Tennsmith 36 Guide

Model 52T Shown

MODEL 36 and 52 FOOT SQUARING SHEARS

OPERATION, PARTS & MAINTENANCE MANUAL

Model: Purchased From:

Serial #: Date Received:

6926 Smithville Hwy., McMinnville, TN 37110

931-934-2211 / Fax: 931-934-2220

www.tennsmith.com

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

2

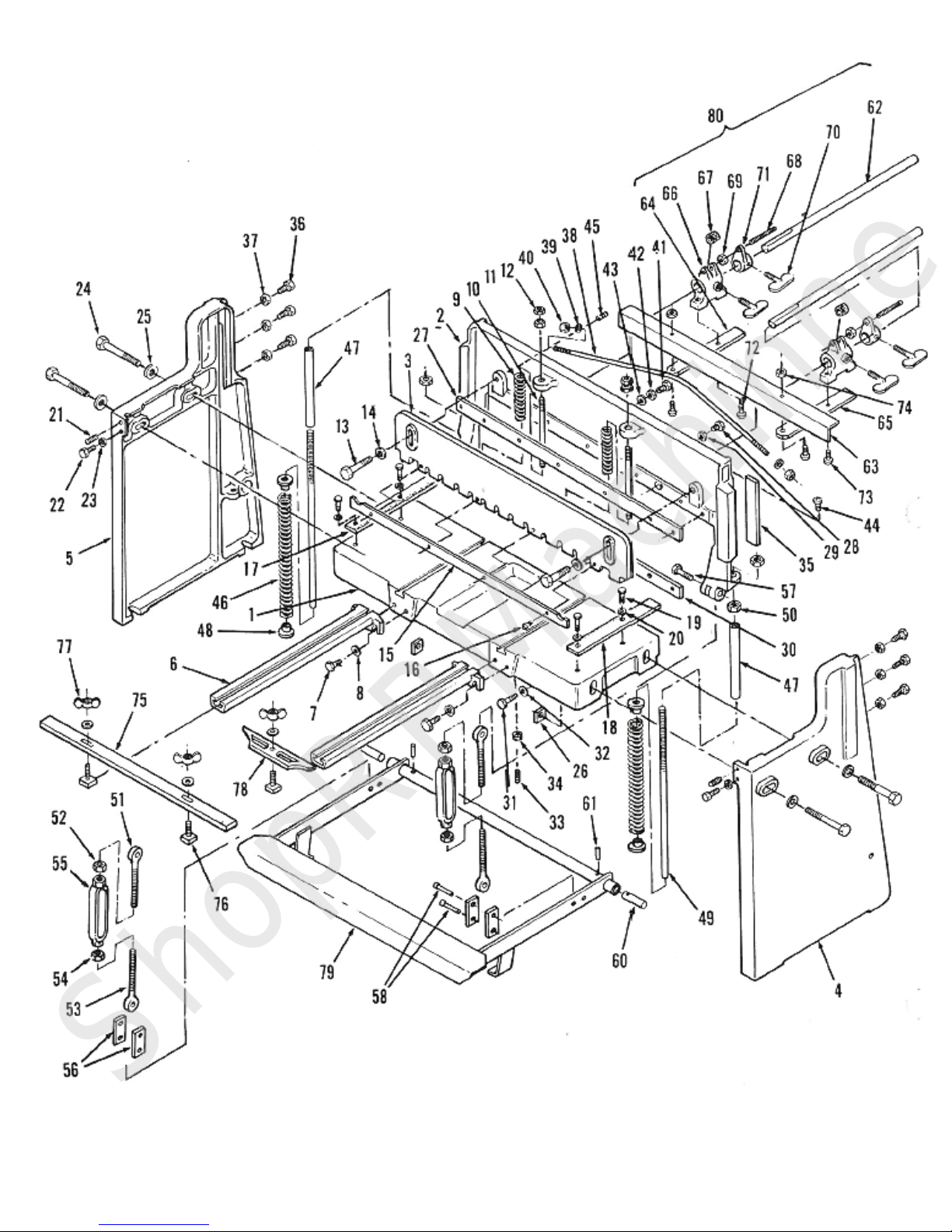

Model 36 and 52 Foot Squaring Shear Parts View

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

3

Model 36 and 52 Parts List

INDEX

NO. 36 52 DESCRIPTION QTY.

