Tempest VSG User manual

POWER BLOWERS®

2012 Version

ELECTRIC

Single Speed

Variable Speed

VSG

VSX

VSM

Operations

Manual

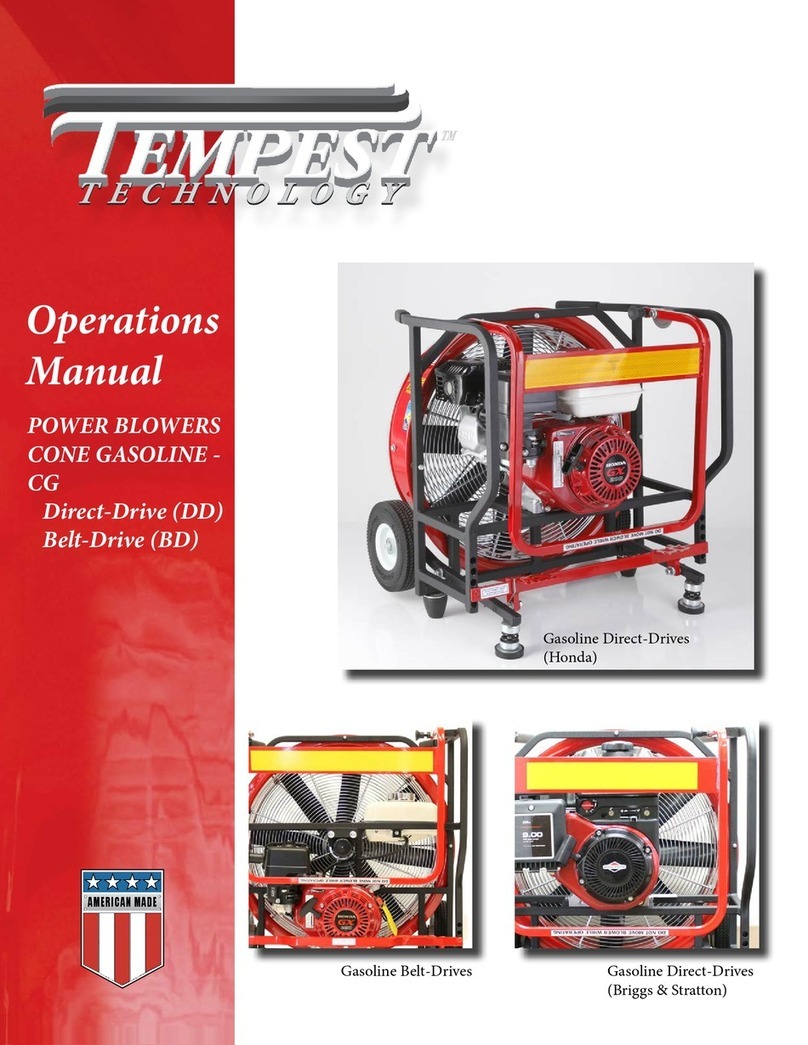

Tempest Gasoline Direct-Drives

(Honda)

Tempest Power Blower

Electric - VSM

Tempest Power Blower

Electric - VSG

Tempest Power Blower

Electric - Single Speed

Tempest Power Blower

Electric - VSX

Introduction

Page 1

TEMPEST TECHNOLOGY CORPORATION® is the leading manufacturer of products

and accessories for environmental management in reghting and industrial applica-

tions.

TEMPEST® began as a manufacturer of gasoline

and electric powered blowers for the re service.

ese departments use the TEMPEST POWER

BLOWER® to provide “Positive Pressure Ventila-

tion / Attack”(PPV/PPA) to remove heat, gases

and smoke from the interior of a burning struc-

ture.

TEMPEST® has expanded into other industries and found new applications for its

products. e TEMPEST POWER BLOWER® and PPV/PPA are used by construction

contractors to control dust, fumes and unhealthy gases like carbon monoxide, greatly

improving safety in conned spaces.

TEMPEST TECHNOLOGY CORPORATION® has earned a reputation as a leader and

innovator in the air movement industry and continues in that role today.

