TerraKing TKV 20 User manual

OPERATOR’S MANUAL

TKV 20 Material Collection System

TK95044

8/8/2018

For your safety, please read and save all

safety and operating instructions prior to

using equipment.

GREY

PMS 427

CMYK C19 M15 Y16 K0

RGB R204 G204 B204

Hex #CCCCCC

Threa Light Ash

BLUE

PMS 647

CMYK C91 M60 Y4 K0

RGB R20 G103 B172

Hex #1268AC

Thread Farm Blue

ORANGE

PMS 715

CMYK C0 M69 Y98 K0

RGB R243 G113 B33

Hex #F37121

Thread Tennessee Orange

BLACK

PMS TBD

CMYK C0 M0 Y0 K100

RGB R0 G0 B0

Hex #000000

Thread Black

GREY

PMS 428

CMYK C27 M17 Y17 K0

RGB R195 G197 B200

Hex #c3c5c8

Thread Light Gray

BLUE

PMS 287

CMYK C100 M87 Y20 K10

RGB R32 G61 B124

Hex #203d7c

Thread Dark Royal

GOLD

PMS 3965

CMYK C1 M14 Y99 K0

RGB R254 G212 B2

Hex #231f20

Thread NFL Yellow

2

Introduction

Table of Contents

Introduction .................................................................... 2

Product Compatibility .................................................... 2

Safety Labels ..............................................................3-5

Safety ............................................................................. 6

Parts in Kit ..................................................................... 7

Tractor and Other Requirements ................................... 7

Assembly .................................................................. 8 -11

Operation ..................................................................... 12

Troubleshooting ...................................................... 13-14

Maintenance ........................................................... 15 -17

Specifications............................................................... 18

Warranty....................................................................... 20

Using Your Operator’s Manual

Read this entire manual in its entirety, especially the safety

information, before operating.

This manual is an important part of your TKV 20 Material

Collection System (MCS). Keep this manual in a

convenient location so that it can be accessed easily.

Use the safety and operating information in this manual

in order to operate and service the attachment safely and

correctly.

If you have any questions or concerns with the assembly,

installation, or operation of the TKV 20, contact TerraKing

Warranty information regarding the TKV 20 can be found in

the Warranty section of this manual.

Product Compatibility

The TKV 20 is designed for use on sub-compact and

compact tractors with mid-mount side discharge mower

decks. Refer to the Tractor Requirements section

on page 7 and to your tractor’s operators manual to

determine compatibility.

3

Safety Labels

Understanding the Machine Safety Labels

Safety labels shown in this section are placed in

important areas on your machine to draw attention to

potential safety hazards.

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safety-alert

symbol. DANGER identies the most serious hazards.

This manual explains potential safety hazards whenever

necessary in special messages that are identied with the

word, CAUTION, and the safety-alert symbol.

Be sure to replace missing or damaged safety labels.

Use this manual for correct safety label placement.

Additional safety information on parts and components

sourced from suppliers might not be represented in this

section.

ST48295

AVOID INJURY FROM

MOVING PARTS

• Keep hands, fingers

and feet away

• Disconnect power

before servicing

ST48453

AVOID INJURY FROM

MOVING PARTS

• Do not operate without

shields in place

• Disconnect PTO

before servicing

ST48454

AVOID INJURY FROM

MOVING PARTS

• Do not operate without

hose connected

• Disconnect PTO

before servicing

DANGER

ROTATING DRIVELINE:

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT:

• All driveline gua rds, tractor and equipment

shields in place

• Dr ivelines securely attached at both ends

• Dr iveline guards that turn fre ely on driveli ne

4

Safety Labels

ST48454

AVOID INJURY FROM

MOVING PARTS

• Do not operate without

hose connected

• Disconnect PTO

before servicing

WARNING

To Avoid Injury From Thrown Objects

• Keep bystanders away

• Shut off engine before opening hopper top

• Keep chutes in place

• Never allow riders on hopper top or on frame

• Disconnect power before servicing

DANGER

Bagger May Impair Rear Vision

• Look down and behind before and while backing

WARNING

To Avoid Injury From Moving Parts

• Do not operate without hose connected

• Disconnect PTO shaft before servicing

CAUTION

To Avoid Injury

• Install front ballast per tractor’s operator’s manual

ST48295

AVOID INJURY FROM

MOVING PARTS

• Keep hands, fingers

and feet away

• Disconnect power

before servicing

WARNING

Avoid Injury From Moving Parts

• Keep hands, feet and clothing away

• Disconnect mechanical and electrical power

before servicing

5

CAUTION

No Step

• Do not step, stand or sit on this surface

• Improper use may cause injury and/or equipment damage

Safety Labels

DANGER

ROTATING DRIVELINE:

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT:

• All driveline guards, tractor and equipment

shields in place

• Drivelines securely attached at both ends

• Driveline guards that turn freely on driveline

DANGER

Rotating Driveline: Contact Can Cause Death

Keep Away!