1 10101 10151 TABLE 1

2 10102 10152 CUTTER BAR 1

3 10103 10153 HOLDDOWN 1

4 10051 10051 R.H. SIDE PANEL 1

5 10052 10052 L.H. SIDE PANEL 1

6 10053 10053 FRONT ARM EXT. 2

7 05055 05055 SCREW, FRONT ARM EXT. 4

8 05673 05673 WASHER, FRONT ARM EXT. 4

9 10054 10054 SPRING, HOLDDOWN 2

10 10111 10164 STUD, HOLDDOWN SPRING 2

11 05880 05880 NUT, HOLDDOWN STUD 2

12 05907 05907 CAP NUT, HOLDDOWN STUD 2

13 05060 05060 SCREW, HOLDDOWN 2

14 05673 05673 WASHER, HOLDDOWN SCREW 2

17 10055 10055 SCALE, L.H. TABLE 1

18 10056 10056 SCALE, R.H. TABLE 1

19 05021 05021 SCREW, TABLE SCALE 4

20 05639 05639 WASHER, TABLE SCREW 4

21 05327 05327 SET SCREW, TABLE ADJ. 2

22 05035 05035 SCREW, TABLE LOCK 2

23 05670 05670 WASHER, TABLE LOCK SCREW 4

24 05075 05075 BOLT, TABLE 4

25 05676 05676 WASHER, TABLE BOLT 4

26 05925 05925 NUT, TABLE 4

27 10105 10155 KNIFE, UPPER 1

28 05033 05033 SCREW, UPPER KNIFE 7/9

29 05670 05670 WASHER, UPPER KNIFE 14/18

30 10106 10156 KNIFE, LOWER 1

31 05035 05035 SCREW, LOWER KNIFE 6/8

32 05670 05670 WASHER, LOWER KNIFE 12/16

33 05246 05246 SET SCREW, LOWER KNIFE ADJ. 6/8

34 05759 05759 NUT, LOWER KNIFE ADJ. 6/8

35 10064 10064 SHIM, C’BAR 2

36 05249 05249 SCREW, C’BAR SHIM 6

37 05762 05762 NUT, C’BAR SHIM SCREW LOCK 6

38 10107 10157 STRAIGHTENER ROD, C’BAR 1

39 05673 05673 WASHER, STRAIGHTENER ROD 3

40 05787 05787 NUT, STRAIGHTENER ROD 3

41 10112 10165 ADJ. SCREW, STRAIGHTENER ROD 1

44 05331 05331 SET SCREW, BACKGAUGE ROD 2

45 05331 05331 SET SCREW, HOLDDOWN LOCK 2

46 10302 10302 SPRING, FOOT PEDAL 2

47 15053 15053 SPRING GUIDE 2

48 15057 15057 CAP, SPRING 4

49 15055 15055 STUD, SPRING 2

50 05787 05787 NUT, SPRING STUD 8

51 10069 10069 LINKAGE BOLT, C’BAR 2

52 05827 05827 NUT, LINKAGE BOLT, C’BAR 2

54 05826 05826 NUT, STUD 8

55 10071 10071 TURNBUCKLE 2

56 10073 10073 LINK, PEDAL 4

57 06354 06354 PIN, LINKAGE, MOUNTING 2

62 10058 10058 ROD, BACKGAUGE 2

63 10110 10163 STOP, BACKGAUGE 1

64 10065 10065 R. EXT. BAR, BACKGAUGE 1

65 10066 10066 L. EXT. BAR, BACKGAUGE 1

66 10059 10059 ADJ. BLOCK, BACKGAUGE 2

67 10060 10060 ADJ. DIAL, BACKGAUGE 2

68 10075 10075 ADJ. SCREW, BACKGAUGE 2

69 05762 05762 NUT, ADJ. SCREW 2

70 10061 10061 LOCK SCREW, BACKGAUGE 4

71 10062 10062 ADJ. BRKT. BACKGAUGE 2

72 05027 05027 SCREW, EXT. BAR 2

73 05325 05325 SWIVEL BOLT 3

74 10109 05765 NUT, SWIVEL BOLT 2

75 10159 10159 STOP, FRONT MATERIAL 1

76 10074 10074 “T”-NUT 3

77 05938 05938 WING NUT, “T”-NUT 3

78 10063 10063 BEVEL GAUGE 1

80 10108 10158 BACKGAUGE ASSEMBLY 1

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

4

FOREWORD

This manual has been prepared for the owner and operators of the TENNSMITH Model 36 and 52 Shears.

Its purpose, aside from operation instruction, is to promote safety through the use of accepted operating

procedures. Read all instructions thoroughly before operating your shear.

Also contained in this manual is the parts list for your shear. It is recommended that only TENNSMITH

factory authorized parts be used for replacement parts.

3-YEAR LIMITED WARRANTY

TENNSMITH machinery and component parts are carefully inspected at various stages of production and

are tested and inspected prior to shipment. We agree that for a period of twelve (12) months from the

date of delivery from our authorized distributor to replace, at our option, any machine (or component part

thereof) proving defective within the above period. Additionally, we agree that for a period of thirty-six (36)

