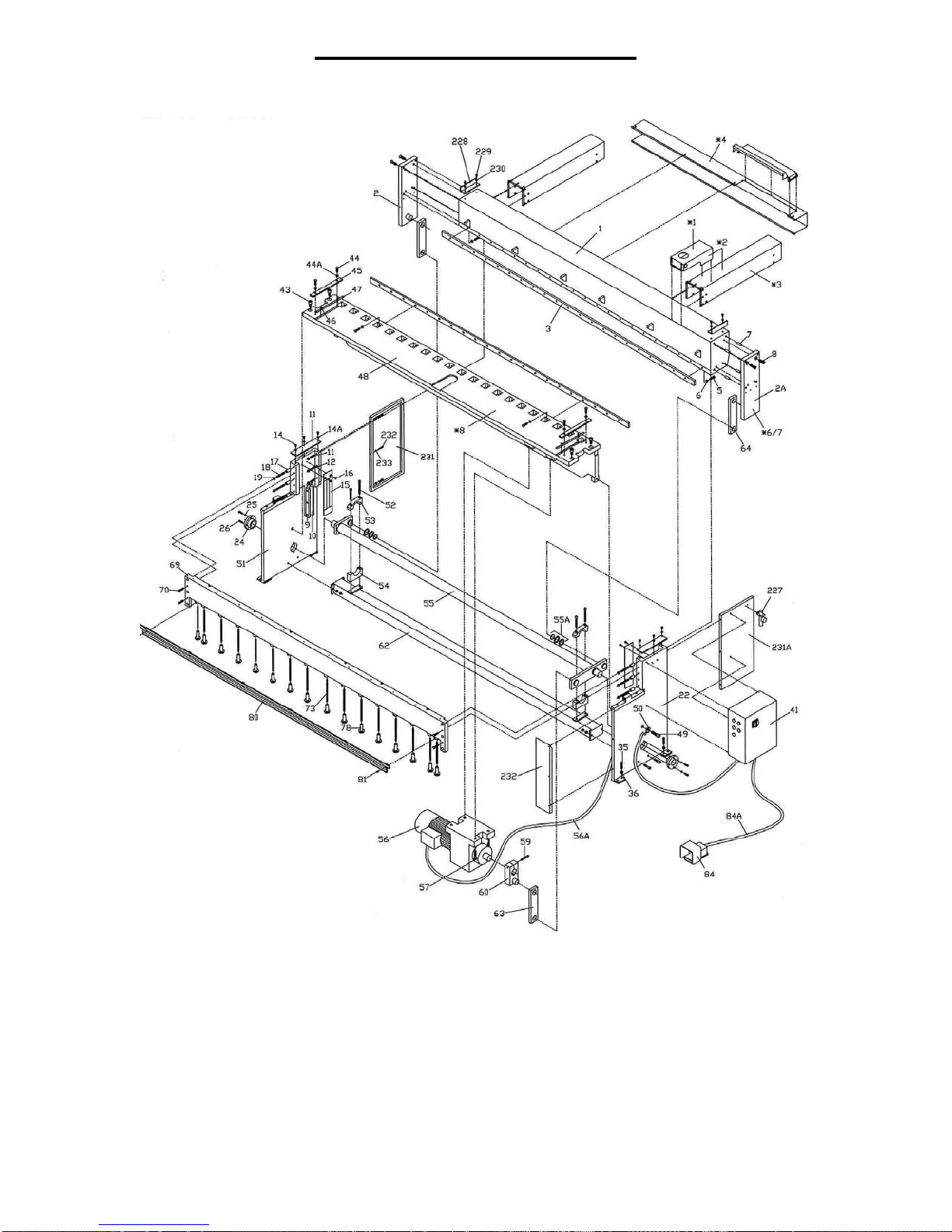

15

MODEL LM1010 PARTS LIST

ITEM# LM PART# DESCRIPTION QTY.