Do Not Operate Without:

• All driveline guards, tractor and equipment

shields in place

• Drivelines securely attached at both ends

• Driveline guards that turn freely on driveline

ST48453

AVOID INJURY FROM

MOVING PARTS

• Do not operate without

shields in place

• Disconnect PTO

before servicing

WARNING

To Avoid Injury From Moving Parts

• Do not operate without shields in place

• Disconnect PTO shaft before servicing

6

Safety

General Safety

• The TKV 20 is limited to collecting only grass or leaves.

• Be aware when maneuvering your machine because

the TKV 20 increases vehicle length and also alters its

center of gravity.

• Be aware of the potential pinch point when closing

the tailgate and lid.

• DO NOT allow anyone to ride in or on the TKV 20.

Operating Safely

• Read the tractor and this operator’s manual carefully.

Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

tractor and disengage the controls quickly.

• The TKV 20 is only intended for use in lawn and property

maintenance applications. TerraKing does not advise

or recommend this product for any other uses.

• Do not modify the TKV 20’s safety devices. Unauthorized

modifications may impair its function, safety, and

void the warranty.

• Do not let children or an untrained person

operate machine.

• Make any necessary adjustments before you

operate. Never attempt to make any adjustments

while the engine is running, unless if recommended

in adjustment procedure.

• Look behind machine before and while you back up.

Back up carefully.

• Do not let anyone, especially children, ride on

machine or attachment. Riders are subject to injury

such as being struck by foreign objects and being

thrown off. Riders may also obstruct the operator’s

view and alter weight distribution, resulting in the

machine being operated in an unsafe manner.

• Disengage any power to the attachment when the

machine is transported or not in use.

Parking Safety

1. Stop machine on a level surface

2. Lock the park brake

3. Stop the engine

4. Remove the key

5. Wait for engine and all moving parts to stop before

leaving the operator’s seat

Practice Safe Maintenance

• Only qualified, trained adults should service this machine.

• Understand service procedure before doing work.

Keep area clean and dry.

• Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

• Never lubricate, service or adjust the machine or

attachment while it is moving. Keep safety devices in

place and in working condition. Keep hardware tight

and check regularly.

• Keep hands, feet, clothing, jewelry, and long hair away from

any moving parts, to prevent them from getting caught.

• Lower the TKV 20 completely to the ground or to an

existing attachment mechanical stop before servicing.

Disengage all power and stop the engine. Lock park

brake and remove the key. Let machine cool.

• Before servicing machine or attachment, carefully

release pressure from any components with stored

energy, such as hydraulic components and springs.

• Release hydraulic pressure by lowering attachment

or cutting units to the ground or to a mechanical stop

and move hydraulic control levers.

• Securely support any machine or attachment elements that

must be raised for service work. Use jack stands or lock

service latches to support components when needed.

• Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Replace all worn or damaged safety and instruction decals.

• Check all hardware at frequent intervals to be sure the

equipment is in safe working condition.

Wear Appropriate Safety Equipment

• Always wear eye protection when operating the machine.

• Wear close fitting clothing and safety equipment

appropriate for the job.

• While operating this machine, always wear substantial

footwear and long trousers. Do not operate the

equipment when barefoot or wearing open sandals.

• Wear a protective hearing device such as earplugs.

Loud noise can cause impairment or loss of hearing.

PLEASE READ: CRITICAL SAFETY WARNINGS

• DO NOT operate with the Steel Coil Hose off or

with the Cleanout Door open.

• DO NOT remove the Steel Coil Hose or open the

Cleanout Door while the tractor is running.

• DO NOT get near the rear of the tractor when the

PTO is engaged.

• DO NOT operate without front ballast.