About This Manual

Page 2

is manual is produced solely for the use of purchasers and operators of TEMPEST

TECHNOLOGY CORPORATION® equipment. Any reproduction, retransmission, or

other use of the contents of this manual without written consent of TEMPEST TECH-

NOLOGY CORPORATION® is strictly prohibited.

It is the intent of this manual to provide the owner/operator of TEMPEST® products

with both general and specic information regarding the safe and proper operation and

maintenance of the equipment described within.

If aer careful review, any questions arise concerning any portion of this

manual, please contact TEMPEST TECHNOLOGY CORPORATION® for

assistance:

TEMPEST TECHNOLOGY CORP.®

4708 N. BLYTHE AVENUE

FRESNO, CA 93722

Toll Free: 800.346.2143

Phone: 559.277.7577

Fax: 559.277.7579

E-MAIL: response@tempest-edge.com

WEB PAGE: www.tempest-edge.com

CONTACT:

Table of Contents

Page 3

INTRODUCTION 1

ABOUT THIS MANUAL 2

CONTACT INFORMATION 2

SAFETY GUIDE 4

GENERAL INFORMATION 5

BLOWER IDENTIFICATION 5

SERIAL NUMBER LOCATION 5

WARRANTY 5

POWER BLOWER DATA 6-7

POWER BLOWER INFORMATION 8

OPERATING PROCEDURES 9-12

PRE OPERATION 9

VISUAL INSPECTION 9

OPERATION 9

SET-UP 9

STARTING, ADJUSTING, STOPPING - VSX 10

STARTING, ADJUSTING, STOPPING - VSG 11

STARTING, ADJUSTING, STOPPING - VSM 11

STARTING, ADJUSTING, STOPPING - Single Speed 12

MAINTENANCE PROCEDURES 13-16

MAINTENANCE SCHEDULE 13

BLADE REMOVAL AND INSTALLATION, 3-BOLT DESIGN 13-14

BLADE REMOVAL AND INSTALLATION, 2-BOLT REAR DESIGN 15

TROUBLE SHOOTING - VSX 16-18

TROUBLE SHOOTING - VSG 19

TROUBLE SHOOTING - VSM 20

TROUBLE SHOOTING - Single Speed 21

NOTES 22

EXPLODED VIEW - VSM & SINGLE SPEED 23

PARTS LIST - VSM & SINGLE SPEED 24

EXPLODED VIEW - VSX & VSG 25

PARTS LIST - VSX & VSG 26

Safety Guide

Page 4

Failure to follow the operating, maintenance and lubrication requirements set forth in

this Operation and Maintenance Manual may result in serious personal injury and/or

damage to equipment.

e following WARNING statements indicate potentially hazardous conditions for op-

erators and equipment. Make certain that anyone who works on or around the blower

has read and fully understands the safety precautions listed.

1. Carefully read this Operation and Maintenance Manual before attempting to

operate, service or disassemble any part of your TEMPEST POWER BLOWER®.

2. DO NOT operate the unit when mentally or physically fatigued or impaired.

3. Stay away from rotating parts; avoid wearing loose jackets, shirts, and ties. Keep

hands and feet away from the blower.

4. Keep all unauthorized personnel at a safe distance from the blower.

5. Keep all guards in place. DO NOT make repairs while the unit is running. DO

NOT operate if any guard or grill is not in place.

6. Always wear eye protection. Loose debris can be picked up in the air

stream and own in the air.

7. Hearing protection is required. Motor and air noise may exceed safe dB levels.

8. DO NOT move blower while it is running!

9. It is the sole responsibility of the owner/operator to develop and practice the

proper use of the TEMPEST POWER BLOWER® in accordance with generally

accepted ventilation procedures as well as the department’s own operating proce-

dures before placing the unit into service.

General Information

Page 5

Blower Identication

Each TEMPEST POWER BLOWER® has a model number as well as a serial number. e

model number signies information such as blade diameter, engine type and horsepow-

er. e serial number relates to information referencing the date of manufacture. is

information is useful should it become necessary to contact the factory regarding your

Power Blower.

SERIAL NUMBER LOCATIONS

ELECTRIC POWER UNITS:

e serial number is located on a small plate

welded to the frame.

Please write the Serial Number of your TEM-

PEST POWER BLOWER® in the spaces

below. is will aid us in identifying which

model you have when assisting you.