months from date of delivery to replace component parts proving defective within the stated period. All

warranty claims are made F.O.B. our plant, providing such machine (or component part) is returned

freight prepaid to our plant, or a designated service center of the undersigned, for our examination. This

warranty does not include repair or replacement required because of misuse, abuse, or because of

normal wear and tear; or electrical components which are warranty by their manufacturer. Further, we

cannot be responsible for the cost of repairs made or attempted outside our factory or designated service

center without our authorization. No claims for defects will be honored if the name and data place has

been removed. This warranty is made expressly in place of all other warranties or guarantees express or

implied, with respect to fitness, merchantability, quality or operative ness. This warranty becomes

effective only when the accompanying warranty card is fully and properly filled out returned to the factory

within ten (10) days from date of delivery.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

5

SAFETY INSTRUCTIONS

1. Know the safety and operating instructions contained in this manual prior to operation of this shear.

Become familiar with and understand the hazards and limitations of this shear. Always practice

safety.

2. Wear approved eye safety protection, such as safety glasses or goggles, etc., when operating the

shear to protect your eyes.

3. Protective type footwear should be worn, and jewelry such as rings, watches, necklaces, etc., should

be removed prior to operation of this shear.

4. Do not remove the front hold-down guard (Index # 3). This is a protective device. If the hold-

down is inoperable, immediately stop using the machine, and contact Tennsmith or your

authorized distributor for a replacement part.

5. Keep the hold-down (Index #3) at the minimum gap required to feed the material into the

shear. The gap should never be higher than 3/16” from the table. If you have questions

regarding the Hold-down, please consult the factory.

6. Always keep hands clear of the blade.

7. Do not misuse the shear by using it for other than its intended purpose.

8. Never exceed the rated capacity of this machine.

9. Keep the work area clear and clean to avoid tripping or slipping.

10. Any malfunction or abnormality pertaining to this machine should be reported to the maintenance

supervisor immediately.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

6

RECEIVING THE SHEAR

Examine the shear and accessories package for evidence of any possible damage sustained during transit.

Any damage should be reported to your distributor immediately.

INSTALLING THE SHEAR

Carefully remove the shear from the shipping pallet. Locate the shear in a well-lighted area on a solid level

floor. Use lag screws or bolts with expandable shields or similar holding devices through the mounting feet,

located on the bottom of the side panels.

Place an accurate machinist level on the table top, and check the level of the machine in both directions.

Use metal shims between the floor and the shear mounting surface to adjust the level. After the machine is

level, tighten the mounting bolts.

Periodically, recheck the unit for levelness.

NOTE: Proper levelness greatly affects the performance of your shear, it is very important to ensure

your machine is level prior to operation.