7

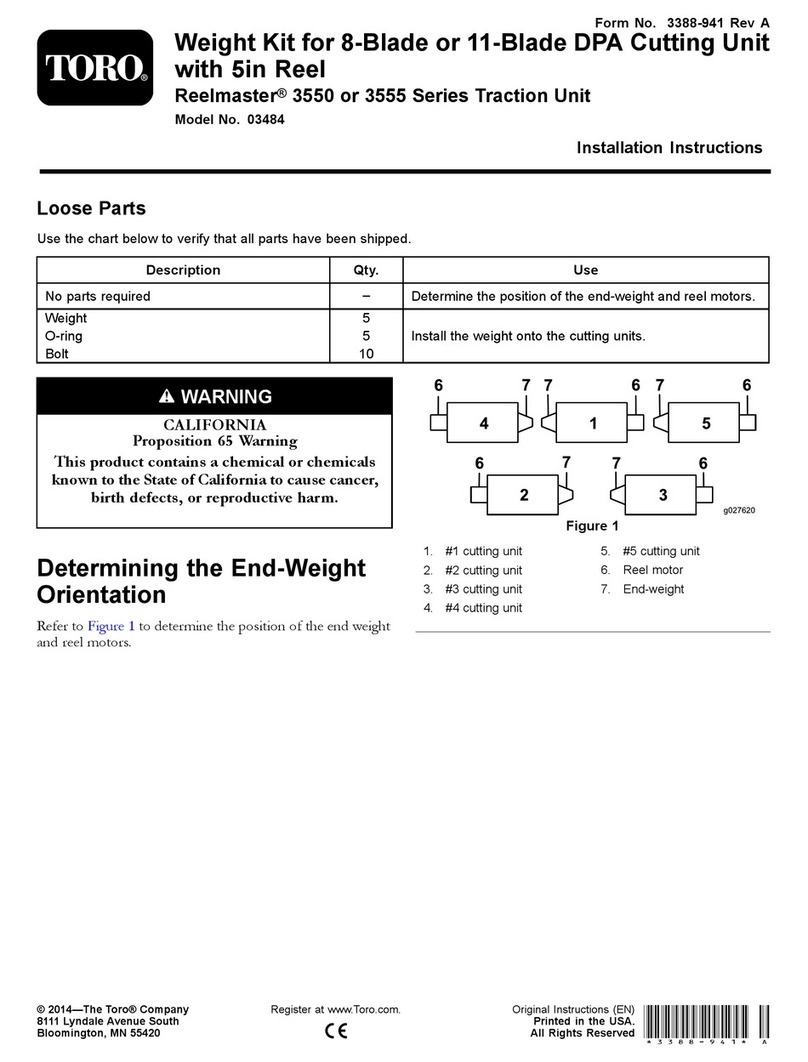

Parts in Kit

A B

C D

Main Components

Description Qty.

ATKV 20 Main Assembly 1

B5' of 8"dia. Steel Coil Hose 1

CHose Clamps 2

DPTO Shaft 1

ESMV Sign 1

FPlastic End Cap 4

Other Requirements

Front Ballast

A full TKV 20 can weigh upwards of 600 pounds. Refer

to the manufacturer or dealership for proper ballasting

requirements.

Boot Kit (See Dealer)

A boot for your mower deck is required to attach the

TKV 20’s 8" dia. hose. Please consult your dealer to

acquire this part for your tractor.

Front Weight Bracket Kit

Part # TK95054 - Fits Kubota BX2360, BX2660, BX2370,

BX2670, BX2380, BX2680

Properly ballasting your tractor is important to ensure safe

operation with the TKV 20, especially when full.

A minimum of 200 lbs. (91 kg) is required.

Stay Chain Kit

Part # TK95052 - Fits Kubota BX2380, BX2680

Part # TK95053 - Fits Kubota BX2350, BX2360, BX2660,

BX2370, BX2670

This kit stabilizes a TKV 20 when in operation on inclines

and keeps the PTO shaft aligned when the tractor’s mower

deck is lowered

Wiring Harness Kit

Part # TK95051 - Fits Kubota BX2360, BX2660, BX2370,

BX2670, BX2380, BX2680

A dedicated wiring harness connects the TKV 20 to your

tractor. Included is a rocker switch with a ROPS-mounted

bracket to operate the electric actuator.

Tractor Requirements

Tractor horsepower should be within the range noted below.

Tractors outside the horsepower range must not be used.

Horsepower Rating............................................20-60 HP

Rear PTO Shaft......................................... 1-3/8" 6-Spline

Rear PTO Speed.................................................540 RPM

Hitch Type ...............Category 1 3-Point, Quick-Hitch Ready

3-Point Lift Capacity (24 in. behind link arms)....... 650 lb.

EF

8

Assembly

Initial Set Up

Attach TKV 20 to the tractor’s 3-point arms or Category 1

quick hitch.

