Tendring Pacific CheckPoint II Operating manual

1 7thMarch2013

Revision1

CheckPoint II

Preventative Maintenance Guide

Tendring Pacific – Technical Support

Telephone. 01223 492080

Email. [email protected]

2 7thMarch2013

Revision1

SafetyInstructions

Personneloperatingandmaintainingthedevicemustbefamiliarwithallaspectsofits

operationandbeproficientinmaintenance.

SuchPersonnelshouldreviewthefollowingprecautionstopromotesafetyawareness.

General

•Alwaysrefertothemanualbeforeoperatingormaintainingtheequipment.

•ObserveallWARNINGS,CAUTIONSandNOTES.

•Donotopenthedevice.IncaseoftechnicalproblemspleasecontactTendringPacific.

•Donotcoverthemachinewithaclothorpieceofplastictoprotectitfromdust,asthis

preventsfreeaircirculationaroundthemachineandmightleadtooverheatinganderrors

inthesensorread‐out.

•Donotexposetheequipmenttoheavymoistureorheatandkeepitawayfromdirect

sunlight.

•Nevershortcircuitorremovesafetydevices.

Installation

•Toensurethebestinstallationwiththeleasttechnicalproblems,pleaseinstall

equipmentasdescribedinthemanual.

•Neverinstalltheequipmentinexplosiveenvironments.

•Alwaysusecorrectfittingswhenconnectinggasfromthegasbottle.

•Provideadequatespacearoundtheequipmentforproperventilation.

•TheunitsareClass1appliancesandmustbeconnectedtoanearthedmains connection.

•Itistheresponsibilityoftheownerandoperator(s)oftheequipment,thatthe

installationismadeinaccordancewithlocalrulesandregulations.

•Wheninstallingtheequipmentitisnecessarytoensureproperventilationintheroom

oftheinstallationinaccordancewithrequirementsfrommanufacturer.

•TheManufacturercannotbeheldresponsibleforanydamagecausedbyincorrect

installationofthisequipment.

OperationandMaintenance

•Besuretodisconnectelectricalpowerandunplugtheunitbeforeperforminganycleaning

ormaintenance.

•Allpanelsandprotectiveguardsmustbeinplacebeforeoperatingtheequipment.

•Whenoperatingormaintainingtheequipmentalwaysobeytherelevantrulesand

regulationsforworkerssafety.

•Repairorreplacedamagedpowercordsimmediately.

•Neverblockgasoutlets.

3 7thMarch2013

Revision1

CleaningandMaintenance

General

Caution!Personnelperforminganymaintenanceorcleaningmust

familiarizethemselveswiththe“SafetyInstructions”before

attemptinganyoftheseprocedures.

Cleaning

Allofthedevice’ssurfacesmustonlybecleanedusingamildsoapsolutionand

asoftwrungcloth.

Caution!Neverusehardtoolsorabrasivematerialswhencleaning

anypartofthedevice.

Warning!Neverusecleaningagentscontaininganykindofacid.

Theseconstituteahealthhazardandcoulddamagetheinstrument.

4 7thMarch2013

Revision1

CheckPointIIMaintenance

InadditiontoAnnualService&Calibration,itisrecommendedtocarryoutthe

followingMaintenancechecksattheintervaltimesstatedbelow.