OPERATION INSTRUCTIONS

The mild steel capacity of the Model 36 and 52 shear is 16 gauge. Included in the manual is a standard

shearing, bending, and forming conversion chart for various materials including Aluminum, Stainless, and

Plastics. If you have any capacity related questions on materials that do not appear on the chart, please

contact Tennsmith technical support to help determine the exact capacity ratings.

NEVER ATTEMPT TO SHEAR ANY MATERIAL GREATER THAN THE MAXIMUM RATING FOR YOUR

SHEAR.

The 36 and 52 is a fixed angle designed machines. Reducing the maximum width of your material does not

increase the capacity rating of this shear.

Never attempt to shear any material which would be less than a ½” cut across the full length of the

table under full capacity.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

7

BLADE GAP ADJUSTMENT

The factory setting for the gap between the upper and lower blade is .002. This setting was achieved using

a piece of shim stock. However, if this is unavailable, the thickness of news print will approximate this

dimension. The factory setting is the optimal clearance for the entire range of material likely to be sheared

on this machine. Different materials and thickness may require a larger or slightly smaller clearance. If you

have any specific questions regarding optimal blade gap, please consult Tennsmith.

To begin, loosen the four bolts (24) securing the table (1) to the side panels (4, 5). Pull the table towards

you and depress the foot pedal (79) fully. Standing on the foot pedal, start on the left hand side (facing) of

the shear by snugging the table bolts. Next, insert the shim stock between the upper and lower blades.

Tighten the table adjusting screw (21) until the shim is held fast between the blades. Then, keeping upward

tension on the shim stock, progressively tighten the table locking screw (22) until the shim stock is freed of

pressure and can be removed. Retighten the table bolts and repeat the procedure on the opposite side of

the shear.

After completing alignment, check the entire length of the blades for proper clearance using your shim stock.

You may find that you either have too much or not enough clearance in the center of the blades. This

adjustment is accomplished by increasing or decreasing pressure on the bow adjustment bolt (41) located at

the rear of the cutter bar.

Note: A properly aligned shear will produce a scissor like sound when the blades transcend and will

leave a minimal burr on sheared stock.

CUTTER BAR ADJUSTMENT

The cutter bar (2) should move freely throughout its range of travel without binding. This should be the case

with a new shear. If the shear does bind, recheck for levelness.

The gibs should adjusted for snug yet nonbinding movement. To accomplish this, loosen all six gibb screws

(36). Beginning at the right hand side of the shear, depress the foot pedal fully and lock the center gibb

screw so that the cutter bar remains down. Then, gradually loosen the screw until the cutter bar returns to its

upright position. Proceed to back the screw off an additional quarter turn and lock the jam nut (37) in place.

Continue by repeating this procedure for the remaining gibb screws.

Cutter bar lift is controlled by the amount of pressure exerted by the pedal springs (46). Appropriate tension

was applied to the springs at the factory. However, over a period of years the springs may fatigue slightly

and require additional compression.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

8

LINKAGE ADJUSTMENT

The linkage on your TENNSMITH shear is comprised of two turnbuckle assemblies (55). Rotation of the

turnbuckles is the means by which blade rake and pedal height is set. There should be no need for this

adjustment on a new shear.

Rake angle settings:

MODEL 36

Use a marker to mark the shear bed 2 inches to the from the right side edge of the table. Next, measure

over 36 inches from the right side edge of the table and make another mark. Starting at the right hand side

(facing the machine) at the designated mark on the table, rotate the turnbuckle (55) until the distance

between the top and bottom blades is approximately 3/8 of an inch. At the opposing end, repeat the

procedure allowing 1 1/2 inches clearance between the upper and lower blades. After you have the desired

clearance between the upper and lower blades slightly adjust the turnbuckles so that they have an equal

amount of tension. That is, if one turnbuckle has more play or lost motion in it than the other, it should be

readjusted accordingly. Once the rake has been set and equal tension verified between the turnbuckles,

retighten the jam nuts (54) and lock the turnbuckles in place.