Sizing the PTO Shaft

1. Slide PTO Shaft apart and connect the half with the

round hole to the TKV 20 and the spline half to the

tractor’s PTO shaft.

2. Lift and lower the 3-point arms to nd the position

where the two ends are closest together. Lay the two

sides of the shaft side by side and mark the amount

to be cut. Measurer this distance and cut the same

amount off both ends of the shields and both ends of

the shaft. Ensure that when the shaft is in the position

where the two shafts are farthest apart, there will still

be 1/2 of the shaft overlapping.

3. Cut the distance measured off each half of the shaft.

The guard should be cut back an additional 1.5-1.6

inches on each half to leave the end of the driveline

tube exposed.

4. Round off sharp edges and remove any burrs on

the driveline tubes. Apply good quality lithium

soap compatible E.P. grease (meeting the N.L.G.I.

#2 specication and containing no more than 1%

molybdenum disulde) to the outside of the smaller

diameter driveline tube.

5. Reassemble driveline halves together making sure they

slide (telescope) easily and ensure guards rotate freely.

WARNING: If the PTO shaft is cut too short, it can

disengage during operation and cause injury.

If you are unsure how to properly cut the PTO

shaft, please see your dealership.

9

Assembly

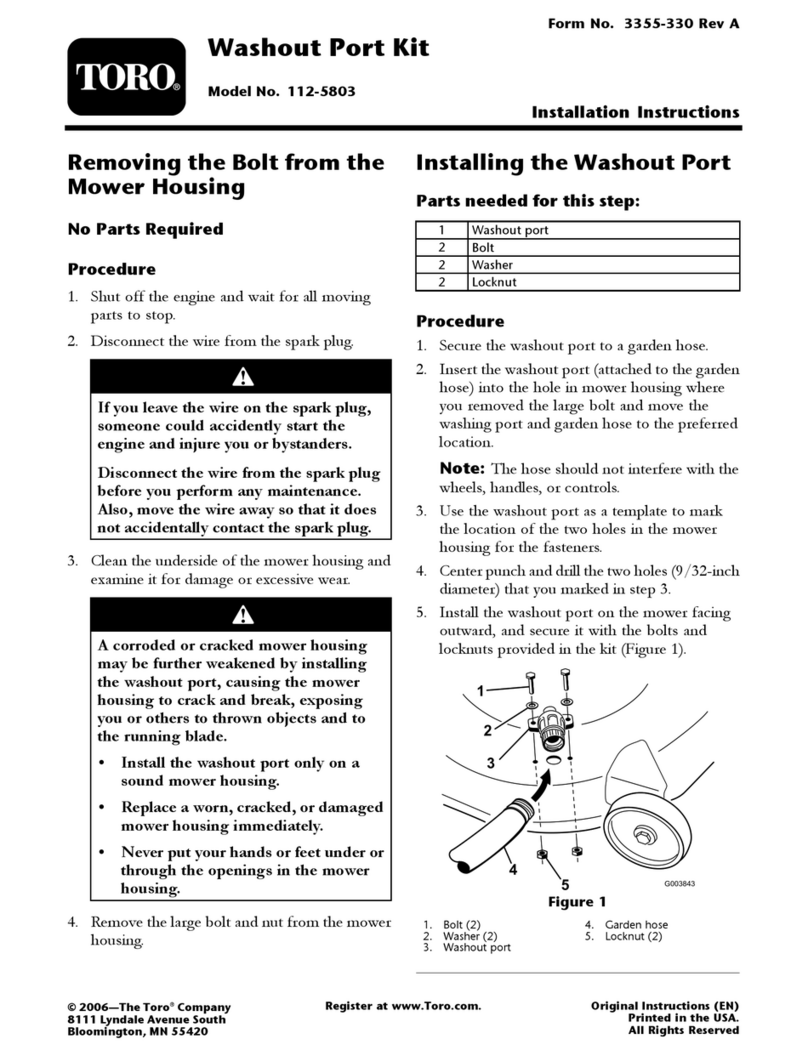

Connecting the PTO Shaft

1. Flip up the shield (A). With square key (B) in keyway

of the shaft, slide the PTO shaft onto the TKV 20 and

tighten the setscrew (C) to 28 +/-2 ft. lbs.

2. Connect the PTO shaft to the tractor’s PTO and

ensure lock pin (D) is engaged.

3. Lift the tractor’s 3-point arms up and down to ensure

that the PTO telescopes freely. Ensure that the PTO

shaft does not come apart when the 3-point arms are

at their highest point.