Model

Date

Serial No.

Warranty

Please visit www.tempest-feedback.com to complete your warranty information

and activate your warranty.

Blower Identication

is plate/information may be

located on the le or right side

of the Blower.

Power Blower Data

Page 6

TYPE:

Positive Pressure Ventilator

BLADE:

Air Flex Fiberglass Reinforced Polyamide

BUSHING:

Keyed Sha and Set or Cap Screws.

SHROUD:

Turbo 2000 Tapered Aluminum.

DRIVE:

Direct-drive Electric Motor.

BEARINGS:

Locking, Self-Aligning and Permanently Lubricated.

FRAME:

Rugged, Lightweight, Square-Steel Tubing with Powder-Coat Finish.

TILT MECHANISM:

Patented Five-Positions, Foot-Operated Tilt Mechanism (e Winning Step).

GRILL:

Continuous Circular-Wound, External-Weld Steel Wire with 8 Tie Points for Ad-

ditional Safety.

VIBRATION DAMPENERS:

Steel-Reinforced Rubber.

Power Blower Data Continued

Page 7

SINGLE SPEED ELECTRIC POWER BLOWERS

VSG VARIABLE SPEED BLOWERS

VSX VARIABLE SPEED BLOWERS

VSM VARIABLE SPEED BLOWERS

Model Part # Blade Size Dimensions (WxDxH) Weight CFM

EBS-16 700-108 16” 18.75” x 14.25” x 19.50” 47 lbs. 3,200

EB-16 700-099 16” 18.50” x 20.00” x 20.50” 66 lbs. 11,804

EB-18 700-056 18” 22.25” x 21.00” x 24.00” 71 lbs. 8,748

EB-21 700-060 21” 25.00” x 21.00” x 26.00” 72 lbs. 11,968

EB-24 700-062 24” 28.25” x 22.50” x 30.00” 75 lbs. 12,867

Model Part # Blade Size Dimensions (WxDxH) Weight CFM

EB-16-VSG 700-316 16” 19.25” x 19.25” x 21.25” 83 lbs. 11,125

EB-18-VSG 700-318 18” 23.50” x 20.75” x 24.00” 88 lbs. 11,861

EB-21-VSG 700-321 21” 25.50” x 20.75” x 26.25” 94 lbs. 13,414

EB-24-VSG 700-324 24” 28.25” x 21.25” x 30.00” 100 lbs. 12,901

Model Part # Blade Size Dimensions (WxDxH) Weight CFM

EB-16-VSX 700-350 16” 19.25” x 19.25” x 21.25” 86 lbs. 11,804

EB-18-VSX 700-352 18” 23.50” x 20.75” x 24.00” 91 lbs. 8,748

EB-21-VSX 700-354 21” 25.50” x 20.75” x 26.25” 97 lbs. 11,968

EB-24-VSX 700-356 24” 28.25” x 21.25” x 30.00” 102 lbs. 12,867

Model Part # Blade Size Dimensions (WxDxH) Weight CFM

EB-16-VSM 700-261 16” 19.00” x 19.25” x 21.25” 66 lbs. 10,650

EB-18-VSM 700-262 18” 22.25” x 20.75” x 24.00” 71 lbs. 8,465

EB-21-VSM 700-263 21” 25.00” x 20.75” x 26.25” 76 lbs. 11,475

Power Blower Information

Page 8

Figure 1.3

e TEMPEST POWER BLOWER® is a

high powered, portable blower used for

Positive Pressure Ventilation and Attack

(PPV/PPA), ventilation techniques that

quickly and eciently replaces hazardous

interior environments.

PPV and PPA were pioneered in the re ghting industry where re ghters use the

TEMPEST POWER BLOWER® to ventilate smoke, heat, and harmful gases from build-

ings. is creates a safer environment for them to work in and makes it easier for them

to nd victims and extinguish the re.

PPV amd PPA rely on two principles, (1) a cone shaped air pattern, and (2) pressure. To

accomplish Positive Pressure Ventilation or Attack, the blower is placed on the outside

of the structure. It is positioned so that the cone shaped air pattern created by the blower

completely seals the entrance opening (Figure 1.2). When this seal is achieved, the air

pressure is increased equally at all points inside the structure. When an exhaust opening

is created, all of the interior air moves in one mass towards it. e result is fast, ecient

ventilation of the entire structure.