MODEL 52

Use a marker to mark the shear bed 2 inches to the from the right side edge of the table. Next, measure

over 48 inches from the right side edge of the table and make another mark. Starting at the right hand side

(facing the machine) at the designated mark on the table, rotate the turnbuckle (55) until the distance

between the top and bottom blades is approximately 3/8 of an inch. At the opposing end, repeat the

procedure allowing 1 ¾ inches clearance between the upper and lower blades. After you have the desired

clearance between the upper and lower blades slightly adjust the turnbuckles so that they have an equal

amount of tension. That is, if one turnbuckle has more play or lost motion in it than the other, it should be

readjusted accordingly. Once the rake has been set and equal tension verified between the turnbuckles,

retighten the jam nuts (54) and lock the turnbuckles in place.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

9

FOOT PEDAL ADJUSTMENT: Foot pedal lift is similarly adjusted through turnbuckle rotation. Lift

adjustment serves two purposes. It facilitates an acceptable working height for pedal operation and insures

proper blade penetration across the working length of the shear. First, secure the top gibb screw on each

side of the shear to maintain the blade rake angle. Then, adjust the foot pedal to what would appear to be an

appropriate return lift.

NOTE: When gibs are loosened a slight degree of additional lift will be achieved.

Once you have an approximate setting, loosen the top two gibb screws and depress the foot pedal. Examine

the L.H. side of the machine to determine that the top blade does indeed transcend the bottom blade by at

least 1/8 of an inch. If this is the case, tighten the jam nuts on the turnbuckles themselves or your rake

alignment will be distorted. Should the penetration be less than satisfactory, retighten the gibs to maintain

rake and adjust the turnbuckles for additional pedal lift. This will allow for deeper penetration. Reverse the

procedure for opposite circumstances.

When adjusting the turnbuckles, be certain that both linkages have the same amount of tension applied to

each. That is, if one turnbuckle has more play or lost motion in it than the other, it should be readjusted

accordingly.

As an additional point, it should be noted that there are two leverage holes provide in the foot pedal arms for

connecting the linkage assembly. Your shear was shipped with the pins in the uppermost holes and should

supply adequate leverage for shearing material within the machine’s rated capacity. However, if you will be

operating the shear at its peak capacity, moving the linkage pins to the lower of the two holes will give you

some additional leverage.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

10

HOLD-DOWN ADJUSTMENT

CAUTION: THIS SHEAR SHOULD NOT BE OPERATED WITHOUT THE HOLDDOWN IN PLACE AND

PROPERLY ALIGNED.

The hold-down (3) is designed to engage the material before the blades yet allow only minimal clearance

between the guard’s feet and the table surface. The gap between the hold-down feet and table surface

should never be above 3/16” of an inch. The gap between the hold-down and the table is controlled by

turning the nut on the hold-down studs (11). Clockwise rotation will increase clearance; counter clockwise

turns will decrease the gap.

The guard should be held snug against the milled pads on the cutter bar and not feel loose. You must be

careful, however, that the hold-down bolts (13) are not so tight as to bind the guard when the cutter bar is in

the down position. Properly aligned, the bolts will snug but still allow rotation of the hold-down screw

washers (14). At the rear of the cutter bar you will find two tapped holes wherein hold-down jam screws (45)

are located. Once you have applied proper tension to the hold-down screws, tighten the jam screws to lock

alignment in place. (Note: The milled pads on the front and rear of the hold-down should be greased

periodically to maintain proper action.

BACK GAUGE ADJUSTMENT

Slide back gauge rods (62) through the adjustment blocks (66) and brackets (71). Mount the rods in the

holes found at the rear of the cutter bar. Move the gauge angle (63) up the rods until it contacts with the

lower blade. Observe the pointers attached to the adjustment blocks and adjust the rods in or out until the

embossed scales read zero on the pointers. Tighten the set screws (44) to lock the rods in place.