Blower Inlet Hose

1. Position mower deck in lowest mowing position.

2. Slide hose on front of blower as far as possible. Lay

other end beside the boot. Lift and lower the 3-point

arms to observe the distance between the boot and

the blower inlet. Cut the hose long enough to t in all

positions. The plastic can be cut with a utility knife,

but the wire requires wire cutters or a saw.

3. Slide clamp over hose and hose onto blower inlet.

Close the latch (A) to clamp. If clamp is too loose,

tighten the screw (B). To prevent stripping the screw,

unlatch before tightening.

4. Repeat step #3 on boot end.

5. Lift the tractor's 3-point arms up and down to ensure

that the blower hose moves freely.

6. Ensure that the blower hose does not contact

the ground during operation as this could cause

excessive wear or damage.

B

A

D

C B A

10

1. Install the two plastic end caps onto each foot of the

storage legs.

2. Lift TKV 20 with 3-point, remove the wire lock pin (A)

and the storage stand will drop off. With the shorter end

of the leg down slide the stand into the storage channel

(B), and fasten with the wire lock pin (C). Repeat this

step for the storage stand on the other side.

3. Set the stop down on the 3-point lever where the

PTO shaft sits horizontally. Adjust sway chains

and adjustable lift link on 3-point arms to level

attachment.

4. For hydraulic systems without position control, it is

recommended that the 3-point arms are chained to

ensure that the TKV 20’s PTO shaft remains horizontal.

Machine Set Up

Assembly

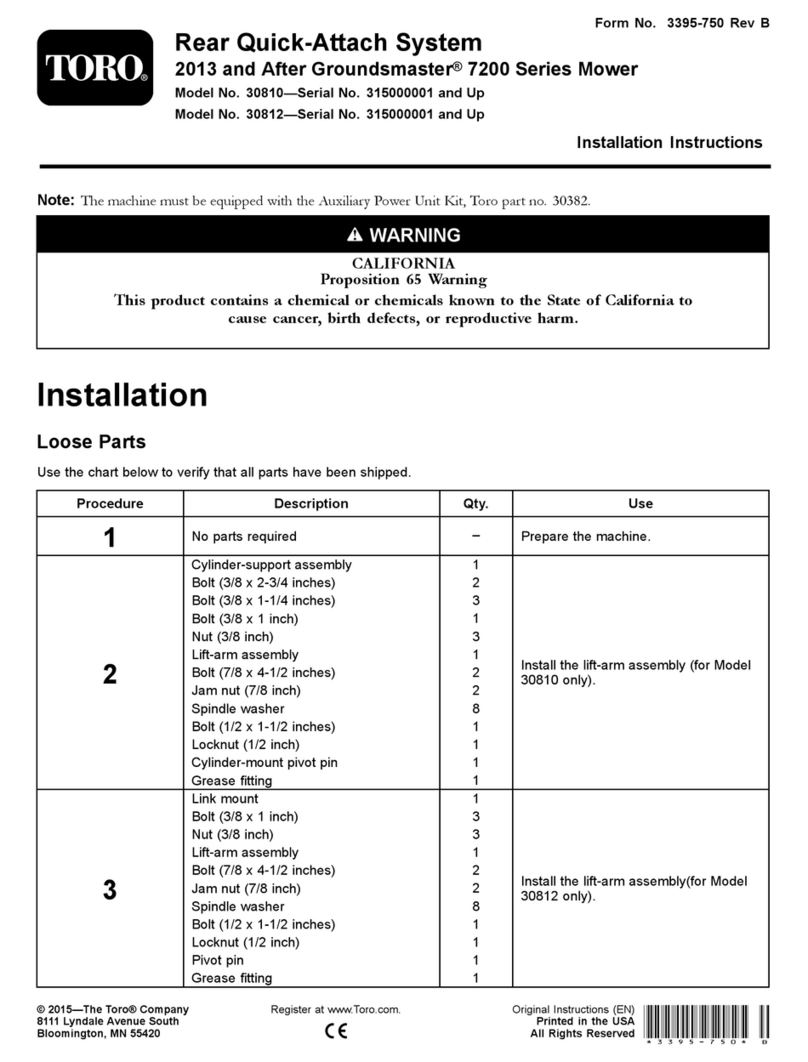

Repositioning the TKV 20’s 3-Point Hitch Pins

For wider tractors, the hose from the boot to the blower

may get close or touch the rear tire of the tractor. The

positioning of the TKV 20’s 3-point hitch pins can be

shifted to the right by 2-1/2" by following the steps below.

