisk-Advance

Nilfisk-Advance Terra 5200B Instructions for use

Black & Decker

Black & Decker GWC3600L manual

Jolog

Jolog SRA07 product manual

Echo

Echo PB-251E - PARTS CATALOG SN P07611001001 - P07611999999 REV... parts catalog

Worx

Worx LeafJet WG543E Original instructions

Cobra

Cobra BV3001E owner's manual