To attain a particular setting, loosen the four lock screws (70) and slide the gauge to an approximate

position. Fine tune adjustments are accomplished by locking the screws of the two adjustment brackets

(71) while keeping those of the blocks (66) loose. The adjustment dial (68) can then be used to position the

gauge in or out.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

11

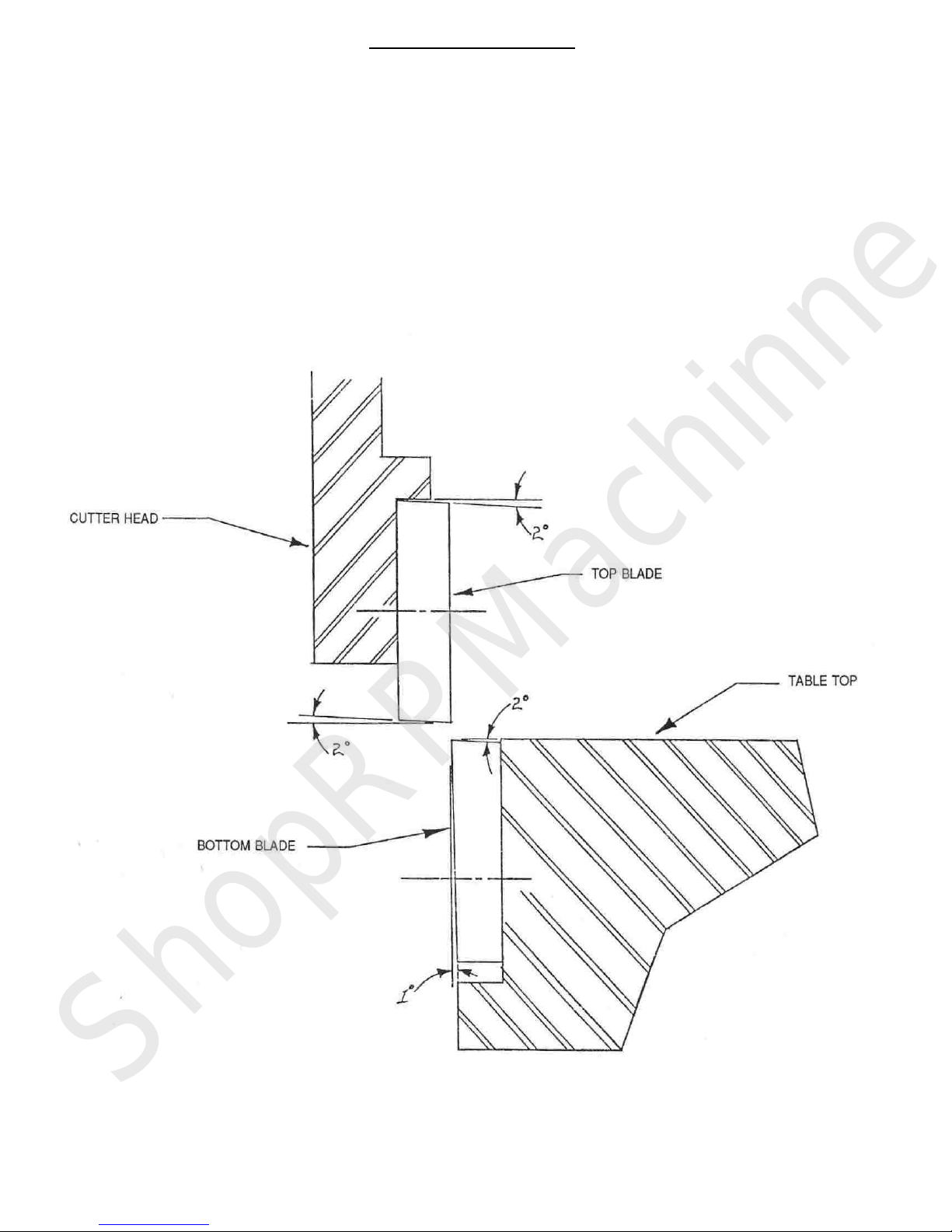

SHARPENING BLADES

Your TENNSMITH shear features “Tri-Action” ground blades. The upper blade has two cutting edges which

are ground with a 2 degree edge relief. The upper blade can be turned over to expose the new cutting

edge. It can be sharpened on a surface grinder by grinding both wide sides to the blade. The lower blade

has one cutting edge with a 2 degree cutting edge relief and a 1 degree face relief. It can be sharpened on

a surface grinder by grinding the wide side of the blade having the 1 degree relief. See Figure 2). Blade

sharpening service is available from the factory.