1 1010001 CUTTER HEAD 1

2L 101002L GIBB PLATE LEFT 1

2R 101002R GIBBPLATERIGHT 1

3 1010003 BLADE TOP & BOTTOM 2

4 1010004 SET SCREW, ROD MOUNTING 4

5 1010005 BOLT, BLADE MOUNTING 21

6 1010006 LOCK WASHER, BLADE 21

7 1010007 DOWEL PIN, GIBB PLATE 8

8 1010008 BOLT, GIBB PLATE 8

9 1010009 GIBB, CUTTER HEAD 2

10 1010010 BEARING MATERIAL, GIBB 4

11 1010011 TOP PLATE, SIDE PANEL 2

12 1010012 NUT, REAR GIBB ADJ. 6

13 1010013 SCREW, REAR GIBB ADJ. 6

14 1010014 BOLT, TOP PLATE SIDE PANEL 6

15 1010015 SPACER PLAET, SIDE PANEL 2

15A 101015A BEARING MATERIAL SPACER 4

16 1010016 BOLT, SPACER PLATE 4

17 1010017 SPACER SLEEVE, HOLD DOWN 6

18 1010018 SCREW, GIBB ADJ. FRONT 6

19 1010019 NUT, SCREW, GIBB ADJ. FRONT 6

20 1010020 BOLT, TABLE ADJ. 4

21 1010021 SCREW, CONTROL BOX MOUNT 4

22 1010022 SIDE PANEL, RIGHT 1

23 1010023 BUSHING, COLLAR 2

24 1010024 COLLAR, TREADEL MOUNT 2

25 1010025 LOCK WASHER, BOLT COLLAR 4

26 1010026 BOLT, COLLAR MOUNTING 4

27 1010027 ARM, SWITCH TRIP 1

28 1010028 BOLT, ARM MOUNTING SWITCH 1

29 1010029 PIN, ARM MOUNTING SWITCH 2

30 1010030 LOCK WASHER, BOLT, ARM MOUNTING 1

31 1010031 NUT, ADJUSTER, SWITCH TRIP 1

32 1010032 ADJUSTER, SWITCH TRIP 1

33 1010033 LIMIT SWITCH 1

34 1010034 SCREW, SWITCH MOUNTING 2

35 1010035 BOLT, LEVEL ADJUSTING 4

36 1010036 NUT, BOLT, LEVEL ADJUSTING 4

37 1010037 BOLT, SUPPORT BEAM MOUNTING 4

38 1010038 SCREW, COVER MOUNTING SWITCH 4

39 1010039 COVER, SWITCH 1

40 1010040 SCREW, SPACER PLATE MOUNTING, SIDE 4

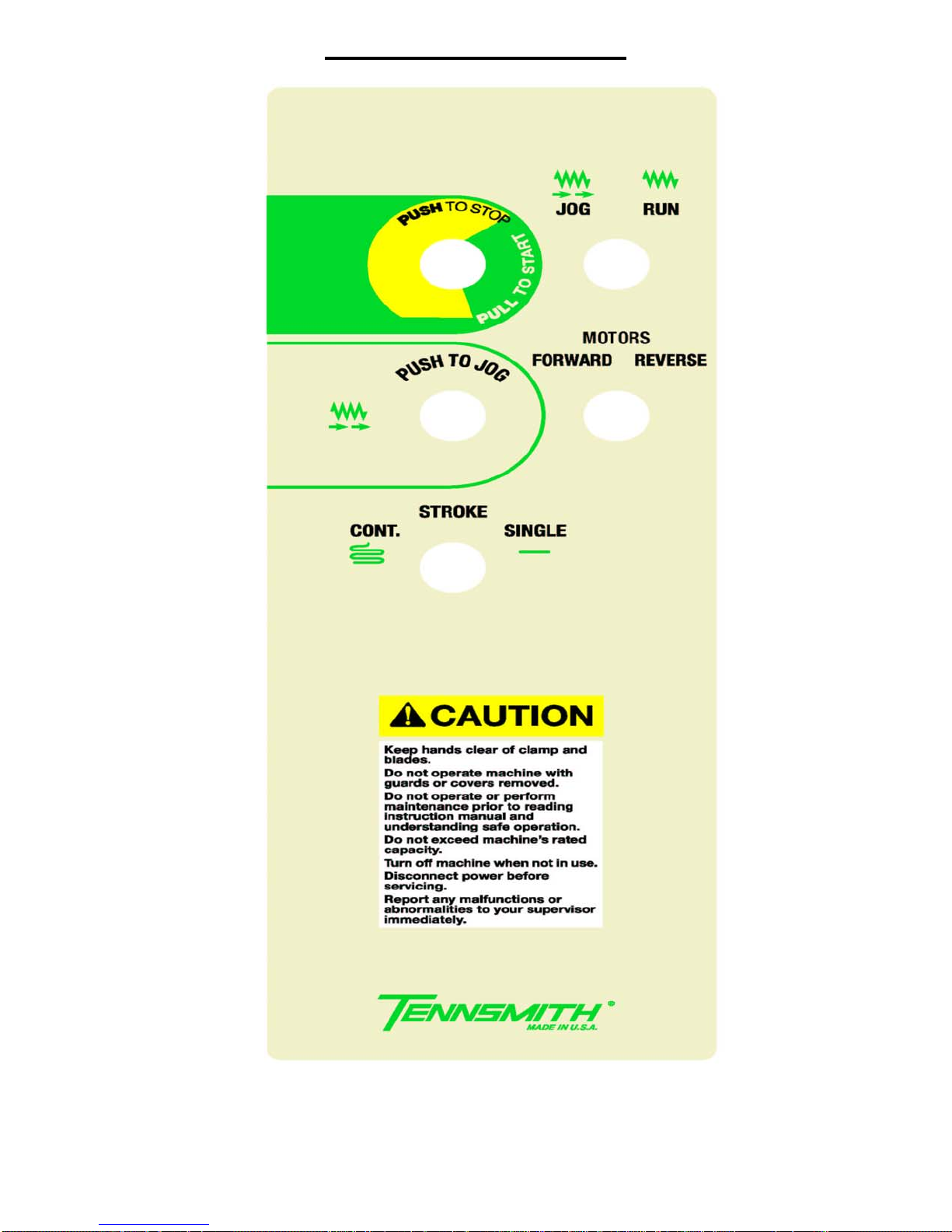

