Tempest POWER BLOWER User manual

POWER BLOWER

OPERATIONS MANUAL

APRIL 2007

Tempest Technology, Inc.

4708 N. Blythe Ave

Fresno, CA 93722

800-346-2143

www.tempest-edge.com

Introduction

®TEMPEST TECHNOLOGY CORPORATION

is the leading manufacturer of products and

accessories for environmental management in

firefighting, industrial, and golf/turf applications

TEMPEST began business as a

manufacturer of gasoline and electric

powered blowers for the fire service,

whose departments use the ®TEMPEST

POWER BLOWER to provide “Positive

Pressure Ventilation”(PPV) to remove

heat, gases and smoke from the interior of

a burning structure.

TEMPEST has expanded into other

industries and found new applications for

its products. The ®TEMPEST POWER

BLOWER and PPV are used by

construction contractors to control dust,

fumes and unhealthy gases like carbon

monoxide; greatly improving safety in

confined spaces.

®TEMPEST TECHNOLOGY

CORPORATION has established a

reputation as a leader and innovator in the

air movement industry and continues in

that role today.

About This Manual

This manual is produced solely for the use of

purchasers and operators of ®TEMPEST

TECHNOLOGY CORPORATION equipment.

Any reproduction, retransmission, or other use of

the contents of this manual without written

consent of ®TEMPEST TECHNOLOGY

CORPORATION is strictly prohibited.

It is the intent of this manual to provide the

owner/operator of ®TEMPEST products with

both general and specific information regarding

the safe and proper operation and maintenance of

the equipment described within.

Contact

If after careful review, any questions arise

concerning any portion of this manual, contact

®TEMPEST TECHNOLOGY CORPORATION

for assistance at:

®TEMPEST TECHNOLOGY, INC.

4708 N. BLYTHE AVENUE

FRESNO, CA 93722

Phone (559) 277-7577 1 800-346-2143

FAX: (559) 277-7579

WEB PAGE: www.tempest-edge.com

Table of Contents

SAFETY PAGE

Safety Guide 2.1

GENERAL INFORMATION

Blower Identification 3.1

Warranty Card 3.2

Power Blower Data 3.3

Power Blower Information 3.6

OPERATION

Operating Procedures 4.1

Pre-Operation 4.1

Fuel, and Fuel Tank Capacities 4.2

Operation 4.3

Set-Up, Starting and Stopping Instructions 4.4

MAINTENANCE

Maintenance Procedures 5.1

Oil Change 5.1

Air Cleaner and Elements 5.2

Cooling System, Spark Plug 5.3

Emissions Control System 5.4

Belt Adjustment for Belt-Drive Power Blowers 5.4

Belt Replacement for Belt-Drive Power Blowers 5.5

Blade Removal 5.7

Blade Installation 5.8

Maintenance Schedule 5.8

PPV

PPV Set-up Procedures 6.1

Single Blower Placement 6.1

Multiple Blower Placement 6.2

Exhaust Opening 6.4

Weather Effects on PPV 6.6

TROUBLESHOOTING

Blower Troubleshooting 7.1

Blower Fails To Start 7.1

Poor Blower Performance 7.2

Blower Movement 7.2

PART NUMBERS

Honda Belt Drive Blowers 8.1

Honda Direct Drive Blowers 8.2

Tecumseh Belt Drive Blowers 8.3

Tecumseh Direct Drive Blowers 8.4

Briggs & Stratton Direct Drive Blowers 8.5

Bushings for Blade Replacement 8.6

BLOWER DRAWINGS

Direct Drive Units (Gas or Electric) 9.0

Belt Drive Unit 9.0

Pole Mount Unit (Electric) 9.0

Safety Guide

Safety Guide Failure to follow the operating, maintenance and

lubrication requirements set forth in this

Operation and Maintenance Manual may result in

serious personal injury and/or damage to

equipment.

The following WARNING statements indicate

potentially hazardous conditions for

operators and equipment. Make certain that

anyone who works on or around the blower

has read and fully understands the safety

precautions listed.

1. Carefully read this Operation and Maintenance

Manual before attempting to operate, service or

disassemble any part of your ®TEMPEST

POWER BLOWER.

2. Never operate the unit when mentally or

physically fatigued.

3. Stay away from rotating parts; avoid wearing

loose jackets, shirts, and ties. Keep hands and feet

away from the blower.