1. Remove the three shields (A).

2. Remove the side pin brackets (B and C), ip them

over and reinstall them in the opposite positions. B

is now reinstalled where C was, and vice versa. (This

allows the side pin to stay on the bracket). Reinstall

hardware and torque to 30 +/-1 ft. lbs.

WARNING: Place storage stands in storage

channel before mowing to prevent damage.

CAUTION: Operating PTO on an angle will cause

excessive wear or damage.

B C

A

C B

A

11

3. Remove the four bolts on the top pin brackets (D) and

support bracket (E) and slide them over to the next set

of holes on the frame. Reinstall hardware and torque to

30 +/-1 ft. lbs.

4. Reinstall the shields.

Assembly

D E

12

Operation

Before Operation

1. Make sure the lid is latched, the access door is

closed tightly and the hose is rmly connected and lid

extension is free to rotate outward.

2. Ensure that the tractor’s PTO Selection Lever on the

side console is in the position to allow the mid PTO

(mower deck) and the rear PTO (TKV 20) to operate.

3. Slowly lower the 3-point arms to a position where the

PTO shaft is horizontal for mowing.

4. For longer belt life on the mower deck and the TKV 20,

engage the PTO with the tractor at idle and throttle up

to full PTO RPMs. Lower the RPMs back to idle before

disengaging the PTO.

How to Determine If the Hopper is Full

NOTE: The rate at which the hopper lls is dependent upon

many factors including the type of material being collected

as well as its depth, moisture content and the tractor's speed.

NOTE: It is normal to have ne, dry grass escape from the

side panels during operation.

1. The lid fabric cover will begin to deate.

2. There will be a slight change upward in the pitch of

the blower.

Emptying the Hopper

1. To empty, disengage the PTO, lift the 3-point arms

all the way up and hold the rocker switch in the open

position until the tailgate is fully opened. Drive forward

away from the pile before closing. To close, hold the

rocker switch in the close position until fully closed.

NOTE: It is normal to hear the electric actuator make a

ratcheting sound when the PTO shaft is fully extended or

retracted while operating the rocker switch.

2. To prevent damage to the TKV 20, do not back up the

tractor while emptying material. Do not use the TKV

20’s tailgate to push material as damage may occur.

3. Lower the 3-point arms to position the PTO shaft

horizontally, engage PTO, and resume mowing.

WARNING: The TKV 20 will become unbalanced

when material is inside the hopper. Do not

disconnect the TKV 20 from the 3-point arms

or rest it on the storage stands while there is

material in the hopper.

Removal and Storage

1. Empty the hopper.

2. Lift the 3-point arms to their highest position.

3. Ensure that the storage stands are

installed at the lowest position and

that the tractor position labels (shown

at right) on both storage stands are

pointing towards the tractor.

4. If chains or a Stay Chain Kit were used

to prevent the TKV 20 from lowering

below the PTO horizontal position,

unhook the chains from

the tractor.

5. Disconnect and remove the wire to

the actuator switch.

6. Unlatch the hose clamps and remove the hose.

7. Lower the TKV 20 onto the storage stands.

8. Disconnect the tractor’s 3-point arms or quick hitch

from the TKV 20. This may require loosening the

tractor’s sway chains/links on the 3-point arms.

9. Disconnect the PTO shaft from the tractor.

Transportation

1. Ensure that the SMV sign on the back of the TKV 20

is in front of the hopper lid extension and visible from

the rear.

2. Transport the TKV20 as low as possible.

3. Ensure that the hopper lid extension is secured in

its lowered position if transporting on a trailer at

highway speeds.

T

R

A

C

T

O

R

IMPORTANT: Do not leave material inside the

hopper between uses and during storage.

Moisture can damage the hopper and damp

material is a re hazard.

13

WARNING: Rotating blades are dangerous.

Troubleshooting

Below are common symptoms that may be experienced

when the TKV 20 is in operation. Suggested solutions

are listed to help remedy the situation.

Blower Inlet Hose or Boot is Clogging Frequently

• Ensure the rear PTO is engaged and set at 540 RPM.

• Verify that the inlet hose and boot are not clogged.

If they are, consult the Unclogging Fan and Chute

section on page 14.

• Check the belt’s tension and inspect the belt for

wear. If the belt is loose, apply tension according

to Belt Tension section on page 15. If the belt

needs to be replaced, please see Belt Replacement

Instructions on page 15.

• If problem persists, operate the tractor at a slower

speed. If the grass you are collecting is too tall,

consider raising the deck height. If the material you

are collecting is too damp or wet, consider waiting

until it dries further.