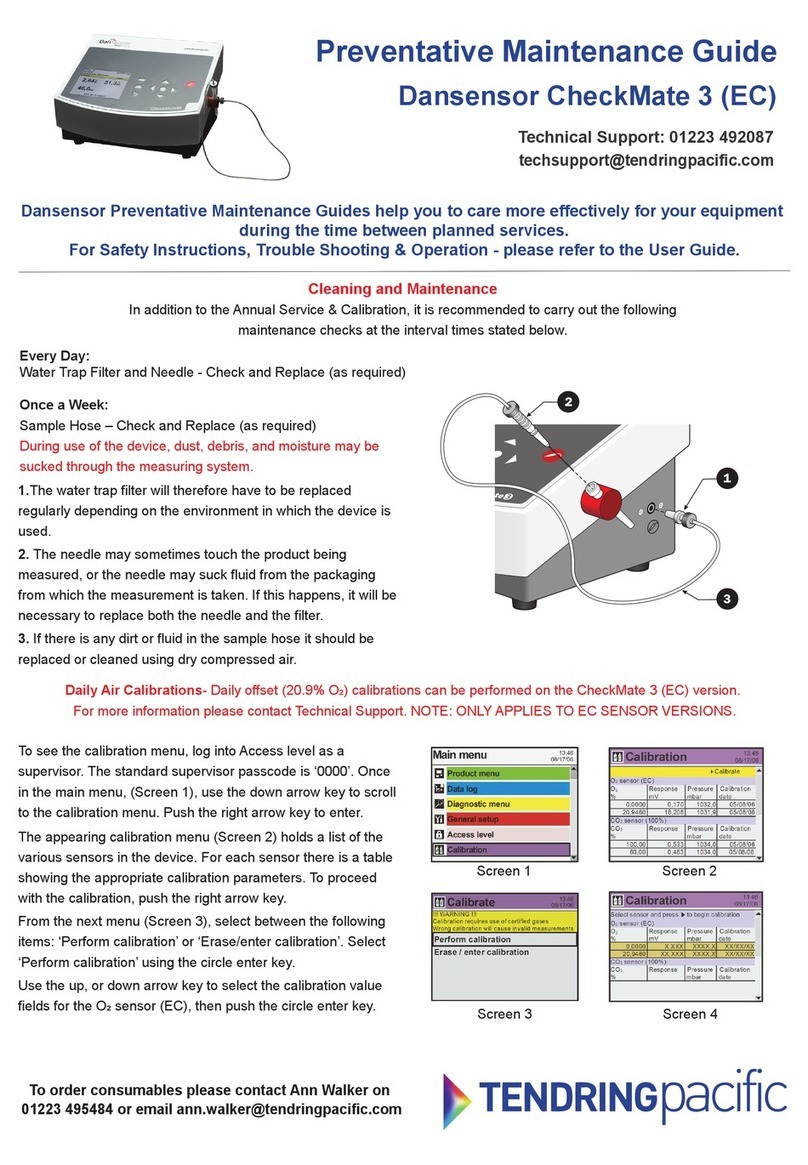

EveryDay:Measuringgashose,filterandneedle(Seeinstructionno.1)

Check/Replace

Offset(20.9%O2)calibration(seeinstructionno.2)

PerformtheoffsetcalibrationoftheO₂sensorbeforestarting

measurements.

Instructionno.1‐Replacingmeasuringgashose,filterandneedle

Duringuseofthedevice,dustwillovertimebesuckedthroughthemeasuring

gassystem.

5 7thMarch2013

Revision1

CMeasuringgasfilterTheFilter(beforeserialno.81121048–partno.

251395,serialno.81121048onwardspartno.980022)

willhavetobereplacedregularlydependingonthe

environmentinwhichthedeviceisused.

DNeedle Theneedlemaysometimestouchtheproductbeing

measuredortheneedlemaysuckfluidfromthe

packagingfromwhichthemeasurementistaken.If

thishappens,itwillbenecessarytoreplaceboththe

needle(partno.220078)andthefilterE(partno.

220079).

EMeasuringgashoseIfthereisanydirtorfluidinthemeasuringgashose,

itshouldbereplacedorcleanedusingdrycompressed

air.Allofthepartscanbeordered(andreplaced)

separatelyorasacompletekit.

(Needlekit–partno.300437)

(Smartpenkit–partno.300433)

Calibration

NOTE!Apartfromthebelowdescribed“Offset(20.9%O2)

calibration”allcalibrationproceduresmustbecarriedoutby

DansensortrainedServiceTechniciansonly,ascalibrationrequires

forspecialskillsandtheaccesstocertifiedcalibrationgasses.

Invalidcalibrationcompromisesmeasurementresults.

Instructionno.2‐Offset(20.9%)Calibration

Itisrecommendedtoperformanoffset(20.9%)oftheO₂sensorevery

daybeforestartingmeasurements.Thisistocompensateforsensorwear.

6 7thMarch2013

Revision1

Note!Asaminimum,aweeklyoffsetcalibrationisrequiredtoretain

the12monthscalibrationintervals!