4. Keep all unauthorized personnel at a safe distance

from the blower.

5. Keep all guards in place. Never make repairs

while the unit is running. Never operate if any

guard or grill is not in place.

6. Always wear eye protection. Loose debris can be

picked up in the air stream and flown in the air.

Safety Guide 2.1

Safety Guide Continued…

7. Hearing protection is required. Motor and air

noise may exceed safe DB levels.

8. Gasoline is extremely flammable and is explosive

under certain conditions. To prevent fire hazards,

do not place flammable objects close to the

engine.

9. Do not overfill the fuel tank. After refueling,

make sure the tank cap is closed properly and

secured. If any fuel is spilled, make sure the area

is dry before starting the engine.

10. Never operate gasoline-powered blowers in an

enclosed or confined area. Exhaust contains

poisonous carbon monoxide gas; exposure may

cause loss of consciousness and may lead to

death.

11. The muffler becomes very hot during operation

and remains hot for some time after stopping the

engine. Be careful not to touch the muffler while

it is hot. To avoid severe burns or fire hazards, let

the engine cool before transporting or storing the

unit.

12. It is the sole responsibility of the owner/operator

to develop and practice the proper use of the

®TEMPEST POWER BLOWER in accordance

with generally accepted ventilation procedures as

well as the department’s own operating

procedures before placing the unit into service.

Safety Guide 2.2

General Information

Blower Identification

Each ®TEMPEST POWER BLOWER has a

model number as well as a serial number

(Figure 1.1). The model number signifies

information such as blade diameter, engine

type and horsepower. The serial number relates

to information referencing the date of

manufacture. This information is useful should

it become necessary to contact the factory

regarding your Power Blower.

PRODUCT

MODEL NO.

SERIAL NO.

TEMPEST TECHNOLOGY CORP.

Fi

g

ure 1.1

Please write the Serial Number of your

®TEMPEST POWER BLOWER in the spaces

below. This will aid us in identifying which

model you have when assisting you.

Model Number:

Serial Number: ____

Date Purchased:

Serial Number Locations

BELT-DRIVE and DIRECT DRIVE

GASOLINE POWERED UNITS: The serial

number is located on the side of the engine

housing.

ELECTRIC POWERED UNITS: The serial

number is located on a plate attached to the

motor.

General Information 3.1

Warranty

Be sure to fill out and return the warranty card

to TEMPEST TECHNOLOGY

CORPORATION in order to activate the

warranty. (Figure 1.2)

Figure 1.2

General Information 3.2

Power Blower Data

TYPE:

Positive Pressure Ventilator

BLADE:

Air Flex Fiberglass Reinforced Polyamide

High Strength Blades, Die Cast Aluminum

or Polypropylene.

BUSHING:

Keyed Shaft and Set or Cap Screws.

SHROUD:

Turbo 2000 Tapered Aluminum.

DRIVE:

Industrial-Type, Straight-Banded V-Belt

(On Belt-Drive Blowers) or Direct Drive

(On Direct Drive Blowers).

BEARINGS:

Locking, Self-Aligning and Permanently

Lubricated.

FRAME:

Rugged, Lightweight, Square-Steel Tubing

with Powder-Coat Finish.

TILT MECHANISM:

Patented Five-Positions, Foot-Operated Tilt

Mechanism (The Winning Step).

GRILL:

Continuous Circular-Wound, External-Weld

Steel Wire with 8 Tie Points for Additional

Safety.

General Information 3.3

Power Blower Data continued…

VIBRATION DAMPENERS:

Steel-Reinforced Rubber.

GAS ENGINES:

TYPE: Single Cylinder, 4 Stroke, Gasoline

COOLING: Forced Air

LUBRICATION: Splash Type Oil Reservoir

STARTING: Recoil with Auto Rewind

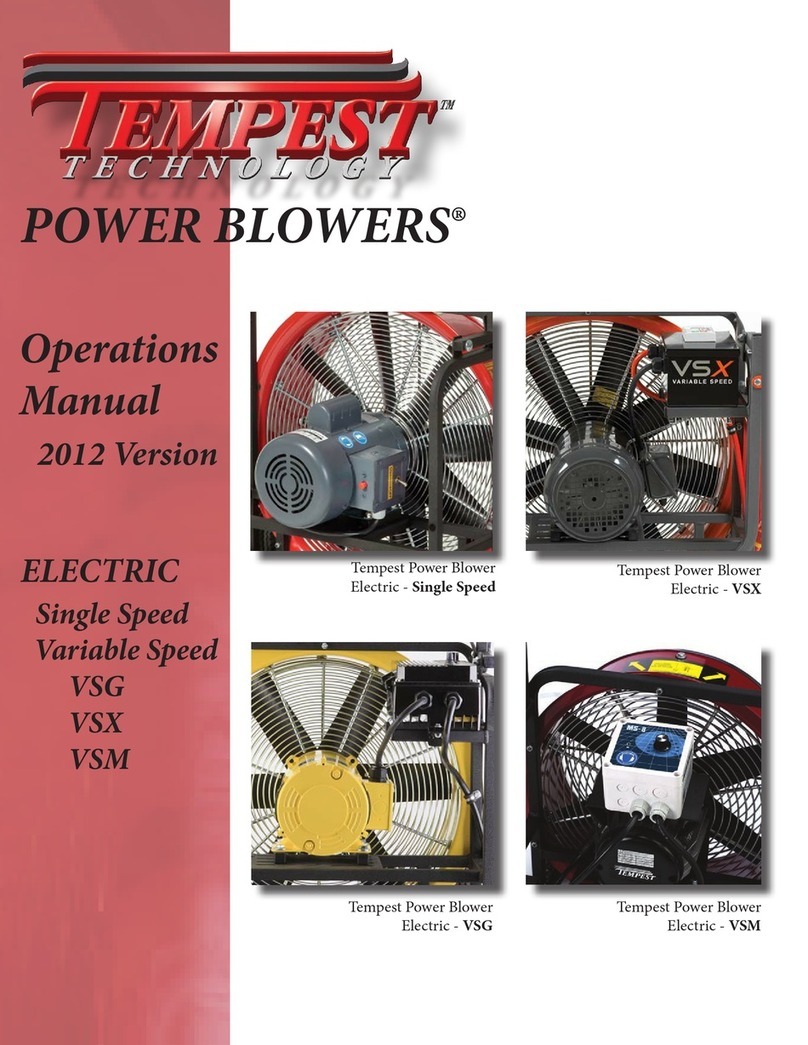

Belt Drive Gasoline Power Blowers

BELT-DRIVE

GAS ENGINE HP CFM S/B RPM WIDTH DEPTH HEIGHT LBS

BD 18-T-5.5 TECHUMSEH 5.5 10,903 8 4,070 21.50 21.00 24.25 79

BD 18-H-5.5 HONDA 5.5 15,023 5 3,870 21.50 21.00 24.25 85

BD 21-T-5.5 TECHUMSEH 5.5 18,673 9 3,350 25.00 22.00 26.25 87

BD 21-H-6.5 HONDA 6.5 17,743 5 3,125 25.00 22.00 26.25 93

BD 24-T-5.5 TECHUMSEH 5.5 17,314 6 3,190 28.25 22.00 31.00 86

BD 24-H-6.5 HONDA 6.5 18,130 5 3,175 28.25 22.00 31.00 92

BD 27-T-10 TECHUMSEH 10.0 23,690 10 2,643 30.50 23.50 32.50 137

BD 27-H-13 HONDA 13.0 23,943 10 2,672 30.50 23.50 32.50 155

Direct Drive Gasoline Power Blowers

DIRECT-

DRIVE GAS ENGINE HP CFM S/B RPM WIDTH DEPTH HEIGHT LBS