ShopRPMachinne

Tennsmith Inc. / 6926 Smithville Hwy. / McMinnville, TN 37110 / 931-934-2211 / Fax 931-934-2220

www.tennsmith.com

12

MACHINE SPECIFICATIONS

Model 36

Maximum shearing capacity, mild steel 16 gauge / 1,6mm

Maximum shearing capacity, stainless steel 20 gauge / 1,0mm

Maximum cutting length 52-1/4 in. / 1327mm

Back gauge range 30 in. / 762mm

Front gauge range 37 in. / 940 mm

Floor space, gauges in position 45 x 80 in. / 1143 x 2032 mm

Overall dimensions, less gauges, LxWxH 46-1/4 x 24 x 42 in. / 1181 x 686 x 1067 mm

Shipping weight 700 lbs. / 317.5 kg

Model 52

Maximum shearing capacity, mild steel 16 gauge / 1,6mm

Maximum shearing capacity, stainless steel 20 gauge / 1,0mm

Maximum cutting length 52-1/4 in. / 1327mm

Back gauge range 30 in. / 762mm

Front gauge range 37 in. / 940 mm

Floor space, gauges in position 60 x 80 in. / 1524 x 2032 mm

Overall dimensions, less gauges, LxWxH 61 x 25 x 42 in. / 1550 x 915 x 1067 mm

Shipping weight 950 lbs. / 431 kg

APPROXIMATE SHEARING, BENDING AND FORMING

CAPCITIES FOR VARIOUS MATERIALS COMPARED TO MILD STEEL

Mild Steel Capacity 20ga. 18ga. 16ga. Mild Steel Capacity 20ga. 18ga. 16ga.

NON-FERROUS METALS FERROUS METALS

Aluminum Iron-dead soft 20ga. 18ga. 16ga.

1100-0, 2024-0 .070 .090 .125 Steel low carbon

5052-0. 6061-T4 .070 .090 .125 1074, 1095 C.R. Spring Steel 24ga. 22ga. 20ga.

2024-T3, 5052-H34 .048 .063 .090 Hot Rolled 20ga. 18ga. 16ga.

5086-H36, 6061-T6 .048 .063 .090 Low carbon Cold Rolled 20ga. 18ga. 16ga.

Copper and Alloys Stainless Steel Annealed 24ga. 22ga. 20ga.

Electrolytic Copper 18ga. 16ga. 14ga. OTHER MATERIALS

Bronze Commercial 18ga. 16ga. 14ga. Plastics

Brass 70-30 18ga. 16ga. 14ga. ABS Compounds .120 .150 .200

Nickel Alloys Polycarbonate .075 .105 .125

Inconel 600 24ga. 22ga. 20ga. Printed Circuit Boards

Monel R405 24ga. 22ga. 20ga. Copper-Clad

Nickel 200A Annealed 24ga. 22ga. 20ga. Epoxy Laminate .086 .115 .150

Zinc as Rolled 20ga. 18ga. 16ga.

Approximate Gauge Equivalents

Gauge 28 26 24 22 20 18 16 14 12 11 10

Inches .015 .018 .024 .030 .036 .048 .060 .075 .105 .120 .135

Millimeters .38 .46 .61 .76 1.00 1.25 1.60 2.00 2.70 3.05 3.50

ShopRPMachinne

This manual suits for next models

2

Table of contents

Other Tennsmith Power Tools manuals

Popular Power Tools manuals by other brands

Bosch

Bosch GST professional Original instructions

Atlas Copco

Atlas Copco ETV ST61-100-13 Original product instructions

Matco Tools

Matco Tools MT2858 Operating instructions, warning information, parts breakdown

Power Craft

Power Craft 67000 instruction manual

Baileigh Industrial

Baileigh Industrial MSS-16 Operator's manual

Bullet tools

Bullet tools Magnum 909 user guide