NOTE:

e TEMPEST POWER BLOWER® is the most ecient tool for PPV and

PPA for two reasons. First, the exclusive Tempest tapered shroud design

creates a wide, stable, conical air pattern. Second, the seven blade air move-

ment impeller used on all Tempest blowers is designed to create high pres-

sure. ese two features make the TEMPEST POWER BLOWER® such a

powerful ventilation tool.

As with any new technique, Positive Pressure Ventilation requires training

and education in order to be implemented properly and safely. Tempest of-

fers access to a complete line of training materials, which cover many appli-

cations for this powerful ventilation technique. For more information visit

www.tempest-edge.com, www.positivepressuretraining.com or contact us at

1.800.346.2143.

Figure 1.2

Operating Procedures

Page 9

Pre-Operation

VISUAL INSPECTION

Aer receiving and unpacking your blower, be sure to carefully inspect it for any dam-

age that might have occurred during shipping. Should you nd any damage:

PLEASE NOTIFY TEMPEST TECHNOLOGY CORP.®IMMEDIATELY AT

1.800.346.2143

Operation

SET-UP, STARTING AND STOPPING

Assuming the previous Pre-Operation instructions have been followed the blower is

now ready to run.

WHEN USING A GENERATOR, IT IS IMPERATIVE THAT THE GEN

ERATOR BE RUNNING AT FULL CAPACITY BEFORE PLUGGING IN

ANY ELECTRIC BLOWER.

CAUTION: DO NOT MOVE THE BLOWER WHILE IT IS IN OPERA-

TION. SEVERE PERSONAL INJURY IS POSSIBLE AS WELL AS DAMAGE

TO THE BLOWER.

ALWAYS SHUT-DOWN THE BLOWER PRIOR TO MOVING!

SET-UP

Position the blower in the desired location, making sure it is placed on a at, hard and

debris free surface.

NOTE:

e following sections cover separate operating instructions for each type of

electric blower. Please be sure to follow the operating instructions specic to

your particular blower model. (ex. VSG, VSX, VSM, Single Speed)

Operating Procedures Continued

Page 10

STARTING - VSX (WILL NOT RUN ON GFCI CIRCUITS)

1. Plug the blower power cord into power source recep-

tacle. e following displays on the LED screen im-

mediately upon applying power:

LED ashes a 3 digit number (parameter version)

momentarily, then...

STOP condition indicator is displayed.

2. Using the INCREASE button and/or the

DECREASE button, set the desired operation

load %. Operation loads range from approximately

10% to 100%.

3. Start the blower by depressing the green button.

ADJUSTING SPEED WITH BLOWER ON

It is safe to change speed while the blower is running

simply depress INCREASE or DECREASE

buttons to set to desired speed.

STOPPING

To stop operation, depress the red button.

NOTE:

RPM setting at shut down will be the same RPM setting at restart.

CAUTION:

DO NOT plug the unit in again until the LED display is clear (blank.)

395

---

l

O

Operating Procedures Continued

STARTING - VSG

1. Check that toggle switch is set to STOP.

2. Plug the blower cord into power source receptacle. If

power is properly brought to the control, the “ON” LED

and the “STOP” LED indicators will be lit.

3. Engage START toggle. e toggle is momentary

switch to start. e center position is the run location.

STOPPING

Stop unit before unplugging from power source. Make

sure toggle is set to STOP.

STARTING - VSM

1. Set speed control knob (rheostat) to STOP.

2. Plug blower power cord into power supply.

3. Adjust rheostat to desired RPM. e GREEN LED

will indicate power is supplied to unit.

STOPPING

Turn rheostat knob to the STOP position to shut the unit o. DO NOT unplug unit

before shutting o.

Page 11

Operating Procedures Continued

STARTING - Single Speed

-NO SWITCH

Plug blower into power source. Unit will begin running

automatically.