DD 16-T-5.5 TECHUMSEH 5.5 10,399 4 3,650 19.00 19.75 21.25 61

DD 16-H-5.5 HONDA 5.5 12,008 4 3,725 19.00 19.75 21.25 67

DD 18-T-5.5 TECHUMSEH 5.5 13,800 5 3,625 22.50 21.00 24.00 71

DD 18-H-5.5 HONDA 5.5 14,733 5 3,765 22.50 21.00 24.00 77

DD 21-B-5.5 BRIGGS 5.5 17,135 7 3,425 25.00 21.00 26.00 73

DD 21-T-5.5 TECHUMSEH 5.5 17,613 7 3,425 25.00 21.00 26.00 72

DD 21-H-6.5 HONDA 6.5 20,152 7 3,740 25.00 21.00 26.00 79

DD 24-B-5.5 BRIGGS 5.5 18,290 7 3,400 28.25 21.25 30.00 76

DD 24-T-5.5 TECHUMSEH 5.5 15,300 7 2,950 28.25 22.50 30.00 76

DD 24-H-6.5 HONDA 6.5 19,606 6 3,450 28.25 21.25 30.00 82

DD 36-B-5.5 BRIGGS 5.5 19,367 8 2,510 41.50 24.00 43.50 97

General Information 3.4

Power Blower Data continued…

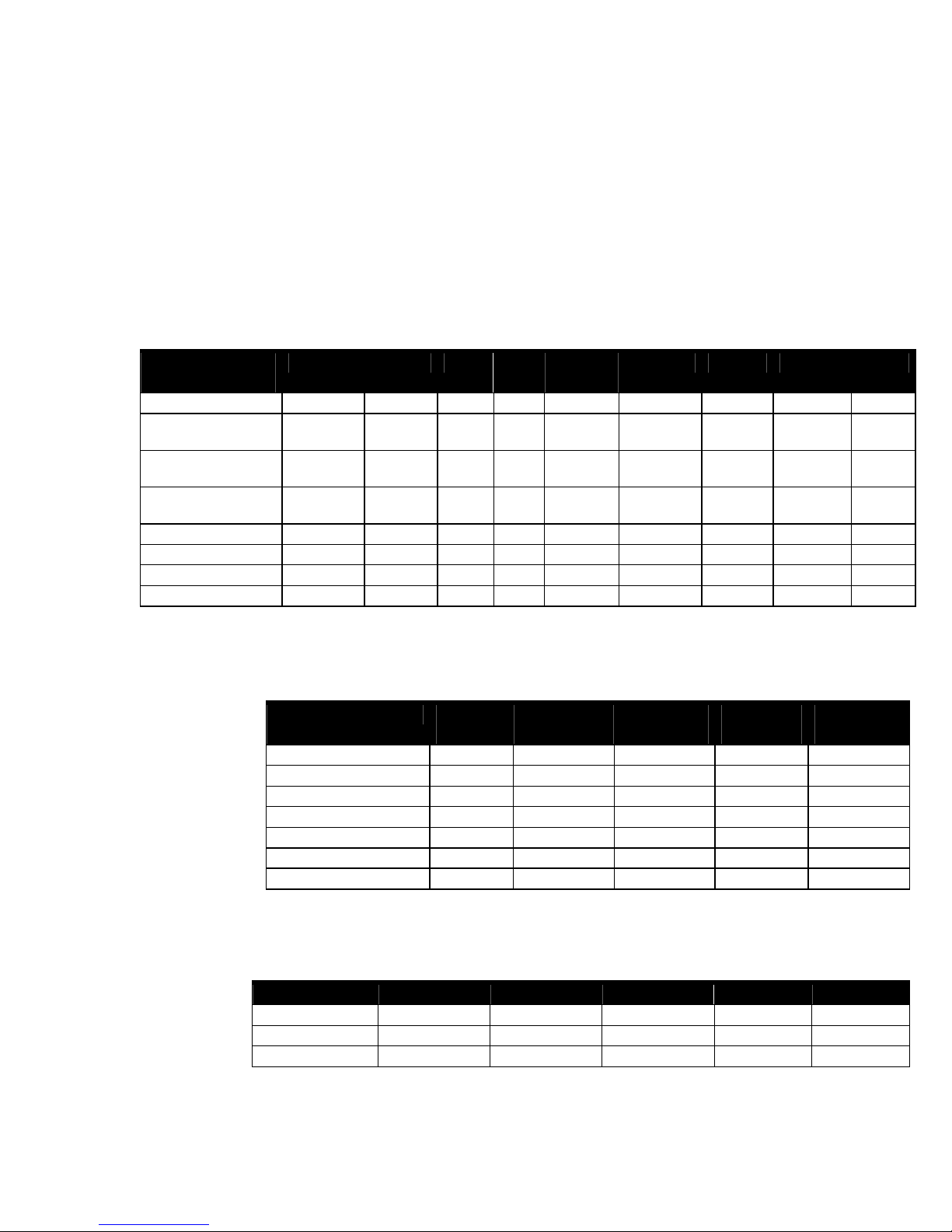

ELECTRIC MOTORS:

All electric motors are single phase, 60

Hz, rigid base, 56 frame, with ball

bearings and manual reset overload

protection.

