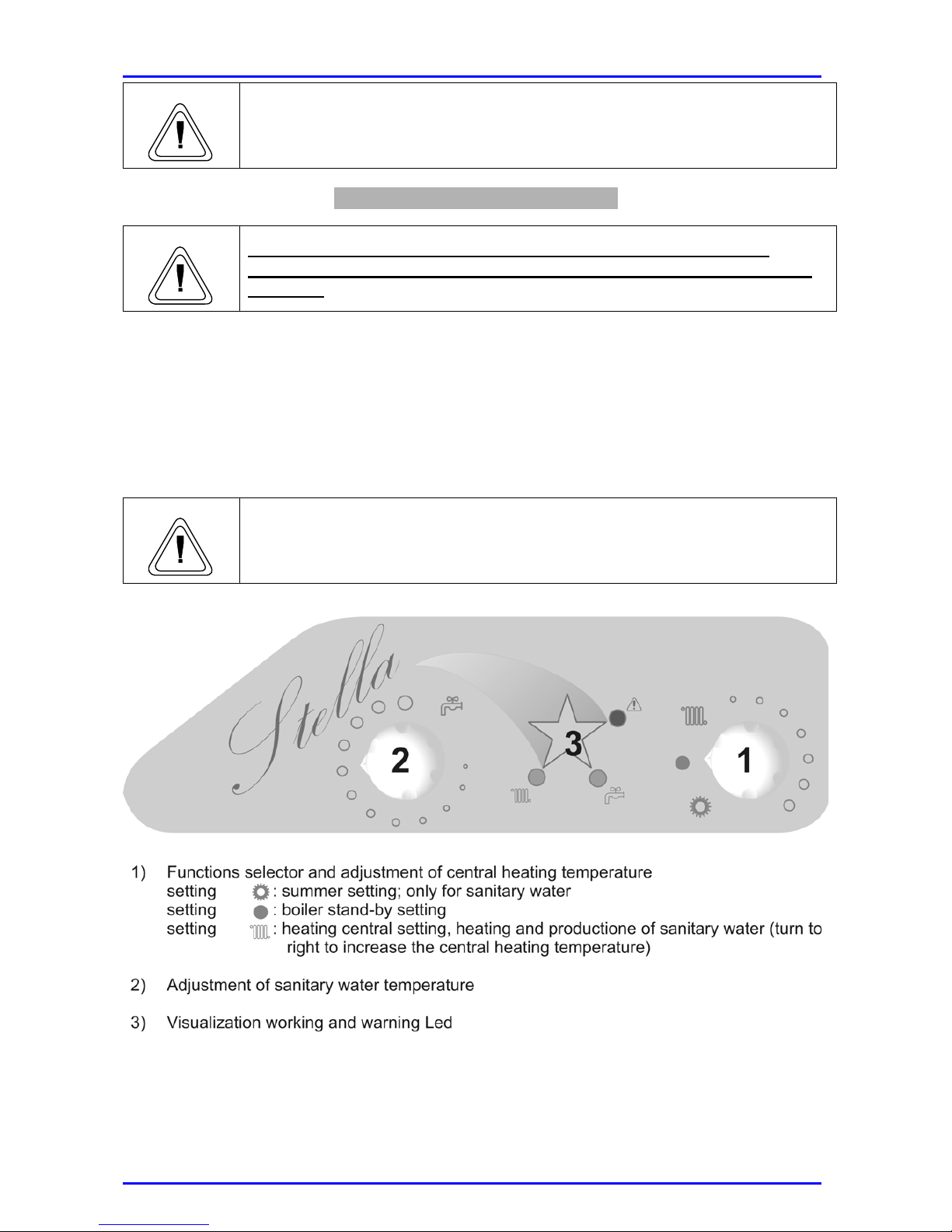

3

Safety Measures

STANDARD RISK

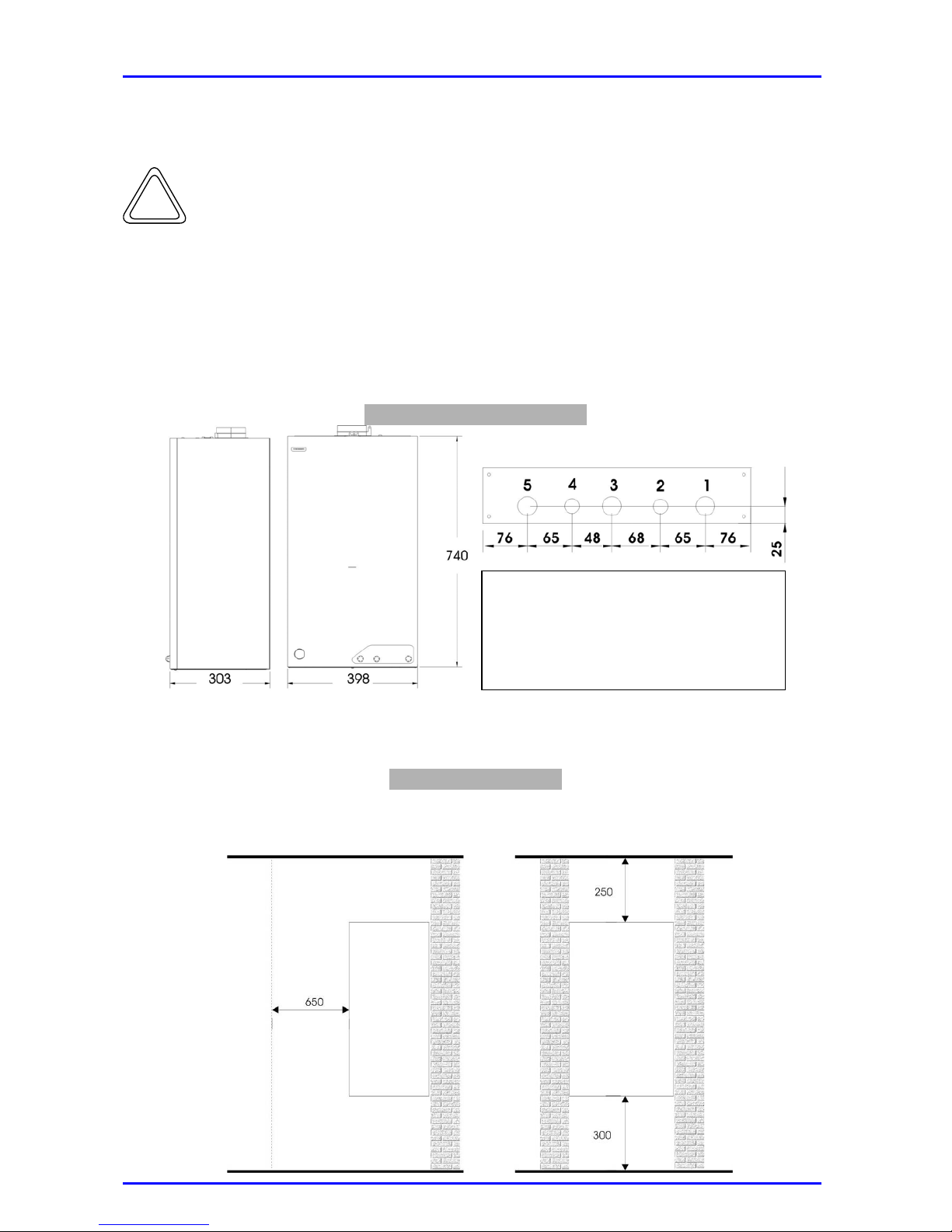

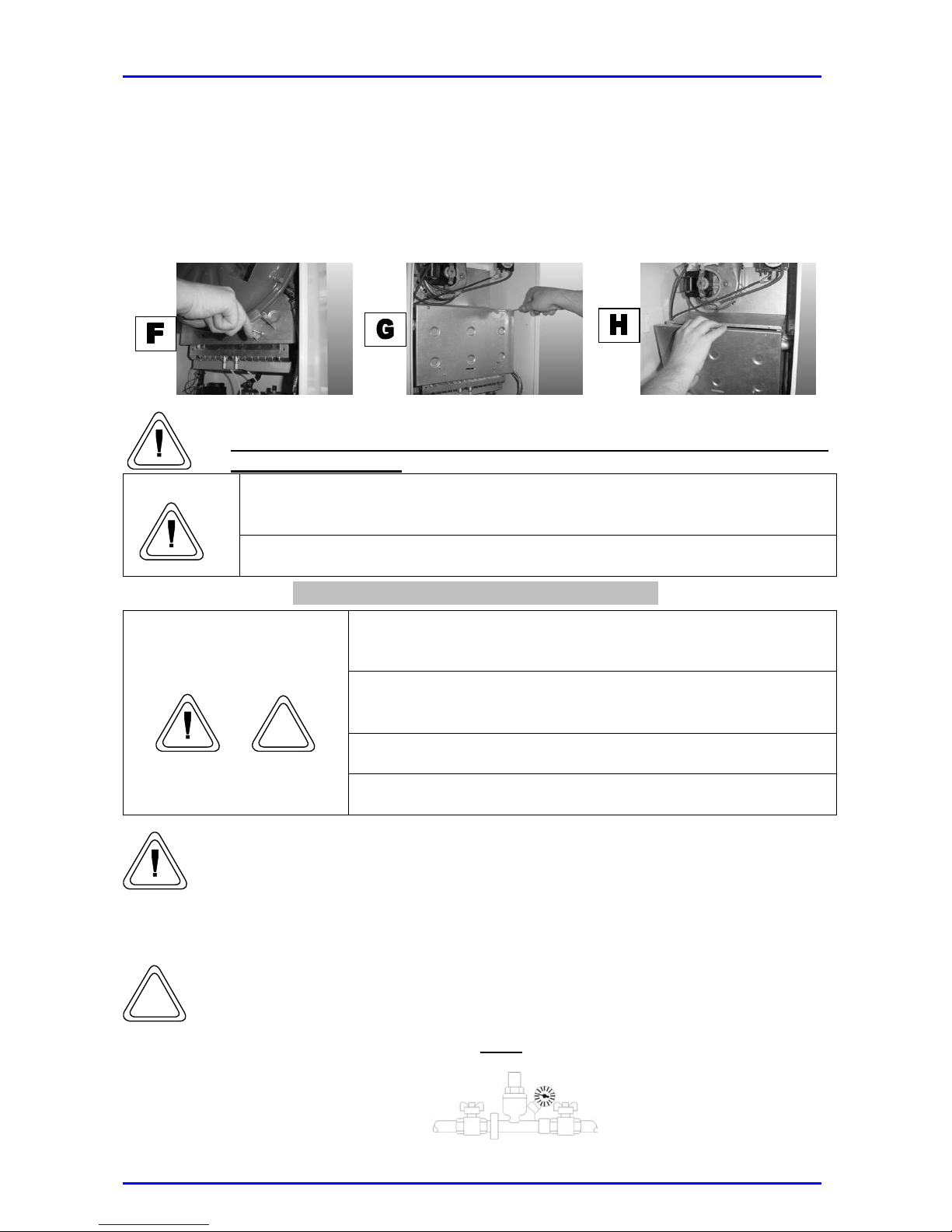

The appliance must be installed on a vibration-free

solid wall.Noise during operation.

Electric shock when coming into contact with live

wires.

Explosion, fire or intoxication due to gas leakage

from damaged tubes.

Be careful not to damage or perforate the wall or

the existing electrical cables and pipes.

Damage to existing systems

Flooding due to leakage of liquid from damaged

tubes.

Use appropriate cable section to carry out the

electrical connections.Fire risk due to overheating caused by electrical

current flowing through undersized cables.

Electric shock when coming into contact with live

wires.

Explosion, fire or intoxication due to gas leakage

from damaged tubes.

Protect pipes and connection cables so that they

cannot be damaged

Flooding due to leakage of liquid from damaged

tubes.

Electric shock when coming into contact with live

wires that are not properly installed.

Explosion, fire or intoxication due to incorrect