-WITH SWITCH

1. Ensure blower toggle is switched to the o position.

2. Plug blower into power source.

3. Switch toggle to the ON position.

STOPPING

-NO SWITCH

Unplug unit from power source or switch o power source.

-WITH SWITCH

Stop unit before unplugging from power source. Make

sure toggle switch is set to STOP.

Page 12

SINGLE SPEED REQUIREMENTS

Model

Motor HP Starting

Amps Starting

Watts Running

Amps Starting

Watts

MAXIMUM POWER CORD LENGTH

Motor HP

14 gauge 12 gauge 10 gauge 8 gauge 6 gauge

EB-16 1.5 54.6 6,300 18.2 2,100

EBS-16 1/3 10.9 1,300 6.3 756

EB-18 148 6,000 16 1,900

EB-21 148 6,000 16 1,900

EB-24 1 48 6,000 16 1,900

EBS-16 215’ 330’ 550’ 850’ 1,350’

EB-16 60’ 95’ 150’ 240’ 380’

EB-18 45’ 65’ 115’ 190’ 300’

Based on 115v blower on a 20 amp circuit

Based on 1 blower on a 20 amp circuit

Maintenance Procedures

Although the Tempest Variable Speed Blowers are designed to eliminate most mainte-

nance issues, it is imperative that the blowers be inspected before startup on each use.

Please review the following list before using this product.

MAINTENANCE SCHEDULE

EVERY USE

INSPECT BLOWER FOR DAMAGE AND FIX IF ANY

TIGHTEN/REPLACE ANY LOOSE OR MISSING PARTS

INSPECT BLADE FOR NICKS/CUTS OR DAMAGE

EVERY MONTH OR 10 HOURS

INSPECT & CLEAN SHROUD & GRILLS

If the blade has made contact with a hard object, and damage has occurred, please fol-

low these simple instructions for removing and reinstalling the blade assembly.

BLADE REMOVAL/INSTALLATION

PROCEDURES

IMPORTANT: Tempest Variable and Single Speed Electric Power Blowers feature

two dierent blade to sha mount designs. When attempting to remove/install a blade

to your electric blower, you will need to identify which design your blower uses. e

instructions on the following pages touch on both designs individually. Using the im-

ages provided, match the blade-sha design you have with the ones shown in order to

decide which set of directions to follow. If you have any questions, please contact us a

1.800.346.2143

BLADE REMOVAL PROCEDURES

1. Remove the eight bolts holding the front grill in

place and remove the grill. (Figure 4.1)

Figure 4.1

Page 13

Maintenance Procedures Continued

2. Remove the three bolts from blade and remove the

blade from the hub. (Figure 4.2) Remove the two bolts

that secure the bushing to the hub. Put the two bolts in

the threaded part of the bushing and turn evenly until

bushing separates from hub.

BLADE INSTALLATION PROCEDURES

Make sure that the sha and keyway are clean and

smooth before installing the bushing. Remove the

hub from the new blade assembly.

Put “Loc-Tite” on the screws that secure the bushing

to the hub. Insert the cap screws through the clear-

ance holes in the bushing and loosely place the bush-

ing into the hub of the blade. Do not press the bush-

ing in. Hand start the screws into the hub, turning

them just enough to engage the threads in the tapped

holes on the hub. e bushing should be loose in the

hub. Place the hub and the bushing onto the motor

sha. Insert the key into the keyway (Figure 4.3) and

tighten the two bolts drawing the bushing and hub

together.

Slide the blade onto the bushing/hub assembly and place “Lock-Tite” on the three

bolts, then insert the three bolts through the blade and turn evenly but do not tighten.

Make sure blade is in line with hub then tighten bolts (Figure 4.3). Locate the blade

and bushing so that the blade tips do not hit the rear grill eyelets.

Tighten the cap screw bolts progressively with a wrench. Tighten each cap screw, par-

tial turns successively until all are tight. Final tightening should be done with torque

wrench with the torque set at 7.5 /lbs. for each screw. Over tightening will cause the

cap screws to break or crack the blade. (Figure 4.2)

Carefully turn the blade and check for clearance between the blade and shroud. Con-

rm that the blade is free to rotate without hitting other parts.

Reinstall the front grill and test the blower.