ELECTRIC

UNITS ENGINE HP CFM S/B RPM WIDTH DEPTH HEIGHT LBS

EB-12 ELECTRIC 1 TEFC 7,683 N.A. 3,450 16.00 19.50 21.50 45

EBS-16 ELECTRIC 1/3

TEFC 3,200 N.A. 1,736 18.75 14.25 19.50 47

EBS-16M

(W/MISTER) ELECTRIC 1/3

TEFC 3,200 N.A. 1,736 18.75 14.25 19.50 47

EB-16 ELECTRIC 1.5

TEFC 11,804 6 3,450 18.50 20.00 20.50 66

EB-18 ELECTRIC 1 TEFC 8,748 6 1,750 22.25 21.00 24.00 71

EB-21 ELECTRIC 1 TEFC 11,698 7 1,731 25.00 21.00 26.00 72

EB-24 ELECTRIC 1 TEFC 12,867 7 1,736 28.25 22.50 30.00 75

EB-36 ELECTRIC 1 TEFC 13,281 8 1,750 41.50 24.50 43.50 94

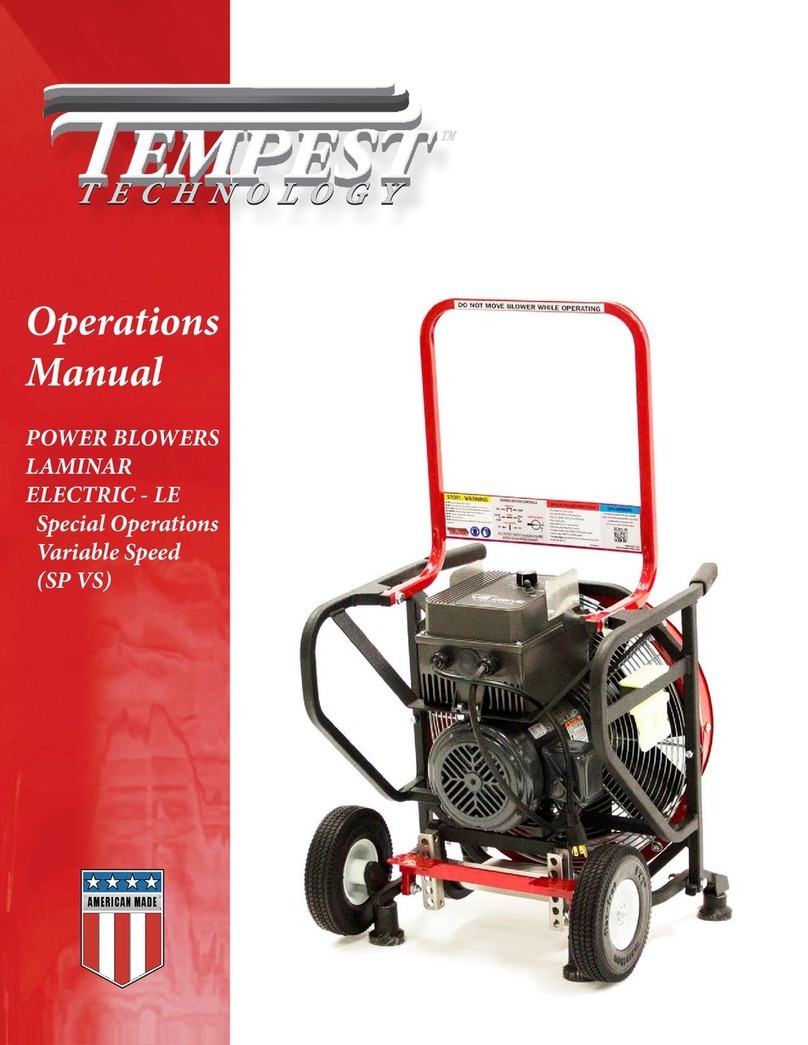

Electric Blower Power Requirements*

Based upon 115 v blower on a 20 amp circuit.