Material is Blowing Out of the Vent on the Back

of the Chute or Side of the Hopper Lid

• Ensure that the hopper is not being overlled. If full,

empty the hopper.

• Verify that the holes in the screen of the hopper lid

are not lled with material. If plugged, clean screen

by wiping material from screen.

• Verify that hopper tailgate and its side panels do not

have lodged grass which can prevent the tailgate

from closing tightly.

• Verify the lid extension is free to rotate.

Belt are Slipping/Smoking During Startup

• Check to see if the fan is jammed. If so, consult

Unclogging Fan and Chute section on page 14.

• Check the belt tension and inspect for belt wear.

If the belt is loose, apply tension according to Belt

Tension section on page 15. If the belt needs to be

replaced, please see Belt Replacement Instructions

on page 15.

Fan or Drive System is Vibrating Excessively

• Check for loose hardware.

• Inspect fan blade for material buildup. If debris is

present, clean off the fan blades, supports, and plate.

• Check the tightness of the bolt on the center of the

fan shaft. If loose, apply red thread lock and re-tighten

to 18 +/- ft. lbs.

• Check the belt tension and inspect for belt wear.

If the belt is loose, apply tension according to Belt

Tension section on page 15. If the belt needs to be

replaced, please see Belt Replacement Instructions

on page 15.

• If vibration continues, contact TerraKing for support.

Bin Not Opening to Dump Collected Material

• Check the inline fuse located on the positive wire

near the battery. If the fuse is blown, replace it with a

30 amp slow-blow fuse.

• Make sure all wire connections are tight and clean.

• Make sure the wiring harness is not damaged and is

free of nicks.

• Using a voltmeter, verify that 12 volts DC is present

at the actuator connector when the rocker switch is

pressed in either direction. The voltage will be either

positive or negative depending on the switch position.

• If bin still does not open, contact TerraKing for support.

14

Unclogging Fan and Chute

The common symptoms of a clog include:

• Loss of tractor power

• Slipping belts

• Throwing material out from under deck

• Heavy and/or wet material

1. Ensure that the PTO and the mower deck have

stopped moving and turn off the tractor. Remove the

tractor’s key, set the parking brake and disconnect

the PTO shaft.

2. Loosen the lock knob (A).

3. Rotate the door (B) counterclockwise.

4. Reach into the chute and remove any clogged material.

The top of the chute may be reached from inside the

hopper.

5. Unlatch the hose clamp (C) and remove the hose.

6. Remove the clogged material from inside of the blower

housing.

7. Rotate the fan to ensure it is not stuck. Fan should

rotate with minimal resistance clockwise or counter-

clockwise. If fan is stuck, contact TerraKing for support.

CAUTION: Do not overfill hopper. Overfilling can

result in grass clogging chute. Material stuck in

chute may also fall into blower causing fan to

jam or vibrate on restart.

Troubleshooting

B

C

A

DANGER: Contact with rotating driveline (PTO)

can cause death or serious injury. Do not

attempt to service while tractor is running.

DANGER

ROTATING DRIVELINE:

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUT:

• All driveline guards, tractor and equipment

shields in place

• Drivelines securely attached at both ends

• Driveline guards that turn freely on driveline

15

Belt Tension

1. Remove the front shields. Tension the belts (A)

by tightening the nuts (B) until the springs (C) are

stretched to 4.6" (inside hooks). Belt tension can be

veried using a spring gauge. Deection at center of

belt should be 4 lbs. at 1/4" deection.

2. Check the belt tension after 5 hours of initial use.

Check the belt for wear and re-tension if necessary

every 50 hours of use or annually (if less than 50 hours

per year).

Maintenance

Belt Replacement

Blower Belt

1. Disconnect PTO shaft.

2. Remove the two shields from locations (A) and loosen

the idler bolt (B).

3. Loosen nuts (C) and rotate the shield (D) as shown.

Remove the belt (E) from the pulley behind the blower.

4. Remove the belt from the large pulley and install a

new belt. (B51 V-belt)

5. Re-tighten the idler to proper belt tension and reinstall

the shields.

Maintenance Schedule

Each

Use

Initial

5 Hrs

8

Hrs

50

Hrs Annually

Belt tension: Check

and adjust/replace X X X

PTO shaft cross

and bearing, lube X X

PTO shaft

telescoping

member, lube

X X

Hopper screen,

cleanout X X

Fan and chute,

cleanout X

Drive frame

housing, cleanout X

B

C

A

A

B

C

D

E

16

Maintenance

Belt Replacement

PTO Belt

1. Disconnect the PTO shaft.

2. Remove the two shields (A) and the nut (B) from the

idler.