Alsowhenmovingthedevicefromcoldtowarmtemperaturesorviceversa,you

shouldallowthedevicetostabilizeforapprox.10‐15minutes,thenperform

offset(20.9%)calibrationoftheO₂sensorrightbeforeeachmeasurementseries

untilthedevicehasstabilized.Thiswillbringthecalibrationbackinlinewiththe

currentresponse.

Tomakeoffset(20.9%)calibrationdothefollowing:‐

1.Placetheneedleonthetablenexttothedevicetomakesurethatitmeasures

thesurroundingO₂content.

2. Fromthemeasuringscreen…..

Press keytoentertheMainmenu.

3.Use orkeytoscrolltotheCalibrationscreen.

O

2

CO

2

7: Ham 200 gr.

Ready

Main menu

Main menu

7 7thMarch2013

Revision1

4. Press to enter calibration function.

5.UseorkeytoselectO2:20.95%calibration.

6.Presstostartcalibration.

ThepumpwillstartandthedisplaywillcontinuouslyshowthemeasuredO2

content.

7.Whenmeasurementhasstabilized,presstocalibratesensortothe

currentconditions.

8. Presskeytwicetoreturntothemeasuringscreen.

O:

2

CO :

2

CO :

2

20.95%

0.00%

100.00%

O : 20.95%

2

20.9

Calibrate: Yes

8 7thMarch2013

Revision1

Errors

Ifanerroroccursduringoperationorcalibration,anerrorscreenappears:‐

Anerrorisidentifiedbythenumber(ex.2801)

Fewoftheerrorsmaybecausedbytheuser.Thesearelistedbelowas“User

errors”.

Allothererrorsaredividedintogroupsandlistedas“Deviceerrors”

UserErrors

No.ErrorRemedy

502O₂sensorcalibrationfailed.

Calibrationresultisnot

stored.

Thesensoroutputindicates

thatagasfarawayfrom

20.9%O₂issupplied,eg.Pure

N₂or80%O₂

•Makesurethattheneedlesucksonly

Atmosphericairwhenperforminga20.9%

O₂calibration.

•Iftheerrorrepeats,turndevicecompletely

off(removedevicefrompowersupplyand

pressI/Oforapprox.5secs)

•Iftheerroroccursagainwhencalibrating,the

devicemustbesentinforservice.

2801CO₂sensorcalibrationfailed.

The0.0%CO₂calibration

failed.Calibrationresultis

notstored.Thesensoroutput

indicatesthatagaswitha

concentrationabove25%CO₂

issupplied.

•Makesurethattheneedlesucksonlythe

correctgaswhenperforminga0.0%CO₂

calibration.

•Iftheerrorrepeats,turndevicecompletely

off(removedevicefrompowersupplyand

pressI/Oforapprox.5secs)

•Iftheerroroccursagainwhencalibrating,the

devicemustbesentinforservice.

9 7thMarch2013

Revision1

2802CO₂sensorcalibrationfailed.

The100.0%CO₂calibration

failed.Calibrationresultisnot

stored.Thesensoroutput

indicatesthatagaswitha

concentrationbelow50%CO₂

supplied.

•Makesurethattheneedlesucksonlythe

correctgaswhenperforminga100.0%CO₂

calibration.

•Iftheerrorrepeats,turndevicecompletely

off(removedevicefrompowersupplyand

pressI/Oforapprox.5secs.)

•Iftheerroroccursagainwhencalibrating,the

devicemustbesentinforservice.

No.Error

101to199Producterror

Allerrorsinthismaycausethatproductsarenothandledcorrect.

Alarmlights,measuretime,andalsotheproductlistdisplayedin

theCheckpointIImaybeaffected.

501to599O₂sensorerror

Checkthe“Usererrors”.Othererrorsindicateotherproblemswith

calibrationdatafortheO₂sensor.

TheseerrorsmayhaveinfluenceonO₂(andCO₂)readings.

601to699Pressuregaugeerror

ThepressuresensorisusedforcompensationofO₂sensorreading

(andCO₂sensorifinstalled)

TheseerrorsmayhaveinfluenceonO₂(andCO₂)readings.