BLOWER MODEL MOTOR

HP STARTING

AMPS STARTING

WATTS RUNNING

AMPS RUNNING

WATTS

EB-12 1.0 48 6,000 16 1,900

EB-16 1.5 54.6 6,300 18.2 2,100

EBS-16 1/3 10.9 1,300 6.3 756

EB-18 1.0 48 6,000 16 1,900

EB-21 1.0 48 6,000 16 1,900

EB-24 1.0 48 6,000 16 1,900

EB-36 1.0 47.3 6,000 12.1 1,452

*Starting amps and watts are momentary

Maximum Power Cord Length (in feet)**

MOTOR H.P. 14 GAUGE 12 GAUGE 10 GAUGE 8 GAUGE 6 GAUGE

1/3 215’ 330’ 550’ 850’ 1,350’

1.0 60’ 95’ 150’ 240’ 380’

1.5 45’ 1.75’ 115’ 190’ 300’

**Calculations based upon one blower connected to 20 amp circuit.

General Information 3.5

Power Blower Information

The ®Tempest Power Blower is a high

powered, portable blower used for Positive

Pressure Ventilation (PPV), a ventilation

technique that quickly and efficiently replaces

hazardous interior environments.

PPV was pioneered in the fire fighting industry

where fire fighters use the ®Tempest Power

Blower to ventilate smoke, heat, and harmful

gases from buildings. This creates a safer

environment for them to work in and makes it

easier for them to find victims and extinguish

the fire.

Fi

g

ure 1.

3

PPV relies on two principles, (1) a cone shaped

air pattern, and (2) pressure. To accomplish

Positive Pressure Ventilation, the blower is

placed on the outside of the structure. It is

positioned so that the cone shaped air pattern

created by the blower completely seals the

entrance opening (Figure 1.3). When this seal

is achieved, the air pressure is increased

equally at all points inside the structure. When

General Information 3.6

Power Blower Information continued…

an exhaust opening is created, all of the interior

air moves in one mass towards it. The result is

fast, efficient ventilation of the entire structure.

For additional information on how to

accomplish PPV, refer to “PPV Set-Up

Procedures” in this Manual.

Note: The ®Tempest Power Blower is the most

efficient tool for PPV for two reasons. First,

the exclusive Tempest tapered shroud design

creates a wide, stable, conical air pattern.

Second, the seven blade air movement impeller

used on all Tempest blowers is designed to

create high pressure. These two features make

the ®Tempest Power Blower such a powerful

ventilation tool.

As with any new technique, Positive Pressure

ventilation requires training and education in

order to be implemented properly and safely.

Tempest offers a complete PPV TRAINING

PROGRAM, which covers many applications

of this powerful ventilation technique. For

more information contact your local dealer or

the Tempest factory direct for a free brochure

on PPV.

General Information 3.7

Operating Procedures

The information and instructions in this section

should be routinely reviewed and followed before

the actual operation of ®Tempest Power Blowers.

Pre-Operation

VISUAL INSPECTION

After receiving and unpacking your blower, be

sure to carefully inspect it for any damage that

might have occurred during shipping. Should you

find any damage: PLEASE NOTIFY TEMPEST

TECHNOLOGY IMMEDIATELY AT:

1-800-346-2143

ENGINE OIL

Be sure to use only high quality detergent oil.

Detergent oils keep the engine cleaner and retards

the formation of gum and varnish deposits.

RECOMMENDED OILS

HONDA engines: SF or SG SAE 10W-30 oil.

TECHUMSEH engines: SF, SG, SH, or SH/CD

SAE 30 oil

BRIGGS & STRATTON engines: SE, SF, SG

SAE 30 oil

Operating Procedures 4.1

Pre-Operation continued…

OIL SUMP CAPACITIES

ENGINE CAPACITY QUARTS / LITRES

BRIGGS 5.5 HP 20 FL. OZ. .66 QUARTS OR .59 LITERS

HONDA GX160 5.5 HP 20 FL. OZ. .63 QUARTS OR .6 LITERS

HONDA GX200 6.5 HP 20 FL. OZ. .63 QUARTS OR .6 LITERS

HONDA GX390 13 HP 37 FL. OZ. 1.16 QUARTS OR .77 LITERS

TECHUMSEH OHH5 5.5HP 21 FL. OZ. .66 QUARTS OR .62 LITERS

TECHUMSEH HM100 10 HP 26 FL. OZ. .81 QUARTS OR .77 LITERS

FILLING THE CRANKCASE

Place blower on a level surface and make sure that

the engine is level. Remove the oil fill plug or

dipstick. POUR OIL SLOWLY into the

crankcase. Replace oil fill plug or dipstick and

tighten securely. Refer to the engine

manufacturers Owners Manual for additional

information regarding specific oil requirements.