If you have any trouble removing or installing the blade on your blower, contact the

factory for assistance at 1.800.346.2143.

1.

2.

3.

4.

5.

6.

7.

NOTE:

On some models the blade and bushing may be in beyond or out away from the end

of the sha up to ¼” but no further. is is necessary for proper blade clearance.

Figure 4.2

Figure 4.3

Page 14

Maintenance Procedures Continued

BLADE REMOVAL PROCEDURES

Remove the eight bolts holding the front grill in

place and remove the grill. (Figure 4.1, Page 13)

Remove the three Allen bolts from blade/hub assem-

bly. DO NOT remove the four nuts/bolts holding

the two blade hub halves that secure the blade ns.

(Figure 5.1)

Insert bolts into adjoining threaded holes of blade/

hub assembly, hand tighten.

(Figure 5.2)

With Allen wrench, consecutively tighten bolt 1,2,3

half turn and repeat until blade separates from bush-

ing.

BUSHING REMOVAL

Loosen Allen set screw. Insert small screw driver into

bushing slot applying a little pressure to release bushing

from engine sha. (Some bushings may have a set screw

securing the bushing to the key on the motor sha). Be

careful not to damage end of sha. (Figure 5.3)

BLADE INSTALLATION

Check key. A worn key should be replaced. Make

sure motor sha keyway is clean.

Align bushing keyway with sha key and position

bushing on sha to insure blade ns are centered

between front and rear grill mounting bolts. Put blue

“Loc-Tite” on bushing allen set screw and tighten.

Align non-threaded holes of blade/hub assembly

with threaded holes of bushing. Put lock washers on

bushing bolts. Put blue “Loc-Tite” on bushing bolts.

Insert through non-threaded holes of blade/hub as-

sembly, hand tighten. With Allen wrench tighten

bolts 1,2,3 consecutively until tight, torque to 7

pounds. (Figure 5.4)

Reinstall the front grill and test the blower.

1.

2.

3.

4.

1.

2.

3.

4.

Figure 5.1

Figure 5.2

Figure 5.3

Figure 5.4

Page 15

Trouble Shooting - VSX

Many factors can contribute to or be the sole cause of problems for electric power blow-

ers. is section will identify some of these problems and provide solutions to correct

them.

BLOWER FAILS TO START

MAKE SURE BLOWER IS CONNECTED TO POWER SOURCE.

IF LED DISPLAY DOES NOT LIGHT UP:

Conrm that adequate power is being supplied to blower. If power supply is adequate,

DISCONNECT BLOWER FROM POWER SOURCE and check for loose or faulty wir-

ing on blower electrical system and repair.

Connect blower to power source and attempt restarting, if blower still does not run,

contact Tempest at 1.800.346.2143.

IF LED DISPLAY LIGHTS UP AND:

Fault Code is given, reference Fault Code Table on the next page for diagnostics.

If “---“ appears on LED, but motor does not run, DISCONNECT BLOWER FROM

POWER SOURCE and check wiring between drive and motor, repair any faulty wiring.

Also check to ensure that the EPM chip is fully inserted into the socket on the top of the

blower control. Connect blower to power source and attempt restarting, if blower still

does not run, contact manufacturer.

BLOWER RUNS THEN CUTS OFF

Check generator rating. e VSX blower series requires minimum 3.5kw rating for

maximum load operation.

Aer the blower cuts o, check the fault code reading on the LED. Reference the fault

code chart on the next page.

Figure 5.1

Figure 5.2

Page 16

Trouble Shooting - VSX

FAULT CODES

FAULT DESCRIPTION & POSSIBLE

CAUSES

ACTION

JF KEYPAD FAULT: THE COM-

MUNICATION LINK BE-

TWEEN THE DRIVE AND

THE KEYPAD HAS BEEN

LOST.

CHECK KEYPAD WIRING AND MAKE

NECESSARY REPAIRS.

LF LOW DC BUS VOLT-

AGE FAULT: TYPICALLY,

CIRCUIT BREAKER HAS

TRIPPED DUE TO EXCES-

SIVE AMP DRAW.

L. CHECK CIRCUIT BREAKER SIZE,

RECOMMENDED SIZE FOR VSX SE-

RIES IS 20 AMP. CHANGE CIRCUIT

BREAKER IF TOO SMALL.