ventilation of discharge fume pipes.

Make sure that the area where the appliance is

installed and the systems to which it is connected

comply with the regulations in force

Damage to the appliance due to malfunction.

Risk of personal injury from ejected splinters or

fragments, dust inhalation, impacts, cuts,

punctures and scratches.

Use adequate tools correctly (make sure that the

tools are not damaged and that the handles are

complete and correctly fixed). Secure them.

Replace them after use.

Damage to the appliance or adjacent objects due

to ejected splinters, knocks and cuts.

Risk of personal injury from ejected splinters or

fragments, dust inhalation, impacts, cuts,

punctures, scratches, noise or vibration.

Use adequate electrical equipment correctly (make

sure that the feed cable and the plug are not

damaged and that the parts with rotary and

reciprocating motions are adequately fixed). Make

sure that the feed cables do not cause an

obstruction and are correctly secured. Disconnect

and replace them after use.

Damage to the appliance or adjacent objects due

to ejected splinters, knocks and cuts.

Make sure that the rolling ladder is sturdy and

firmly set against the wall, that the steps are not

damaged or slippery, and that the ladder is fitted

with a handrail up to the top and with a protected

platform.

Risk of personal injury due to accidental falls from

a height or from the severing of limbs (double-

sided ladder).

Make sure that the fall-safe ladder is sturdy and

firmly set against the wall, that the steps are not

damaged or slippery. Make sure that ladder does

not move when in use. Any operation requires the

assistance of a second person.

Risk of personal injury due to accidental falls from

a height.

Make sure that, when carrying out interventions at

a height (of at least two-metres) all safety

measures for preventing accidental falls-protection

guards surrounding the working area or personal

harnesses-have been taken. Make sure that there

are no dangerous objects in the path of a possible

fall and that the fall would be cushioned by a semi-

rigid or soft surface.

Risk of personal injury due to accidental falls from

a height.