CAUTION: DO NOT OVERFILL THE ENGINE.

EXCESS OIL VAPOR CAN BE EJECTED

FROM THE ENGINE BREATHER WHILE

RUNNING IN FULL TILT POSITION.

FUEL

Always use clean, fresh, lead-free gasoline with

an octane rating of 86 or higher. DO NOT USE

leaded gasolines. Refer to the engine

manufacturers Owners Manual for acceptable

substitute gasolines.

Operating Procedures 4.2

Pre-Operation continued…

CAUTION: PRECAUTIONS MUST BE

FOLLOWED WHENEVER REFUELING

GASOLINE ENGINES. PLEASE FOLLOW

THE LISTED GUIDELINES.

NEVER FILL THE FUEL TANK INDOORS.

NEVER FILL THE FUEL TANK WHILE THE

ENGINE IS RUNNING OR HOT.

DO NOT SMOKE DURING REFUELING.

NEVER FILL THE FUEL TANK COMPLETELY.

FILL THE TANK TO BOTTOM OF FILLER

NECK TO PROVIDE SPACE FOR FUEL

EXPANSION.

WIPE ANY SPILLAGE FROM ENGINE AND

COMPONENTS BEFORE STARTING THE

ENGINE.

FUEL TANK CAPACITY

ENGINE CAPACITY QUARTS / LITRES

BRIGGS 5.5 HP 96 FL. OZ. 3 QUARTS OR 2.85 LITERS

HONDA GX160 5.5 HP 121.6 FL. OZ. 3.8 QUARTS OR 3.6 LITERS

HONDA GX200 6.5 HP 121.6 FL. OZ. 3.8 QUARTS OR 3.6 LITERS

HONDA GX390 13 HP 192 FL. OZ. 6 QUARTS OR 6.34 LITERS

TECHUMSEH OHH5 5.5HP 64 FL. OZ. 2 QUARTS OR 2.11 LITERS

TECHUMSEH HM100 10 HP 128 FL. OZ. 4 QUARTS OR 4.22 LITERS

Operation

SET-UP, STARTING AND STOPPING

Assuming the previous Pre-Operation instructions

have been followed the blower is now ready to

Operating Procedures 4.3

Operation continued…

run. Please review the engine manufacturers

Owners Manual regarding starting and stopping as

well as the instructions in this section before

actually starting the blower.

CAUTION: NEVER MOVE THE BLOWER

WHILE IT IS IN OPERATION. SEVERE

PERSONAL INJURY IS POSSIBLE AS WELL

AS DAMAGE TO THE BLOWER.

ALWAYS SHUT-DOWN THE BLOWER

PRIOR TO MOVING!

SET-UP

Position the blower in the desired location,

making sure it is placed on a flat, hard and debris

free surface.

STARTING

1. Set the fuel valve in the “ON” position.

2. Set the stop switch to the “ON” position.

3. Set (if equipped) the choke lever to the

“CLOSED” or “STARTING” position.

4. Set the throttle lever to the “STARTING”

position.

5. Grasp the starter handle, take up the slack, and

pull the rope briskly. Let the rope return slowly.

Repeat as necessary until the engine starts. Do not

over pull the rope.

Operating Procedures 4.4

6. If equipped with a choke, move the choke lever to

the ½ position until the engine runs smoothly and

then to the open or off position.

7. Move the throttle to the desired speed. NOTE:

Some blowers may tend to “walk” if the throttle is

not in the full position.

STOPPING

1. Move the throttle to the “IDLE” position.

2. Move throttle lever to the “OFF” position unless

equipped with a stop switch. If a stop switch is

provided, turn the switch to the “OFF” position.

Operating Procedures 4.5

Maintenance Procedures

Proper maintenance is necessary to ensure that

your ®Tempest Power Blower operates as

efficiently and trouble-free as possible. By

following the instructions in this section you will

be providing the maintenance needed to achieve

this goal.

CAUTION: THE ENGINE MAY START

SIMPLY BY ROTATING THE BLADES.

ALWAYS REMOVE THE SPARK PLUG WIRE

PRIOR TO WORKING ON THE BLADE SIDE

OF THE MOTOR.