LL. CHECK GENERATOR KW RATING,

IF TOO SMALL, UPGRADE GENERA-

TOR, OR RUN BLOWER LOWER THAN

MAXIMUM BLOWER SPEED.

LLL. CHECK LINE VOLTAGE AT J-

BOX RECEPTACLE. LINE VOLTAGE

SHOULD BE 120V, ±10%. MAKE NEC-

ESSARY ADJUSTMENTS TO INSURE

PROPER SUPPLY VOLTAGE.

LLLL. CHECK FOR UNDERSIZED

POWER SUPPLY CORD. ACCEPTABLE

CORD IS 10/3 AWG X 200 FT. MAX.

CHANGE CORD ACCORDINGLY.

PF CURRENT OVERLOAD

FAULT: EXCESSIVE CUR-

RENT DRAW BETWEEN

DRIVE AND MOTOR.

L. CHECK FOR UNDERSIZED POWER

SUPPLY CORD. ACCEPTABLE CORD

IS 10/3 AWG X 200 FT. MAX. CHANGE

CORD ACCORDINGLY.

Page 17

Trouble Shooting - VSX

CHANGING EPM PROGRAM CHIP

When replacing the EPM (program chip), use a ¼” nut driver to remove the opposing

self tapping screws on the black cover of the VSX box. e EPM is located in the upper

le corner of the white controller under a small piece of protective lm. Remove the

tape and using needle nose pliers, remove the EPM and replace with new one. Replace

the tape over the EPM, replace black cover and opposing screws.

BLOWER MOVEMENT OR “WALKING”

• Adjust the rubber footpads on the back of the Blower by turning them either in or out.

Adjust the side that is walking. is will help to evenly distribute the weight of the

Blower to all four points of the frame

• Most Blowers will walk if not running at full speed, make sure the Blower is running at

full speed.

• Make sure the Blower is sitting at and not on small rocks or other objects.

Page 18

Trouble Shooting - VSG

Many factors can contribute to or be the sole cause of problems for electric power blow-

ers. is section will identify some of these problems and provide solutions to correct

them.

MAKE SURE BLOWER IS CONNECTED TO POWER SOURCE.

IF THE “ON” AND THE “STOP” LEDS DO NOT LIGHT UP:

Conrm that adequate power is being supplied to blower. If power supply is adequate,

DISCONNECT BLOWER FROM POWER SOURCE and check for loose or faulty wir-

ing on blower electrical system and repair.

Connect blower to power source and attempt restarting, if blower still does not run,

contact Tempest at 1.800.346.2143.

BLOWER RUNS THEN CUTS OFF:

Check that the overload indicator light is lit. If the light is lit, this means there is insu-

cient voltage going to the unit. is can be caused by too long of a extension cord, faulty

extension cord or low voltage from the power source. If none of the above exist, the unit

may be set to draw more amperage than the power supply delivers. If this is the case,

there is an adjustment inside the drive to correct the amperage draw when running at

100%. Please contact Tempest for instructions.

BLOWER SURGES WHEN RUNNING ON GENERATOR:

Check generator that it meets the proper voltage output to operate the blower.

BLOWER MOVEMENT OR “WALKING”

• Adjust the rubber footpads on the back of the Blower by turning them either in or out.

Adjust the side that is walking. is will help to evenly distribute the weight of the

Blower to all four points of the frame

• Most Blowers will walk if not running at full speed, make sure the Blower is running at

full speed.

• Make sure the Blower is sitting at and not on small rocks or other objects.

Page 19

This manual suits for next models

18

Table of contents

Other Tempest Blower manuals

Tempest

Tempest VSM Series User manual

Tempest

Tempest POWER BLOWER User manual

Tempest

Tempest LAMINAR ELECTRIC - LE User manual

Tempest

Tempest VS1-18-BLDC User manual

Tempest

Tempest BD-21-H-6.5 User manual

Tempest

Tempest Power Blower Direct-Drive Series User manual

Tempest

Tempest BB-16 User manual

Tempest

Tempest Direct-Drive User manual

Tempest

Tempest SP Power Blower User manual