701

–

799 Pumperror

Thepumpsucksgastothegassensor(s).Ifthepumpisnotrunning

theCheckpointIIreadingwithbefaulty.

901

–

999Internalmemoryerror

Memoryusedforstoringhourcountersandthelikeisnotworking.

TheseerrorshavenoinfluenceonO₂(andCO₂)readings.

1101‐1199Keyboarderror

Thesoftwarewhichencodeskeypresseshasdetectedanerror.

Someorallofthekeysmaynotwork.If/I/Okeyisnotworking,

youmustwaituntiltheCheckpointIIrunsoutofbattery(orthe

batterymaybedisconnectedtorestarttheCheckpointII)

10 7thMarch2013

Revision1

TheseerrorshavenoinfluenceonO₂(andCO₂)readings.

1600to1699Realtimeclockerror

BatterybackupReal‐timeclockisnotworking.Everylog(data

collection)isstoredwithatimestamp.Thismaybeincorrect.

WhentransferringdatacollectionstotheCheckpointIIPC

software,collecteddatamaybeinsertedintothedatabasewith

wrongtimestamps,thuscorruptingcorrecthistoricalorderof

loggeddata.

TheseerrorshavenoinfluenceonO₂(andCO₂)readings.

2001to2199Beeperror

Beepermaynotworkcorrect.

TheseerrorshavenoinfluenceonO₂(andCO₂)readings.

2201to2299Display

Softwareforhandlingofdisplaycontrastisnotworking.

TheseerrorshavenoinfluenceonO₂(andCO₂)readings.

2501to2599USBDataTransfer

AlldatainterchangebetweenCheckpointIIPCSoftwareishandled

bya“USBdataTransfer”moduleintheCheckpointII.Thismodule

hasreportedanerror.

Itmaynotbepossibletoestablishaconnectionbetween

CheckpointIIandCheckpointIIPCsoftware.

TheseerrorshavenoinfluenceonO₂(andCO₂)readings.

2601to2699Scannererror

Scannerhasdetectedanerror.Scannermaynotoperatecorrectly.

TheseerrorshavenoinfluenceonO₂(andCO₂)readings.

2801to2899CO₂sensorerror

Checkthe“Usererrors”.Othererrorsindicateotherproblemswith

calibrationdatafortheCO₂sensor.

TheseerrorsmayhaveinfluenceonO₂andCO₂readings.

2901to2999Datacollectionerror

Thedatacollectionmodulehasdetectedanerror.Datamaynotbe

stored/collectedcorrectly.

TheseerrorshavenoinfluenceonO₂(andCO₂)readings.

3001to3099Powermanagement

Moduleresponsibleforswitchingdeviceinto“Off”modeor

11 7thMarch2013

Revision1

shuttingitdownmaynotworkproperly.Itmaynotbepossibleto

turndeviceoff.

TheseerrorshavenoinfluenceonO₂(andCO₂)readings.

ConsumableParts

•Kit,standardconsumablePartno.280243

‐NeedlekitØ0.8mm(10pcs)Partno.220078

‐Kit,filterwatertrap0.45my(10pcs) Partno.310449

‐Samplingkitspotcheck0.45myPartno.310431

‐SeptumsØ15mmgrey(1000pcs)Partno.310337

•Kit,standardconsumablePartno.310316

‐NeedlekitØ0.8mm(10pcs)Partno.220078

‐Kit,filterwatertrap0.2my(10pcs) Partno.310335

‐Samplingkitspotcheck0.2myPartno.310323

‐SeptumsØ15mmgrey(1000pcs)Partno.310337

•NeedlekitØ0.8mm(10pcs)Partno.220078

•NeedlekitØ0.8mm(100pcs)Partno.280204

•SeptumsØ15mmgrey(100pcs)Partno.310336

•SeptumsØ15mmgrey(1000pcs)Partno.310337

•SeptumsØ15mmgrey(10000pcs)Partno.220157

•SeptumsØ15mmwhite/hard(100pcs) Partno.220235

•SeptumsØ15mmwhite/hard(1000pcs) Partno.220236

•Kit,filterwatertrap0.45my(10pcs)Partno.310449

•Kit,filterwatertrap0.45my(100pcs) Partno.280208

•Kit,filterwatertrap0.2my(10pcs)Partno.310335

•Kit,filterwatertrap0.2my(100pcs) Partno.310339

•SamplingkitSmartPen0.45myPartno.260486

•SamplingkitSmartpen0.2myPartno.300792

12 7thMarch2013

Revision1

ForanyfurtherinformationortobookanAnnualService&

CalibrationofyourCheckpointIIpleasecontactTendringPacific

TechnicalSupport.