OIL CHANGE

Oil Filler Ca

p

Check the engine oil level before each use. The

oil should be changed after the first three (3)

operating hours and every 50 hours thereafter. Oil

changes should be performed more frequently if

the blower is being operated in dusty or dirty

conditions. Changing the oil is easier when the

engine is still warm (not hot) from a recent

running.

PROCEDURES

1. Position the blower so the engine oil drain plug

is the lowest point on the engine.

2. Place a two quart or larger container under the oil

drain plug for the oil to drain into.

3. Remove the oil drain plug.

4. Install the oil drain plug and tighten securely.

Maintenance 5.1

Table of contents

Other Tempest Blower manuals

Tempest

Tempest BB-16 User manual

Tempest

Tempest Direct-Drive User manual

Tempest

Tempest VSG User manual

Tempest

Tempest BD-21-H-6.5 User manual

Tempest

Tempest LAMINAR ELECTRIC - LE User manual

Tempest

Tempest Power Blower Direct-Drive Series User manual

Tempest

Tempest SP Power Blower User manual

Tempest

Tempest VSM Series User manual

Tempest

Tempest VS1-18-BLDC User manual

Popular Blower manuals by other brands

Leister

Leister Vulcan E operating instructions

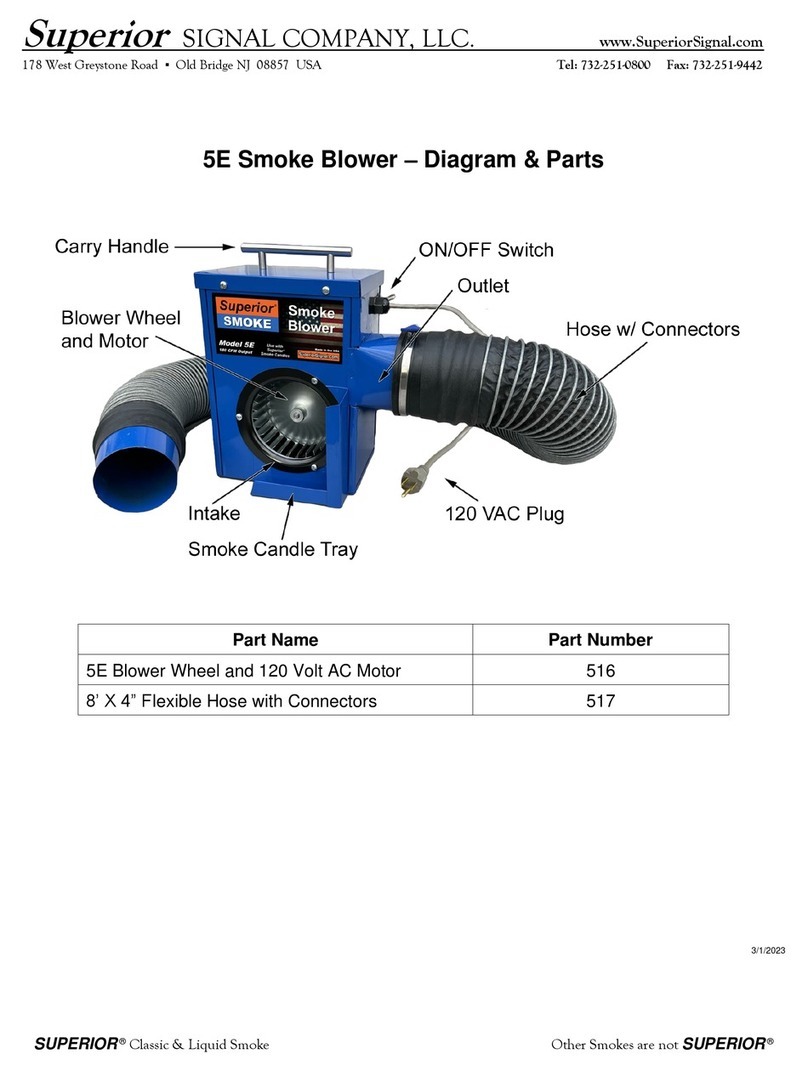

Superior Signal

Superior Signal 5E quick start guide

Texas A/S

Texas A/S GBV270 user manual

Black & Decker

Black & Decker BL950 instruction manual

Gude

Gude 205/18 LB Set Translation of the original instructions

Auger Torque

Auger Torque SWEEPER BROOM quick start guide