3. Remove the four bolts (C) to remove the center drive

pulley assembly.

4. Remove the four bolts (D) and the bolt on the idler

brackets (E).

5. Remove idler.

6. Twist the bracket (F) and remove the belt from the

pulley around the bracket. It may be necessary to

loosen the nuts (G) to allow the bearing to rotate in

the anges.

7. Install a new belt (B51 V-belt) onto the pulley and

reassemble the center drive-pulley assembly. Torque

the 3/8" bolts to 30 +/- ft. lbs.

8. Reinstall center drive-pulley assemly into drive frame

and torque bolts to 30 +/- ft. lbs.

9. Wrap the belt around the small pulley and reassemble

the idler to the proper belt tension.

10. Reinstall the two shields.

C

C

A

B

D

E

F

G

17

Maintenance

CAUTION: Replacement parts are not lubricated.

Replacement parts must be lubricated at

time of assembly and during use, per the lube

manufacturer’s recommendations.

PTO Shaft Lubrication

NOTE: See page 15 for recommended service intervals in

Maintenance Schedule table.

1. Lubricate all ttings with lithium soap compatible E.P.

grease meeting the N.L.G.I. #2 specications and

containing no more than 1% molybdenum disulde.

2. An E.P. grease meeting N.L.G.I. #2 specications

and containing 3% molybdenum disulde may be

substituted in the telescoping members only.

3. The rotating guard bushings should be lubricated

upon replacement.

Cleaning and Seasonal Storage

1. Empty the hopper before removing from the tractor.

2. Raise the hopper lid and clean the screen using a

cloth or soft-bristle brush.

3. Carefully remove any debris stuck to the fan and spray

with a light oil to prevent rusting.

4. Remove shields and clean out debris stuck in drive

frame. Reinstall the shields before storing.

18

Hopper

Capacity 20 bu. (705 L)

25 cu ft (0.7 m3)

Weight Empty: 390 lb. (177 kg)

Full: 650 lb. (295 Kg); Varies based on material

Ground Clearance 6-3/8 in. (162 mm.) (Distance between lower 3-point pins to bottom of hopper)

Material Sides: 1/16 in. (1.58 mm) aluminum

Gate: 1/16 in. (1.58 mm) steel

Storage Stands 1-1/2 in. (38.1 mm) square 11 gauge tubular steel

Blower System

Drive Type Belt

Belts Blower Belt: B51 V-belt

PTO Belt: B51 V-belt

Materials Fan: 7 gauge steel

Fan Housing Front and Rear: 11 gauge steel

Fan Housing Ring: 11 gauge 304 stainless steel

Fan Diameter 15-in. (381 mm.)

Number of Fan Blades 5

Fan Speed 3,000 RPM

Hose

Material Steel-coil vacuum hose

Diameter 8 in. (203 mm)

Length 5 ft (1.5 m)

Tractor Requirements

Horsepower Engine: 20+ HP

PTO: 17+ HP

Power Take-Off 540 RPM rear PTO shaft

3-Point Hitch Category 1 with 650+ lb. lift capacity

Electrical 12V / 30A connection

Mower Deck Mid-mount side-discharge deck

54 in. (1372 mm ) and 60 in. (1524 mm)

Counterweight Refer to the manufacturer or your dealer for proper ballasting requirements

Specifications

This page intentionally blank

19

20

Warranty

Limited Warranty

TerraKing’s products are guaranteed to be free from

defects in material and/or workmanship and to perform as

advertised when properly assembled, installed, used, and

maintained in accordance with written instructions. Failure

to adhere to this will void the warranty. TerraKing will not

be responsible for labor, loss, or consequential damage of

any kind or character caused by defective parts, or for charges

incurred in the replacement or repair of defective parts.

Warranty Period

The TerraKing TKV 20 Material Collection System is

warranted for a period of 1 (one) year after the purchase

date for residential use, and 6 (six) months after the

purchase date for commercial use. This product is

warranted by TerraKing to the original purchaser/

customer against defects in material and workmanship

under normal operating conditions.

All information, illustrations and specifications in this

manual are based on the latest information available at

the time of publication. TerraKing reserves the right to

make changes at any time without notice.

For service parts and customer support, contact

TerraKing by Superior Tech, Inc.

Form # TKOM-002B-08/18

Table of contents