Contactdetails:

T:01223492080

Table of contents

Other Tendring Pacific Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

GAGEMAKER

GAGEMAKER IT-5100 Operation manual

Rigol

Rigol DL3032 user guide

Geokon

Geokon 4855 instruction manual

Armstrong Monitoring Corporation

Armstrong Monitoring Corporation AMC-CD2 instruction manual

Mazi

Mazi HTVR-0410LT Quick manual

Test Equipment Depot

Test Equipment Depot BST-TDS01 instruction manual

WeatherMate

WeatherMate WM300 manual

smart-me

smart-me 212062 quick start guide

Nidec

Nidec Kato Engineering KRM2000 user manual

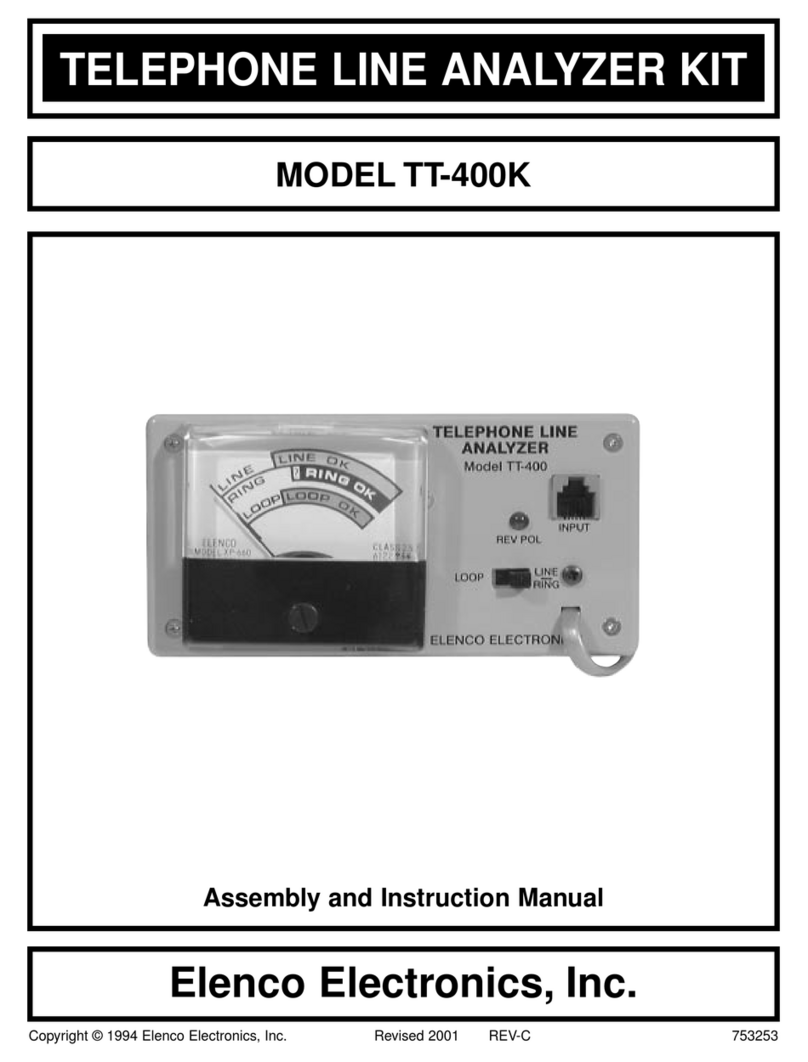

Elenco Electronics

Elenco Electronics TT-400K Assembly and instruction manual

Tektronix

Tektronix P6339A instruction manual

PCE Health and Fitness

PCE Health and Fitness PCE-TDS 100 H user manual