41 1010041 ELECTRIC CONTROL BOX 1

42 1010042 SWITCH, FORWARD REVERSE 1

43 1010043 BOLT, TABLE MUNTING, TOP 4

44 1010044 BOLT, MATERIAL GUIDE BAR MOUNTING 4

45 1010045 MATERIAL GUIDE BAR 2

46 1010046 SCREW, SCALE MOUNTING, TABLE 2

47 1010047 SCALE, TOP 2

48 1010048 TABLE 1

49 1010049 BOLT, TABLE MOUNTING, ENDS 2

50 1010050 FLAT WASHER, BOLT, TABLE MOUNTING 2

51 1010051 SIDE PANEL, LEFT 1

52 1010052 BOLT, BEARING BLOCK MOUNTING 2

52A 101052A BOLT, BEARING BLOCK MOUNTING 2

53 1010053 BEARING BLOCK, UPPER 2

54 1010054 BEARING BLOCK, LOWER 2

55 1010055 DRIVE SHAFT 1

55A 101055A SPACER, SNAP RING, DRIVE SHAFT LINK 6

56 1010056 ELECTRIC GEAR MOTOR 1

57 1010057 BOLT, MOTOR AND GEAR BOX MOUNTING 4

58 1010058 KEY, SHAFT, GEAR BOX 1

59 1010059 BOLT, ARM AND PIN ASSEMBLY, GEAR BOX SHAFT 1

60 1010060 ARM AND PIN ASSEMBLY, GEAR BOX FRONT LINK 1

61 1010061 BEARING MATERIAL, BEARING BLOCK 2

62 1010062 SUPPORT BEAM 1

63 1010063 LINK, FRONT 1

64 1010064 LINK, REAR 2

65 1010065 REAR CHUTE 1

66 1010066 SCREW, REAR CHUTE MOUNTING 5

67 1010067 RETAINER RING, LINK MOUNTING 6

68 1010068 SPACER, LINK 12

69 1010069 HOLD DOWN 1

70 1010070 BOLT, HOLD DOWN MOUNTING 4

71 1010071 JACK SCREW, HOLD DOWN 6

72 1010072 NUT, STUD, FOOT MOUNTING, HOLD DOWN 16

73 1010073 STUD, FOOT MOUNTING, HOLD DOWN 16

74 1010074 BUSHING, QUILL, HOLD DOWN 16

75 1010075 FOOT, HOLD DOWN 16

76 1010076 RUBBER PAD, FOOT, HOLD DOWN 16

77 1010077 FINGER GUARD, HOOLD DOWN 1

78 1010078 SCREW, FINGER GUARD MOUNTING 6

79 1010079 FOOT SWITCH 1

79A 101079A CABLE, FOOT SWITCH 1